Ian Melin-Jones

Stora Enso will permanently close down Kopparfors Sawmill and the pellet mill

Stora Enso’s co-determination negotiations at Kopparfors Sawmill in Sweden have been concluded. On 22 March 2011 Stora Enso announced plans for permanent closure of Kopparfors Sawmill and the pellet mill by the end of 2011. The main reason for the planned closure has not changed: Kopparfors is loss-making with no significant prospect of improvement. Kopparfors Sawmill and the pellet mill will therefore be permanently closed down by the end of 2011.

Stora Enso’s co-determination negotiations at Kopparfors Sawmill in Sweden have been concluded. On 22 March 2011 Stora Enso announced plans for permanent closure of Kopparfors Sawmill and the pellet mill by the end of 2011. The main reason for the planned closure has not changed: Kopparfors is loss-making with no significant prospect of improvement. Kopparfors Sawmill and the pellet mill will therefore be permanently closed down by the end of 2011.

“Now that the decision has been taken, we will strive to find individual options for every employee in close co-operation with the local community and authorities. This will take time, but our target is clear: to help every employee affected by the closure to find re-employment options. We will now also continue to look for other businesses to utilise the mill site. We have already had some contacts which we can now analyse further,” says Hannu Kasurinen, EVP, Stora Enso Wood Products.

Kopparfors Sawmill has an annual production capacity of 310 000 m3 of sawnwood. The pellet mill has an annual capacity of 160 000 tonnes. The sawmill and pellet mill have 110 employees.

International Paper Named to IDG Computerworld's 2011 List of Best Places to Work in Information Technology

International Paper has been named one of the Top 100 Best Places to Work in IT by IDG's Computerworld Magazine. International Paper was recognized as one of the Top 100 organizations that challenge its IT staff while providing great benefits and compensation. The Company's ranking moved up 31 slots from 90th in 2010 to 59th in 2011. Honorees will be included in Computerworld's coverage along with results from the 18th annual Best Places to Work in IT survey.

"It's exciting that we've been recognized as one of the Best Places to Work in IT again this year," said John Balboni, senior vice president, Chief Information Officer. "Our IT team members are committed to insuring our daily operations are efficient and effective. They also play an integral role in helping our businesses and staff groups achieve their strategic direction."

"I want to thank and congratulate our IT team for their on-going commitment, dedication and contributions to International Paper. The work being completed across IT - whether here in the U.S. or at our locations in Europe, Asia and South America - is making a positive difference," Balboni said.

International Paper's IT organization employs more than 1,200 IT professionals throughout its global operations. The group is responsible for designing, implementing, upgrading and sustaining the information infrastructure, and systems that support and enable its worldwide operations.

"To be among the Best Places to Work in IT, it's not enough to seek out and hire the most talented IT professionals, offer them competitive pay and provide great benefits," said Scot Finnie, editor in chief of Computerworld. "Smart IT people realize that they need to get up to speed on their employer's revenue opportunities. The organizations that made this year's Best Places to Work list are creating a work environment that both trains and encourages IT personnel to pursue business-driven priorities."

Clearwater Paper Celebrates Grand Opening of Its Shelby Converting Facility

At a ceremony held in Shelby, N.C., Clearwater Paper Corporation announced the grand opening of its newest tissue facility located in Cleveland County. Gov. Bev Perdue, who has provided assistance to the project, was onsite to participate in the dedication.

"The dedication of this facility today ties back to one of Clearwater Paper's core business strategies — to focus on growing the consumer products segment of the company," said Gordon Jones, chairman, president and CEO of Clearwater Paper. "The fantastic level of support we have received from city, county and state officials in North Carolina has reinforced our decision to build this facility at Shelby."

Clearwater Paper has hired 100 local employees and expects to hire approximately 150 more workers before the project is completed. The project is expected to include seven converting lines capable of producing ultra-grades of private label tissue products and includes a Through-Air-Dried (TAD) paper machine, which is expected to be completed by the end of next year. The first two production lines have already started up at the site.

"Many critical commitments were made and fulfilled during this massive effort, demonstrating a great deal of dependability and integrity from all parties involved," said Vince Reese, Shelby plant manager. "But we are not done yet. Next comes our TAD paper machine, which will give us the ability to increase our premium and ultra tissue offering to better compete with nationally branded products."

When completed, the facility is expected to produce approximately 10 million cases of bathroom tissue and paper towels each year. The paper machine is expected to produce 70,000 tons annually.

Source: Clearwater Paper Corporation

Sappi uses the ABB Optical Caliper Sensor and QCS to improve reel-building quality for its customers.

Sappi’s Somerset Mill is on a mission to continually improve its reel building quality, and the ABB Optical Caliper Sensor has helped Sappi to effectively manage optimum reel-building conditions in real-time.

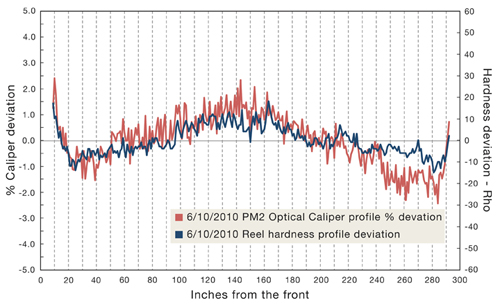

Uniform caliper is extremely important for good roll-building on coated and calendered papers. Because the paper is so dense and smooth, very little caliper profile deviation can be tolerated before the effect is seen on the hardness profile of the reel, and subsequently in the quality of the rolls coming off the winder. PM2 at Sappi’s Somerset Mill used to rely on manual off-line testing of reel hardness profiles using a hand-held hardness tester to assist with the process of troubleshooting reel-building. While this approach was sufficient to enable Sappi to meet its quality targets, the infrequency of these hardness tests represented an opportunity for Sappi to further optimize reel-building conditions, and their available manpower.

“The stability and repeatability of the Caliper Sensor allows the operator to trust the profile shape and make reel-building corrections in real-time rather than wait for an off-line hardness profile test,” says Dave Moore, Senior Process Engineer at Sappi Somerset Mill.

The Optical Caliper Sensor contacts the sheet on one side using a smooth ceramic stabilizing plate with vacuum applied by concentric rings. On the other side of the sheet is a unique optical (confocal) measurement. The confocal measurement is combined with a magnetic reference measurement, and the result is caliper measurement. The simplicity of this design provides reliable performance day after day in the harsh paper mill environment.

Even with the sensor applied very soon after the calendering process on high-gloss grades, Moore adds that, “We have not seen any sheet marking issues with this design.”

Caliper correlation within ±1% between the laboratory and the Optical Caliper Sensor was one goal of the project: “The optical sensor has met our requirement of reproducible CD profile correlation without marking the sheet surface,” reports Moore.

Equally important for Sappi was the correlation to the hand-held hardness instrument. Figure 1 shows that the correlation was good enough to allow operators to make corrections before out of specification limits were reached.

ABB has been working with the Sappi Somerset Mill to implement service and evolve its Quality Control Systems (QCS) for more than 25 years on its three paper machines. Over that period of time, ABB and Sappi have worked together to evolve the systems in a step-wise approach, with manageable capital investments.

Buckeye Plans to Close Delta Nonwovens Facility by End of 2012

Improves capacity utilization, profitability and return on invested capital

Expect to generate $30 million cash benefit from closure

Expect non-cash impairment charge of $15 million and $5 million restructuring costs

Buckeye Technologies Inc. has announced plans to close its Delta, B.C., Canada airlaid nonwovens facility by the end of calendar 2012. The Company will work closely with its customers to continue to meet their needs by sourcing products currently produced at Delta from its facilities in Gaston County, N.C. and Steinfurt, Germany.

Buckeye Chairman John B. Crowe said, "This closure has become necessary due to several factors including unfavorable site location relative to customers and raw material suppliers, a strong Canadian dollar, and low capacity utilization. It is unfortunate that this closure will result in the eventual termination of employment for approximately 95 dedicated employees. We have owned and operated the Delta facility since 1997 and we value and appreciate the many contributions of the organization over the past 14 years. In the fall of 2010, we consolidated our production from a two machine operation to one airlaid machine in an attempt to improve the profitability of the site. Even after this consolidation, which did improve margins, the plant's forecasted financial performance remains at an unacceptable level.

"We are making this announcement now to allow adequate time to address employee and customer needs. This 18 month period will allow us time to implement changes that may be needed at Gaston and Steinfurt to meet the needs of our current Delta customers. This closure and consolidation of business will improve capacity utilization, profitability and return on invested capital for our Nonwovens business. We expect to incur a non-cash asset impairment charge of about $15 million and $5 million in restructuring expenses between now and December 31, 2012. The closure is expected to generate about $30 million in cash over the next 18 months, primarily through the sale of land and buildings and a net reduction in working capital. From now until the end of 2012, we will focus on meeting the needs of our customers and on maximizing cash flow generation at the site."

Buckeye, a leading manufacturer and marketer of specialty fibers and nonwoven materials, is headquartered in Memphis, Tennessee, USA. The Company currently operates facilities in the United States, Germany, Canada, and Brazil. Its products are sold worldwide to makers of consumer and industrial goods.

Certain matters discussed in this press release may constitute forward-looking statements within the meaning of the federal securities laws that involve risks and uncertainties, including but not limited to economic, competitive, governmental, and technological factors affecting the Company's operations, financing, markets, products, services and prices, and other factors.For further information on factors which could impact the Company and the statements contained herein, please refer to public filings with the Securities and Exchange Commission.

SOURCE: Buckeye Technologies Inc.

Changes in the Executive Management Team of Ahlstrom Corporation

Patrick Jeambar (65), Executive Vice President, Label and Processing Business Area, will step down from the Executive Management Team of Ahlstrom Corporation as of September 1, 2011.

Daniele Borlatto (42), Vice President, Release & Label and Supply Chain, will succeed Patrick as the Executive Vice President, Label and Processing Business Area. He will take over his new role on September 1, 2011, when he will also become a member of the Executive Management Team. Daniele Borlatto will report to Jan Lång, President and CEO.

Daniele Borlatto has been working at Ahlstrom since 1990 in various senior roles, including as a member of the Executive Management Team in 2007-2010.

Patrick Jeambar will continue to work at the company during a transition period to support Daniele Borlatto in taking over his duties. Patrick Jeambar joined Ahlstrom in 1996 and has been a member of the Executive Management Team since 2003.

Domtar launches "The Paper Trail," a resource calculator with unmatched transparency

New Tool Shares Environmental and Social Impacts of Making Domtar Paper, Discloses Successes and Challenges

A new environmental tool from Domtar Corporation offers customers the ability to view the environmental impacts of specific paper grades, providing unmatched transparency among today's industry calculators.

The online tool that we call the "Paper Trail" discloses what it takes to manufacture Domtar paper and assists businesses and consumers to measure their impact on the environment while also providing guidance in their choice of product.

The Paper Trail (www.domtarpapertrail.com) develops personalized reports that measure Domtar products across five categories: water usage, the distance fiber travels to a paper mill, greenhouse gas (GHG) emissions, waste sent to landfills and renewable energy usage. The data is displayed in real-world equivalents, with comparisons to issues such as the amount of water the average household uses or the amount of waste it generates. The Paper Trail will also illustrate how Domtar compares to the rest of the industry in these particular categories.

"We know consumers are increasingly aware of their effect on the environment and want to know where their paper comes from. We think we have a good story to tell, and part of that story is being transparent," said Lewis Fix, Domtar Vice President of Sustainable Business and Brand Management.

"Other paper calculators often give only part of the story," Fix said. "They usually compare recycled and non-recycled grades and the differences in resources used, and they estimate savings based only on industry averages. The Paper Trail will show Domtar mill-specific data, and since no company is environmentally perfect, it indicates what we are doing well and what needs to be improved. We think it's crucial to share all the information, and then let the customers make their own decisions."

The Paper Trail is Domtar's most recent project indicating its leadership as a sustainable paper company and highlighting its environmentally preferable paper products, which have earned the support of well-known environmental organizations such the Rainforest Alliance.

Initially, the Paper Trail will measure the impact of two Domtar products: EarthChoice® Office Paper and Cougar®, both of which have been certified to the standards of the Forest Stewardship Council" (FSC®), which is recognized by the Rainforest Alliance as the world's most comprehensive certification for responsible forest management. As part of the EarthChoice product line, they help form the broadest and most flexible collection of environmentally responsible papers available in the marketplace. More products and mills will likely be added to this new and exciting online tool in the future.

The Paper Trail will also provide users with a look at Domtar's mills - all of which are in North America - with additional information about each facility's environmental impact and the social and economic benefits the mills have in their communities. In areas where the environmental impact can be improved, Domtar will voluntarily disclose the information, as well as provide efforts for improvement.

"Transparency means sharing everything, not just the highlights, and just as we are committed to developing responsible products, we are committed to transparency," Fix said. "Realizing our paper comes from sustainable sources and is easily recycled, Domtar customers can see the differences and use our products with greater confidence."

Metso supplies its 300th RM3 retention analyzer to the paper and board industry

Metso, the pioneer in measuring and controlling retention, has reached an important milestone with the delivery of its 300th Metso RM3 retention analyzer to the paper and board industry. It was installed on BM 2 at Stora Enso Imatra Mills’ Kaukopää production unit in Imatra, Finland, in May. The wet end of the machine that produces packaging and graphic grades was equipped with a total of three analyzers for measuring white water consistency of all layers online. The delivery also included two Metso MCA microwave consistency sensors for measuring total consistency after the machine chest.

Metso, the pioneer in measuring and controlling retention, has reached an important milestone with the delivery of its 300th Metso RM3 retention analyzer to the paper and board industry. It was installed on BM 2 at Stora Enso Imatra Mills’ Kaukopää production unit in Imatra, Finland, in May. The wet end of the machine that produces packaging and graphic grades was equipped with a total of three analyzers for measuring white water consistency of all layers online. The delivery also included two Metso MCA microwave consistency sensors for measuring total consistency after the machine chest.

Earlier the white water analyses on BM 2 were carried out in the mill laboratory with water samples taken manually from the production line. Now the RM3 analyzers measure white water consistency online.

“With the help of the new white water consistency measurements, we are able to stabilize retention better than before. This decreases machine fouling, in addition to improving runnability and product cleanliness,” says BM 2 Supervisor Riku Suurnäkki.

Reliable and accurate RM3 is suitable for all monitoring and closed loop control applications. It is the only optical measurement on the market able to measure both true ash consistency and total consistency from a continuous sample flow. It can also be used to measure stock flocculation. Retention and ash controls based on reliable measurements provide excellent tools for enhancing production efficiency, improving quality and lowering production costs in a paper or board production process.

RM3 represents the third generation in Metso’s retention measurement technology, which has become an industry standard. The analyzer’s success is based on over 20 years’ experience in optical consistency measurements as well as on continual, fruitful cooperation with paper and board makers. The analyzers are widely used at paper and board mills and DIP plants around the world.

The Kaukopää production unit is part of Stora Enso’s Imatra Mills with an annual capacity of over a million metric tons of board and paper. Specialized in packaging, paper and wood products, Stora Enso has about 26,000 employees globally. Its net sales in 2010 reached 10.3 billion euros.

Metso’s new cost-efficient valve design

Metso has strengthened its product offering with the addition of a new valve design derived from our traditional V-port segment valve series. The new two-way-tight, single-seat design is suitable for a wide range of applications and is available for R-series valves. The optional two-way-tight feature covers the size range from DN25 up to DN700 (1” up to 28”) in all available pressure classes.

Metso has strengthened its product offering with the addition of a new valve design derived from our traditional V-port segment valve series. The new two-way-tight, single-seat design is suitable for a wide range of applications and is available for R-series valves. The optional two-way-tight feature covers the size range from DN25 up to DN700 (1” up to 28”) in all available pressure classes.

Cost-efficient shut-off

With our V-port segment valve series, we are able to improve process performance and reduce variability in control applications. However, there are a lot of applications where two-way-tight, on-off type performance is required. The customer benefit of the new V-port segment valve design is that it offers the possibility of combining control and on/off performance in a single valve assembly. The standard bi-directional shut-off classifications of the V-port segment valves are according to 10x ISO Rate D / FCI 70.2 Class IV; optional improved tightness classes are ISO Rate D / FCI 70.2 Class V @ dp 20 bar.

Economical solution provider

One of Metso’s paper mill customers installed a DN 600 RE flanged, V-port segment valve in a steam discharge application. In this particular case, low-pressure, superheated steam flows through the two-way-tight valve at 200 deg C. A traditional valve solution for this application would have been a two-way-tight ball valve. However, by selecting the new two-way-tight, V-port segment valve, the customer was able to save 50% on his capital costs.

In pulp mills there are many applications where two-way tightness is required. For example, there are many such valves next to batch– and continuous digesters. In the bleaching department, the on-off valve after the chemical mixer is typically quite large and can require the two-way tightness feature.

Availability of the new two-way-tight option

The two-way-tight option is available for both RA and RE valve series for all standard pressure classes and flange drillings. It is also available in all standard body materials. If there is a requirement for other materials, the local Metso sales office can help.

Naturally Advanced Technologies and Ashland Inc. Agree to Jointly Develop CRAiLEX High Grade Dissolving Pulp

Naturally Advanced Technologies Inc., and Hercules Incorporated, a subsidiary of Ashland Inc., has announced that they have entered into a joint development agreement for CRAiLEXä high-grade dissolving pulp.

CRAiLEX is the brand name for the purified pulp created from a patented process that is exclusively held by Naturally Advanced Technologies Inc. In recent tests, CRAiLEX has proven to exhibit higher-grade value pulps than any other hard- or soft-wood pulps. The pulps are used by Ashland to create its line of cellulosic products for multiple industries.

"This is the start of our CRAiLEX technology roll out," said Ken Barker, CEO of NAT. "In the same manner and strategy we employed to bring our CRAiLAR(r) technology to commercialization, partnering with an industry leader such as Ashland Inc. is a key milestone in the development of CRAiLEX. We are extremely proud of the opportunity and partnership potential in working with Ashland."

Naturally Advanced Technologies Inc.

Naturally Advanced Technologies Inc. develops renewable and environmentally sustainable biomass resources from flax, hemp and other bast fibers. The Company, through its wholly owned subsidiary, CRAiLAR(r) Fiber Technologies Inc., has developed proprietary technologies for production of bast fibers, cellulose pulp, and their resulting by-products in collaboration with Canada's National Research Council and the Alberta Innovates. CRAiLAR technology offers cost-effective and environmentally sustainable processing and production of natural, bast fibers resulting in increased performance characteristics for use in textile, industrial, energy, medical and composite material applications. The Company was founded in 1998 as a provider of environmentally friendly, socially responsible clothing. For more information, visit www.naturallyadvanced.com.