Ianadmin

Asia Pulp and Paper signs New York Declaration on Forests at UN Climate Summit to help tackle climate change

Mr. Teguh Ganda Wijaya, Chairman of Asia Pulp and Paper Group (APP), has joined a number of companies, governments and NGOs to sign the New York Declaration on Forests at an event at the UN Climate Summit 2014. The declaration is an unprecedented international, multi-sector commitment to safeguard the world’s forests and to help tackle climate change.

Mr. Teguh Ganda Wijaya, Chairman of Asia Pulp and Paper Group (APP), has joined a number of companies, governments and NGOs to sign the New York Declaration on Forests at an event at the UN Climate Summit 2014. The declaration is an unprecedented international, multi-sector commitment to safeguard the world’s forests and to help tackle climate change.

“We at APP also believe that forest-based products can help in this regard because they retain carbon, are recyclable and, when sourced from responsibly managed plantations, are often more sustainable than the alternatives.”

All signatories of the Declaration have committed to a vision of slowing, halting, and reversing global forest loss while simultaneously contributing to economic growth, poverty alleviation, rule of law, food security, climate resilience and biodiversity conservation.

The declaration, which was formalised at an event hosted by UN Secretary General, Ban Ki-moon, highlights that reducing emissions from deforestation and increasing forest restoration are key to tackling climate change. Partners are called on to work together to:

- At least halve the rate of loss of natural forests globally by 2020 and strive to end natural forest loss by 2030

- Restore 150 million hectares of degraded landscapes and forestlands by 2020 and significantly increase the rate of global restoration thereafter, which would restore at least an additional 200 million hectares by 2030

- The full list of commitments have the collective target of achieving a reduction in emissions by 4.5-8.8 billion tons per year by 2030.

Teguh Ganda Wijaya, Chairman of APP said: “United Nations Secretary-General Ban Ki-moon has done the planet and some of its most critical ecosystems a great service in convening this ground-breaking meeting of governments, global business leaders and NGOs. Business can take the lead in delivering these commitments, but we must work closely with all stakeholders including governments and NGOs to truly tackle deforestation and climate change. One of the most effective ways to do this is by conserving forest, planting trees, and protecting the natural forest that surrounds.

“We at APP also believe that forest-based products can help in this regard because they retain carbon, are recyclable and, when sourced from responsibly managed plantations, are often more sustainable than the alternatives."

Aida Greenbury, APP’s managing director of sustainability added: “We have shown through our own Zero Deforestation policies that ambitious targets to protect the world’s remaining forests can be agreed, implemented and achieved by companies operating in emerging economies. Our view is that wherever a company is involved in the forest supply chain, they should be implementing these policies immediately. There is no time to waste.”

APP announced its Forest Conservation Policyand zero deforestation commitment in February 2013 and over the last 18 months, has been working successfully to implement this policy. Earlier this year, the company made a further commitment to support the protection and restoration of one million hectares of tropical rainforest landscapes in Indonesia, one of the most ambitious conservation commitments ever made by a private company.

The New York Declaration on Forests is an important milestone in the journey to the UNFCCC COP 21 meeting in Paris in December 2015.

As part of the Forest Conservation Policy Asia Pulp and Paper have been implementing high carbon stock and high conservation value assessments across their entire supply chain. Renowned environmentalist Tony Juniper visited APP’s facilities to see the assessments being conducted, and created a series of short videos which illustrate how the commitments outlined in the FCP can be practically delivered. The videos can be viewed on the links below.

Asia Pulp and Paper: Sustainability and the Growing Demand for Paper

Asia Pulp and Paper’s Forest Conservation Policy

Asia Pulp and Paper: High Carbon Stock Assessments

Asia Pulp and Paper: Landscape Conservation

About Asia Pulp & Paper

Asia Pulp & Paper Group (APP) is a trade name for a group of pulp and paper manufacturing companies in Indonesia and China. APP is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper. On any given day, our products find their way into the hands of consumers in various branded forms from all over the world.

Started in 1972 with Tjiwi Kimia producing caustic soda, now we run operations across Indonesia and China with an annual combined pulp, paper, packaging product and converting capacity of over 19 million tons per annum. Today, APP markets its products in more than 120 countries across six continents.

Over the years, we have expanded our operations significantly through the acquisition and expansion of several of our pulp and paper mills. It’s our commitment to customer satisfaction that enables us to grow our share in paper sales worldwide and broaden our presence through offices in many countries. We believe ‘tradition and modernity go hand in hand’ which means we value long term relationships as part of our Eastern traditions, while we also are eager to embrace the modern values of innovation and efficiency.

Maintaining the integrity of our supply chain is also crucial to APP’s operations as well as our commitment to our Sustainability Roadmap Vision 2020. Learn more about APP’s path to operational excellence by reading our Sustainability Reports and Forest Conservation Policy.

Contacts

Asia Pulp and Paper Group

Darragh Ooi, +62 (0) 21 29650800

Global Head of Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tla'amin First Nation and City of Powell River complete transaction to purchase Catalyst Paper's interest in the PRSC Limited Partnership

The Tla'amin First Nation and City of Powell River have completed the transaction to purchase Catalyst Paper Corporation's interest in the PRSC Limited Partnership, a unique joint venture that was established by the three parties in 2006 to sell and redevelop lands that were surplus to Catalyst's operations in the community.

The Tla'amin First Nation and City of Powell River have completed the transaction to purchase Catalyst Paper Corporation's interest in the PRSC Limited Partnership, a unique joint venture that was established by the three parties in 2006 to sell and redevelop lands that were surplus to Catalyst's operations in the community.

Through its wholly owned corporations, Powell River Waterfront Development Corporation (City) and Tees'kwat Land Holdings Ltd (Tla'amin), the parties retired the mortgage being carried by PRSC and acquired Catalyst's interest in the Limited Partnership for $3 million. The transaction was approved by the courts in 2012 when Catalyst was undergoing financial restructuring while under creditor protection.

Powell River Mayor Dave Formosa stated that "We looked at it as an opportunity for Sliammon and the City to develop and carry out their strategic initiatives, while simultaneously assisting Catalyst during its restructuring. We felt the amount to retire the mortgage and acquire the company's interest in the Limited Partnership was more than fair."

Tla'amin Chief Councillor Clint Williams says, the completion of the purchase re-establishes a connection to lands that are economically important to Sliammon, and to the City of Powell River. As part of the transaction, Sliammon and the City agreed to secure two equally sized parcels of land (5.5 acres each) on PRSC's Marine Industrial property (District Lot 4070) for individual economic development goals. The parcel that will be secured by the First Nation will fulfill a long standing goal for its business interests. "One of the reasons Tla'amin became involved in the Limited Partnership, was to secure land to establish a log dump and sort for its forestry operations. This transaction not only allows PRSC to retire the mortgage for a fair price, but to secure the lands necessary to ensure the success of Thichum Forest Products."

"We are pleased to arrive at the final stages of this jointly beneficial agreement," says Catalyst President and CEO Joe Nemeth. "This transaction represents a mutual investment in community prosperity and continued cooperation between community and our industry. It addresses the City and Tla'amin's need for a diversified economy while enabling Catalyst to focus on core operations."

As a result of this transaction the Limited Partnership Board will be restructured to have 3 representatives from each partner. Representing Tees'kwat will be Chief Councillor Clint Williams, Councillor Walter Paul and Sliammon Development Corporation President Roy Francis. Representing PRWDC on the PRSC Board will be City CFO Shehzad Somji, and Powell River citizen appointees Kevin Sigouin and Chris Roddan.

SOURCE: Catalyst Paper Corporation

For further information:

Mac Fraser

CAO

City of Powell River

604-485-6291

Rod Allan

CAO

Tla'amin First Nation

604-483-9646

Brian Baarda

CFO

Catalyst Paper Corporation

604-247-4710

This information is being distributed to you by / Cette information vous est transmise par : Catalyst Paper Corporation

Valmet's new BioTrac pilot plant for hydrolysis of biomass started up

Valmet has installed a new bio pilot plant in its research and development center in Sundsvall, Sweden. The equipment, called BioTrac, is a hydrolysis system which is used for process optimization and testing of raw materials based on biomass. This is part of Valmet's investment into developing new technologies for biorefinery applications, in order to deliver technology and process solutions to reduce CO2 emissions globally.

Valmet's BioTrac is flexible both when it comes to different raw materials and process alternatives, and can be adapted to several downstream process steps. Hydrolysis is often the first step in a biorefinery, and a step that has to be passed, regardless of subsequent process chosen. Further refining of the biomass can for example be production of bioethanol, bio based chemicals and biomaterial, such as bio based plastics.

"Many companies want to replace fossil fuels in favor of renewable raw materials. The product streams from our BioTrac system, and from the subsequent processes, can be used as bio based raw materials for production of for example plastics and chemicals. We are confident that our customers appreciate that they now can test their own ideas in our pilot plant, which in all essential parts correspond to the full scale equipment they are interested in," says Rickard Andersson, Vice President, Bio Technology and Environmental Systems, Valmet.

"In the new BioTrac system it is easy to handle a variety of biomasses and we can closely control and follow what is happening in the process. The system represents world class and is based on technology which was originally developed for the pulp and paper industry, where Valmet has extensive experience going over hundred years back," says Olof Melander, Manager, Valmet Fiber Technology Center in Sundsvall.

About hydrolysis

Hydrolysis is a chemical process that, under elevated temperature and pressure, makes cellulose and hemicellulose available to be split into different sugars and lignin in subsequent processes. The lignin is obtained as a solid residue. Both sugars and lignin can then be further refined.

Information about Valmet's Fiber Technology Center in Sundsvall, Sweden

Valmet's Fiber Technology Center in Sundsvall employs about 20 persons, among them a number of researchers. In addition to several different pilot plants, e.g. for washing, screening and refining, the technology center also houses a laboratory for bleaching trials and various chemical, pulp and paper analyses.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

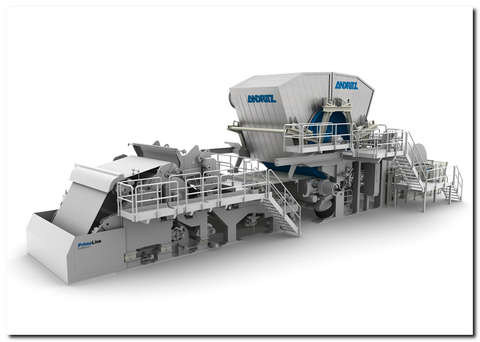

ANDRITZ to supply tissue machine with steel Yankee to Guangdong Shaoneng, China

International technology Group ANDRITZ has received an order from the Guangdong Shaoneng Group to supply a PrimeLineCOMPACT II tissue machine with steel Yankee to its location in Shao Guan, Guangdong province, China. Start-up is scheduled for the end of 2015.

Guangdong Shaoneng is one of the leading producers of pulp and paper in China. Bamboo pulp produced at the mill location will also be used in tissue production.

The ANDRITZ machine has a design speed of 1,600 m/min and a width of 2.85 m. The order also includes the complete stock preparation plant, automation, and drives.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,100 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long term.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

For further information, please contact:

Oliver Pokorny

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.

Voith upgrades disk filters at WEIG-Karton – significantly improved filtrate values after rebuild

![]() Moritz J. WEIG GmbH & Co. KG in Mayen, Germany, chose Voith for the rebuild of its third-party disk filter. After a successful startup following the rebuild, significant improvements in filtrate values were recorded, while at the same time maintenance costs are now demonstrably lower. This was achieved by integrating the modern Voith disk filter technology, which includes BaglessPlus disk filter sectors and a new filtrate valve.

Moritz J. WEIG GmbH & Co. KG in Mayen, Germany, chose Voith for the rebuild of its third-party disk filter. After a successful startup following the rebuild, significant improvements in filtrate values were recorded, while at the same time maintenance costs are now demonstrably lower. This was achieved by integrating the modern Voith disk filter technology, which includes BaglessPlus disk filter sectors and a new filtrate valve.

BaglessPlus disk filter sectors made from corrugated stainless steel provide increased capacity by up to 15% to 20%, while at the same time improve filtrate quality. Clear filtrate and super-clear filtrate quality have significantly exceeded customer expectations. Initial measurements recorded 180 ppm in the clear filtrate and 60 ppm in the super-clear filtrate. Since the high filtrate quality will remain unchanged during the entire lifecycle of the BaglessPlus sectors, ranging from 10 to 20 years, large quantities of fresh water can be saved.Moreover, BaglessPlus disk filter sectors are maintenance free, with holes in filter bags no longer being an issue.

The new filtrate valve ensures a consistently high vacuum and further ensures the high filtrate quality. The rebuild switched the mounting by plain bearing to reliable roller bearing with the new central shaft. In addition, the disk filter was equipped with new knock-off and cleaning spray pipes featuring patented nozzles.

The upgraded disk filter now replaces four drum thickeners, which had become susceptible to failure due to high screen wear.

WEIG-Karton’s trust in Voith is based on many years of collaboration. Two years ago another third-party disk filter had already been successfully rebuilt to BaglessPlus sectors and HiCon. Thanks to the conversion to HiCon, this disk filter is now being operated at an intake stock consistency of up to 2%.

The Voith disk filter technology has been developed for BlueLine, a product and component range designed to keep energy, fiber and water consumption in stock preparation as low as possible. Voith disk filter components can be installed in machines from all manufacturers.

Moritz J. WEIG GmbH & Co. KG is among Europe’s leading manufacturers of recycled board. At its main location in Mayen, approximately

620,000 metric tons of board from recovered paper is produced annually.

Further information is available on the Voith website at

www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 43,000 people, generates € 5.7 billion in sales, operates in about 50 countries around the world and is today one of the biggest family-owned companies in Europe.

Completing the Loop: Recycled Coffee Cups Re-Enter the Consumer Market

Disposed-of paper cups return to consumer hands as James Cropper launches ‘Coffee’, a range of high-specification papers using fibres extracted from previously unrecyclable paper cups.

Single-use disposable coffee cups finally became recyclable in July 2013, when James Cropper unveiled a purpose-built Reclaimed Fibre Facility, the first commercial processing plant able to separate valuable pulp fibres from the polythene lining of billions of cups thrown away each year. The British manufacturer now returns those fibres to the supply chain in Coffee, a range of papers that demonstrate the highest standards in sustainable, luxury paper production.

Launching at Packaging Innovations 2014 (Tue 30 September - Wed 1 October), Coffee is comprised of 50% reclaimed fibres (RCF) that were once ‘single use’ coffee cups, offering luxury brands, including food and drink producers, the opportunity to repurpose a high quality paper source previously lost to landfill. The range has been initially produced in a range of six colours inspired by the skills of Baristas and the alchemy of coffee making - Latte, Cappuccino, Caramel, Hazelnut, Mocha and Espresso.

James Cropper has been announced as coffee cup sponsor of the Packaging Innovations 2014 event at the Business Design Centre, London. Integral thermal sleeves on the event cups have been made with RCF, effectively reintroducing recycled coffee cups to their original use for the very first time. The messaging on the event cups encourages drinkers to ‘Be In The Loop’ by taking their cups to the James Cropper Stand, E57, and posting used cups into a collection device to start the recycling process all over again.

Chris Brown, Commercial Director said: “Disposable coffee cups were a problem for our industry and now we’ve turned them into an opportunity. Technology has moved on so that we can create new products using high-levels of reclaimed materials, which are indiscernible in their quality from papers that are made wholly from virgin fibres. Packaging manufacturers and suppliers are under increasing consumer pressure to prove they are responsible with natural resources, and the Coffee range is just one of the ways in which our investment in new recycling processes makes it easier for them to respond to those demands, without compromising their products and brand values.”

Opened by Her Majesty The Queen, James Cropper’s Reclaimed Fibre Facility based in Cumbria, UK is the result of a £5million investment and has been recognised by the paper industry as a landmark development in the progression of sustainable paper production. The Luxepack In Green Award was presented to James Cropper in October 2013 in recognition of this contribution. In the year since opening, thousands of coffee cups and other food and drink packaging materials have been recycled to create new paper products, but Coffee sees the percentage of RCF pulp increase to 50% for the very first time.

Earlier this year, James Cropper PLC became one of 14 international companies to formally join the Paper Recovery and Recycling Group (PCRRG), drawing together paper and paper cup manufacturers with high street coffee retailers, to conduct in-market trials of recycling processes and end products, with emphasis on the UK market.

James Cropper PLC maintains significant investment in new technologies not only within its paper division, incorporating converting capabilities, but also Technical Fibre Products, a specialist supplier into to the composites market for non-wovens for aerospace, automotive and construction.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens into the composites market, which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

AkzoNobel and Photanol developing chemical compounds of the future

![]() AkzoNobel and cleantech company Photanol have teamed up to develop a process for harnessing the power of the sun to make chemicals.

AkzoNobel and cleantech company Photanol have teamed up to develop a process for harnessing the power of the sun to make chemicals.

The two companies will work on creating sustainable technology which mimics the way plants use photosynthesis. The aim is to produce "green" chemical building blocks that will eventually replace raw materials AkzoNobel currently obtains from fossil-based production.

"Given the challenges the world is facing in terms of resource scarcity, we are actively looking for bio-based alternatives for our chemicals and Photanol's existing technology is a potential game-changer," explained Peter Nieuwenhuizen, AkzoNobel's Director of Innovation and Partnerships.

"We are constantly looking for less traditional solutions as we strive to do more with less and this exciting partnership - which has the potential to significantly reduce our carbon footprint - is a perfect example of our Planet Possible approach to sustainability."

The collaboration is focused on Photanol's existing proprietary technology, which uses light to directly convert CO2 from the air into predetermined raw materials such as acetic acid and butanol. The only by-product is oxygen.

Michiel Lensink, Photanol CEO, added: "The cooperation with AkzoNobel is of major strategic importance to us. Not only does it give us access to a large potential market, but AkzoNobel's processing technology expertise also means that we will shorten our time to market."

The two companies will start by developing a number of specific chemicals that are currently used by AkzoNobel's Specialty Chemicals Business Area. The partnership is intended to be a stepping stone for potential commercial production of fourth generation bio-based chemicals.

AkzoNobel's chemicals are used extensively by the chemicals, detergent, construction, food, pulp and paper and plastic industries.

NewPage Introduces Ed #16: Digital Possibilities

"Ed" is an industry leading educational resource for all things paper, printing and design

NewPage Corporation (NewPage) announced today the release of Ed #16: Digital Possibilities, the newest brochure in its popular "Ed®" series which has been delivering educational tips and advice on printing techniques, new technologies and sustainability topics relevant to customers and other stakeholders for more than a decade. In this new brochure, Ed explores the growth and expanding print capabilities of digital printing.

NewPage Corporation (NewPage) announced today the release of Ed #16: Digital Possibilities, the newest brochure in its popular "Ed®" series which has been delivering educational tips and advice on printing techniques, new technologies and sustainability topics relevant to customers and other stakeholders for more than a decade. In this new brochure, Ed explores the growth and expanding print capabilities of digital printing.

In just a few short years, digital printing has gone from an emerging to an established technology. With offset-level quality and almost limitless ability to personalize to your target, the realm of possibility has exploded. Like so many technologies today, digital printing capabilities are advancing in shorter and shorter cycles every day. Equipment productivity and speed continues to improve overall economics. With new print techniques like metallic inks, varnishes, embossed-like dimensionality, ultraviolet ink and more, digital printing is winning over even the biggest skeptics. And with the convergence of data, GPS and other technologies, the realm of possibility has exploded for targeted, highly personalized print strategies.

"NewPage has been a leader in manufacturing digital papers since digital printing technology first emerged, with specialized expertise, dedicated production capacity and one of the broadest offerings of digital-specific products in the industry," said Dennis Essary, director, Digital Papers for NewPage. "All of our digital products are designed and manufactured specifically for digital printing."

At the high end of the digital papers line, NewPage offers Futura®, Sterling® Premium Digital™ and Sterling® Premium Digital™ for HP Indigo with pleasing optics, premium surface quality and budget-friendly pricing. Productolith Pts. Digital® is available for heavier weight packaging and direct mail and Blazer Digital® is the economy digital coated paper of choice. NewPage also offers award-winning TrueJet®, a specialized line of digital coated papers for production inkjet presses that not only optimizes quality but also is designed to deliver significant savings in ink costs. All, from Futura to TrueJet, with multiple original equipment manufacturers (OEM) certified performance.

"OEMs like HP, Kodak, Xerox, Konica Minolta and a host of others are investing aggressively to offer the next big thing in toner-based and inkjet technologies," said Aaron Haas, director, Commercial Product Management for NewPage. "Why? Because they know what Ed knows—when it comes to reaching and motivating an audience, print works. And when smart technologies meet smart marketers and designers, print works even better than ever."

To obtain a copy of the Ed #16: Digital Possibilities brochure, please contact your NewPage sales representative. To learn more, visit one of our websites: www.NewPageCorp.com, www.EdLivesHere.com or Facebook.com/NewPageCorp.

About NewPage

NewPage is a leading producer of printing and specialty papers in North America with $3.1 billion in net sales for the year ended December 31, 2013. NewPage is headquartered in Miamisburg, Ohio, and owns paper mills in Kentucky, Maine, Maryland, Michigan, Minnesota and Wisconsin. These mills have a total annual production capacity of approximately 3.5 million tons of paper.

The company's portfolio of paper products includes coated, supercalendered and specialty papers. These papers are used in commercial printing to create corporate collateral, magazines, catalogs, books, coupons, inserts and direct mail as well as in specialty paper applications including beverage bottle labels, food and medical packaging, pressure-sensitive labels and release liners. To learn more, visit www.NewPageCorp.com.

All copyrights, trademarks, tradenames and logos mentioned or used in this publication are the property of their respective owners.

SOURCE NewPage Corporation

For further information: Shawn Hall, 937-242-9373

2 out of 4 Yuen Foong Yu’s PMP Intelli-Tissue® 1600 Advanced lines are up and running

At the end of April 2013, Yuen Foong Yu (one of Asia’s leading tissue producers) has signed a contract with PMP Group for the delivery of four (4) complete PMP Intelli-Tissue® 1600 Advanced lines. Taking all projects into consideration, the new order have made a total amount of seven (7) new PMP Group machines in the YFY’s fleet. Thus it is our pleasure to announce that on August 28th 2014 another PMP Intelli-Tissue® 1600 Advanced line was brought on stream at the YFY’s Yangzhou mill in China.

The new 2.8 m width CF tissue machine (PM#8) of operating speed 1600 mpm and daily capacity of 75 t produces virgin fiber-based tissue in the basis weight range at reel from 13-31.3 gsm - for conversion into facial tissue, toilet rolls and kitchen towels. The scope of supply covers stock preparation, entire tissue machine (double-layer Intelli-Jet V® headbox, Intelli-Former® Crescent Former, Intelli-Press® with 16’’ steel YD and high efficiency steam hood and Intelli-Reel®) including also auxiliary systems like mechanical drives, lubrication system, steam & condensate, dust removal system, as well as controls and start-up services. Especially noteworthy however, is the double-layer Intelli-Jet V® hydraulic headbox which is a highly advanced, technological unit that guarantees production of premium quality tissue.

This was the second (out of four) start-up’s that will be performed by YFY and PMP Group in 2014/2015. At present Yuen Foong Yu brands, including Mayflower, Tender and Delight, play a significant role in the premium tissue sector in China and Taiwan. Through production expansion, product line extensions, and strengthening branded products, YFY’s goal is to be ranked as one of the top 5 tissue producers in China. PMP Group is proud that YFY has trusted the company to be a part of this development strategy. Fruitful partnership, that has been developing over the years between those two companies, has resulted in extremely fast start-ups and overall, positive cooperation based on win-win solutions. PMP Group is looking forward to future projects and is confident that the Intelli-Tissue® Advanced lines will help YFY in achieving their market goals and ambitions.

The President of Uruguay, José Mujica, visits UPM’s Biofore House

As part of an official working visit to Finland, Uruguay’s President José Mujica today visited UPM’s Biofore House in Helsinki hosted by UPM’s CEO Jussi Pesonen. In the meeting Jussi Pesonen expressed UPM’s appreciation to the President and the Government of Uruguay for their continuing support for the development of UPM’s operations and the forestry sector in Uruguay.

“UPM considers further industrial development of the Uruguayan forest sector as a positive opportunity and we welcome the invitation to engage in further dialogue with the Government of Uruguay. The current focus of discussions is on the development areas required for further industrial growth, notably the infrastructure for logistics and plantations as well as education to nurture versatile skills and expertise”, says Jussi Pesonen.

For further information:

Jaakko Sarantola, Senior Vice President, UPM Pulp Business, tel.+358 40 707 0221

UPM in Uruguay

UPM’s operations in Uruguay include the Fray Bentos pulp mill, the forestry and wood sourcing company UPM Forestal Oriental which has two nurseries, as well as the UPM Foundation, which in cooperation with local organisations contributes to education, entrepreneurship and improving the quality of life through projects focusing on the rural areas where the company operates.

The Fray Bentos pulp mill started operations in 2007 and it is still one of the world’s most modern and efficient pulp mills. Its annual production capacity is 1.3 million tonnes of chemical eucalyptus pulp. Besides pulp, the Fray Bentos mill is a significant biomass based energy producer - its electricity production accounting for 10% of Uruguay’s total energy production. The mill’s wood raw material comes from sustainably managed local plantations.

UPM Forestal Oriental owns about 230,000 hectares of land, of which about 60% is planted with eucalyptus. The rest of the land is protected or is used for forestry-related infrastructure, cattle grazing and other non-plantation operations. All of UPM's forest plantations are certified to FSC® and PEFCTM standards. About 70% of the Fray Bentos mill’s fibre wood comes from the plantations managed by UPM Forestal Oriental and the rest is supplied by the company’s long term partners.

In Uruguay, UPM has 550 direct employees and employs indirectly around 3,400 people. The value chain of UPM’s Uruguay operations creates altogether 6,400 jobs and its contribution to Uruguay’s GDP is approximately 1.3%.

UPM

Through the integration of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 21,000 people and its annual sales are approximately € 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

UPM Pulp

UPM is one of the world’s leading producers of northern softwood, birch and eucalyptus pulp supplying global customers mainly in the growing end use segments such as tissue, speciality papers and board through its own sales and technical service network close to the customers. UPM Pulp operates four modern pulp mills, three in Finland and one in Uruguay as well as eucalyptus plantations in Uruguay. UPM Pulp employs approximately 1,500 people and has an annual pulp production capacity of 3.3 million tonnes. Pulp Business is part of the UPM Biorefining Business Area. To learn more, visit: www.upmpulp.com