Ianadmin

NewPage Introduces Fourth New PAPER@WORK Brief At Labelexpo Americas 2014: UNTAPPED POTENTIAL: How paper labels make your craft beers shine.

NewPage Corporation (NewPage), a leading supplier of specialty papers, has launched the fourth edition of its PAPER@WORK Brief series at Labelexpo Americas titled, UNTAPPED POTENTIAL: How paper labels make your craft beers shine.

NewPage Corporation (NewPage), a leading supplier of specialty papers, has launched the fourth edition of its PAPER@WORK Brief series at Labelexpo Americas titled, UNTAPPED POTENTIAL: How paper labels make your craft beers shine.

This new PAPER@WORK Brief explores how the rapid growth of craft beers in America is creating a greater need for breweries to better differentiate themselves in a crowded cooler, and how paper labels can be used in compelling new ways to better connect with consumers.

"A renaissance of local brewing is taking place all across America," said Ed Buehler, vice president of specialty papers for NewPage. "The changing tastes of consumers are driving bold new opportunities for craft beers, and our new brief outlines the role paper beer labels can play in conveying a brewery's core values, as well as techniques for using paper to attract and inspire consumers.''

PAPER@WORK is an ongoing series of briefings from NewPage detailing a spectrum of important topics impacting the world of specialty papers.

Please visit www.wherepaperworks.com/UntappedPotential-brief to download this FREE PAPER@WORK Brief or obtain a copy by visiting the NewPage booth #1539 at Labelexpo Americas 2014 in Chicago, Illinois, September 9 - 11, 2014.

SOURCE NewPage Corporation

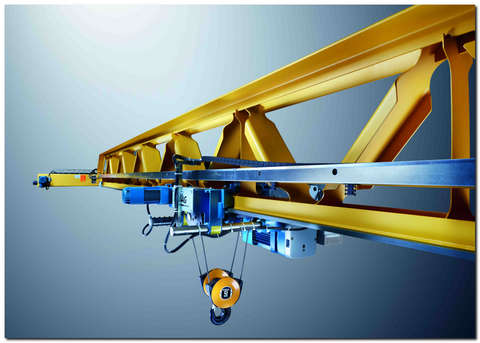

New, revolutionary crane generation: the Demag V-type crane

Vince Maynard see's first hand the latest innovation from Terex Material Handling & Port Solutions

Terex Material Handling has launched a new generation of cranes which sets a new standard in the industry with its Demag V-type crane. Thanks to its V-type design, which uses less material and helps to save resources, the V-type girder weighs on average 17 per cent less than comparable box-section profile girders. The reduced crane deadweight produces less wheel pressure, minimises the forces transmitted to the existing building structure and increases the maximum load capacity. Consequently, the new Demag V-type crane gives architects greater freedom for planning new factory buildings and is also suitable for companies that want to employ it in existing assembly and production bays.

- 17 per cent less deadweight than cranes with box-section girders

- Oscillation characteristics cut by up to 30 per cent

- More than 500,000 changes of load double the service life

The design (patent pending), which features diaphragm joints, also cuts oscillation of the crane girder by up to 30 per cent. The reduced oscillation characteristics cause lower loads to be transmitted to the crane and its components, as well as to the entire building, and double the service life of the crane to more than 500,000 changes of load. In addition, the improved oscillation characteristics enable heavy and sensitive loads, such as glass panels, fluids or aluminium shell sections for aircraft, to be positioned more precisely and quickly.

“The new V-type girder is the result of our continuous development in the crane engineering sector”, explains Andreas Hambrock, Head of the Universal Cranes Business Line at Terex Material Handling. “The new crane is an ideal supplement to our existing range of rolled and box-section girders. Thanks to its special design, sensitive loads can also be transported safely and precisely indoors and in outdoor applications. We are now able to cater to our customers‘ needs even better and can offer them solutions to meet their specific load handling requirements, boost their productivity and, at the same time, improve their operating safety.”

The new Demag V-type girder is initially available as a single-girder crane on the German market. It can be employed for various crane types, such as overhead travelling cranes, suspension cranes, portal cranes or wall-mounted travelling cranes.

Demag V-type crane: versatile, fast, long service life

Oscillation is a natural phenomenon that occurs in cranes. Lifting and travel motions result in forces that can cause a crane to resonate. That not only subjects the crane to loads. If the crane oscillates too much, it becomes difficult for the crane operator to handle loads precisely.

Terex Material Handling has developed a crane that is specially designed for transporting sensitive loads with its Demag V-type crane.

V-type design for efficient material flow

Whether for logistics contractors, aircraft manufacturers or steel producers – all sectors of in- dustry now face strong international competition. To maintain their position in today’s market, they need optimum efficiency throughout their material flow processes. “That already begins with fast and precise load handling”, explains Andreas Hambrock, Head of the Universal Cranes Business Line at Terex Material Handling. “We want to give our customers the best possible support with our cranes.” For this reason, the development of the Demag V-type crane focussed on factors such as handling rates, a high lifting-capacity-to-deadweight ratio, high load capacity and stability. Cost effectiveness and the certainty of a reliable investment also played an important role. “The goal of our engineers was to design a high-performance crane that operates with a high level of precision for a lower weight and longer service life.”

The result is a new design. “The crane girder is designed according to bionic engineering principles based on nature”, explains Andreas Hambrock. In a similar way to bone structure, material is only employed where it is necessary. Parts that are subjected to high loads are provided with additional stiffeners. “Diaphragm joints provide for optimum dissipation of force and, at the same time, an even distribution of pressure and tensile forces. That makes the Demag V-type crane extremely resilient to loads.” The result is a crane girder that weighs up to 17 per cent less, has up to 30 per cent less oscillation and offers double the service life. Terex Material Handling has patents pending for the new technologies incorporated in the Demag V-type crane.

Lower deadweight, higher load capacity

Thanks to its V-type design, Terex Material Handling has cut the deadweight of the Demag V-type girder by an average of 17 per cent with reference to a comparable box-section girder. This enables companies to utilise any reserves offered by their building structures and – de- pending on the load classification of the relevant rope hoists – to increase the lifting capacity of their installations even further. In this way, they are able to transport greater loads and no longer have to operate in the upper load capacity range. The lower deadweight also means that V-type cranes exert lower wheel pressures and transmit lower loads to the existing build- ing structure. Cranes can be integrated into existing workshops, assembly and production bays, often without the need for costly building refurbishment or changes to the building superstruc- ture. In addition, the eco-friendly use of materials also helps to protect the environment.

Lower oscillation and improved precision

The optimised deadweight-to-lifting ratio and improved dissipation of force enable the crane to steady the load more quickly. Crane owners benefit from higher performance and improved handling rates, since crane operators can position valuable and sensitive loads, such as glass panels, fluids and aluminium shell sections for aircraft, more gently and precisely.

And this can already be accomplished without the need for electronic control systems. The

Demag V-type crane as standard already offers more performance.

A further benefit: thanks to its reduced oscillation characteristics, the entire crane installation, including its components, the crane runway and its supports as well as the building and its foundations are subjected to lower loads. This is reflected by reduced wear, for example. In addition, the crane also boosts cost-effectiveness, since heavier loads can be moved in exist- ing building without the need for companies to modify the building structure. Furthermore: the Demag V-type crane can manage some 500,000 changes of load and, therefore, can achieve double the service life with reference to a comparable crane that has a box-section girder. That provides greater certainty of a reliable investment.

One crane to meet all requirements worldwide

Thanks to its new design, the V-type crane is also suitable for outdoor operation, since its surface area that is exposed to the wind is up to 55 per cent smaller in comparison with crane that has a box-section girder. For indoor operation, the girder allows 30 per cent more light to pass in comparison with conventional box-section girders, which provides for a brighter and more attractive working environment. The improved light situation also allows companies to save costs for indoor lighting. Besides allowing more light to pass through, the improved view also benefits safety at the workplace: users have an improved field of view and can see what is happening on the other side of the crane.

Compared to enclosed box-section girders, this benefit also pays off for service technicians, who can view the workshop through the crane girder. Since the design of the V-type crane affords a view of all weld seams, inspections and maintenance work can be carried out more easily.

In principle, most of the drive motor output is needed simply to move the crane. A further benefit of the new Demag V-type crane: the lower crane deadweight may enable motors with a reduced rating to be employed for improved energy efficiency. That saves operating costs and is kinder to the environment.

Emphasis was also placed on eco-friendly manufacturing processes for production of the crane. For example: the crane is blast-cleaned with dry ice before it is painted. The actual paints are water-soluble, thus avoiding the use of solvents that are harmful to the environment.

At the product launch, the Demag V-type crane will initially be available in single-girder design in the form of overhead travelling, suspension, portal and wall-mounted travelling cranes.

The overhead travelling and suspension cranes are available with spans of up to 30 metres and cover load capacities up to 12.5 tonnes. The Demag V-type crane is initially available in five different model variants for an optimum match with individual building contours. Depending on the situation – such as a bevelled or sloping inclined roof or installed pipes and conduits – the shape of the crane girder end will vary accordingly. Thanks to the new variable design, the V-type crane can be adapted with millimetre accuracy to the height of existing or planned buildings and modified in line with specific needs. Experienced Demag sales engineers can configure the best possible girder design for the given application based on customer wishes with a completely new Designer Tool in advance. Example for the height: depending on how much space is available between the crane runway and the lower edge of the building, the corresponding X and U dimensions are entered into the Crane Designer system to determine the optimum height of the crane.

ANDRITZ to supply complete ONP line to Lee & Man Group, China

International technology Group ANDRITZ has received an order from Lee & Man Group, one of the leading pulp and paper producers in Asia, to supply a 2-loop ONP (Old Newsprint) line for paper machine PM13 in Chongqing, China. Start-up is scheduled for the second quarter of 2015.

The scope of supply includes a deinking system with drum pulping for a line capacity of 300 tons per day. The pulp will be used for the production of white top testliner.

ANDRITZ successfully starts up paper machine at Naberezhnye Chelny Paper Mill

ANDRITZ successfully starts up paper machine at Naberezhnye Chelny Paper Mill, Russia, following a rebuild

ANDRITZ successfully starts up paper machine at Naberezhnye Chelny Paper Mill, Russia, following a rebuild

International technology Group ANDRITZ has successfully started up the PM K-28 paper machine at ZAOR “Narodnoye Predpriyatie Naberezhnye Chelny Paper Mill named after S.P. Titov”, Russia after completing a major rebuild.

Saleable paper was already obtained on the second reel produced. The machine has a design speed of 800 m/min at a width of 4.75 m and produces testliner and kraftliner.

ANDRITZ supplied two new headboxes (PrimeFlow SW) with PrimeProFiler dilution control and two PrimeForm Fourdriniers, as well as adding a new press with a PrimePress X shoe press in the second position. PrimeRun M web stabilizers and a new QCS system were also installed, as well as two new paper machine approach systems and a broke pulper. New process pumps from ANDRITZ will help to further raise efficiency.

Brighter Unilux LED-12 Leads Second Generation of Handheld Strobe Lights

Faster, more flexible response to production and maintenance inspection needs

Unilux has introduced the LED-12, the first handheld strobe light in its H2LED Series of second-generation LED inspection lights for the printing, converting, papermaking, metals and textiles industries. The lights are designed for additional applications, including maintenance, speed measurement, machine vision, camera inspection, motion timing and motion analysis.

The LED-12 has twice the light output of its predecessor and is available in standard and UV models. The UV strobe light is available as an optional fixed-mount unit. The second generation adds an internal phase control for greater flexibility in handling production and maintenance operations. Its narrow-beam spot illumination covers a 45cm diameter when 90cm from the target.

“LED technology continues to get better and better,” said Mike Simonis, President, Unilux. “Our second-generation handheld inspection lights raise brightness to the levels of our traditional strobes and deliver superior UV inspection capabilities that are so critical to the security needs of label and package printers. With much more extensive controls for more inspection and motion analysis capabilities, we can now provide an effective tool for product quality improvements and machine maintenance.”

The LED-12 features an adjustable flash rate from 300 to 50,000 flashes per minute, internal and external phase control, flexible triggering sources and white light approaching the visible spectrum of sunlight. Its environmentally friendly diodes are ozone-free. The rechargeable battery provides up to one hour of continuous use for the standard LED and up to four hours for the UV model, depending on usage patterns.

Unilux LED strobe lights use the stroboscopic effect to visually freeze detailed images of flat surfaces or machine parts moving at full production speed. Images allow process operators, technicians and engineers to use their knowledge and experience to spot and determine the causes of defects and to implement repair solutions.

Simonis said the new Unilux lights should help users reduce waste, unscheduled downtime and maintenance costs while raising yield.

Valmet Advantage DCT tissue line successfully started up at Kimberly Clark de México's Bajío mill

Kimberly Clark de México S.A.B. de C.V.'s seventh tissue machine, supplied by Valmet, was recently started up at the Bajío mill in San Juan del Rio, Mexico. The new Advantage DCT 200TS tissue line adds 60,000 tpy of high quality tissue paper to the current production of facial, toilet, napkin and towel per year. The project was started in 2013.

Kimberly Clark de México S.A.B. de C.V.'s seventh tissue machine, supplied by Valmet, was recently started up at the Bajío mill in San Juan del Rio, Mexico. The new Advantage DCT 200TS tissue line adds 60,000 tpy of high quality tissue paper to the current production of facial, toilet, napkin and towel per year. The project was started in 2013.

The Bajío mill now operates four tissue machines out of which two are supplied by Valmet. The mill produces structured tissue products for the domestic and global markets.

"We are pleased with the overall execution and start-up of the Bajío machine 4. Our internal team of project engineers developed the site, oversaw engineering, procurement and machine installation with very good support from Valmet throughout the process. The machine is currently operating as expected after a very short start-up curve, thanks to the strong involvement by Valmet and the mill's manufacturing staff," says Bernardo Aragón, Kimberly Clark de Mexico's Operations Director.

"This successful project and start-up is another milestone in our excellent relationship with Kimberly Clark de México. The check out and commissioning were done in a record setting pace thanks to very good cooperation and planning. This start-up also marks the first Advantage ViscoNip press in North America as part of an Advantage DCT machine," says Jan L Larsson, Sales Director, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The tissue machine has a width of 5.4 m and a design speed of 2,000 m/min and is optimized to save energy and to enhance final product quality.

Valmet's delivery included a complete tissue production line featuring stock preparation system and an Advantage DCT 200TS tissue machine. The tissue machine is equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It is also featured with the Advantage tissue technology including a ViscoNip press for improved press dryness, an AirCap hood with air and heat recovery system as well as a SoftReel reel with center wind assist.

Valmet's project scope included basic mill engineering, process equipment and process ventilation, as well as the installation supervision, training and commissioning of the new tissue line. The delivery also included an automation package from Metso with the process control system.

Information about Kimberly Clark de México

Kimberly Clark de México S.A. B. de C.V. was founded in 1959 and is the leading tissue producer in Mexico. The company operates five tissue mills in Mexico producing facial, toilet, napkin and towel grades for the domestic consumer & away-from-home markets as well as for exports. Through the new investment the total production capacity of Kimberly-Clark de México will be approximately 700,000 tpy.

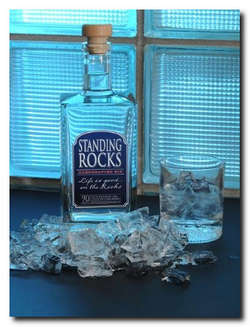

NewPage Introduces Reflections™ High Gloss Premium Label Paper

NewPage Corporation (NewPage) today announced the introduction of Reflections™, a new 60 lb. (89 gsm) high gloss cast coated alternative label paper designed for high-end wet glue and pressure sensitive applications that require smooth printing and a mirror gloss appearance, such as spirits, wine and pharmaceutical labels.

NewPage Corporation (NewPage) today announced the introduction of Reflections™, a new 60 lb. (89 gsm) high gloss cast coated alternative label paper designed for high-end wet glue and pressure sensitive applications that require smooth printing and a mirror gloss appearance, such as spirits, wine and pharmaceutical labels.

Reflections resembles cast coated grades with superior surface uniformity and features a high gloss effect achieved without the use of varnishes, UV or aqueous coatings. Reflections is Food and Drug Administration (FDA) compliant for direct and indirect food contact.

"Label printers and pressure sensitive laminators have long sought alternatives to traditional cast coated label papers, seeking new options that perform well and broaden their luxury label offerings," said Ed Buehler, vice president of specialty papers for NewPage. "Our partners looked to NewPage for innovative alternatives, and we created Reflections for visually stunning and demanding premium labels."

Reflections is available with third-party chain-of-custody certifications to the Forest Stewardship Council™ (FSC®), the Sustainable Forestry Initiative® (SFI®) and the Programme for the Endorsement of Forest Certification (PEFC™).

Reflections joins the broader range of label papers from NewPage which includes DuraPoint™, EcoPoint™, LithoPoint™, OmniPoint™, ProPoint™, Sterling®, OptiLabel™, Oxford™ and OptiPrime™ product brands. In addition, NewPage manufactures specialty papers used in flexible packaging, technical and release liner applications.

For more information, visit the NewPage booth #1539 at Labelexpo Americas in Chicago, Illinois, September 9 – 11, 2014, email This email address is being protected from spambots. You need JavaScript enabled to view it., or call 888-557-3565.

SOURCE NewPage Corporation

NanoGloss: New calender roll cover from Voith ensures long-lasting gloss and uniform smoothness

With NanoGloss, Voith brings a new calender roll cover onto the market that combines two important characteristics: a high level of mechanical stability and a high level of gloss on the paper. In its first field tests, the new cover achieved impressive results with an increase in gloss points. The paper produced with NanoGloss stands out with its high level of gloss and uniform smoothness.

NanoGloss is a multilayer roll cover which can be used in all positions on super, soft and multi-nip calenders. The proven, innovative finer surface topography achieves a high level of gloss improvement. In contrast to conventional calender roll covers, NanoGloss retains its exceptional surface characteristics between each regrind. The matrix structure of NanoGloss also guarantees the highest levels of stability and resistance. Furthermore, NanoGloss can be repaired just as easily as any other Voith calender roll cover.

Thanks to the characteristics of the new calender roll cover, inflexibility, wear and damage are prevented. Paper manufacturers can therefore enjoy reliable operation with NanoGloss.

Metso's Nomination Board consist of representatives of Cevian Capital, Solidium, Varma and Ilmarinen

Representatives of the four largest shareholders registered in Metso's shareholder register as of September 1, 2014 are elected to the Shareholders' Nomination Board along with the Chairman of the Board of Directors as an expert member. Nomination Board is responsible for making proposals regarding the composition of the Board and the remuneration paid to Board members for the Annual General Meeting in 2015.

Representatives of the four largest shareholders registered in Metso's shareholder register as of September 1, 2014 are elected to the Shareholders' Nomination Board along with the Chairman of the Board of Directors as an expert member. Nomination Board is responsible for making proposals regarding the composition of the Board and the remuneration paid to Board members for the Annual General Meeting in 2015.

According to the shareholder register, Metso Corporation's four largest shareholders on September 1, 2014 were:

- Cevian Capital (Cevian Capital II Master Fund L.P. and Cevian Capital Partners Ltd) (20 813 714 shares and votes, or 13.83% of share capital and votes),

- Solidium Oy (17 521 287 shares and votes, or 11.65% of share capital and votes),

- Varma Mutual Pension Insurance Company (5 548 465 shares and votes, or 3.69% of share capital and votes)

- Ilmarinen Mutual Pension Insurance Company (4 410 126 shares and votes, or 2.93% of share capital and votes).

Metso Corporation plans to hold its 2015 Annual General Meeting in March 2015.

Metso is a leading process performance provider, with customers in the mining, oil and gas, and aggregates industries. Metso's cutting-edge services and solutions improve availability and reliability in minerals processing and flow control, providing sustainable process and profit improvements. Metso is listed on the NASDAQ OMX Helsinki, Finland. In 2013, Metso's net sales totaled EUR 3.8 billion. Metso employs approximately 16,000 industry experts in 50 countries. Expect results

Stora Enso to build demonstration plant in Louisiana, USA

Following its recent acquisition of the US-based biotechnology company Virdia, Stora Enso is investing EUR 32 million (USD 43 million) in a demonstration and market development plant to be built at Raceland, Louisiana, USA. The plant will be used for industrial validation of the newly acquired extraction and separation technology developed by Virdia that enables cellulosic biomass, such as wood or agricultural waste, to be converted into highly refined sugars. The investment serves the feasibility of the technology on industrial scale in the future, possibly also in some of Stora Enso’s existing pulp mills.

Following its recent acquisition of the US-based biotechnology company Virdia, Stora Enso is investing EUR 32 million (USD 43 million) in a demonstration and market development plant to be built at Raceland, Louisiana, USA. The plant will be used for industrial validation of the newly acquired extraction and separation technology developed by Virdia that enables cellulosic biomass, such as wood or agricultural waste, to be converted into highly refined sugars. The investment serves the feasibility of the technology on industrial scale in the future, possibly also in some of Stora Enso’s existing pulp mills.

The demonstration plant will be located in the vicinity of existing sugar cane plantations and will use bagasse waste as feedstock. Sugar cane bagasse is a sustainable, non-genetically-modified feedstock that does not compete with food. It will be used to produce high purity five-carbon sugars and in particular xylose. These sugars will be converted and upgraded for applications in, for example, food and personal care.

“This investment marks the next step in our strategy for new markets and applications. It will enable validation of the technology developed by Virdia and its applicability to different types of biomass. Our goal is to develop and commercialise cost-effective renewable solutions to address well-identified market-driven needs and add value to our current cellulosic streams,” says Juan Carlos Bueno, EVP, Stora Enso Biomaterials.

The Raceland demonstration plant is scheduled to start production early 2017.