Ianadmin

SCA’s transfer of Chinese hygiene business to Vinda approved

SCA’s, a leading global hygiene and forest products company, and the majority shareholder in China’s third-largest tissue company, Vinda International Holdings Limited (“Vinda”), agreement with Vinda to transfer its hygiene business in China (Mainland China, Hong Kong and Macau) has today been approved by the independent shareholders of Vinda.

SCA’s, a leading global hygiene and forest products company, and the majority shareholder in China’s third-largest tissue company, Vinda International Holdings Limited (“Vinda”), agreement with Vinda to transfer its hygiene business in China (Mainland China, Hong Kong and Macau) has today been approved by the independent shareholders of Vinda.

Vinda is listed on the Hong Kong Stock Exchange, and the agreement which strengthens the cooperation between SCA and Vinda (announced July 18, 2014) was subject to approval by the independent shareholders of Vinda.

The transaction is expected to close on October 1, 2014. As of the closing date, Vinda will have the exclusive license to market and sell the SCA brands; TENA, (incontinence products) Tork (Away from Home tissue), Tempo (consumer tissue), Libero (baby diapers), and Libresse (feminine care) in China (Mainland China,Hong Kong and Macau). In these markets, Vinda will hold the rights to these brands and acquire SCA’s Dr P and Sealer brands, while SCA will continue to provide innovation and technical support for the business.

- The approved cooperation and transaction will generate mutual benefits for both SCA and Vinda particularly in distribution, sales, innovation and R&D. Vinda will get access to a broader product portfolio and SCA’s brands will have the potential to reach a broader base of consumers and customers via the extensive and robust distribution network of Vinda in China, says Jan Johansson, President and CEO of SCA.

SCA has been a shareholder in Vinda since 2007, became its majority shareholder in late 2013, and has consolidated Vinda financials since the first quarter of 2014.

SCA’s hygiene business in China (Mainland China, Hong Kong and Macau) had net sales of approximately SEK 600m in 2013. The purchase consideration amounts to HKD 1,144m (approx. SEK 1,000m) on a debt-free basis.

For additional information please contact:

Johan Karlsson, VP Investor Relations, 46 8 788 51 30

Boo Ehlin, VP Media Relations, 46 8 788 51 36

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2013 amounted to approximately SEK 93bn (EUR 10.7bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Södra's interim report January-August 2014: Positive performance and improved profitability

Södra's earnings to date this year (accumulated January-August) improved to SEK 1,012 million (loss: 786) and amounted to SEK 509 million (loss: 687) for the second four-month period. The earnings improvement was primarily attributable to increased demand and higher prices for finished goods.

Södra's earnings to date this year (accumulated January-August) improved to SEK 1,012 million (loss: 786) and amounted to SEK 509 million (loss: 687) for the second four-month period. The earnings improvement was primarily attributable to increased demand and higher prices for finished goods.

"Demand and orders for Södra's products improved during the second four-month period and the Group reported a positive performance and improved profitability. All of the Södra Group's business areas continued to improve their earnings. The improvement is mainly the result of a more favourable market in addition to the Group's own productivity enhancing measures and continued efficiency gains," says Södra's President and CEO Lars Idermark.

Net revenue for the first eight months of the year increased to SEK 11,429 million (11,137), primarily the result of increased volumes and higher prices. Net revenue for the second four-month period amounted to SEK 5,591 million (5,599).

Operating profit for the first eight months of the year amounted to SEK 1,012 million (loss: 786). The accumulated result includes a positive effect of SEK 173 million from the sale of equipment from Södra Cell Tofte AS. Earnings in the preceding year were charged with restructuring costs for the discontinuation of Södra Cell Tofte AS. Consolidated operating profit for the second four-month period amounted to SEK 509 million (loss: 687) and all business areas displayed a continued positive earnings trend.

Profit after finance income and expenses improved to SEK 953 million (loss: 801) for the first eight months of the year and amounted to SEK 476 million (loss: 702) for the second four-month period.

1 May - 31 August 2014

- Net revenue SEK 5,591 million (5,599)

- Operating profit SEK 509 million (loss: 687)

- Profit after finance income and expenses SEK 476 million (loss: 702)

- Cash flow after investments SEK 260 million (396)

1 January - 31 August 2014

- Net revenue SEK 11,429 million (11,137)

- Operating profit SEK 1,012 million (loss: 786)

- Profit after finance income and expenses SEK 953 million (loss: 801)

- Cash flow after investments SEK 775 million (278)

>>Read more: The interim report

To find out more, please contact:

Lars Idermark, President and CEO

tel: +46 470 894 35

Carina Olson, CFO

tel: +46 470 892 62

Annica Gerentz, Director of Communications

tel: +46 470 894 81

Södra's 74-tonne wood-chip truck now rolling fully loaded

On 15 May, Södra's two truck rigs with a maximum weight of 74 tonnes officially entered service. They are now rolling fully loaded.

Shortly after entering service, a dispensation was received for one of the rigs, a timber truck with a five-axle trailer. Dispensation for the wood-chip truck was not granted until 10 September and, during the waiting period, the truck operated as a 60-tonne truck. Now both rigs are in full production and both are included in the Forestry Research Institute of Sweden's ETT - Modular System for Timber Transport project named One More Stack.

"We are relieved to finally get started. It will be interesting to follow how much more we will be able to transport for different products and what this will mean in terms of fewer journeys and lowered emissions," says Åsa Forss, Transport Manager at Södra.

Södra is one of the stakeholders in the Forestry Research Institute of Sweden's project for larger and heavier timber transportation vehicles. The project is evaluating a number of vehicles in practical operation, where areas include environmental impact (fuel consumption and emissions), road safety and costs. Two primary types of longer and/or heavier vehicles are being evaluated:

. ETT rigs, (One More Stack) with a length of 30 metres (max. 32 metres) and a maximum weight of 90 tonnes

. ST rigs (Bigger Stacks) with a normal length of (max. 25.25 metres) and a maximum weight of 74 tonnes.

To find out more, please Contact:

Håkan Larsson, President, Södra Skog, tel: +46 70 589 45 10

Annica Gerentz, Director of Communications, Södra, tel: +46 470 894 81

Åsa Forss, Transport Manager Södra, tel: +46 470 856 41

ANDRITZ to supply dispersing systems, disc filters, and refiners for Zhejiang Chuancheng, China

International technology Group ANDRITZ has received an order to supply dispersing systems, disc filters, and refiners for Zhejiang Chuancheng Industrial’s paper machines PM1 and PM2, China. Start-up is scheduled for the fourth quarter of 2015.

The scope of supply for PM1 includes two dispersing systems, a save-all disc filter, five thickeners, two TwinFlo refiners, and three MC pumps to produce 350,000 tons of kraft liner per year. PM2 (production of corrugated medium grades with a capacity of 250,000 tons per year) will be equipped with one save-all disc filter, two thickeners, and one refiner.

Zhejiang Chuancheng is a member of the Yongtai group, one of the leading paper producers in China.

“Photo: ANDRITZ”.

Domtar celebrates sale of five million tons of Forest Stewardship Council® certified paper

Widest range of FSC® certified, sustainable North American papers on the market

Domtar Corporation has announced that it has sold its five millionth ton of Forest Stewardship Council® (FSC®) certified uncoated fine paper, a first for the North American market. Domtar's EarthChoice® Product Line represents the widest range of FSC certified papers available today, and the milestone solidifies the company's position as a longstanding industry leader in responsible fiber sourcing and sustainable practices.

"EarthChoice Products by Domtar (CNW Group/Domtar Corporation)"

Domtar revolutionized the industry when it became the first company in North America to offer FSC certified copy paper in 2005. By breaking from the norm and embracing sustainable goals, Domtar helped create a new model of collaboration - one that has led to long-standing partnerships with some of the world's leading environmental organizations, including the Rainforest Alliance and World Wildlife Fund (WWF).

"We are thrilled to have continued our work with Domtar as it delivers on its commitment to bring sustainability into the mainstream via its EarthChoice product line," said Tensie Whelan, President of Rainforest Alliance. "The Rainforest Alliance CertifiedTM seal and the FSC logo featured on EarthChoice products assure consumers they are supporting healthy forests - crucial for clean air and water, carbon sequestration and wildlife habitat. With over five million tons of EarthChoice product sold, this is a prime example of sustainability making good business sense."

Linda Walker, Director, Global Forest & Trade Network-North America, World Wildlife Fund, added, "We are losing forests at a rate of eight football fields every 10 seconds. One of the best things that can be done to address this dramatic statistic is to put FSC products on the shelves. Domtar is a leader in this. The more FSC-labeled products consumers see, the more we can ensure forests will thrive for generations to come."

Today, the EarthChoice family of products includes FSC certified paper for business, publishing, converting, printing and specialty uses, and accounts for more than 20 percent of Domtar's total paper sales.

"I am proud to say that some of the most recognized companies in the world have put their own commitment to responsible environmental practices on paper by choosing Domtar's FSC certified EarthChoice products," said John D. Williams, President and Chief Executive Officer. "I would like to thank our nearly 10,000 employees, our loyal customers and our supplier partners for helping us sell five million tons of Forest Stewardship Council certified paper, an impressive milestone that once again demonstrates Domtar's sustainability leadership within industry."

"The support Domtar is demonstrating for FSC certification is generating concrete social and environmental benefits for the world's forests and the people who depend on them. The sale of five million tons of FSC certified paper is another landmark in Domtar's commitment to sustainability. Congratulations to Domtar for its continued leadership and its commitment to healthy and sustainable forests," said Kim Carstensen, Director General of FSC International.

To learn more about the role of responsible fiber sourcing within the EarthChoice commitment to sustainable business, please visit www.domtar.com/earthchoice

SOURCE Domtar Corporation

Voith upgrades deliver energy and machinery efficiency to Newark America in Fitchburg, Massachusetts

Voith has completed an upgrade of the stock preparation at Newark Recycled Paperboard Solutions (Newark America) in Fitchburg, Massachusetts, reducing production cost and boosting efficiency in the process. As a result of the upgrades, the facility can now use OCC (Old Corrugated Containers) instead of less contaminated recycled board as a raw material for the production of high quality linerboard. In addition, the upgrade ensures minimal fiber loss during the production process.

Voith has completed an upgrade of the stock preparation at Newark Recycled Paperboard Solutions (Newark America) in Fitchburg, Massachusetts, reducing production cost and boosting efficiency in the process. As a result of the upgrades, the facility can now use OCC (Old Corrugated Containers) instead of less contaminated recycled board as a raw material for the production of high quality linerboard. In addition, the upgrade ensures minimal fiber loss during the production process.

“We are very pleased with the upgrade at our Fitchburg facility”, said Barry Jensen, Vice President Newark Recycled Paperboard Solutions. “The upgrade process went according to plan and the startup was the smoothest we have encountered, which is even more impressive considering complexity of the project. Within a few hours of pressing the start button, the plant was supplying the machine with quality fiber at design capacity. The upgrade project has met all the quality objectives, and power consumption is lower than expected.”

The main upgrade consisted of improving the current pulper detrashing loop using Voith’s IntensaMaxx. IntensaMaXX prevents tail formation and spinning so that even content with high levels of contaminant can be easily processed. Another advantage of IntensaMaXX is its low energy consumption. IntensaMaXX can be used in continuous low consistency (LC) pulping with recovered paper grades containing contaminants or in high consistency (HC) pulping as a dumping machine after the batch HC pulper.

In addition, Newark Fitchburg upgraded a multi-stage fine cleaning system with Voith’s unique HCL5C cleaner with HW and LW removal combination, while adding a three stage fine screening upgrade with the C-bar screen basket. These upgrades included a new third stage MultiMizer with optimum slots configuration for a fiber savings final stage screening concept.

The HCL5C technology is a multi-stage system for cleaning fiber suspensions. It removes heavy weight and light weight contaminants in the stock preparation and approach flow systems. The C-bar screen basket is used in stock preparation and approach flow and can be used for increasing the capacity of existing pressure screens. It has a large open screening area with high slot width precision, providing up to 20% more capacity than conventional screen baskets. The MultiMizer improves the overall system performance and provides cost savings by reducing the amount of flakes in the reject stream of the fine slotted screening system.

Newark, originally The Newark Group, was founded in 1912. In 2013, Newark became Newark Recycled Paperboard Solutions. The company was rebranded to better reflect the upward direction that the company was taking. They are the largest open-market sellers of recycled paperboard in North America. Newark operates six mills that produce over 450,000 metric tons of 100% recycled paperboard annually.

Xerium Announcing Long-Term Growth and Debt Pay Down Plans

Presenting at Imperial Capital Global Opportunities Conference

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, today announced that it will be presenting at the Imperial Capital Global Opportunities Conference in New York and conducting one-on-one meetings with interested investors. Xerium will use the forum to provide further details on its strategy for long-term growth and plans to pay down debt. Harold Bevis, President and CEO, Cliff Pietrafitta, Executive Vice President and CFO, and Dave Pretty, President of North America and Europe, will be the company's attendees and will be presenting at the conference at 9:30 am ET on Thursday, September 18, 2014.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, today announced that it will be presenting at the Imperial Capital Global Opportunities Conference in New York and conducting one-on-one meetings with interested investors. Xerium will use the forum to provide further details on its strategy for long-term growth and plans to pay down debt. Harold Bevis, President and CEO, Cliff Pietrafitta, Executive Vice President and CFO, and Dave Pretty, President of North America and Europe, will be the company's attendees and will be presenting at the conference at 9:30 am ET on Thursday, September 18, 2014.

A webcast of the presentation management will provide will also be available on the company's investor relations website. Interested parties should click on the webcast link above the event titled "Xerium Technologies at Imperial Capital Global Opportunities Conference" on the company's investor relations homepage at www.xerium.com/investorrelations. From there, they will be taken to an Event Details page where they can register for and access the webcast by clicking on the link below "Webcast Presentation." Interested parties may also go directly to the webcast registration page for the conference by going to wsw.com/webcast/imperial16/xrm.

A replay of the presentation and a copy of the materials used in the presentation will also be made available by clicking on the webcast link above the event titled "Xerium Technologies at Imperial Capital Global Opportunities Conference" on the company's investor relations homepage at www.xerium.com/investorrelations or by clicking on the "Investor Presentations" tab on the left hand side of the investor relations homepage.

The company will also be available to meet one-on-one with investors the day of the presentation. If you have interest in one of these sessions please contact Orlagh Vagnoni at (212) 351-9721 or at This email address is being protected from spambots. You need JavaScript enabled to view it..

Revival of Softwood Fiber-Based Forest Industry in the Nordic Countries with Investments of 3 Billion Dollars in Pulp, Bio Energy and Bio-Materials

Forest companies in Northern Europe have announced plans to investment three billion dollars in 2014 in attempt to move beyond mostly producing newsprint and commodity packaging grades. The idea is to diversify their product lines to include new bio-products from wood fiber and to generate bioenergy to reduce the region’s dependence on fossil fuels, reports the Wood Resource Quarterly.

Forest companies in Northern Europe have announced plans to investment three billion dollars in 2014 in attempt to move beyond mostly producing newsprint and commodity packaging grades. The idea is to diversify their product lines to include new bio-products from wood fiber and to generate bioenergy to reduce the region’s dependence on fossil fuels, reports the Wood Resource Quarterly.

The pulp and paper industry in the Nordic countries has started to see a new dawn with a growing demand for pulp and paper products made from long wood fiber from the vast conifer forests in Northern Europe. Just over the past few months, there have been a number of announcements in investments made by forest companies in Finland, Norway and Sweden totaling close to three billion dollars, as reported in the Wood Resource Quarterly (WRQ).

The primarily end-products will be softwood market pulp and virgin fiber-based container board, but major investments are also being consider in increasing the utilization of forest biomass for energy on a larger scale. Although the investment decisions have not been finalized for all projects, these ruminations are a sign that the forest industry in this part of the world sees the future in a much brighter light than just a few years ago.

In addition to the investments in the pulp and paper industry, there has also been an announcement that the Swedish forest owner federation Sodra, together with the Norwegian energy company Statkraft, Europe’s largest producer of renewable energy, intends to establish an biofuel conglomerate at the site of the now closed pulpmill in Tofte, just south of the capital Oslo.

In Finland, Metsä Fiber has plans to invest 1.5 billion dollars in a plant that will produce softwood pulp, renewable bioenergy and what the company categorizes as “various bio-materials”.

Some of the factors that have placed softwood fiber in a new positive light are: limited investments in the establishments of softwood plantations worldwide, favorable global supply/demand balance for softwood pulp over hardwood pulp, (if you are a pulp manufacturer), increased demand for packaging material requiring wood fiber with high strength, and a rise in research in new products made from trees, sometimes as substitutes to non-renewable materials such as plastic and metal.

These recent developments in the Nordic countries may very well be the beginning of the biggest transformation of the softwood fiber-based forest industry we have seen in decades, not only in Northern Europe but in other regions of the world as well where coniferous forests is the dominant forest-type.

Global pulpwood and timber market reporting is included in the 52-page quarterly publication Wood Resource Quarterly (WRQ). The report, which was established in 1988 and has subscribers in over 30 countries, tracks sawlog, pulpwood, lumber and pellet prices, trade and market developments in most key regions around the world. To subscribe to the WRQ, please go to www.woodprices.com

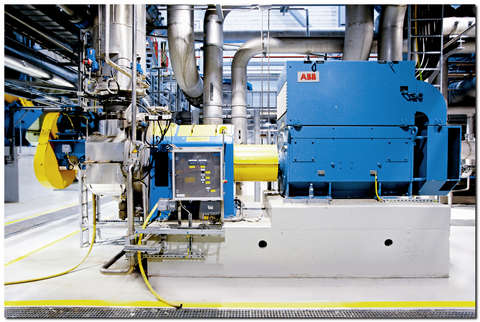

Kemira invests in its hydrogen peroxide plant in Oulu

Due to the growing demand for pulp chemicals in Finland, Kemira has decided to make a multi-million euro investment in its hydrogen peroxide plant in Oulu. The improved efficiency and operational capabilities will enable Kemira to serve pulp and paper producers even better in the future.

Due to the growing demand for pulp chemicals in Finland, Kemira has decided to make a multi-million euro investment in its hydrogen peroxide plant in Oulu. The improved efficiency and operational capabilities will enable Kemira to serve pulp and paper producers even better in the future.

Kemira continues to commit to the pulp and paper industry in Europe also by investigating other bleaching chemical investment needs to support the pulp and paper industry and the announced future pulp mill expansions.

ANDRITZ to supply complete reject handling system for Shandong Sun Paper, China

International technology Group ANDRITZ has received an order to supply a complete reject handling system for Shandong Sun Paper Industry’s paper machines PM31 and PM32, China. Start-up is scheduled for the second quarter of 2016.

The scope of supply includes coarse and fine shredding systems, a ballistic separator, reject compactors, sand separators, as well as coarse and fine metal separators, including ferrous and non-ferrous metal separation. The ANDRITZ reject handling system has a total capacity of approx. 200 tons of light rejects per day. The residuals from both recycled fiber lines will be prepared for combustion or for further cleaning and recycling, while valuable components like metals will be separated.

Shandong Sun Paper is one of the leading Chinese pulp and paper producers.

The ANDRITZ GROUP

The ANDRITZ GROUP is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors. The publicly listed, international technology Group is headquartered in Graz, Austria, and has a staff of around 24,100 employees. ANDRITZ operates over 250 production sites as well as service and sales companies all around the world. The ANDRITZ GROUP ranks among the global market leaders in all four of its business areas. One of the Group’s overall strategic goals is to strengthen and extend this position. At the same time, the company aims to secure the continuation of profitable growth in the long-term.

“Photo: ANDRITZ”.