Ianadmin

Metso to supply paper-to-packaging grade conversion rebuild for Blue Paper in France

The target is to produce packaging materials based on recycled raw materials

Metso will supply Blue Paper with a grade conversion rebuild of their paper machine at their mill site in Strasbourg, France. The target is to produce packaging materials on a paper machine that previously produced LWC, light weight coated paper, a grade that is suffering from a drastic decline in demand. The start-up of the rebuilt machine is scheduled for the last quarter of 2013.

“This delivery is an example of much called-for innovative approach to the structural change the paper industry is facing. By retrofitting the existing printing paper machine with a few new key components Metso is able to provide the customer and the Strasbourg papermaking community with a solution that enables continuation of industrial operations on-site,” says Markus Laitila, Vice President of Paper Mills business unit, Metso.

The main part of the order is included in Metso’s Pulp, Paper and Power fourth quarter 2012 orders received. The automation system modification is included in Automation’s fourth quarter 2012 orders received.

Technical information

Metso’s delivery will comprise headbox and forming area modernizations and modernization of the press, dryer and sizing sections and reel. Metso will also modify air systems and automation systems.

The original paper machine has a trimmed width of 8.5 m and it produced LWC paper at a speed of 1,500 m/min. After the grade conversion rebuild, the paper machine will have a high annual capacity of fluting and testliner grades in the basis weight range of 70-130 g/m².

Blue Paper SAS is a joint venture established by the Belgian VPK Packaging Group NV and the German Klingele Papierwerke. VPK Packaging Group NV is an integrated packaging group with 33 companies across twelve European countries. Klingele, a German family-owned company, is one of the leading independent producers of containerboard and packaging made of corrugated board. The company consists of one paper mill, six integrated corrugated plants and seven converting plants in Europe and Africa. Klingele and VPK have a combined corrugated packaging production of more than 1 million tonnes per year and a paper production of 600,000 tonnes per year.

New Revolution press fabric developed by Voith

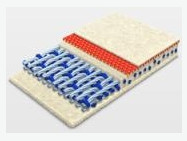

Voith’s newly developed Revolution press felt has now been launched into the market for production of board and packaging paper. With the aid of this innovation, paper production is even more efficient.

Along with increased drying performance, Revolution ensures shorter start-up phases, energy savings and consistent quality characteristics over its entire service life. The key innovation of Revolution is its structure, which has a special polymer layer. Revolution can thus control the flow of water before, during and after passage through the nip. For this reason, it dewaters better and contaminates less. The dry content is higher by up to 2% than with a conventional felt. The self-cleaning effect also helps to ensure the performance of the press felt remains the same over its entire service life.

Along with increased drying performance, Revolution ensures shorter start-up phases, energy savings and consistent quality characteristics over its entire service life. The key innovation of Revolution is its structure, which has a special polymer layer. Revolution can thus control the flow of water before, during and after passage through the nip. For this reason, it dewaters better and contaminates less. The dry content is higher by up to 2% than with a conventional felt. The self-cleaning effect also helps to ensure the performance of the press felt remains the same over its entire service life.

Paper produced with the aid of Revolution has especially good surface characteristics due to the larger contact surface with the paper or board web. It was confirmed in practical testing that this new press felt allows substantially shorter start-up times. From the beginning, the level of nip dewatering is very high. Revolution thus has a positive effect on the energy balance.

Emerson introduces wireless position monitor with on/off control for discrete valves

Fisher® 4320 provides users with a cost-effective way to achieve wireless valve control with position feedback for quarter turn valves

Emerson Process Management has expanded its Smart Wireless solutions family with the release of the Fisher® 4320 Wireless Position Monitor with On/Off Control Output Option - the first and only WirelessHART® valve automation solution that includes linkage-less position feedback and discrete valve control.

Emerson Process Management has expanded its Smart Wireless solutions family with the release of the Fisher® 4320 Wireless Position Monitor with On/Off Control Output Option - the first and only WirelessHART® valve automation solution that includes linkage-less position feedback and discrete valve control.

Most process plants have thousands of discrete valves that are manually operated. From customers surveyed, 90% have had valve alignment issues in the past 12 months, resulting in spills, lost batches, and safety incidents. These customers are automating discrete valves each year; however the wiring costs of traditional automation prevent many from being converted from manual to automated control.

The Fisher 4320 Wireless Position Monitor with On/Off Control Output Option changes the economics of automating discrete valves as an alternative to solenoids and limit switches. By eliminating the need for wires, the project cost and project time are reduced by minimising engineering time, materials, control system I/O, and installation labour. For simplicity, traditional quarter turn valves and pneumatic actuators are used - only air is needed to automate a valve. Wireless valve solutions from Emerson install and commission quickly, providing users with a cost-effective way to achieve real-time discrete valve control with position feedback.

Like other devices in the Emerson wireless family, the Fisher 4320 has secure and reliable performance, a 5 to 10 year SmartPower™ battery life, and is fully compatible with existing Smart Wireless self-organising mesh networks.

Xerium Announces 350 Ton Press Felt Production Expansion

Xerium Technologies, Inc. (NYSE:XRM) a leading global manufacturer of engineered textiles and roll covers and provider of mechanical services used in the production of paper, paperboard, building products, nonwoven materials, and general industry, today announced a 350 ton global press felt production increase through a combination of the following actions:

- Equipment investments in base fabric making, card making, needling and heat setting

- A centerpiece investment in a new, state-of-the-art DILO needle loom

- Additional production in Xerium’s Asian and South American plants

Xerium is increasing its capacity in its press felt plants in response to strong global demand from customers for Xerium’s high-end surface sensitive press felts. This additional capacity will be coming on line beginning in Q2 2013 and continue through Q4 2014. Xerium is largely capacity constrained with regards to press felt sales growth and, therefore, somewhat hampered in terms of partnering with growing customers, growing areas of the market and growing regions of the world.

The DILO needle loom is a special machine used in the production of high-end surface sensitive felts. These products are used on paper machines, fiber cement machines used in the production of building products and general purpose industrial textile machines. The high-speed, high-density needling capabilities of DILO’s Hyperpunch machine will expand Xerium’s current platform of needling looms used to manufacture Xerium’s most technologically advanced press felts. The DILO machine is on order.

“We are excited to be investing for sales growth and expanding our capacity to make press felts of all types - paper machine press felts, fiber cement products, nonwoven products, and general purpose industrial textiles. Xerium’s ability to grow in these areas has been limited by available capacity. These actions give our customers and sales teams more flexibility to pursue growth plans and additional new products. There are many parts to increasing our global capacity in a high-quality manner and it is a top priority at Xerium. We are expanding our base fabric capabilities, our heat setting capabilities, our needling capabilities, our card making capabilities and our finishing capabilities,” said Harold Bevis, Xerium’s President and CEO. “These actions increase our global capacity, lower our costs, increase our quality, and balance our production more efficiently to improve our lead times to customers. We are committed to reducing our total costs, growing our sales and maintaining our global technology leadership positions. These actions help us achieve these goals.

We have also reorganized our global machine clothing Operations team so that Xerium can optimize outcomes and efficiency across all regions of the world. We have four new leaders in charge of these matters.

- Jürgen Hartmann – based in Germany, VP & Global Operations Leader for Forming Fabrics

- Alain Cayer – based in Canada, VP & Global Operations Leader for Press Felts

- Jürgen Heiss – based in Germany, Director of Global Planning and Scheduling for Forming Fabrics

- Lynn Height – based in USA, Director of Global Planning and Scheduling for Press Felts

Proper leadership will make these investments a reality for our customers and we are proud to announce these four promotions from within the ranks of Xerium. They are all veterans of our company and of the industry.”

Source:

Tembec introduces Kallima® Coated Cover C2S 14 pt

Tembec is proud to announce the official launch of FSC®-certified Kallima Coated Cover C2S 14 pt – the latest extension of its line of bleached paperboard products. This new product release stems from Tembec’s continuous investment into its research and development operations as well as a relentless focus on providing customers with superior quality products and solutions.

The new 14 pt caliper coated two-side substrate offers commercial printers yet another Kallima Coated Cover solution with superior printability, runnability and market renowned cost savings. Printers can benefit from savings of up to 20% over competing products due to Kallima’s basis weight advantage achieved through its unique high-bulk, low-density construction. Kallima’s on-press reliability, visual performance and savings potential make it an ideal choice for business cards, post cards, direct mail, POP displays, advertising collateral and pocket folders. “Kallima’s new light-weight C2S 14 pt coated cover grade will be particularly attractive for commercial printers whose business model involves a high volume of shipments of printed product to multiple locations. Due to Kallima’s light weight construction, printers will find significant savings on mailing and shipping fees alone,” highlighted Renee Yardley, Vice President, Sales and Marketing, Tembec Paper Group.

Kallima Coated Cover C2S 14 pt is available in rolls and sheets (skids only), and is fully compatible with post press production effects such as die cutting, UV and aqueous coating, folding, scoring, embossing, debossing and foil stamping. Kallima® Coated Cover 14 pt is FSC-certified and available with 10% recycled content upon request.

Tembec is currently taking pre-orders of Kallima Coated Cover C2S 14 pt for deliveries in late April, 2013.

Tembec to sell its NBSK pulp mill in Skookumchuck, British Columbia

Tembec Inc. has announced that it has reached an agreement to sell its NBSK pulp mill and related assets and liabilities located in Skookumchuck, British Columbia to Paper Excellence Canada Holdings Corporation (“Paper Excellence”) for a purchase price of $89 million, which includes working capital. Closing of the transaction is expected to occur in the second calendar quarter of 2013 and remains subject to certain conditions and regulatory approvals.

“This transaction supports the continuing transformation of the Company and the reshaping of its business portfolio,” stated Tembec President and CEO James Lopez.

Tembec acquired the Skookumchuck pulp mill in 1999 as part of the acquisition of Crestbrook Forest Industries Ltd. This mill, where 290 employees currently work, started up in 1968. Its pulp is shipped to North American and Asian customers primarily for tissue applications.

BofA Merrill Lynch served as the exclusive financial advisor to Tembec.

Voith strengthens its position in the Russian energy market and establishes a joint venture with RusHydro

Voith Hydro and RusHydro, one of the largest supplier of hydropower in the world, signed a contract establishing the inception of the joint venture VolgaHydro LLC in Moscow. Each company holds a share of 50 percent of the joint venture. RusHydro will exercise the industrial leadership, Voith Hydro will be responsible for the operational management. Voith Hydro will appoint the Chief Executive Officer (CEO) and RusHydro will announce who will become the Chief Financial Officer (CFO). Any decision over VolgaHydro will be made by RusHydro and Voith Hydro commonly. The headquarters of VolgaHydro will be the city of Balakovo in the Russian Federation.

“Having founded this joint venture, Voith strengthens its position in the significant Russian hydropower market sustainably”, says Dr. Roland Münch, Chief Executive Officer of Voith Hydro. VolgaHydro will closely keep in touch with its customers providing excellent know-how and the entire range of expertise.

With a technical potential of 424 GW power, the hydromarket in Russia has a bright outlook. By now, only 46 GW of hydropower has been installed. Besides the possibility to build new hydropower plants, the joint venture focuses on extensive modernizations of old hydropower stations. For instance, Voith and RusHydro have already started to renew the plants Miatlinskaya and Saratovskaya. Voith also modernized the technical equipment of the hydropower plant Uglich for RusHydro as a customer. Voith supplied a complete machine set for the plant and, furthermore, equipped Uglich with electrical and mechanical equipment and automation systems.

Voith’s commitment in Russia goes back to the year of 1899. In that year, the company delivered the first full-fledged paper machine to the city of Sokol. Today, Voith conducts its business at six locations in the Russian Federation. Generally, the Russian market has high potential in the field of energy, oil, gas, raw materials, logistics and automotive. Voith considers these markets as its key sphere of activity.

Resolute Forest Products Issues 2012 Annual Report

Resolute Forest Products has issued its 2012 Annual Report, which includes an overview of the Company's 2012 sustainability performance. While Resolute will continue to produce its Annual Sustainability Report using Global Reporting Initiative (GRI) guidelines, the Company is now also integrating sustainability performance information into its annual financial disclosure.

"Resolute recognizes that focusing on sustainability is good business. Our decision to produce a report combining financial and sustainability performance demonstrates our commitment to balancing environmental, social and economic priorities," said Richard Garneau, President and Chief Executive Officer. "We work hard to integrate sustainability into the way we do business because we believe this approach brings value to our customers, our shareholders, our employees and the communities where we live and work."

In 2012, Resolute made important progress on several of its key sustainability commitments, including:

Carbon Management - As part of its membership in the World Wildlife Fund's Climate Savers program, Resolute committed to achieving a reduction in absolute greenhouse gas emissions of 65% below 2000 levels by 2015. In 2012, Resolute achieved a reduction of over 62% and is on track to meet its WWF commitment.

Fiber Sourcing - The Company obtained chain of custody certification at all of its North American pulp and paper mills and wood products facilities, to either Forest Stewardship Council® (FSC)®, Programme for the Endorsement of Forest Certification (PEFC) or Sustainable Forestry Initiative® (SFI®) standards.

Forest Certification - Resolute is at the forefront of fiber certification, with 100% of the woodlands managed by the Company certified to internationally recognized sustainable forest management standards. Resolute is progressing toward its commitment to add FSC certification to 80% of its managed woodlands by 2015, and as of press time for the report, the Company had reached 65% certification. In 2012, Resolute achieved the distinction of being the largest manager of FSC-certified forests in the world. Taken all together, the Company's FSC-certified forests cover an area larger than Greece.

Product Stewardship - The Company launched its AlignTM brand of eco-efficient, budget-friendly, high-performance papers, which are made using 50% less fiber and fewer chemicals than competitive papers. Depending on the grade, the carbon footprint for Align papers is 35% to 86% lower than for competitive papers.

First Nations - Resolute developed and published a formal policy on First Nations relations.

Health and Safety - The Company achieved a world-class Occupational Safety and Health Administration (OSHA) incident rate of 1.13, meeting Resolute's goal of 1.2 or below. For 2013, the Company is committed to further reducing the number of workplace injuries and has set an OSHA target of 1.0 or below.

While the 2012 Annual Report is Resolute's first report combining financial and sustainability performance, this is the Company's fourth year publishing sustainability-related performance data. More comprehensive data and details related to the Company's sustainability performance for 2012 will be included in its GRI-compliant Annual Sustainability Report to be released online later this year.

SOURCE: Resolute Forest Products Inc.

Russian forest industry revenue increased by 6.5% to €18.46 billion in 2012

Russian forest industry earned 733.6 billion Rubles (€18.46 billion) in 2012, which is 6.5% higher than in 2011, as said in the annual report published by WhatWood analytic department. Sales profit amounted to 52.88 billion Rubles, which is 16.3% lower year-on-year.

In 2012, Russian economy grew twice as slower as in 2000-2008.

Economic growth slowed down due to declining demand on Russian export goods, which was in turn caused by global economy downturn, cut of company inventories by the end of the year and crop failure after dry season. Russian GDP amounted to 62.36 trillion Rubles (€1.57 trillion) in 2012.

Federal Forestry Agency (Rosleskhoz) gave much attention to forest renewal matters. Volume of reforestation in the last five years stabilized on the level of 810-860 thousand hectares. Share of artifical reforestation amounted to 22%.

On August 22, 2012, Protocol on Russia’s accession to WTO came into power. According to the protocol, new quotas on roundwood export from Russia were imposed. Under 4.13 million cu m, duties for spruce, fir and pine logs now make up 13% of the customs value. For exporting roundwood over this volume duty increases up to 80%, but not less than

€55.2 per cubic meter. Quotas are not imposed for birch and aspen logs, export duties for these grades will stay at 7% and 5% respectively.

Following the results of 2012, Top priority project investment list incudes 121 projects with total volume of investments at 403.7 billion Rubles. These projects are being implemented in 35 Russian regions.

Logging volume in 2012 amounted to 192.1 million cubic meters, which is 2.5% lower on-year.

China remained the largest exporter of Russian logs, but since 2007 export is constantly falling. Last year, export fell by 22.8% down to

11.5 million cu m.

Lumber production in Russia made up 30.8 million cu m, 2.7% lower on 2011. Export of lumber also declined by 2.6% down to 19.1 million cu m.

Pulp output stayed at 2011 levels. Production dynamics through the year, however, was varied: in Q2 there was decline by 2.9% to Q1, in

Q3 – growth by 5.1% to Q2, in Q4 – decline by 4% to Q3.

Paper production declined by 1.5% down to 4.7 million tons, with newsprint production falling by 5.8% to 1.81 million tons. Board production, however, grew by 5.2% to 2.95 million tons.

Detailed statistics on volumes and prices, analysis of WTO accession, comments of market players, major legislation changes and key events of the year are available in the annual study of WhatWood analysts.

Pankaboard strengthens its speciality strategy – establishes its own sales office in the UK

Pankaboard, a leading Finnish specialty cartonboard producer, will open a new sales office in the UK, to strengthen its local presence in the market.

The new office and sales execution in the UK is lead by the Regional Sales Director, Mr. Mark Aubrey, who has extensive experience and knowledge in the cartonboard market.

The office will be located in Nottingham (15, Wheeler Gate, Nottingham, NG1 2NA) and will be fully operational as of the 22nd of April 2013 with a skilled back-office team to ensure highest service level.

The opening of a new sales office in the UK is a natural step for Pankaboard as we continue to deepen our speciality strategy through own sales organization in UK. This highlights our long term commitment to existing and new customers in the UK.