Ianadmin

Upgraded Invercote G gets Quick Printing award

The US newsletter Quick Printing conducted their 3rd annual Readers’ Choice Top Products Awards competition in mid-2015. The newsletter is targeting people in the quick printing business globally, and the goal was to gather opinions from print service providers about what they consider to be the most significant products introduced to the commercial printing industry over the last 15 months. Voting was open to all print service providers worldwide.

In the category Digital Print Media Upgraded Invercote G from Iggesund Paperboard was voted to be the best choice with the following motivation:

“Invercote G is certified for a variety of digital print technologies and is recognized as the market leader by digital printers when they need a thicker or stiffer material than usual. The upgraded Invercote G gives customers who want a clear difference between the paperboard’s two sides but who still want to be able to print on both sides using their digital presses precisely what they’re looking for.

The secret lies in the new coating on the reverse side of the upgraded Invercote G. Iggesund’s engineers created a reverse side with improved printing properties – in both offset and digital – but without compromising on the natural feel that has been the product’s hallmark for many years.”

Jannes Dahlgren, CEO at the Swedish digital printing house Digaloo is not surprised by the award.

“The improved printability on the reverse side has taken Invercote G to a new level for digital printing. We can use it for a larger range of print and packaging applications than before”, he says.

The award will be given to Iggesund at a ceremony at GraphExpo 15 in Chicago on Sunday September 13th.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

FOEX WRI Wood Chip Prices Indices for Overseas Trade in July 2015

In July 2015, prices for overseas traded hardwood chip were 14% below their peak four years ago, according to the latest FOEX Chip Price Indexes

Prices for hardwood chips traded overseas have been in steady decline since November 2011. In less than four years, the FOEX hardwood chip price index (PIX-HCG) has fallen almost 14% to reach US$178.34 per oven-dry metric ton (odmt) in July 2015. The downward trend of the index has partly been the result of lower prices for hardwood chips, in US dollar terms, imported to Japan from Australia, Chile and South Africa.

Prices for hardwood chips traded overseas have been in steady decline since November 2011. In less than four years, the FOEX hardwood chip price index (PIX-HCG) has fallen almost 14% to reach US$178.34 per oven-dry metric ton (odmt) in July 2015. The downward trend of the index has partly been the result of lower prices for hardwood chips, in US dollar terms, imported to Japan from Australia, Chile and South Africa.

Global overseas trade of hardwood chips has slowed down in 2015 with the total trade for the first six months of the year being almost 14% lower than the same period in 2014.

The FOEX softwood chip price index (PIX-SCG) has fluctuated more than the PIX-HCG the past two years and has been on an upswing for the past three months after having declined since last summer. In July, the Index was up almost four percent month-over-month to US$173.20/odmt, the highest level since December of 2014. The increase in the price index was due in part to higher import prices in Japan and Turkey.

About the PIX wood chip prices indices

FOEX and Wood Resources International (WRI) have cooperatively launched two wood chip price indices, the Softwood Chip Global (SCG) and Hardwood Chip Global (HCG), both part of the PIX index family of FOEX. The Indices represent prices (CIF) for wood chips that are traded globally overseas for the manufacturing of wood pulp and wood-based panels. The Indices are reported monthly the third Tuesday of the month on the FOEX web site (www.foex.fi). If you are interested in participating as a data provider, subscribing to the index histories (data available from January 2010), or are considering using the Indices commercially, please contact This email address is being protected from spambots. You need JavaScript enabled to view it..

About FOEX Indexes Ltd

FOEX Indexes Ltd is a private, independent company which specializes in providing audited, trade-mark registered price indices for pulp, paper, recovered paper, biomass and wood chips. Financial institutions use the FOEX Indices as benchmarks when setting prices for SWAP-deals and other financial instruments hedging against product price risks.

The PIX Indices are trademark registered by FOEX Indexes Ltd. Any commercial use of the indices is subject to permission from FOEX and the terms outlined in the License Agreement between the user/-s and FOEX. If you are considering commercial use of PIX-SCG or PIX-HCG, please do not hesitate to contact FOEX for further guidance.

About Wood Resources International LLC

Wood Resources International LLC, an internationally recognized forest industry-consulting firm established in 1987, publishes two quarterly timber and pulpwood price reports and has subscribers in over 30 countries. The Wood Resource Quarterly, established in 1988, is a 50-page quarterly market report which includes global prices for sawlogs, pulpwood, wood chips, lumber and pellets, as well as market commentary about developments in the global timber, biomass and forest industry. If you have any questions, please contact Hakan Ekstrom (This email address is being protected from spambots. You need JavaScript enabled to view it.).

Ahlstrom has sold Munksjö shares worth EUR 10 million

![]() Ahlstrom, a global high performance fiber-based materials company, has sold 1,300,981 shares in Munksjö Oyj for approximately EUR 10 million. Ahlstrom will book a capital gain of approximately EUR 3.2 million from the transaction in its third-quarter 2015 results.

Ahlstrom, a global high performance fiber-based materials company, has sold 1,300,981 shares in Munksjö Oyj for approximately EUR 10 million. Ahlstrom will book a capital gain of approximately EUR 3.2 million from the transaction in its third-quarter 2015 results.

According to Ahlstrom's knowledge 902,000 shares valued at approximately EUR 6.9 million were sold to AC Invest Five B.V. The entity is Ahlstrom Corporation's related party.

Following the sale of shares, Ahlstrom's shareholding in Munksjö has been reduced to zero percent.

For more information, please contact:

Juho Erkheikki

Financial Communications & Investor Relations Manager

Tel. +358 10 888 4731

Satu Perälampi

VP, Communications

Tel. +358 10 888 4738

Ahlstrom in brief

Ahlstrom is a high performance fiber-based materials company, partnering with leading businesses around the world to help them stay ahead. We aim to grow with a product offering for clean and healthy environment. Our materials are used in everyday applications such as filters, medical fabrics, life science and diagnostics, wallcoverings and food packaging. In 2014, Ahlstrom's net sales amounted to EUR 1 billion. Our 3,400 employees serve customers in 22 countries. Ahlstrom's share is quoted on the NASDAQ OMX Helsinki. More information available at www.ahlstrom.com.

Historically strong earnings for Södra

Södra reported a strong earnings trend for the first eight months of the year. Operating profit rose to SEK 1,660 million (1,012), sales increased to SEK 12,186 million (11,429) and the operating margin was 14 percent (9).

Södra reported a strong earnings trend for the first eight months of the year. Operating profit rose to SEK 1,660 million (1,012), sales increased to SEK 12,186 million (11,429) and the operating margin was 14 percent (9).

“Södra is performing well. A healthy second four-month period has finished with a historically strong overall result for the Group for the period through August. This is largely due to high price levels for finished goods and mainly to a favourable currency situation – but also because Södra is becoming an increasingly efficient, innovative and value-generating Group,” said CEO Lars Idermark.

Operating profit for the second four-month period amounted to SEK 718 million (509) and sales to SEK 5,943 million (5,591), which yielded an operating margin of 12 percent (9). The improved earnings were due to positive demand for Södra’s products and a favourable currency situation.

“The Södra Cell business area continues to deliver a very strong performance. Stable and efficient production at the mills, while we are investing SEK 5 billion to increase production, is impressive. The profit trend for Södra Wood is more problematic. Efforts to improve operational efficiency are progressing well, but lower prices and weaker market conditions are putting pressure on profitability. Eventually, structural changes will also be required to improve profitability. Several minor measures have already been implemented, such as concentrating more of our business operations into fewer and larger units,” added Idermark.

Södra in brief, January-August 2015 period:

| 2015 | 2014 | 2015 | 2014 | 2014 | |

| May-Aug | May-Aug | Jan-Aug | Jan-Aug | Jan-Dec | |

| Net sales, SEK million | 5,943 | 5,591 | 12,186 | 11,429 | 17,339 |

| Operating profit before depreciation, amortisation and impairment (EBITDA), SEK million | 1,028 | 824 | 2,292 | 1,656 | 2,552 |

| Operating profit, SEK million | 718 | 509 | 1,660 | 1,012 | 1,516 |

| Operating margin, % | 12 | 9 | 14 | 9 | 9 |

| Cash flow after investing activities, SEK million | 141 | 260 | 881 | 775 | 267 |

| Return on capital employed, % | 20 | 13 | 13 |

For questions, please contact:

Lars Idermark, Chief Executive Officer

Telephone: +46 470 894 35

Sonoco’s New FlatStack Ultralight Tier Sheet Offers Value, Consistency

Product to be Demoed at Pack Expo 2015 in Las Vegas

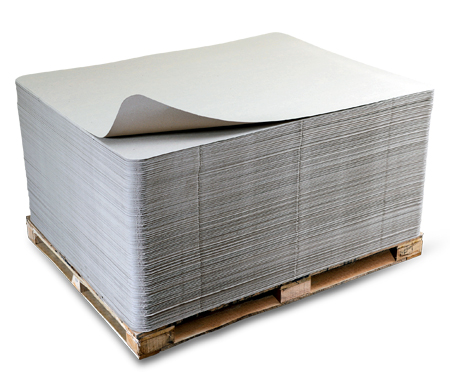

Sonoco (NYSE:SON), one of the largest diversified global packaging companies, has expanded its line of FlatStack® paperboard tier sheets to include FlatStack® Ultralight™, a value-priced alternative to lightweight gypsum and paperboard sheets.

“The new Ultralight option offers our customers exceptional performance for a great price,” said Michael Krawson, account manager for sheets. “Plus, it comes straight from our paper mills, meaning we can assure consistency in quality and security of supply.”

With the introduction of Sonoco’s Ultralight grade, Sonoco now produces sheets in the caliper range of 10 to 50pt. Sonoco’s wide range in caliper offering, coupled with in-house design and testing capabilities, enables the Company to create custom solutions to meet customers’ unique manufacturing requirements (including integration with automated equipment), saving them time and money.

The Ultralight option supplements Sonoco’s original FlatStack® paperboard tier sheet. Made from 100 percent recycled fibers and completely recyclable, the original FlatStack paperboard sheets are a cost-effective solution that protects products on pallets during shipping, storage and retail display. Compared to typical corrugated tier sheets, FlatStack sheets offer a minimum 5 percent reduction in weight and generally garner a minimum of 15 percent cost savings across the supply chain. They also offer five times the amount of sheets per unit storage, and more than twice as many sheets shipped per truckload.

To learn more about FlatStack Ultralight and Sonoco’s original FlatStack tier sheets, visit www.sonoco.com/flatstack, or visit Booth S-5984 at the upcoming Pack Expo 2015 tradeshow in Las Vegas, Sept. 28-30.

About Sonoco

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and display and packaging services. With annualized net sales of approximately $5.0 billion, the Company has 20,800 employees working in more 330 facilities in 34 countries, serving many of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index. For more information on the Company, visit our website at www.sonoco.com.

Södra takes new steps with ground-breaking, eco-friendly material

On 22 September, the first pilot machine for manufacturing products from the ground-breaking bio-composite DuraPulp was inaugurated. With DuraPulp, Södra is able to offer a viable alternative to fossil-fuel based products.

On 22 September, the first pilot machine for manufacturing products from the ground-breaking bio-composite DuraPulp was inaugurated. With DuraPulp, Södra is able to offer a viable alternative to fossil-fuel based products.

DuraPulp is a biodegradable and renewable material that is malleable and mouldable. It can be used for a wide range of applications and sophisticated designs. The material is stable, water resistant and highly durable. DuraPulp has been developed by Södra and will now be produced on a pilot machine so that customers can trial the material for themselves for the first time.

On the threshold of the future

The inauguration represents a first step towards industrial-scale production of DuraPulp and bespoke products. Both the material and its products are very different to those made from traditional cellulose recipes and require a high level of technical expertise in the manufacturing process and technical support for customers, which Södra will provide. The foundations for a facility that can be used for technical presentations are currently being laid. It will also be made available to new customers to help their product development process.

DuraPulp is a mix of cellulose and a corn-based polymer called polylactic acid (PLA). It is completely new to the market. DuraPulp represents a potential solution to the replacement of fossil-fuel based products offering the chance to create bespoke new solutions rather than off-the-shelf options. DuraPulp is an extremely eco-friendly alternative to plastics with major potential in terms of product design, user-friendliness and durability.

A sustainable future

Södra has been working on the development of sustainable new materials to replace fossil-fuel products for some time. While DuraPulp's basic components are simple, the process of forming the actual material is considerably more complex. Using the right technique, the polymer melts and bonds with the cellulose, while also reinforcing the cellulose fibres.

Demo products produced with DuraPulp to date include the award-winning Parupu children's chair, exclusive packaging and industrial components.

For comments:

Urban Blomster, Business Developer Durapulp, Södra,

Tel: +46 (0)70 -683 77 85

Press contact:

Ciccie Jisborg, Communication Strategist

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +46 (0)72-581 82 59

Frida Nielsen, Communicator

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +46 (0)72-245 16 70

Facts:

The project is a collaboration with the Innventia Cluster Research Programme, as well as Södra's partners SWT and James Cropper PLC.

DuraPulp has two basic components: virgin softwood fibre (long fibre) and a polymer based on corn starch, polylactic acid (PLA).

ZELLCHEMING-Expo 2015 – Analysis confirms quality of the event

The evaluation of the exhibitor and visitor survey confirms ZELLCHEMING-Expo as an important dialogue platform for the European pulp and paper industry. 90 % of the exhibitors are planning to participate in 2016 again and 87 % of the visitors intend to visit ZELLCHEMING-Expo 2016.

Exhibitors meet their target group

ZELLCHEMING-Expo offered 153 exhibitors the possibility to present their products and solutions to an experienced audience. 83 % of the exhibitors evaluated the quality of the visitors with very good and good. Almost 80 % of the 1,832 visitors are involved in the procurement decisions in their companies. 86 % of the visitors declared that they have found the information which they were looking for and 78 % of the visitors evaluated the managed expert discussions with exhibitors as very good and good. With an increase in visitor numbers of more than 10 %, the quantity of the visitors rose compared to the previous year. 93 % of the exhibitors recommend ZELLCHEMING-Expo.

Increase in internationality

41 % of the exhibitors came from abroad and spread across 14 different countries. This represents an increase of 4 %. The top 5 foreign exhibitor countries 2015 were Finland, Sweden, Italy, the USA as well as Switzerland. Furthermore, the number of international visitors rose by 3 % compared to the previous year. Therefore, 24 % of the visitors came from abroad which spread across 30 countries worldwide.

Exchange of knowledge on a high level

According to the slogan “Paper & Fiber World 2030 – What does the future hold for the paper industry?” the congress offered a top-class and informative lecture program that was pursued with great interest by 400 congress participants.

Please see the detailed analysis at www.zellcheming-expo.com

Note the date for 2016

The next event takes place from 28 – 30 June 2016 in hall 11.0 at the Frankfurt exhibition site. All important information can be found at www.zellcheming-expo.com

About Mesago

Mesago Messe Frankfurt GmbH, founded in 1982 and located in Stuttgart, specializes in exhibitions and conferences on various topics of technology. The company belongs to the Messe Frankfurt Group. Mesago operates internationally and is not tied to a specific venue. With 120 members of staff Mesago organizes events for the benefit of more than 2,700 exhibitors and over 100,000 trade visitors, conference delegates and speakers from all over the world. Numerous trade associations, publishing houses, scientific institutes and universities work with Mesago closely as advisers, co-organizers and partners. (mesago.com)

About ZELLCHEMING e. V. - The Association of Chemical Pulp and Paper Chemists and Engineers is an association which has dedicated itself fully to the various issues and topics surrounding chemical pulp production and paper making. We see ourselves as a technical-scientific professional association for the chemical pulp paper industry as well as its suppliers. Anybody who is involved with chemical pulp production and paper making in Europe will find that we offer a comprehensive range of information as well as strong representation of interests for the concerns and issues affecting our high-tech sector. We provide our members with an international network for the exchange of information and technical contacts in which topics discussed range from research and development concerning paper making through to ecology and the future of the chemical pulp industry and paper industry. (zellcheming.com)

Kadant Nordic Combines Scandinavian Operations

Kadant Nordic AB, a subsidiary of Kadant Inc. (NYSE:KAI), announced that it has combined Kadant Johnson Scandinavia AB and Kadant M-Clean AB and will operate these businesses under the name of Kadant Nordic AB. Kadant Nordic AB offers Kadant’s Fluid-Handling and Doctoring, Cleaning, & Filtration product lines to the paper and other process industries in Sweden, Finland, Denmark, Iceland, and Norway.

Kadant Nordic AB, a subsidiary of Kadant Inc. (NYSE:KAI), announced that it has combined Kadant Johnson Scandinavia AB and Kadant M-Clean AB and will operate these businesses under the name of Kadant Nordic AB. Kadant Nordic AB offers Kadant’s Fluid-Handling and Doctoring, Cleaning, & Filtration product lines to the paper and other process industries in Sweden, Finland, Denmark, Iceland, and Norway.

Joakim Östling, managing director of Kadant Johnson Scandinavia, has been appointed managing director of Kadant Nordic, and Daniel Strom, sales manager at Kadant M-Clean, has been appointed sales director at Kadant Nordic. The company’s primary office will be located in Huskvarna, Sweden with sales and service personnel located throughout the Nordic region.

Kadant Nordic AB, based in Huskvarna, Sweden, is a leading provider of paper machine fabric and roll cleaning systems. Its fluid-handling products and systems are used in papermaking and other industrial processes to enhance process efficiency and optimize energy utilization.

Kadant Inc. is a global supplier of high-value, critical components and engineered systems used in process industries worldwide. The company’s products, technologies, and services play an integral role in enhancing process efficiency, optimizing energy utilization, and maximizing productivity in resource-intensive industries. Kadant is based in Westford, Massachusetts, with revenues of $402 million in fiscal 2014 and 1,800 employees in 18 countries worldwide. For more information, visit www.kadant.com.

The following constitutes a “Safe Harbor” statement under the Private Securities Litigation Reform Act of 1995: This press release contains forward-looking statements that involve a number of risks and uncertainties, including forward-looking statements about our products and technologies. Our actual results may differ materially from these forward-looking statements as a result of various important factors, including those set forth under the heading "Risk Factors" in Kadant’s quarterly report on Form 10-K for the year ended January 3, 2015 and subsequent filings with the Securities and Exchange Commission. These include risks and uncertainties relating to adverse changes in global and local economic conditions; the variability and difficulty in accurately predicting revenue from large capital equipment and systems projects; the variability and uncertainties in sales of capital equipment in China; currency fluctuations; our customers’ ability to obtain financing for capital equipment projects; changes in government regulations and policies; the oriented strand board market and levels of residential construction activity; development and use of digital media; price increases or shortages of raw materials; dependence on certain suppliers; international sales and operations; disruption in production; our acquisition strategy; our internal growth strategy; competition; soundness of suppliers and customers; our effective tax rate; future restructurings; soundness of financial institutions; our debt obligations; restrictions in our credit agreement; loss of key personnel; reliance on third-party research; protection of patents and proprietary rights; failure of our information systems or breaches of data security; fluctuations in our share price; and anti-takeover provisions. We undertake no obligation to publicly update any forward-looking statement, whether as a result of new information, future events, or otherwise.

Hit all the right notes with MAESTRO®

MAESTRO® office paper re-launch: The new MAESTRO® live in concert

Mondi, an international packaging and paper company, announces the re-branding of its MAESTRO® brand. New packaging designs of the product will be available in stores from early autumn onwards. The rebranding of the MAESTRO® product range was inspired by the orchestra maestro’s ability to handle all kind of musicians with diverse styles, just as Mondi aims to satisfy diverse customer needs with its broad MAESTRO® product portfolio.

Mondi, an international packaging and paper company, announces the re-branding of its MAESTRO® brand. New packaging designs of the product will be available in stores from early autumn onwards. The rebranding of the MAESTRO® product range was inspired by the orchestra maestro’s ability to handle all kind of musicians with diverse styles, just as Mondi aims to satisfy diverse customer needs with its broad MAESTRO® product portfolio.

In recognition of its strong international brand awareness and success, Mondi is revitalising the brand with a re-launch campaign, including new packaging designs, videos and jingles of different music styles. To highlight the unique qualities offered by the individual products, which are designed to meet the needs of today’s business world, every product of the portfolio refers to one musical style.

“The broad range of the MAESTRO® portfolio offers our customers optimal solutions for every need, just as musicians find the right song for their audience’s current mood. So you can count on MAESTRO® to set the stage for an impressive performance,” says Johannes Klumpp, Marketing and Sales Director of Mondi Uncoated Fine Paper.”

Broad applicability and reliable quality

Mondi strives to understand and exceed customer expectations and to fulfil their printing needs every day. In order to flexibly cater to customer requests, MAESTRO® offers the right solution for a range of modern compositions in office paper. Elegance, versatility, strength, smartness or an urban feel – whatever needs to be expressed, MAESTRO® office papers have the right offering. “From dynamic contrasts for printing texts and colourful graphics with MAESTRO® extra, or MAESTRO® color with 30 different eye-catching colours to choose from, to efficient black-and-white printing with MAESTRO® standard, the MAESTRO® portfolio enables you to hit all the right notes,” explains Klumpp.

MAESTRO® papers are optimally suited for diverse office applications, with the portfolio ranging from high white to tinted papers with a high level of opacity and minimum dust generation, which consequently leads to less machine wear and cost savings with regards to maintenance and servicing. The proven ColorLok® Technology for MAESTRO® supreme, MAESTRO® extra and MAESTRO® bulky delivers excellent results on inkjet printers and enables bolder blacks, vivid colours and faster drying.

Sustainable. Every day.

Also with regards to sustainability the MAESTRO® brand offers a strong environmental profile. The entire MAESTRO® portfolio is FSC® or PEFC™ certified and thus part of Mondi’s Green Range. Mondi makes continuous efforts to further improve the environmental performance of its products and processes every day. Sustainability is a fundamental and integral part of Mondi’s corporate strategy. Mondi’s Green Range, introduced in 2006, is recognised as a symbol for strong environmental performance in the sustainable paper production, with all Green Range papers FSC®/PEFC™ certified, 100% recycled or produced totally chlorine free (TCF). The company’s commitment is underpinned by close collaborations with public organisations and NGOs, resulting in numerous renowned certifications: FSC®, PEFC™, EU Ecolabel, Blue Angel, Austrian Ecolabel, PPI Awards for Mondi‘s environmental strategy and the long-term partnership with the World Wide Fund for Nature (WWF).

For more information visit: www.mondigroup.com/maestro

We are Mondi. IN TOUCH EVERY DAY.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers and end consumers. In 2014 Mondi had revenues of €6.4 billion and a return on capital employed of 17.2%.

The Mondi Group is fully integrated across the packaging and paper value chain – from managing forests and producing pulp, paper and compound plastics to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual-listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc under the ticker code MNDI.

For us, sustainable development makes good business sense. We don’t just talk about sustainability; we make it part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

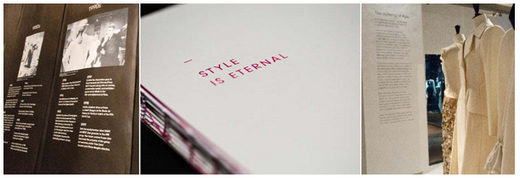

YSL Exhibition Unfurled

Paper replaces walls in the innovative installation of landmark Style is Eternal show celebrating the work of fashion designer, Yves Saint Laurent.

Where most exhibitions are constructed of wood panels and metal nails, part of the remarkable exhibition of Yves Saint Laurent’s work and life at The Bowes Museum, County Durham has been intricately dressed with paper. As if walking into the designer’s sketch books, a room designed by Paris’ agence NC, Nathalie Crinière has taken stock from British master papermakers, James Cropper Paper and formed an immersive, paper-based appreciation of Saint Laurent’s creative process.

Yves Saint Laurent: Style is Eternal, the first exhibition in the UK to show a comprehensive display of the French designer’s work is dominated by paper, from initial sketches to specification forms and the patterns for his famous final designs. Understanding that paper is riven through the creative process, Agence NC designer Nathalie Crinière and installation company, North Exhibition Services set about to ensure the natural look of paper was dominant as a backdrop to the exhibition experience. A white cube of pristine white paper cocoons a range of Saint Laurent’s earliest creations in trademark monochrome fabrics, making good use of The Bowes Museum’s high ceilings with a dramatic drop of uninterrupted, five to six metre sheets.

Unaware as to how the paper would respond directly from rolls, or precisely how to match paper elements with other parts in glass and steel, the versatility of the stock soon became an advantage as complex cuts were made with only blades and scissors. The sense of understatement is emboldened by the texture of the 120gsm paper, which curls naturally at the foot of each hung sheet, evoking the gnarled edges of a well-worn notebook or the flick of a lavish evening dress. A slight movement in the paper as large numbers of visitors pass through the space adds an unexpected, sensuous sense of animation.

Specialists in black papers, James Cropper supplied a deep natural black paper in 120gsm to carry white text as information panels to guide viewers through the chronology of Saint Laurent’s career, instead of more standard exhibition installations that see vinyl lettering applied directly to walls or foamboard mounts. The effect is striking, yet in keeping with the exhibition’s understated style.

Doug Lamond, Founding Director of North Exhibition Services, said: “This was a first for us being asked to use paper to create the backdrop for an exhibition on this scale. It was a challenge in the sense that it was an unknown how the paper would behave straight off a roll. We needn’t have been worried as the paper worked very well as a backdrop for the show for many reasons, including its natural texture, weight and starkness of the white print on black. I would certainly recommend it as a finish whenever the aesthetic calls for it and on the scale we have just delivered, it has a great impact while being understated and subtle.”

James Cropper Paper, which supplies many of the world’s leading luxury brands with custom papers for their packaging requirements, also featured in the VIP launch invitation (Vanguard White, 620gsm and envelope in Vanguard Dark Grey), promotional print materials for the exhibition (Vanguard Silver Grey, 160gsm) and within the pages of the stunning 120 page catalogue (Vanguard Silver Grey, 120gsm and Vanguard Silver Grey, 300gsm), resplendent in a foiled and embossed cover and hand-finished binding.

Yves Saint Laurent: Style is Eternal, presented by The Bowes Museum and the Fondation Pierre Bergé - Yves Saint Laurent runs at The Bowes Museum, Barnard Castle, Teesdale, County Durham until Sunday 25 October 2015.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. A proud sponsor of artists and exhibitions including events at Frieze Masters and NYCxDesign, James Cropper Paper is committed to supporting creativity. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of paper making expertise.

In supporting Yves Saint Laurent: Style Is Eternal, James Cropper reflects on the strong link between paper and design, with Saint Laurent himself expressing early creativity in the meticulous execution of handcrafted paper dolls. The company’s paper plays a role as a backdrop to the exhibition itself with small reels of white paper, specially cut to length, hanging in the ‘Glass Cube’ and reels of a black board printed to create a timeline along the entire length of the gallery. Uncoated papers in classic white and grey shades from the Vanguard collection feature as VIP invitations, sections within the Yves Saint Laurent book and also the exhibition guide.

As well as paper products, James Cropper PLC also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com

About the Fondation Pierre Bergé - Yves Saint Laurent

The Fondation Pierre Bergé - Yves Saint Laurent, which opened in 2004 in the former Yves Saint Laurent couture house on 5 Avenue Marceau, Paris, is founded on 40 years of creativity. Recognised as a public organisation, it has three missions:

- The rigorous museological conservation of a unique heritage comprising five thousand haute couture garments and fifteen thousand accessories, as well as thousands of sketches, collection boards, photographs, and objects;

- The organization of exhibitions, in both the refurbished spaces at 5 Avenue Marceau and museums around the world, promoting Yves Saint Laurent’s work.

- The support of cultural institutions encouraging the contemporary arts.

About The Bowes Museum

The Bowes Museum was created over 100 years ago by John and Joséphine Bowes. Together they built up the greatest private collection of European fine and decorative arts in the North of England and constructed a magnificent French chateau in 17th century style, to house them in. The collection contains thousands of predominantly French objects including furniture, paintings, sculpture, ceramics, textiles and many other items covering an extensive range of European styles and periods.

For much of their lives John and Joséphine Bowes lived in Paris. Josephine was formerly an actress and performed in theThéâtre des Variétés, which John Bowes subsequently purchased.

The Bowes Museum has an internationally renowned exhibition programme. Recent exhibitions have included Tim Walker: Dreamscapes; Henry Poole Founder of Savile Row; and Stephen Jones ‘From Georgiana to Boy George’. Current exhibitions are ‘Birds of Paradise –

Plumes and Feathers in Fashion’ initiated by MoMu Fashion Museum, Antwerp, and ‘Julian Opie Collected Works’, which presents works by and inspirations for the contemporary artist.

The Bowes Museum is located in Barnard Castle, County Durham and is open daily from 10.00am – 5.00pm

About Yves Saint Laurent

Yves Saint Laurent was born on 1st August 1936 in Oran, Algeria, where he spent all his youth. In 1955, after a period at theChambre syndicale de la haute couture in Paris, he was introduced by Michel de Brunhoff, then director of ParisVogue, to Christian Dior, who immediately took him on as his assistant. When Dior died in 1957, Yves Saint Laurent became artistic director of the House of Dior. His first collection, the «Trapèze» collection, presented in January 1958, was an immense success. Called up to do his military service and hospitalised at the Val de Grâce, he was dismissed by the House of Dior in 1960.

In association with Pierre Bergé, whom he had met in 1958, Yves Saint Laurent decided to create his own couture house and his first collection was presented on 29th January 1962 at 30 bis rue Spontini in Paris. They remained there for 12 years during which Yves Saint Laurent invented the modern woman’s wardrobe.

From the end of the 1950s and throughout his career Yves Saint Laurent created costumes for theatre, ballet and cinema. He collaborated with Roland Petit, Claude Régy, Jean-Louis Barrault, Luis Buñuel, François Truffaut... and dressed Jean Marais, Zizi Jeanmaire, Arletty, Jeanne Moreau, Isabelle Adjani and Catherine Deneuve, who became a long-standing close friend.

As early as 1965 Yves Saint Laurent paid tribute to artists in his haute couture collections with the famous Mondrian dresses, then in 1966 with the pop art dresses and in 1967 with his major homage to African primitive art. Yves Saint Laurent would travel to Marrakech for a fortnight on 1st December and 1st June of each year in order to design his haute couture collections. Morocco, a country he discovered in 1966, was to have a major influence on his work and his colours, as did all his travels: Japan, India, Russia, China and Spain all provided sources of inspiration for his collections. In 1974, Yves Saint Laurent and Pierre Bergé moved the couture house to 5, avenue Marceau in Paris, where the former would assert his style.

In 1983 the New York Metropolitan Museum of Art devoted a retrospective exhibition to the couturier “Yves Saint Laurent 25 years of design”. It was the first time that a living fashion designer had received such an accolade there. Large-scale exhibitions were subsequently held in Beijing, Moscow, Tokyo and, of course, Paris, at the Musée des Arts de la mode, in 1986.

In 1998 Yves Saint Laurent dressed 300 models who appeared on the pitch of the Stade de France for the final match of the FIFA World Cup.

On 7th January 2002 he announced at a press conference that he was ending his career. On 22nd January of the same year, at the Centre Georges Pompidou, a retrospective show went back over 40 years of creation with over 300 models including his last Spring-Summer 2002 collection.

On 10th March 2004, the Fondation Pierre Bergé – Yves Saint Laurent opened to the public with an exhibition entitled Yves Saint Laurent -Dialogue avec l’Art, which then travelled to the Caixa Galicia Foundation in Spain in 2007. The Yves Saint Laurent Style exhibition was presented in 2008 at the Fine Arts Museum of Montreal, and then at San Francisco’s de Young Museum.

On 1st June 2008, Yves Saint Laurent passed away at his Paris home in his seventy second year.

In 2010, the Fondation organised a major retrospective of Yves Saint Laurent’s work at the Petit Palais in Paris, which travelled to the MAPFRE Foundation in Madrid (2011) and the Denver Art Museum (2012). In 2013, a new exhibition project, Yves Saint Laurent, a visionary, was presented at the ING Cultural Center in Brussels.