Ianadmin

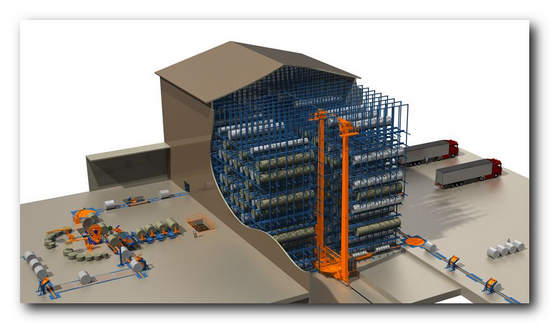

Automated Roll Warehouse (ARW) with large conveyor and wrapping system to Stora Enso

Stora Enso invests 70 MEUR in new polyethylene (PE) extrusion coating plant and an automated roll warehouse (ARW) at its Imatra mills in Finland. The Imatra complex, which comprises the Kaukopää and Tainionkoski mills, has a capacity of more than one million tons/yr of carton board and specialty packaging paper. With this investment Stora Enso aims to increase and meet increasing customer demand for food service board and liquid packaging board.

The full roll handling scope for this investment with the new automated warehouse was ordered from Pesmel, and it’s commissioning is expected to be completed early Q4/2017. The roll handling system is one of the biggest deliveries in Pesmel’s history requiring 80 man years work. ”The system is good example of our Material Flow How -concept, where the high bay warehouse synchronizes the production processes flexibly and efficiently. With packing and loading included, all the components of our concept will be delivered.” tells the vice president of paper division Mr. Kaj Fahllund from Pesmel.

TransRoll concept selected

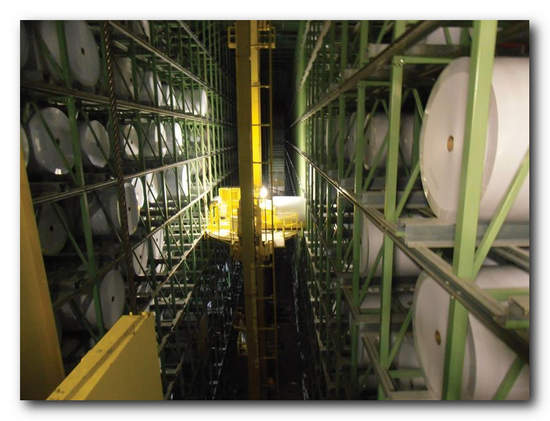

The heart of this new system layout is Pesmel’s TransRoll ARW concept, which is connected with 7 in-out connections at different floor levels between the mill production and converting lines. It has ~30,000 tons buffering capacity for intermediate rolls to be used at mill converting, and also for finished rolls to be shipped out to end customers.

This concepts storing volume can be expanded in the future, as well as the number of its connections. The whole footprint of this warehouse is only ~4500 m2 with high ~8 t/m2 effective storing density. And as true heart of mills material flow, it has whopping 900 t/h fully automated in-out handling and sorting capacity with two stacker cranes.

TransRoll ARW is equipped with full Pesmel WMS warehouse management system, which is connected to MIS (mill information system) to track the roll flow and to keep the real-time storage inventory for the converting and shipping operations.

Fully automated OptiWrap Multi Kraft wrapper

Pesmel’s roll handling scope includes along large connecting conveyor system also new high capacity kraft wrapping line, with robotized core plugging and head insertion. The handling capacity is set to 120 r/h, but this can be increased in the future 20 - 40%.

Automated truck loading eliminates the roll damages

With automated truck loading the unpacked rolls are transported from TransRoll warehouse to a coating mill situated one kilometer away. The rolls are loaded and unloaded fully automatically in horizontal position, which eliminates the possible roll end damages totally. Transferring the rolls unpacked generates remarkable savings to packing costs.

FlowCare to ensure efficiency and reliability

This delivery includes custom tailored Pesmel FlowCare portal. This digital IoT (Internet of things) interface collects, saves and analyzes information from the delivered system, and helps to foresee service needs and to eliminate mill’s bottlenecks with material flow. FlowCare portal gives access to e-shop, spare part, maintenance and document services, ticketing system and to 24/7 customer support.

Pesmel TransRoll ARW merits:

- Safety and quality

- Clamp handling eliminated in mills internal handling.

- Rack storages fire safety with inbuilt wet sprinkler system.

- Cost efficiency

- Automated, non clamp handling, with full inventory control.

- Minimized space utilization with possibility for future expansion.

- Production sorting and buffering capacity - no pre-sorting needed.

- Reliability

- Elimination of human errors - right products, at right time, to right address.

- Minimized need for handling equipment.

- FlowCare portal for service and operation support.

- Environment friendliness

- No need for fossil fuels.

- Minimized space need.

Pesmel:

Pesmel is global supplier of highly automated internal logistic, storing (AS/RS) and packing systems for the metal, paper and converting industries.

During the four decades Pesmel has delivered over 400 handling and packing projects and around 120 storage systems with more than 200 stacker cranes. The company employs over 200 professionals, of which abt. 120 is situated in Finland.

For more information, please visit www.pesmel.com

Stora Enso Imatra Mills:

Imatra Mills consist of two production units: Kaukopää and Tainionkoski. Together, they employ approximately 1,000 people and produce one million tonnes of board and paper annually. More than 90 per cent of production is exported, mostly to countries in Europe, but a substantial share is also exported to Southeast Asia.

Imatra produces liquid packaging board for beverage cartons and food service boards for paper cups and various food packages. Typical customers include the food, confectionery and tobacco industries.

High-quality packaging papers and graphical boards used for book covers, cards and luxury packaging are also made at the Imatra Mills.

ArborGen : and International Paper Brazil Expand Eucalyptus Sales and Development Agreement

ArborGen, a world leader in the development and commercialization of technologies that improve the productivity of trees, has just announced that it is expanding its agreement with International Paper Brazil by granting ArborGen additional access to IP’s Eucalyptus germplasm. This will allow an increased effort to develop and sell new varieties of seedlings with improved traits and capable of being grown in regions of Brazil where there is growing interest in Eucalyptus plantations. Since 2013 when the company began its commercial sales operation sales have increased to a current projection of 47 million Eucalyptus seedlings and nine million Pine seedlings in 2016.

The Brazilian forestry industry is one of the largest, fastest growing in the world; Brazil is the world’s largest producer and exporter of hardwood pulp. The Eucalyptus market utilizes approximately 700 million seedlings per year. With the original agreement, private landowners gained access to elite Eucalyptus clones that were once only available to integrated producers. This new agreement will increase that access and allow for additional development of advanced genetics for landowners.

The Brazilian forestry industry is one of the largest, fastest growing in the world; Brazil is the world’s largest producer and exporter of hardwood pulp. The Eucalyptus market utilizes approximately 700 million seedlings per year. With the original agreement, private landowners gained access to elite Eucalyptus clones that were once only available to integrated producers. This new agreement will increase that access and allow for additional development of advanced genetics for landowners.

ArborGen formed ArborGen Brazil in 2004 as a product and business development center. The company initially began working with several large integrated Eucalyptus and Pine pulp and paper companies and has conducted extensive field trials with biotech products. Since 2013 ArborGen do Brasil increased its interests in the Brazilian Eucalyptus seedling market through its operation of the Luiz Antonio nursery and working with other contract nurseries to produce and sell improved varieties to the open market. “This expanded agreement allows ArborGen to utilize its advanced technologies and tree breeding expertise with IP germplasm to continue to improve the genetics of existing seedlings. We will also be able to offer additional benefits such as increased yields and improved growth to landowners while expanding the breeding program to other regions of Brazil and other sectors as sawtimber, bioenergy, etc.,” said Gabriela Monnerat, managing director of ArborGen of Brazil.

For over 110 years – more than 50 of them in Brazil – International Paper has been one of the companies that most cares about the environment. Thus, the expanded agreement only reinforces the company's commitment to the development of the forestry sector. "We know the genetic material choice is fundamental to guarantee the success of any new forestry development, so the expansion of the agreement with ArborGen provides the opportunity for other companies to produce wood with top quality genetic material. IP continues investing in actions and programs which contribute to the growth of the forestry sector in Brazil," highlights Luis Fernando Silva, Fiber Production Senior manager at International Paper.

About ArborGen

ArborGen is revolutionizing productivity in commercial forestry. ArborGen is the largest global supplier of seedling products and a leading provider of improved technologies to the commercial forest industry. Through innovations in conventional breeding, improved genetics and emerging biotechnology advances, ArborGen is developing high-value products that significantly improve the economic returns and productivity of a given acre of land. These products enable ArborGen’s customers to grow trees that yield more wood per acre with greater consistency and quality in a shorter period of time. ArborGen’s work is improving the sustainability of working forests while helping to meet the world’s growing need for wood, fiber and energy. For more information, please visitwww.arborgen.br.com.

About International Paper

International Paper (NYSE: IP) is a leading global producer of renewable fiber-based packaging, pulp and paper products with manufacturing operations in North America, Latin America, Europe, North Africa, Asia and Russia. We produce packaging products that enable world-wide commerce; pulp for diapers, tissue and other personal hygiene products; papers that drive communication; paper bags that carry groceries; and paper cups and food containers that provide convenience. We are headquartered in Memphis, Tenn., and employ 55,000 colleagues located in more than 24 countries. Net sales for 2015 were $22 billion.

In Brazil the company works in the businesses of printing and writing papers, containerboard and corrugated packaging, employing approximately 5,000 employees.

The integrated system of printing and writing paper production from International Paper in Brazil consists of three mills: two in the State of São Paulo and one in Mato Grosso do Sul. Its products – printing and writing paper lines Chamex e Chamequinho and graphic paper line Chambril – are 100% produced from certified eucalyptus forests.

The packaging business consists of three containerboard plants located in the State of São Paulo, and four units to manufacture corrugated packaging and sheets: two in the State of São Paulo, one in Goiás and one in Amazonas.

For more information about International Paper, our products and global citizenship efforts, please visit internationalpaper.com

Lib Dem leader visits leading manufacturing firm

South Lakeland MP Tim Farron recently visited Cumbria-based manufacturing firm James Cropper PLC to hear about the latest developments at the company and discuss the challenges facing the industry.

Tim met with the CEO and group finance director of the company, and heard how James Cropper PLC continues to grow and develop, taking on more staff and expanding into new areas, in addition to their traditional paper business. Also on the agenda was the need for a British industrial strategy that supports the manufacturing industry, as well as the challenges that are faced post-Brexit.

Tim said: “It was fantastic to visit James Cropper once again and to hear about the exciting developments at the company, particularly as the firm expands into new markets. As the largest private sector employer in our area, the company’s success is good news for all of us.

“James Cropper is a shining example of the best of British manufacturing, complementing their traditional paper business with the latest technology and innovation, and creating skilled local jobs and apprenticeships. As a country, it is vital that we support businesses and develop the skill base required so that other firms can follow James Cropper’s example. I will also continue to push the government to ensure that any post-Brexit deal does not harm the ability of businesses like James Cropper to trade with the EU.”

Phil Wild, CEO at James Cropper, said: “The paper manufacturing industry has seen a lot of changes in recent years, so the need to innovate, develop and improve is more important than ever. Our people sit at the heart of these initiatives.

“Continued investment into research and development in technology, whether that’s in technology, equipment, product development or materials, is crucial for us to maintain and expand our foothold in the industry. We sell our products all over the world to sectors ranging from luxury goods to aerospace. Our customers demand information on the environmental impact and sustainability of our processes and on working practices.This is an increasingly important objective for businesses as they strive to reduce their impact on the environment. In the papermaking arm of the business, our unique coffee-cup reclaimed fibre plant has enabled us to become an unrivalled driving force in eco-friendly innovation in our sector. In our Technical Fibre Products (TFP) business, new products have been introduced to provide super lightweight solutions for aerospace composite bodies; and the newest division 3D Products (3DP), provides sustainable alternatives to plastic packaging using highly engineered, brightly coloured moulded fibres.”

Isabelle Maddock, finance director at James Cropper, adds: “The global market continues to be essential for growth and development, with about 50 per cent of our products being exported. Post-Brexit, there is some concern about how it will affect industry in the UK. Britain offers a huge pool of knowledge and skills supporting innovation, therefore we would strongly oppose the introduction of tariffs as they restrict trade and ultimately have a detrimental effect on innovation, which is driven by the reinvestment of profits. That said, our global business model has proven to be robust and the group is well placed to face the challenges of Brexit.”

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About James Cropper 3D Products

James Cropper 3D Products answers a global demand for sustainable packaging with the next generation of moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product is design-engineered and has a clear focus on quality. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. 3D Products are made from 100 per cent renewable natural fibres and are recyclable with paper.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP),manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

For further information visit: www.jamescropper.com www.jc3dp.com and www.tfpglobal.com.

James Cropper makes trio of appointments

British master papermaker James Cropper has made a number of appointments across senior roles within the company.

Steve Adams, who was appointed as managing director of the company’s paper business in September 2016, has now commenced his post.

Steve Adams, who was appointed as managing director of the company’s paper business in September 2016, has now commenced his post.

He brings with him more than 30 years’ experience and has a strong commercial and business leadership background. Formerly working for 3M across Europe, his roles included business director for display and graphics and, most recently, business director for electronics and energy.

Steve said: “I’m excited to join James Cropper at a time when the business is flourishing and looking to grow and develop in new areas. The company has a fantastic reputation in the paper manufacturing arena and I look forward to bringing my knowledge and skills to help it build and further cement its position.”

Alison Daniels has joined James Cropper as marketing director, and will oversee the marketing strategy of the paper manufacturing arm of the business. She joins the company after 15 years’ marketing experience with Bayer Crop Science UK.

Alison Daniels has joined James Cropper as marketing director, and will oversee the marketing strategy of the paper manufacturing arm of the business. She joins the company after 15 years’ marketing experience with Bayer Crop Science UK.

Completing the trio, Ivan Iannetta, a paper and packaging industry expert, has been appointed as sales manager for the east coast of the USA to provide local client support and promote the company’s offering in the region.

Phil Wild, CEO at James Cropper, said: “The paper manufacturing industry has seen a lot of changes in recent years, so the need to innovate, develop and improve is more important than ever. Our people sit at the heart of these initiatives.

“2017 is set to be another exciting year for James Cropper with the roll out of our latest paper range, Dolcelicious – a food contact approved paper – and our Tailor Made paper service across global markets.”

“We’re confident that our latest recruits bring with them the necessary skills and experience that will help us in our continued quest to be at the forefront of our industry, whether it’s technical development, enhanced marketing strategies or increased sales.”

For more information about James Cropper, visit www.jamescropper.com

Cortec’s EcoShield® Heat Sealable Paper Offers Flexible Custom Recyclable Packaging Solutions!

Cortec® has made it easy for industries to create their own custom-sized recyclable bags and envelopes with EcoShield® Heat Sealable Paper! Whether a company needs to manufacture its own standard or custom bag for a specific product, or whether extra wide paper is needed to make paper bags, sleeves, or envelopes on demand, EcoShield® Heat Sealable Paper is ready to use. Simply cut the paper to the desired size; fold and shape into an envelope, sleeve, or bag; and apply heat to seal.

EcoShield® Heat Sealable Paper is coated with a water-based heat sealable adhesive coating. When the coated sides are placed together and heat is applied, the paper seals and forms a bond that is stronger than the paper. The paper is non-toxic, fully repulpable, and readily recyclable, making it ideal for environmentally friendly disposal considerations. These properties also make it an excellent choice for packaging situations where a product can be left in the bag and thrown into application conditions that will disintegrate the paper (e.g., certain concrete mixing situations).

EcoShield® Heat Sealable Paper is coated with a water-based heat sealable adhesive coating. When the coated sides are placed together and heat is applied, the paper seals and forms a bond that is stronger than the paper. The paper is non-toxic, fully repulpable, and readily recyclable, making it ideal for environmentally friendly disposal considerations. These properties also make it an excellent choice for packaging situations where a product can be left in the bag and thrown into application conditions that will disintegrate the paper (e.g., certain concrete mixing situations).

EcoShield® Heat Sealable Paper comes in large stock rolls of 600’ (182.88 meters) by 36” or 48” wide (1-1.22 meters), with customizable widths available up to 68” (1.73 meters), making it easy to construct standard or custom envelopes, bags, or sleeves in a variety of sizes. The paper can be printed with product identification and details before assembly.

EcoShield® Heat Sealable Paper conforms to the following test methods: TAPPI T-410 (Basis Weight), TAPPI T-411 (Caliper), TAPPI T-452 (Brightness of pulp, paper, and paperboard), and ASTM F88-99 (Seal strength of flexible barrier materials).

To learn more about EcoShield® Heat Sealable Paper, please visit:

http://www.cortecvci.com/Publications/PDS/EcoShield_Heat_Sealable_Paper.pdf

To find out more about Cortec’s innovative packaging solutions, please visit:

http://www.cortecpackaging.com/

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide. ISO 9001, ISO

14001:2004, & ISO 17025 Certified.

Investors turn back on Phuong Nam pulp mill

The Ministry of Industry and Trade has been calling for investors to participate in a multi-million-dollar pulp mill but to no avail, according to Le Tan Dung, vice chairman of Long An Province, at a review meeting on Wednesday.

The main entrance to the Phuong Nam pulp mill in Thanh Hoa District, Long An Province. Many potential investors have turned their back on the plant - PHOTO: TRUNG CHANH

He said the State-owned Phuong Nam plant is under the administration of the Vietnam Paper Corporation and that the Ministry of Industry and Trade is trying to restructure the project after huge amounts of capital have been poured into the project in the Mekong Delta province.

Local authorities have introduced the project to many potential investors so far but no investors have shown interest.

The ministry is seeking to equitize the poor-performing pulp mill project. However, many investors have turned their back on the project, according to Nguyen Xuan Hong, deputy director of the provincial Department of Industry and Trade.

Trillions of Vietnam dong has been poured into this paper pulp project owned by the Transport and Communication Development Investment Company (Tradico), but the plant still could not be commissioned. The Prime Minister has decided to transfer it from Tradico to the Vietnam Paper Corporation.

The new investor has upgraded the mill and sought to start operation again as directed by the Government. However, the whole production chain failed to work properly during the pilot period, resulting in long delays.

Even though foreign experts have been invited to inspect the plant, they still could not fix the problem.

Baldwin creates global UV curing powerhouse by acquiring Air Motion Systems

Top players in UV and LED unite to form the world’s largest provider of energy-efficient curing solutions

Two major players in the UV curing systems industry, Air Motion Systems, Inc. (AMS) and Baldwin Technology Company, Inc., are merging their expertise to create the premier provider of UV and LED curing technology across the globe.

Baldwin, the world leader in highly reactive UV, LED UV and IR drying systems, has acquired Air Motion Systems, the world’s leading provider of LED UV curing technology for the graphic arts industry, expanding its position as the number one customer choice within the market. The new entity of Baldwin, part of the $2+ billion Barry-Wehmiller family of companies, will rebrand as AMS SPECTRAL UV and combine AMS with Baldwin’s UV division. AMS SPECTRAL UV locations will continue to grow their operations in River Falls, Wisconsin; Easton, Pennsylvania; and Slough, U.K.

Baldwin, the world leader in highly reactive UV, LED UV and IR drying systems, has acquired Air Motion Systems, the world’s leading provider of LED UV curing technology for the graphic arts industry, expanding its position as the number one customer choice within the market. The new entity of Baldwin, part of the $2+ billion Barry-Wehmiller family of companies, will rebrand as AMS SPECTRAL UV and combine AMS with Baldwin’s UV division. AMS SPECTRAL UV locations will continue to grow their operations in River Falls, Wisconsin; Easton, Pennsylvania; and Slough, U.K.

“This acquisition marks the beginning of a new era in providing high-performance solutions for the UV industry,” said AMS SPECTRAL UV President Steve Metcalf. “We’re bringing the top industry minds, technology and experience together to tap an unprecedented opportunity in LED and UV, and to serve an ever-widening range of markets and applications.”

The AMS LED UV product portfolio has become the de-facto standard for LED curing in sheetfed offset printing and flexo packaging, with an installed base nearly 10 times that of its nearest competitor. Complementing this technology, Baldwin’s UV division has vast experience in highly reactive UV curing and numerous LED applications outside of traditional print markets. Further, the new curing-technology entity will leverage a massive base of experience serving OEM and industrial markets.

“What AMS SPECTRAL UV will provide customers is a doubling of research and development, engineering, manufacturing capacity and service to meet their growing needs in the market,” said Pat Keogh, one of the commercial leaders of AMS SPECTRAL UV. “We are proud to continue to offer innovative solutions in a new world being driven by the rapid advancement in UV and LED curing technologies.”

According to market intelligence provider Yole Development, the total value of the UV LED market worldwide is projected to grow to US$1 billion-plus in the next five years. AMS SPECTRAL UV aims to capture a large share of the anticipated market by leveraging the scale and resources of Baldwin which, through its global footprint, supplies process-automation equipment and related consumables, parts and services for the print, film, corrugated, textile and paper and packaging industries.

“The establishment of AMS SPECTRAL UV strengthens our ability to provide value to our existing customers while remaining responsive to emerging market opportunities,” said Brent Becker, CEO of Baldwin. “This exciting investment underscores our commitment to a strategy that blends organic and acquisition growth to enhance our global footprint and the technology we can deliver to our customers.”

ABOUT BALDWIN TECHNOLOGY COMPANY, INC.

Baldwin Technology Company Inc. is a leading global manufacturer and supplier of process-automation equipment and related consumables for the printing, packaging and other industrial segments, including technical textiles, chip and fiberboard, and film extrusion. Through our global footprint, Baldwin offers our customers a broad range of market-leading technologies, products and systems that enhance the quality of industrial-produced products, with a focus on improving the economic and environmental efficiency of the production process. As a total solutions provider, Baldwin not only offers new equipment to our customers, but also dedicates extensive resources to maintaining and servicing existing equipment. Baldwin is privately owned by Forsyth Capital Investors, a Barry-Wehmiller Group company. For more, go to baldwintech.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2+ billion organization with 11,000-plus team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his new book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com

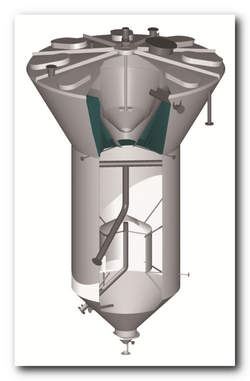

Tall Oil: Unlocking opportunities for pulp mills in the bioeconomy

Thanks to renewable energy regulations, the demand for tall oil is increasing. The by-product of the kraft pulping process industry can improve the efficiency of a pulp mill and be sold as a commercial product to processing industries.

The EU’s ‘Renewable Energy Directive’ requires all EU countries to ensure that at least 10% of their transport fuels come from renewable sources by 2020. The EU is also planning even more ambitious targets for greenhouse gas emission reductions to fulfill its pledges towards the Paris Agreement of which decarbonisation of the transport sector is a cornerstone.

This regulatory nudge has increased interest in tall oil as a biofuel feedstock.However,this emerging demand for the raw material competes with the use for more traditional tall oil derivatives, such as resin and fatty acids produced in distilleries. Whilst the price for crude tall oil has been slowly increasing to around 400-500 EUR/t, due to biodiesel competition and increase of the distillates product prices, the regulatory pull increases the competitiveness of tall oil as a biofuel feedstock from a biofuel manufacturer’s perspective.

What is tall oil?

Tall oil is a commercially important by-product of softwood (i.e. pine or spruce) from pulp production. It is produced by first separating ‘tall oil soap’ from the ‘black liquor’ that is formed in the pulping process. The tall oil soap can then be reacted with acid to product ‘crude tall oil’.

Pulp mills burn the black liquor to generate heat and electricity. As soap removes some capacity of burning the black liquor and hinders the operation of the evaporation plant , it makes sense for the mills to separate the soap from black liquor.

Besides producing tall oil of the separated soap, soap can alternatively be sold or burned for additional electric power but this is often not so profitable.

So in addition to bringing income to the mill as a commercial product (even more than selling the soap as such), separating tall oil from soap improves the overall efficiency and operations of the mill as primary processes are not compromised.

Capacity expansion potential

As the price of crude tall oil increases, coupled with more modern techniques for extracting this raw material at existing softwood pulp mills, it is becoming more and more lucrative for pulp producers.

As the price of crude tall oil increases, coupled with more modern techniques for extracting this raw material at existing softwood pulp mills, it is becoming more and more lucrative for pulp producers.

The key factors impacting the profitability of tall oil production are:

- the local market environment and demand

- the scale of pulp production

When the softwood pulp production capacity is roughly 100,000 tons per year or more, tall oil separation for commercial purposes is usually more profitable than the alternative use of soap.

Currently, there are an estimated 40 softwood pulp mills globally that could utilise tall oil separation based on their annual pulp production capacity but are yet to capitalise on the opportunity. In Northern and Central Europe, tall oil separation is already quite common but the biggest untapped potential with current pulp production assets lies in the US.

Tall oil business case

Investment in a new tall oil plant is a feasible option both for mills with too small or outdated tall oil plants as well as for mills without an existing plant. For mills that sell tall oil soap and do not have a tall oil acidulation plant, the investment payback time is usually between 1-3 years.

In case the mill burns the soap in the recovery boiler, commercial benefits are further improved by the fact that the mill can increase pulp production when recovery boiler capacity can be utilised for black liquor combustion instead of soap burning. If a too small or outdated tall oil plant is renewed with the aim of increasing tall oil production by 25%, the investment payback time varies between 2-5 years.

Based on pulp production growth forecasts up to 2030, an additional 300,000 tons p/a of crude tall oil could enter the market. These capacity expansions would help supply the growing demand for crude tall oil and would mark significant growth opportunities for tall oil applications.

Did you know?

Pöyry provides complete, value adding service offering to pulp mills, from developing raw material sourcing strategies and conducting market research and business case analysis to delivering HDS® (Hydro Dynamic Separator) tall oil plants and providing operational support and performance improvement. Over the past 30 years, we have delivered more than a third of the world’s tall oil plants and helped several mills to design or improve their soap and tall oil separation processes in order to increase profitability and efficiency to drive growth.

Jarno Peltonen Director, Pulp Technology, Industry Business Group, Pöyry Preparing for the future

CEO Per Lindberg comments on the development during Q4 2016:

“When we look back at 2016 we are very happy to see that we across the board have record production and sales volumes. The one issue is our lack of growth within Consumer Board due to the production disturbances earlier in the year. Looking forward we have good reason to believe this will not be a concern. We have stabilised our production and the most important event last year, the decision to build a new board machine in Gruvön, gives us the foundation for long term growth. Together with the decision to make Skärblacka a world leading MG-centre it also optimises our production structure. Looking at the markets we are confident we will be able to deliver continued growth in line with our plans and expectations. The foundation of our business is sustainable packaging materials and solutions and the demand is growing across our markets all over the world.”

“When we look back at 2016 we are very happy to see that we across the board have record production and sales volumes. The one issue is our lack of growth within Consumer Board due to the production disturbances earlier in the year. Looking forward we have good reason to believe this will not be a concern. We have stabilised our production and the most important event last year, the decision to build a new board machine in Gruvön, gives us the foundation for long term growth. Together with the decision to make Skärblacka a world leading MG-centre it also optimises our production structure. Looking at the markets we are confident we will be able to deliver continued growth in line with our plans and expectations. The foundation of our business is sustainable packaging materials and solutions and the demand is growing across our markets all over the world.”

THE RESULT

We deliver a solid performance with an increase in sales volumes of 1% for the full year 2016 compared to 2015. We have record production and sales volumes and on top of that our cash flow and adjusted EBITDA is at an all-time high and our working capital end of 2016 at an all-time low. We are not satisfied with the growth in the Consumer Board segment during 2016, but we have put the production disturbances related to the rebuilds in 2015 behind us, and the anticipated improvements will come as we now are able to run our capacity on higher levels to match market demand and growth. Worth mentioning is also a strong finish in 2016 for business area Packaging Paper with an all-time high profit.

MARKET OUTLOOK

It is fair to say that both in the packaging industry and among brand owners it is a widespread anticipation that the largest potential disruptive development for packaging going forward is a growing environmental awareness among consumers. We have long seen this when we analyse our markets, in dialogue with our customers and partners but also in growing demand for sustainable packaging. In recent times we have also seen a growing interest in sustainability from investors and owners. In a global political context that is unpredictable we still stand firm in our belief that consumers expect more and more from products and companies in terms of sustainability and that this creates growing market opportunities for us.

For each of our business areas the markets were stable in Q4 and we expect that to continue in Q1.

STRATEGY

To seize the long term market opportunities we have a clear strategy of profitable growth that is divided in two main categories – packaging materials and solutions. During 2016 we showed that we are committed to these ambitions. The two major investments announced during the year both underline the intention and provides the platform for growing the materials side of our business. But we have also taken several important steps towards accelerating our growth in solutions. During 2016 we established BillerudKorsnäs Venture AB that will find and invest in young innovative companies with technologies or competence that in combination with our capabilities might create completely new business opportunities. In Q1 we invested in ecoXpac (specialised in advanced 3D-forming) and during Q4 we invested in Kezzler and in Hanhaa (Internet of Packaging). While these investments aim to yield new revenue streams in the long term, solutions are already becoming an important part of the current business areas. This is very evident in Corrugated Solutions with an aggressive growth plan for Managed Packaging – once an acquisition of the company Paccess.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 7 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

ANDRITZ MeWa to supply new processing line for pulper rags to Papier- und Kartonfabrik Varel, Germany

ANDRITZ MeWa, part of international technology Group ANDRITZ, has received an order from Papier- und Kartonfabrik Varel, based in Varel, Germany, to supply a processing line for pulper rags.

Pulper rags are a very tightly entangled mechanical compound of metallic and non-metallic components formed during pulping of recovered paper or pulp in the vortex center of a pulper.

ANDRITZ MeWa will supply a two-stage process for treatment of the pulper rags. In the first section of the plant, the rags will be pre-shredded using the Universal Rotary Shear UC 1300. The slowly rotating, twin-shaft cutter unit is excellently suited for powerful and, at the same time, energy-saving pre-shredding of the stringy input material and is largely insensitive to potential impurities.

ANDRITZ MeWa will supply a two-stage process for treatment of the pulper rags. In the first section of the plant, the rags will be pre-shredded using the Universal Rotary Shear UC 1300. The slowly rotating, twin-shaft cutter unit is excellently suited for powerful and, at the same time, energy-saving pre-shredding of the stringy input material and is largely insensitive to potential impurities.

In a second step, the material is shredded further in the UG 1000 S granulator. By using a replaceable screen with variable screen slot diameters, the customer is able to influence the throughput and the shred-ding result. At the end of the process, the metal fractions produced have a high purity level. The residual fraction is used as substitute fuel.

The convincing results obtained in extensive material tests in the test center at ANDRITZ MeWa’s headquar-ters in Gechingen, Germany, were decisive in placing the order with ANDRITZ MeWa, in addition to the higher throughputs obtained compared to competitors’ equipment.

Papier- und Kartonfabrik Varel was established in1947 and is a medium-sized, family-run company. With more than 500 employees at its location in Varel, the company produces 850,000 tons per year of high-grade paper and board on four production lines as raw material for the packaging industry.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,500 employees. ANDRITZ operates over 250 sites worldwide.

ANDRITZ MeWa

ANDRITZ MeWa is a part of the ANDRITZ GROUP and has been developing and building shredding and crushing machines as well as turnkey recycling plants for many different applications for over 30 years. The main focuses are processing of electrical and electronic scrap, refrigerators, metal composite materials, domestic and industrial waste, old tires, oil filters, as well as organic waste for biogas plants. The company is based in Gechingen, Germany.

Photo - Andritz