Ian Melin-Jones

ABB retains leading distributed control system market share worldwide for 2010

ARC study states that new projects in heavy process industries, power generation contributed to overall market growth

In the newest version of ARC Advisory Group’s “Distributed Control Systems Worldwide Outlook,” study, ABB retained its leading worldwide market position in this core automation market. According to the study, the DCS (distributed control system) market in 2010 rebounded from 2009; the overall market for DCS (distributed control system) increased by 3.3 percent, in part due to an increase of new projects in the heavy process industries.

ARC forecasts that market growth, while improved compared with 2009, will not reach peak 2008 levels until next year, and then will resume normal slow but steady growth. The increase in new projects in the heavy process industries such as oil & gas and petrochemical, as well as a resurgence in power generation projects, helped to drive global demand for DCS in 2010.

Many of the larger projects that contributed to 2010 growth were booked throughout 2009. ABB booked a number of large process industry and power generation orders, which included major greenfield projects as well as system upgrades and expansions for existing installations.

“Innovation, quality products, extensive industry knowledge and application expertise has enabled ABB to establish a large and loyal customer base,” said Barry Young, Principal Analyst at ARC and author of the report. “ABB brings together a product, system and service capability that allow them to deliver complete automation and production solutions across a broad range of industries.”

According to the study, ABB was also the regional market share leader for Latin America, Europe/Mid East/Africa (EMEA), and the worldwide leader in key global verticals including Upstream Oil & Gas, Pulp and Paper, Mining and Metals, and Cement and Glass.

The report also notes that the DCS business has continued to be primarily a services business over the past few years, with combined project, engineering and operational services accounting for more than half of total revenues. In particular, the Main Automation Contractor (MAC) approach, in which the automation vendor manages the overall project and includes a strong project execution and services component, continues to grow stronger and expand in scope.

“ABB’s deep process industry knowledge, extensive global and local resources, and world-class services organization provide the project execution capabilities needed to successfully manage complex projects as the Main Automation Contractor,” said Veli-Matti Reinikkala, head of ABB’s Process Automation division. “In addition, we offer our customers a diverse portfolio of DCS solutions to help any process perform better, from the smallest operation to large integrated operations.”

ABB’s portfolio of DCS includes its flagship System 800xA Extended Automation platform, Symphony Plus control system, Freelance process control system for small to medium process applications, as well as its prior generation systems. All ABB control systems offer a secure evolution path forward to next generation technologies to protect and enhance the control system investment over its lifetime.

Additional information on the DCS Worldwide Outlook, as well as other studies on the global automation market, is available at www.arcweb.com

Founded in 1986, ARC Advisory Group has grown to become the Thought Leader in Manufacturing and Supply Chain solutions. ARC analysts have the expert industry knowledge and first-hand experience to help clients find the best answer to complex business issues. ARC focuses on simple yet critical goals: improving clients’ return on assets, operational performance, total cost of ownership, project time-to-benefit, and shareholder value.

Norske Skog has been ranked the best Norwegian company - and number four in the Nordic region

For the fourth consecutive year Norske Skog is featured in CDP's (Carbon Disclosure Project) annual Nordic 'Carbon Disclosure Leadership Index'. This index, a key component of CDP's annual Nordic 260 report, highlights the Nordic companies which have displayed the most professional approach to corporate governance regarding climate change information disclosure practices.

- The ranking is an important recognition of our efforts to demonstrate openness on climate change issues, systematic reporting and follow-up are necessary if we are to be effective in our efforts to reduce emissions and save energy, says Sven Ombudstvedt, CEO in Norske Skog.

The Carbon Disclosure Project is an independent non-profit organisation which represents 551 institutional investors with $71 trillion in assets under management The CDP gathers information on corporations' greenhouse gas emissions, climate change related risks and opportunities, and sets standards for carbon disclosure methodology and processes.

Stora Enso CEO Jouko Karvinen comments on third quarter 2011 results

“Solid quarter, measures to fight the economic reality continue and increase”

“We finished the third quarter as planned. The business areas performed as expected, but associated companies underperformed, essentially due to currency impact.

“In July we forecast rapidly increasing economic uncertainty and the need to plan for alternative demand scenarios going forward. We described the early signs of weakening demand and sales channel inventory reductions in Fine Paper and Wood Products. Whereas we see for example in coated fine paper stabilisation after inventory corrections, it is clear that going into the fourth quarter our customers, as well as ourselves, will reduce inventories and therefore we will further step up the manufacturing curtailments which we already increased significantly in the third quarter. If temporary lay-offs are planned, they will be subject to co-determination negotiations.

“As before, in a rapidly changing business environment our priorities are clear: cash preservation, defending our margins through active capacity management, minimising the number of underutilised assets by product swaps and continued cost-efficiency actions. The good news is that we are now in a stronger position than a few years ago due to lower fixed costs. We have enhanced flexibility through outsourcing and other means of decreasing the negative earnings impact of reduced demand. This path of improvements in costs and productivity, but also flexibility is one we will continue to follow.

“Looking further ahead, our current strategic projects – the Montes del Plata pulp mill in Uruguay, the Ostrołęka containerboard machine in Poland and the cross-laminated timber investment in Austria – are proceeding according to plan. Inpac acquisition was completed in the third quarter. Our strong balance sheet and cash position gives us a solid platform to pursue our future in our selected growth areas.”

ABB supplies the new film-press feeding station on PM 5 to Clairefontaine

Cellier Activity of ABB France, Process Automation Division, received the order from Clairefontaine for the supply of the feeding station of the film press to be installed on the PM5 in Etival, France. This line will be used for the production of white and coloured papers.

Cellier Activity is in charge of the process and automation engineering, as well as the procurement, the site supervision and the start-up assistance. The feeding station includes two in-line self-cleaning pressure filters, type Filtercel™ LHP. It enables the production of high added-value paper whilst reducing variable costs. The Filtercel™ LHP is designed for the treatment of high-requirement and varied preparations. The optimal filtration quality achieved significantly reduces the number of paper breaks on the paper machine. The Filtercel™ LHP is automatically cleaned during a high pressure cleaning cycle without any intervention from the operator, nor dismantling works. Not only does this mean that it remains available for the production but also it results in important operating and maintenance cost savings.

The start-up successfully took place at the beginning of September 2011.

KapStone Paper and Packaging Corporation Ranked 10th Best Small Company

KapStone Paper and Packaging Corporation ("KapStone") announced that they have ranked 10th overall on Forbes's annual list of the 100 Best Small Companies according to the rankings included in the November 5, 2011 issue. Forbes determined the rankings based upon return on equity, growth of earnings and sales, and the relative stock performance of each company as compared with that of its peers over the past 12 months and over 5 years.

Roger Stone, Chief Executive Officer, commented, "We are very pleased with the recognition from Forbes as the 10th best small company in America, and we will strive to maintain the quality and momentum of our growth with the completion of our latest acquisition of U.S. Corrugated."

About the Company

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is a leading North American producer of unbleached kraft paper products and linerboard. The Company is the parent company of KapStone Kraft Paper Corporation which includes paper mills in Roanoke Rapids, NC, and North Charleston, SC, a lumber mill in Summerville, SC, and five chipping mills in South Carolina. The business currently employs approximately 1600 people. The Company has recently announced plans to acquire U.S. Corrugated for $330 million.

SOURCE KapStone Paper and Packaging Corporation

Science has spoken: Cascades Fine Papers has a small environmental footprint

Dear Reader,

We are pleased to introduce you the results of our Life Cycle Assessment (LCA). Third-party validated to ensure transparency and adherence to rigorous standards, it measures the environmental impact of Cascades' fine papers in comparison to the North American industry average. The science has spoken and the results are impressive: Rolland Enviro100 has the smallest environmental footprint, followed by Rolland Opaque50 which has a smaller footprint than the average for virgin and 100% recycled papers.

With supporting evidence, this comparative LCA demonstrates that Rolland Enviro100 and Rolland Opaque50 each have a much smaller impact, 68% and 46% respectively, as compared to the generic North American papers. These outstanding results are primarily due to the types of energy used, biogas and hydroelectricity, as well as the use of recycled fibers. Generated from landfill waste decomposition, biogas is a local and renewable energy that serves 93% of the thermal energy needs for Cascades' Rolland Mill.

With supporting evidence, this comparative LCA demonstrates that Rolland Enviro100 and Rolland Opaque50 each have a much smaller impact, 68% and 46% respectively, as compared to the generic North American papers. These outstanding results are primarily due to the types of energy used, biogas and hydroelectricity, as well as the use of recycled fibers. Generated from landfill waste decomposition, biogas is a local and renewable energy that serves 93% of the thermal energy needs for Cascades' Rolland Mill.

An LCA breaks through the confusion surrounding green certifications and claims and curbs "greenwashing" by providing comprehensive, quantifiable and rigorous results.

It is a scientific method that assesses the environmental impacts of a product throughout its life cycle. Specifically, for each component of the product under evaluation, its environmental impact is quantified and then aggregated to yield a final result demonstrating the potential damages to Human Health, Ecosystems, Non-Renewable Resources and Climate Change.

Please take a few minutes to watch the Video below.

Cascades is proud to share the results of its LCA , available at www.cascades.com/papers.

Should you have any questions, please do not hesitate to contact your

Cascades Fine Papers Group Sales Representative.

Metso DNA expands to mining and construction - New control applications for energy industries as well as pulp and paper industries

Metso DNA is again leading the way by being the first in the world to introduce new control applications that enhance productivity and profitability in energy industries, pulp and paper industries, and as a new area, mining and construction industries. Metso is the first to introduce embedded machine condition and runnability monitoring within process controls. Metso DNA has also been strengthened with new control applications, such as winder controls, power plant turbine controls and machine condition monitoring. As well, Metso is pioneering usability in process control work.

Metso DNA meets diverse mining and construction industry needs

Metso is a leading supplier in mining and construction machinery. This expertise is now combined with scalable Metso DNA automation systems that adapt to the diverse mining and construction industry needs, from single machine controls to entire plant-wide automation and information management systems.

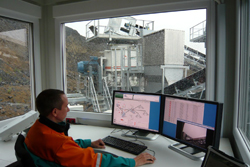

An example of Metso's new offering is the new crushing plant control room solution that connects crushers and screens together, ensuring the effective management of the entire plant from a pleasant and safe control room. The Metso DNA user interface provides production information to ensure a proper and rapid response to plant events. Automatic controls stabilize the process and allow the operators to monitor the plant as a whole.

"As an example of the services, we offer performance studies for crushing plants, using Metso's multi-disciplinary teams of experts, to determine the present level of the plant and process efficiency, and to estimate the improvement potential and benefits from optimization and automation, including ROI calculations. As another example, our machine condition monitoring solutions can reduce plant and machine downtime as well as help avoid safety and environmental hazards," says Mikko Mäkinen, Product manager of minerals applications in Metso's Automation business line.

New solutions for increased efficiency for energy industries

Metso DNA now offers one system for power producers, which includes energy management, plant information management, controls for the boiler, turbine and Balance of Plant, safety integrated systems, as well as emission management.

The integration of applications for turbine control, turbine protection and turbine management into the Metso DNA automation system provides customers with easy and cost-efficient maintenance, and reliability-based redundant process controllers. Metso's pulverized coal-fired combustion optimization manages control reactions to dynamic upsets, such as changes in mill configuration or load demand.

The sootblowing optimization tool calculates, stores and displays the boiler heat transfer characteristics that indicate fouling and deposit accumulation on heat transfer surfaces. It also defines the economically optimal sootblowing sequence. Another new application, machine condition monitoring, has been developed for the condition monitoring of rotating machines, such as flue gas fans, feed water pumps and turbines.

For pulp and paper makers, a single system for all controls

Metso DNA now offers pulp and paper makers a single system for all controls, from the fiber line to baling information, and from headbox to winder.

The new Metso DNA now offers winder controls, which increase the transparency between the winding process and papermaking process controls. The new winder controls enable operators to follow paper profiles through the winder controls, which improve both the runnability and productivity of the winding process.

Metso has also further developed its Metso DNA pulp mill information management offering and upgraded its bale tracking solution for the baling line. The newest application in Metso's pulp mill information management system, Metso DNA Bale Tracker, takes bale tracking to a new level. The new solution is based solely on the Metso DNA automation platform, which makes bale tracking and marking even more reliable. All online quality data needed for each and every bale is also available, thanks to full integration with Metso's Quality Control System (QCS) and Process and Quality Vision (PQV).

Machine condition and runnability monitoring

Mechanical condition monitoring is a part of preventive maintenance for wearing components, such as shafts and bearings, which need to be monitored for possible replacement needs. The new mechanical condition monitoring solution from Metso includes rotating machinery vibration measurements and analysis carried out as part of the automation system. Condition and runnability monitoring has traditionally been a separate system, mostly utilized by maintenance specialists. Thanks to Metso DNA Machine Monitoring, the same information can be shared with machine operators in the control room.

Good usability enables positive emotions and feelings

In addition, Metso is pioneering usability in the process control work. Metso DNA takes a new approach to usability by regarding emotions and feelings as part of the process control work. "Despite being fact-based by nature, process control work at pulp and paper mills includes a lot of feelings connected with solving situations. When all the aspects of business and production processes are under control, people in various tasks can enjoy feeling in control of their work," explains Jaakko Oksanen, Product Manager for Metso DNA.

An example of usability is that Metso DNA is the only system in the world from which the user receives the process data in real time and retrospectively from the same user interface, with one push of a button.

"The user can easily access all the data collected during his/ her absence, for example, over the weekend. Traditionally, the history of this information required separate applications, and data analysis was difficult. This is one example of how we have taken usability into consideration with subsequent positive emotions and positive user experience," Jaakko Oksanen explains.

Metso DNA can be developed, maintained, and upgraded throughout its life cycle

Metso's long experience in automation systems dates back to 1979. So far Metso has delivered thousands of systems to various process industries globally.

Metso DNA is a single automation system for all functions - process, machine, drive and quality controls. It also covers information management and mechanical and field device condition monitoring. Metso DNA is scalable from a single stand-alone controller to mill and plant-wide systems in global organizations.

The unique feature of Metso DNA is its single system architecture enabling lifelong compatibility and upgradeability. This means significant advantage for Metso's customers since Metso DNA enables step-by-step system upgrade paths to develop their systems according to changing process needs.

All Metso automation systems delivered after 1988 can be upgraded with new applications as a whole or in sections. Existing equipment and applications can be used in the upgraded system. The system network may also contain different generation subsystems or even different generations of products within a single system, meaning that new product features can be easily added.

Metso DNA is supported by global network of local experts.

Minerals Technologies Enters into Agreement with Bashundhara Paper Mills Ltd. in Bangladesh

Minerals Technologies Inc. has announced that its wholly owned subsidiary, Specialty Minerals Inc., has entered into an agreement with Bashundhara Paper Mills Limited to build and operate a satellite precipitated calcium carbonate (PCC) plant at Bashundhara's paper mill in Meghnaghat, Bangladesh.

The satellite PCC plant, which will produce about 30,000 metric tons of PCC a year and is expected to become operational in the first quarter of 2013, will be wholly owned and operated by Specialty Minerals Bangladesh Limited.

"We are very pleased to enter this agreement with Bashundhara Paper Mills Limited., and look forward to a long relationship with this papermaker. Minerals Technologies will help Bashundhara produce higher quality paper at a lower cost," said Joe Muscari, chairman and chief executive officer. "This satellite, which will bring our total in Asia to 13, is another indication of the success of our strategy to grow aggressively in emerging regions."

Bashundhara Paper Mills Limited, the leading papermaker in Bangladesh, is part of the Bashundhara Group, which also has enterprises in real estate, cement, steel, bottling and distribution. In addition to its operation at Meghnaghat, Bashundhara also has paper mills in Anapura, Songargon, and Narayangonj, Bangladesh.

PCC is a specialty pigment for filling and coating high-quality paper. By making use of PCC as a replacement for more expensive pulp, customers like Bashundhara Paper Limited are able to produce brighter, higher quality paper at lower cost. Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing North American papermaking from an acid to an alkaline-based technology. Minerals Technologies constructed its first satellite PCC plant in 1986. Today, the company has 55 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

Minerals Technologies Inc. is a global resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. Total sales for the company were $1 billion for 2010.

Munken – Paper worthy of a Nobel prize winner!

Arctic Paper congratulates Tomas Tranströmer, this year's recipient of the Nobel Prize in literature. Tranströmer, one of our era's most important poets, is receiving the prize "because through his condensed, translucent images, he gives us fresh access to reality".

For Arctic Paper, the selection of Tranströmer is a gratifying event from several perspectives. Ever since the attention garnered by his debut in 1954 with the poetry collection, 17 poems, a large portion of his work has been published on design and book paper from Arctic Paper Munkedals. With the approaching new publication of his works, an additional order has been placed for a total of approximately 100 tons of Munken Premium Cream 13.

- Tranströmer is without a doubt one of the world's greatest poets. Many of his popular works have been printed on Munken paper, which feels like a confirmation of the committed work that has been carried out at the plant in Munkedal in order to deliver a truly environmentally-adapted quality paper. It is quite an honour that they are also making the same selection for the new publication," says Martin Folkelind, Business Development Manager within the Arctic Paper Group.

At the publishing house, Bonnier, in Stockholm, it is naturally a great joy to see Tranströmer, who has been one of the top contenders regarding speculations about who will receive the prize, to finally be awarded this prestigious honour.

Lintech International selected for distribution in the Southeast U.S.

Arizona Chemical Selects Lintech International to Expand Distribution of Its Products in the Southeast U.S.

JACKSONVILLE, FL, October 17, 2011 – Arizona Chemical, a world leader of bio-refined products, announced it has entered into an exclusive agreement with Lintech International to expand its long-standing distribution coverage of the company’s adhesives, inks, coatings and chemical intermediate product lines in the Southeast U.S.

“With Lintech’s reach and well-recognized customer focus, we’re confident our customers will be as excited as we are about this expanded distribution arrangement,” said Rob Helwick, Commercial Director-Americas for Arizona Chemical.

Effective December 1, 2011, Lintech International will offer Arizona Chemical’s products that provide a broad range of functionality in a variety of applications, including SYLVALITE™ and SYLVATAC™ rosin esters, AQUATAC™ rosin dispersions, SYLVARES™ terpene resins, UNI-REZ™ ink polyamides, SYLVACOTE™ 7003 and 7097 insoluble maleics, SYLFAT™ tall oil fatty acid and SYLVATAL™ distilled tall oil.