Displaying items by tag: MIAC

ANDRITZ to present innovative technologies for sustainable paper production at MIAC

International technology group ANDRITZ will be presenting its innovative technologies for sustainable paper production at MIAC 2021, booth #71, in Lucca, Italy, from October 12 to 15, 2021.

The ANDRITZ experts are looking forward to presenting the latest innovations and developments in the following areas:

- In fiber preparation, ANDRITZ will present its latest Prime technologies for enhanced fiber quality with economical use of resources, for example the PrimeFilter D, the cutting-edge technology in thickening and fiber recovery.

- For the tissue, paper and board industry, ANDRITZ will show its capabilities in the area of rebuilds, complete lines, and services with focus on sustainability and cost-efficiency, for example steel Yankees – giants up to 26 ft. in diameter – that enable energy-efficient drying at 8-10% better machine performance compared to cast-iron Yankees.

- The experts at ANDRITZ Fabrics and Rolls provide tailor-made roll covers, spreader rolls, shoe press belts and paper machine clothing solutions like the new StrataPress felt technology – a game-changing combination of materials, to deliver high sheet quality and reduced energy consumption at given machine speeds – or ANDRITZ’s durable, high temperature and contamination resistant MasterDry dryer fabrics that are specifically designed for extended fabric running times.

- The ANDRITZ service team will show ways of increasing the reliability, efficiency, and availability of process equipment regardless of the OEM, including service highlights like Yankee coating and on-site assembly.

- In the pumps business, ANDRITZ will show its broad pumps portfolio for all industrial applications and processes in the pulp and paper industry, including topics like model tests and after-sales service.

ANDRITZ will present its latest innovations for state-of-the-art paper production and value-added services at MIAC 2021 (booth no. 71). “Photo: ANDRITZ”.

ANDRITZ will present its latest innovations for state-of-the-art paper production and value-added services at MIAC 2021 (booth no. 71). “Photo: ANDRITZ”.

In conference speeches, ANDRITZ experts will also be presenting the latest solutions for efficient, sustainable paper production:

- Guido Lenzi, Sales Manager ANDRITZ Novimpianti, will be speaking about ANDRITZ’s solutions for upgrade of combustion systems to save resources and costs.

- Vincenzo Melilli, Senior Manager Technology and R&D Paper and Board ANDRITZ, and Mario Bernasconi, Senior Sales Manager Paper and Board ANDRITZ, will be introducing ANDRITZ’s cost-efficient technologies for sustainable paper and board production, including the world’s fastest kraftliner shoe-blade Gapformer and a 2,000 kN/m shoe press.

ANDRITZ is looking forward to meeting you in Lucca! Visit https://www.miac.info/en/preregister/ to register free of charge for the event or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Toscotec to showcase advanced energy-efficient technology at MIAC 2021.

Toscotec will be at MIAC 2021 Booth 109 to showcase world-class energy-efficient technology including customized solutions for turnkey tissue operations and paper machine’s technological rebuilds.

On October 13th, at 3.50 pm in the first session of MIAC Tissue Conference, Toscotec Business Development Director Massimiliano Corsini will present “OPTIMA rewinder line ensures quality and top winding efficiency.”

At its headquarters in Lucca, just a few kilometres away from MIAC Exhibition Center, Toscotec will also showcase its advanced double-width AHEAD tissue machines and OPTIMA slitter rewinders fully pre-assembled before delivery.

Contacts to book an appointment:

Marco Dalle Piagge, Sales Director, Tissue division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Enrico Fazio, Sales Director, Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Like a well-oiled machine: emtec Electronic presents devices for optimum runnability at MIAC Lucca 2021

How can manufacturers significantly improve product quality and process runnability in paper production and converting? This is exactly the question German manufacturer of specialized testing technology, emtec Electronic, addresses at booth 163 at the MIAC 2021 convention in Lucca, Italy from October 13-15.

Leipzig, Germany, 13.09.2021 – After MIAC 2020 was cancelled due to the Covid-19 pandemic, technicians of paper mills and converting sites worldwide once again get the opportunity to update their professional knowledge and experience the charm of Tuscany for three days at the MIAC Exhibition in Lucca, Italy. This year, 250 international exhibitors will present new technologies, machinery, and cutting-edge technical solutions for paper and board production and converting to visitors on-site at the Lucca Exhibition Centre.

Visitors to the convention can visit emtec Electronic at Booth 163 to discover more about emtec’s devices, all of which are self-developed and unique on the market. The assortment includes the device that launched the company, the PDA Penetration Dynamics Analyzer, which measures liquid penetration to predict the gluing, printing, and coating behavior of paper and board.

One of emtec’s most recent devices, the ACA Ash Content Analyzer, will be on display at the event. The ACA allows for a quick and reliable determination of the composition of fillers and fines within a sample without destroying the sample. This process leads to an immense time-saving compared to traditional combustion methods.

In addition, the CAS touch! and FPA touch! will be on location and available for demonstrations. The latter two are improved and more easily portable versions of the original one-of-a-kind testing technology, the Charge Analyzing System and Fiber Potential Analyzer.

Using standard titration techniques, the CAS touch! technology allows technicians to measure the cationic/anionic and acid/base demands of water-based charge systems, easily determine isoelectric and flocculation points of a sample and examine the correlation between pH, titrant demand and streaming potential. The FPA touch! enables the correct dosage of chemically charged additives by providing accurate information regarding the charge of fibers and fillers in a sample based on proven methods of Zeta Potential measurement.

One emtec device not on display due to its size but with video and informational material readily available is the FPO, the Fiber Potential Analyzer Online, which has the added benefit of being connected directly to the process and is so able to constantly monitor the fiber charge, allowing for immediate changes to be made if necessary.

“We’re excited to participate in the MIAC event again this year after last year’s hiatus, and are looking forward to lively discussions and demonstrations with visitors, as well as meeting up with our Italian representatives once more,” says Alexander Gruener, Global Marketing and Business Development Manager for emtec.

Visitors are welcome to stop by the emtec Booth 163 to view the entire emtec palette, exchange ideas, ask questions, see a demonstration of the devices, get their own samples tested onsite, or simply clink glasses with the representatives.

For more information about the MIAC 2021 event and the opportunity to register with no entry fee, visit miac.info.

About emtec Electronic

Emtec Electronic GmbH develops, produces and distributes worldwide testing and measuring devices for the detection of relevant processing properties of paper, board, nonwoven and textile materials. The portable measuring devices enable manufacturers and converters of paper, nonwoven and textile products for example, to control and optimize the manufacturing and converting processes during ongoing production. From the wet end to the final product, the application of the devices enables an efficient process to achieve and ensure the best possible quality with the least possible effort.

For 25 years, we have relied on innovative, highly specialized measuring instruments combined with a high degree of service orientation. Since the company was founded, we have been intensively involved in scientific cooperation with institutes and companies, further developing instruments for our customers and offering a broad network in over 80 countries from our Leipzig location.

For more information about emtec Electronic, please visit the website:

Replus Tissue and Cartiera Capostrada together for a more sustainable future

Some events need to be celebrated. Replus Tissue and EIL have the opportunity to present you a renovation plan of Cartiera Capostrada with which we have been collaborating for several years.

This year they are celebrating their 70th birthday: a perfect opportunity to rebuild and reface their plant to honor heritage while looking at a better future for the environment.

Our project was born with the aim of optimizing production, while maintaining great attention to environmental protection. Since many years we have greatly strengthened our partnership, and now we see a new challenge.

Our project was born with the aim of optimizing production, while maintaining great attention to environmental protection. Since many years we have greatly strengthened our partnership, and now we see a new challenge.

Aimed at the environment, safeguarding the planet from toxic emissions is a shared value between our companies. They decide to enhancing production while guaranteeing eco-sustainability.

We are happy to announce the main changes we have planned. Our work for the Capostrada paper mill has always been aimed at energy efficiency and low emission.

To enhance this effort, we have implemented a plant modernization project. The aim is to optimize operating costs, exploiting the production process and reducing toxic emissions more than ever.

This project is based on engineering that that synergistically combines software and hardware. Our experience in mechanics, aerothermia, automation and electrification allowed the building of plants, designed on the specific needs of every individual customer.

We’ll guarantee not only cost saving but also environmental sustainability, in a way of greater production efficiency. For this reason we have thought of a series of innovative REENERGY+ products, able to improve the performance of the system. Our attention to energy efficiency has pushed us to achieve great goals.

The cast iron Yankee dryer will be replaced with a state-of-the-art steel one having a very high heat transfer capacity. The combustion chamber has been designed to guarantee Nox < 20ppm and Co <10ppm at 15°. The new hood has been designed for blowing air at 700° C and will work at 650° C.

The old boiler will be replaced with an innovative recovery one, which exploit the exhaust air from the hood. The energy that would be dispersed in the atmosphere is recovered and used to produce the steam for the Yankee.

A complete new Yankee doctoring system will improve sheet quality and paper machine production efficiency.

What a great value for Replus Tissue and Cartiera Capostrada partnership.

We guarantee the complete turnkey installation of all elements and specialized assistance for starting up of the system in a few weeks. We have big projects to improve environment safety.

There are all the conditions for a switch.

And now who stops us anymore?

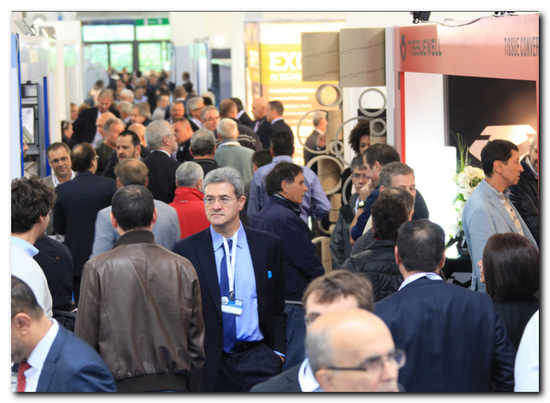

MIAC 2020 is postponed to April 2021 and it is called MIAC RESTART

We wish to inform you that EDIPAP S.R.L., the MIAC Organizer, has decided, after recent consultations with companies in the paper industry sector, to postpone the October 2020 edition of the MIAC Exhibition to April 2021 on 21.22.23 April 2021. The April 2021 edition takes the official name of MIAC RESTART.

"It was a difficult decision, especially because MIAC still had 160 direct Exhibitors ready to exhibit at the exhibition in October 2020. Furthermore, during the last months we have worked to offer both Exhibitors and Visitors a safe environment and fully in line with governmental, regional and local directives in terms of personal safety and health," says Gianmaria Pfeiffer, director of MIAC.

"We have studied very specific protocols to allow people to visit the MIAC Exhibition in a responsible way and in total safety and we have waited for the month of September to make a final decision by evaluating the Covid-19 situation: organizing the exhibition this October, however, would not have guaranteed the Exhibitors and Visitors to 'experience' the MIAC that we all know due to travel restrictions on an international level," continues Pfeiffer," and so we decided to move the exhibition to April 2021 waiting for better times."

MIAC 2020 then becomes MIAC RESTART and is organized on 21.22.23 April 2021 at the Exhibition Centre of Lucca in Italy.

MIAC 2021, on the other hand, remains scheduled in the usual month of October and is organized on 13.14.15 October 2021.

Smart Packaging gets Green AMOTEK at MIAC 2019

The issue of which materials should be used for packaging is becoming increasingly important. Consumers are also paying more and more attention to how environmentally friendly the packaging used for paper hygiene products is. Amotek offers packaging technology for a wide variety of materials including PE film, biofilm and paper, and is providing information on the new, environmentally friendly options at MIAC. The AMOTEK PB192 means that the company is also able to present a highly flexible packaging machine for rolls of paper tissue that significantly reduces the consumption of both electricity and compressed air. For this trade show, Amotek's slogan is "Smart Packaging gets Green".

The AMOTEK PB192 is the new flagship model for packaging rolls of paper tissue in film. Two versions are available: With the AMOTEK PB192 FLEX, the focus is on a particularly large range of formats and rapid changes in format. The AMOTEK PB192 DUAL offers the highest output while taking up less space, with up to 150 packs per minute. As well as the new PB range, there are several tools that are currently helping Amotek's customers manage their production more effectively in the age of industry 4.0. Improvements have also been made in monitoring and consumption, and can now be used successfully on all Amotek baggers.

The AMOTEK PB192 records all process data and machine functions and displays them on a big new high-resolution monitor.

The AMOTEK PB192 records all process data and machine functions and displays them on a big new high-resolution monitor.

Reduced consumption of electricity and compressed air

The system features innovations that significantly reduce the consumption of electricity and compressed air. Servomotors that can recover or save energy during braking and stop phases make a key contribution here. At the same time, a new pneumatic system has been developed that reduces compressed air consumption by around 16 percent, compared to conventional machines. The consumption of energy and compressed air is continuously measured and displayed in real time. If there is any loss of compressed air, this is quickly detected and displayed on the HMI.

Rapid troubleshooting

The AMOTEK PB192 records all process data and machine functions and displays them on a big new high-resolution monitor. This allows any malfunctions to be pinpointed more quickly. The data can also be used to set up a maintenance system that can alert the operator to upcoming maintenance work early on and allow it to be planned more efficiently.

Amotek at MIAC, Lucca, Italy: October 9 to 11, 2019, Stand 121

MIAC opens its doors! This 12.13.14 October in Lucca/Italy! (23rd edition!)

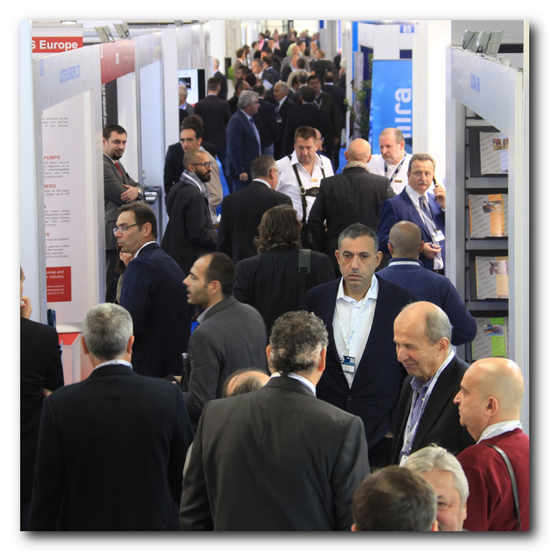

270 Exhibitors, 5000 Visitors: this is MIAC in Lucca (Italy)! Visiting MIAC means obtaining a full overview of the technology and equipment available to the paper industry sector thanks to the constant participation of the leading companies in the sector which present the latest developments in machines, systems and avant-garde solutions to improve the management of the various stages in the paper production cycle.

During the 3 days of Exhibition take place 4 International Conferences, offering very interesting content and studied to provide professional and dynamics information to the participants coming from all over the world.

The paper industry and the district of Lucca

The paper industry in Italy boasts significant numbers: 165 Paper Mills, 20,000 workers, almost 9,000,000 tonnes of paper and cardboard produced every year, with a turnover of 6.8 billion Euros (the volume of production places Italy in the first 4 positions to European level).

Lucca is the only officially acknowledged “Paper District” in Europe: over 140 Paper Mills and Converters, 6,500 workers, 2,000,000 tonnes of paper and cardboard produced (tissue paper and corrugated cardboard), with a turnover of 3.5 billion Euros. Lucca is also home to major companies that supply technologies, machinery and services to the paper industry sector, with a turnover of more than 2,600 million Euros and over 8,000 workers!

In Europe, Lucca is the number one spot for tissue production (24% market share), Italy is also one of the leader countries in the corrugated cardboard sector. But Lucca is not only synonymous with the Paper Industry! It is also one of the major tourist destinations in Italy, and is sure to charm the Visitors of MIAC with its beautiful city Walls, Towers and Squares.

270 Exhibitors, 5000 Visitors: this is MIAC in Lucca (Italy)!

Visiting MIAC (12.13.14 October 2016) means obtaining a full overview of the technology and equipment available to the paper industry sector thanks to the constant participation of the leading companies in the sector which present the latest developments in machines, systems and avant-garde solutions to improve the management of the various stages in the paper production cycle.

MIAC has reached its 23rd edition. It is an international meeting point that allows you to compare the technologies and business proposals of 270 companies present at the Exhibition. Taking part in MIAC means being one of 5,000 Visitors from across the globe who meet in Lucca in October of each year (last year’s MIAC Exhibition registered visitors from 56 Countries).

International meeting point

Rapidly changing technological solutions require continuous education: MIAC is the answer to all this! During the 3 days of Exhibition take place 4 international Conferences, offering very interesting content and studied to provide professional information to the participants coming from all over the world.

MIAC is held in Lucca/Italy, the only officially recognized “Paper District” in Europe. But Lucca is not only synonymous with the Paper Industry! It is also one of the major tourist destinations in Italy, and is sure to charm the Visitors of MIAC with its beautiful city Walls, Towers and Squares.

MIAC is the Official Exhibition of ASSOCARTA, the association of the Paper, Board and Pulp industry manufacturing companies in Italy, and of LUCCA INDUSTRIAL ASSOCIATION

MIAC 2013 : The Show

MIAC - International Exhibition of Paper Industry takes place in Italy every year. It has received a great deal of attention since its first edition (1994) and now it has reached its 20thedition.

The Exhibition has developed through time thanks to its excellent location and constant participation of the leading companies in the sector of the paper industry. Moreover, every year these highly skilled and innovative companies, through MIAC, present the latest developments in machines, systems and avant-garde solutions to improve the management of the various stages in the paper production cycle.

Visiting MIAC is a unique opportunity for paper and converting technicians to find out the latest news in this profession as it provides paper producers with a forum where they can directly address the different demands and problems in the sector. These characteristics make MIAC a very important date in the paper industry’s calendar!

Furthermore, the Exhibition Centre of Lucca is located in a strategic position in the North-Centre of Italy. Pisa Airport is only 20 minutes car distant from Lucca and Florence Airport is 45 minutes car distant from the Exhibition Centre of Lucca.

Also for the 2013 edition, MIAC Exhibition planned several “technical meetings” in order to take stock of the situation regarding trend, future perspectives and new available technologies in the paper sector.

MIAC is “more international” at every new edition. As a matter of the fact, about 35% of Visitors of MIAC 2012 came from foreign Countries.

The Conferences

Also for the 2013 edition, after the success reached in the past editions, MIAC Exhibition planned several “technical meetings” in order to take stock of the situation regarding trend, future perspectives and new available technologies in the paper sector. As every year, participation in MIAC Technology Conference and MIAC Tissue Conference is completely free of charge for all the Paper Mills and Converters technicians.

Simultaneous translation from Italian to English and vice versa is available during the Conferences.