Ianadmin

Cristini Paper Machine Clothing & Diagnostic Systems

Cristini is proud to showcase its Diagnostic systems line at MIAC 2015 in Lucca (Oct 14th-17th), featuring its EasyScan™ family of traversing beams. EasyScan 100, 300 & 500 are different versions available either for the transportation of portable felt scanners or equipped with DCS integrated sensors for the measurement of felt moisture & permeability. The beams are guaranteed maintenance free, with an extremely compact design to fit virtually any position on a paper machine.

Cristini continues to be one of the world’s most innovative clothing producers, offering endless and pin seam press fabrics as well as forming fabrics designed for all paper machines. In MIAC will be presented also EnerMaster™, a new Forming Fabric designed especially for packaging grades to increase forming quality, while reducing energy costs. The new line of Spiral Dryer fabrics for all grades MaxSpiral™, Maximum stability for Maximum life will be also presented at the show. Come visit us at Booth 106.

170 Papers for 170 Years

James Cropper Paper shows at Luxury Packaging to celebrate a landmark anniversary with the paper and packaging industry.

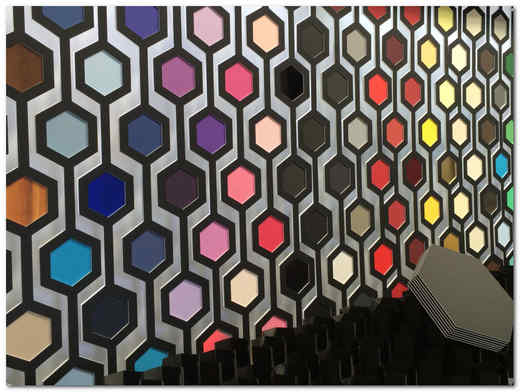

A wall of paper will greet visitors to the James Cropper Paper stand at this year’s Luxury Packaging event, taking place on Wed 16 – Thu 17 September 2015 at Olympia, London. With 170 die-cut samples available to take away in myriad colours and finishes to mark the British Master Papermaker’s 170 years in business at their Lake District mill.

As future-facing as ever, the company will also use the event as the opportunity to inspire visitors with a unique world of individual and distinct papers for packaging. The business focus is on premium and uncoated papermaking that is unrivalled in terms of quality, versatility, sustainability and service.

The wall of coloured paper that provides a dramatic backdrop to the exhibition stand and anniversary celebrations will be made of hundreds of die cut samples, presented in a hexagonal shape that symbolises six generations of the Cropper family at the helm of the company, which was established in the Lake District in 1845.

Chris Brown, Commercial Director of James Cropper PLC, said: “170 years of paper making in our historic home has meant overcoming the challenges of war, economic instability and increased global competition, as well as anticipating the opportunities found in new technologies. We have been ahead of those changes and had the chance to enhance sustainability, efficiency and innovation to become the successful company we are today. We are proud to celebrate 170 years with business partners and friends during Luxury Packaging 2015 and share with them our next wave of high-quality products.”

In addition, James Cropper Paper will introduce two new papers specifically designed to enrich the broadest possible range of printing outcomes - Porcelain, a pure white product that provides the crispest and smoothest of blank canvases for designers and Elation, a high-grade and versatile felt-marked paper available in 8 classic colours. Existing ranges, Comet with its shimmering pearlescent finish and the pastel tones of Lorenzo parchment will also be present at Luxury Packaging Innovations in new variants.

About Technical Fibre Products and James Cropper plc:

About Technical Fibre Products:

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad choice of high quality, technically advanced nonwovens for an array of challenging applications across industries ranging from aerospace and defence to automotive, energy, industrial, construction and healthcare. TFP is part of James Cropper plc and continues the group's 169 year tradition of building highly effective collaborative relationships with customers, enabling the development of custom material solutions to meet unique performance, process and aesthetic requirements.

About James Cropper plc:

James Cropper is based in the Lake District, England’s foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of Technical Fibre Products and James Cropper, please visit www.tfpglobal.com and www.jamescropper.com.

Redefining Paper: Eight Creatives Discover the Potential of White Paper

A creative process often starts with a white piece of paper, sketched on and discarded. But, what happens when you ask a group of artists to make white paper the beginning, middle and end of a creative project? Redefining Paper, initiated by James Cropper Paper, challenged eight creatives to separately explore the potential of white paper, with surprising results.

In all, the white paper has remained pure, no more so than the minimalist, ‘unroll and hang’, customisable wall clock from Leeds-based duo, Rosanna and Clint,its simplicity being a willing and brilliant surrender to the understated grandeur of the material itself. The limits of the paper are pushed in the opposite direction by Manchester contemporary jeweller, Megan Ocheduszko, whose tight spinning of a length of paper forms a wearable necklace, alongside robust, durable rings. The responses say as much about the creative mind’s response to a stark, blank canvas, as it does about the resilience and versatility of the material at hand.

Supplied with a limited amount of Porcelain, a high-quality, smooth white paper made from virgin pulp by the British master papermakers, the hand-picked creatives were given freedom to explore its material properties. The only rules were to resist colouring the paper with dyes and avoid degrading it, such as by soaking in liquid. By early-summer this year, the creatives had returned with the results, showing that the simplest ideas can do most justice to the simplest of materials.

Manchester’s rising architectural protégé, James Donegan brings digital brilliance and a steady hand with his modular sculpture of hundreds of separate, unglued components. A contemporary paper pendant lampshade from London’s Laura Nelson uses incisions more often found in metal work to subtly alter the paper in unforeseen ways. From Daniel Reed’s ethereal soundscape to Daniel Hoolahan’s laboriously cut, layered vase made from over 400 individual paper rings to Thomas Mills’ ceiling sculpture and James Condon’s mesmerising animation, the ideas and executions have demonstrated that there remains much inspiration to be found in white paper.

Chris Brown, Commercial Director for James Cropper Paper, says: “We overlook the versatility of white paper at our peril; it’s the ultimate blank canvas. In engaging with creative collaborators to work with one of our most versatile and immaculate papers, Porcelain, our intention was to prove that you can achieve previously unthinkable results with something so often taken for granted. The results speak for themselves, summing up our collective appreciation for the potential of an agile, creative mind and a simple sheet of white paper.”

Redefining Paper has been initiated as part of James Cropper Paper’s ongoing support for leading creative talent, which has included Steve Messam’s PaperBridge, a bridge made entirely of paper spanning a Lake District river earlier in 2015, and the internationally-renowned Gerald Exhibition at NYC x Design in 2012. Each of the creatives will be in line for selection as a standout ‘Chairman’s Choice’ piece by James Cropper’s sixth generation Chairman, Mark Cropper, and considered for further collaborations with the British manufacturer.

James Donegan, Architect

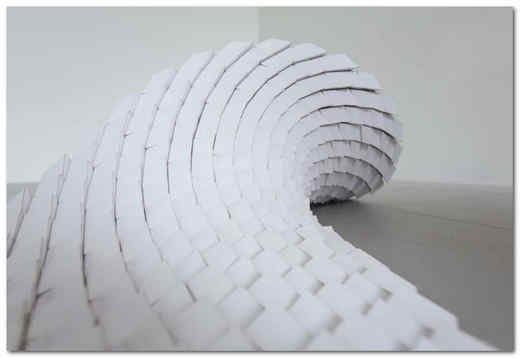

Helix

Digitally designed and hand built, Helix is a prototype of a sculptural form designed to fill gallery spaces. The modular construction involves hundreds of laser etched components, held together by intricate, precise interlocking cuts.

James says: “The process of making paper involves taking a highly structured, organic material and reducing it to a two dimensional blank space upon which one can easily express one’s ideas. The project realises this complexity and attempts to return the structural properties of the material from which it was derived. Through the uses of parametric design and digital manufacturing techniques the structure has been created without the use of any other material, fixings or adhesives.”

Dan Hoolahan, Product Designer

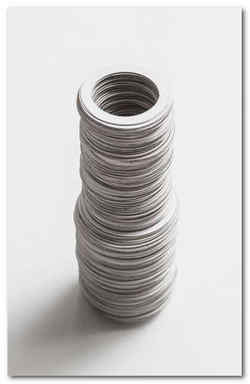

Porcelain Vase

Porcelain Vase

Subtly colouring the paper through the heat of laser cutting, Hoolahan stretches the brief at the same time as directly referencing the name of the paper, Porcelain, in the form of a vase made of hundreds of glued rings.

Dan says: “I immediately wanted my piece to reflect the name of the paper range, Porcelain. Porcelain being commonly associated with ceramics such as bowls and vases it felt natural to play on this theme. Using a laser cutter, my sheet of paper was cut into rings of varying sizes. 449 of these rings, including closed pieces for the base, were then glued together in no particular order to create a structure.”

Laura Nelson, Product Designer

Burneside Shade

Seemingly effortless, yet painstakingly crafted, Nelson has created a highly desirable shade that, in any other material, would appear industrial and cold, yet in paper appears serene as light diffuses through its precise lines and clean cuts.

Laura says: “The Burneside Shade exploits the durability and structural properties of the paper through three-dimensional design. I have chosen a lampshade, as it demonstrates structural properties of the paper and manipulates light in different ways through simple cutting and folding techniques. Two lampshades can be produced from one sheet of 640mm x 900mm paper.”

Rosanna and Clint, Designers

Kairos

Kairos

A product of show-stopping potential as a mass-marketable household item or corporate gift. The paper has barely changed save for a few strategic cuts, all made by hand for prototyping, and yet the raw material has been transformed. Kairos remains a piece of paper as pure as the moment it was made, living a double life as an irrepressibly stylish and customisable home or office accessory.

Rosanna says: “Our initial interpretation of the brief was the importance for the paper’s original characteristics to remain in the finished piece, aiming to do only what was necessary to transform the single sheet of paper. After some exploration and experimentation we liked the idea of creating a timepiece. The opportunity to create an object with such functional purpose is something that excites us in the studio.”

The full range of works included in Redefining Paper can be seen at www.redefiningpaper.com and information about James Cropper Paper at www.jamescropperpaper.com

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. A proud sponsor of artists and exhibitions including events at Frieze Masters and NYCxDesign, James Cropper Paper is committed to supporting creativity. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of paper making expertise.

As well as paper products, James Cropper PLC also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com

Over 100,000 hectares of private forests certified under UPM's FSC® group certificate in Finland

UPM's FSC® group certification scheme for private forest owners in Finland has passed a milestone of 100,000 hectares of certified forest. Since 2012, UPM has offered an FSC forest certification service to private forest owners. UPM's FSC group certificate (FSC® C109750) provides private forest owners with a reliable and internationally recognised means of ensuring that their forests are managed responsibly and according to the latest practices.

UPM's FSC® group certification scheme for private forest owners in Finland has passed a milestone of 100,000 hectares of certified forest. Since 2012, UPM has offered an FSC forest certification service to private forest owners. UPM's FSC group certificate (FSC® C109750) provides private forest owners with a reliable and internationally recognised means of ensuring that their forests are managed responsibly and according to the latest practices.

The FSC certificate is mainly targeted at large and medium-sized forest estates, where it provides most benefits for the forest owners. "An increasing number of forest owners in Finland have become interested in certifying their forests to the FSC scheme. They know that the demand for FSC certified wood is high,” says Eija Kuusisto , Key Account Manager at UPM Wood Sourcing and Forestry. "UPM promotes the advancement of the FSC forest certification in Finland. FSC certified wood creates new opportunities for our businesses in the highly competitive end-use markets. We are looking to increase the share of FSC certified fibre in our operations, with an emphasis on sourcing near our mill sites.”

All UPM's forests in Finland have been certified to PEFC since 2000 and in 2011, UPM had nearly 400,000 hectares of its own forests certified to FSC. "By certifying our own forests, we ensure that our own personnel and entrepreneurs get acquainted with the FSC scheme. We then use this expertise to benefit our private forest owner clients," Kuusisto says.

The FSC certification is proof of responsible forestry. An FSC symbol on an end product means that the wood raw material or fibre used in its products has been responsibly sourced. UPM uses third-party verified environmental certificates and ecolabels to convey the environmental performance of its products, help clients choose the right products and provide information to its stakeholders. UPM offers a wide range of certified products.

"Consumer awareness and demand for FSC certified products is constantly increasing. FSC is a renowned scheme around the world, and we are happy to see its popularity growing in Finland," says Anniina Kostilainen, Director of the Office, FSC Finland.

UPM actively co-operates with FSC both internationally and in Finland to increase the use of FSC-certified wood in its production. It also aims to promote awareness of the FSC forest certification and related responsibility issues both in Finland and around the world. In Finland, UPM aims to make it easy for private forest owners to participate in the certification system and meet the related standards and criteria.

For further information, please contact:

Eija Kuusisto, Key Account Manager, UPM Wood Sourcing and Forestry, tel. +358 (0)400 156 284

Anniina Kostilainen, Director of the Office, FSC Finland, tel. +358 (0)45 801 4333

UPM Wood Sourcing and Forestry sources wood raw material for UPM’s sustainable and recyclable products. We take care of the growth and development of the forests and implement the forestry operations chosen by the forest owner in a professional and sustainable manner. Our forestry expertise is based on the experience and knowledge acquired in managing the UPM owned forests. UPM owns 765,000 hectares of forestry land in Finland. www.metsämaailma.fi (in Finnish), www.facebook.com/metsamaailma (in Finnish)

UPM leads the reformation of bio and forest industries. We are building a sustainable future in six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve a global base of customers. We employ approximately 20,000 people, and our annual sales are approximately EUR 10 billion. UPM's shares are listed on NASDAQ OMX Helsinki. UPM — The Biofore Company — www.upm.com

FSC is an international non-profit membership organisation dedicated to promoting environmentally friendly, socially beneficial and economically viable forest management. FSC certified products are produced using wood from responsibly managed forests or recycled materials. FSC Finland online: fi.fsc.org

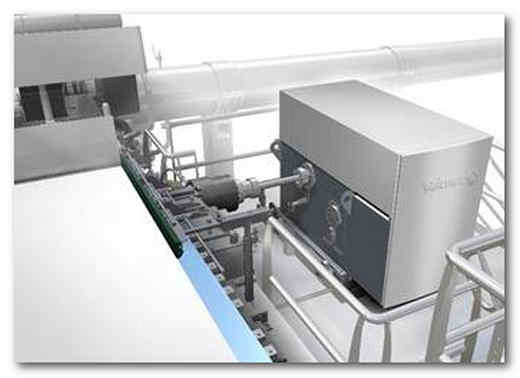

Valmet launches Valmet IQ product family for pulp and paper quality control and monitoring

Valmet launches renewed Valmet IQ product family to the pulp and paper industry customers. Valmet IQ is a scalable, on-line quality management solution to optimize the production processes and the end product quality.

Valmet IQ is designed with the experience of thousands of system deliveries by Valmet over longer than half a century. The renewed solution consists of a quality control system (QCS), profilers, web monitoring (WMS) and web inspection systems (WIS).

Valmet IQ is designed with the experience of thousands of system deliveries by Valmet over longer than half a century. The renewed solution consists of a quality control system (QCS), profilers, web monitoring (WMS) and web inspection systems (WIS).

"The launch of Valmet IQ Quality Management Solution marks a new milestone in pulp and paper quality management featuring a number of innovations like on-line softness measurement for tissue. The new Valmet IQ is a beneficial solution whether our customer is looking to replace aging or obsolete quality control systems or to build up an entirely new quality management solution," says Jari Almi, Director, Quality Management Solutions at Valmet.

Valmet IQ provides innovative solutions in paper quality management

Valmet IQ product family features a number of innovations as well as evolutionary product improvements. New first-in-the-market measurements include: an on-line softness measurement for tissue; a non-nuclear basis weight measurement for pulp drying; camera-based measurements and control for fiber orientation, and a topography-based surface properties and printability prediction.

The profilers, WIS and WMS are renewed in many areas as well: innovations in air-water spray nozzles for re-moisturizing, fully removable diffuser plate with advanced steam injection technology, new advanced solutions for improved image quality, detection and classification.

New Valmet IQ user interface with integrated performance reporting takes the user experience to a new level revealing a clear view of the past, present and the future of the process and product quality through intuitive navigation. It also allows for easy grade management.

The Valmet IQ MD Optimizer brings all process and quality measurements into a single controller for maximizing production efficiency and achieving optimum product quality. Advanced tools for process analysis and adaptive scanning make the life of the operators easier.

Valmet IQ helps to move business performance forward

All Valmet IQ products are based on vast process knowledge and long experience in the pulp and paper industry supported by local expert services to assure lifelong performance at the lowest total cost of ownership. Valmet expertise is also available remotely for all customer mills through remote connections.

All components of Valmet IQ solution are designed to work together. The forward and backward compatibility helps to future-proof the investment and maximize the effectiveness of existing equipment. The products are designed to work seamlessly also with other automation systems and all paper machines regardless of manufacturer. The easy connectivity with any system allows replacements even piece by piece.

For further information, please contact:

Jari Almi, Director, Quality Management Solutions, Automation business line, Valmet, Tel: +358 40 764 7512

Helena Lamberg, Director, Marketing & Planning, Automation business line, Valmet, Tel. +358 40 568 1055

Valmet's breast roll shaker improves board and paper quality

Valmet has introduced its new FormMaster 120 for board and paper machine forming sections. It has proven to offer better board and paper quality with a smoother surface and better printability with reduced raw material costs and lower power consumption.

Improved formation and strength properties

Valmet's new FormMaster 120 improves paper and board formation through even longer strokes and higher shaking force than its predecessor. This self-balancing breast roll shaker can achieve the same strength properties with a lower basis weight, improving the visual appearance of the final product.

With an axial shaking force of 120 kN - double that of the original FormMaster - the new FormMaster 120 improves strength properties and formation by optimizing fiber web structure on the wire. FormMaster 120 makes it possible to use less refining energy, minimize starch usage and reduce calendering, while still achieving the same final quality of board and paper.

FormMaster 120 provides the best stroke length on the market for a large range of breast roll weights.

Best stroke length on the market

"FormMaster 120 is an excellent tool for paper machine operators to optimize the properties of their board and paper. The extended stroke length, achieved with this new breast roll shaker, is key to improved formation and available with a wide range of shaking frequencies," says Pekka Hirsilä, Product Sales Manager at Valmet.

Maintenance issues were also addressed in the design of FormMaster 120 by improving access to the main maintenance points. Customers all over the world have found FormMaster 120 safe, easy and reliable to use and maintain.

Further information, please contact:

Pekka Hirsilä, Product Sales Manager, Paper Technology Sales, Valmet, tel. +358 10 672 6626,

Markku Pohjola, Senior Chief Engineer, Paper Mills, Valmet, tel. +358 10 672 6354,

Valmet receives repeat order for two new tissue production lines from Lee & Man Paper Manufacturing in China

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The start-up of the two new lines is planned to take place in late 2016.

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The start-up of the two new lines is planned to take place in late 2016.

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

The Valmet's Advantage DCT 200HS tissue lines to be delivered are designed for production of high quality tissue products. The new tissue lines will fulfill the high requirements for effective technology and sustainability set by Lee & Man. In 2014, the company ordered an Advantage DCT 200HS tissue line which is planned to start up at the Chongqing mill later this year.

"We see Valmet as strategic partner in the development of our tissue business. Their position as market leader in tissue machinery made us confident to repeat our previous order with Valmet", says Raymond Lee, Chairman of the Board, Lee & Man.

"We are very pleased that Lee & Man have decided to extend the cooperation we started with the delivery of the first tissue machine to Chongqing mill. As seen from earlier installations, it is possible to reach significant drying energy savings and highest paper quality by combining the Advantage ViscoNip press with a cast alloy Yankee cylinder and steam heated Advantage AirCap hood. We also see this order as confirmation of the winning concept," says Svenerik Olsson, Director, Tissue Mills Business Unit, Valmet China.

Valmet's Advantage DCT concept is well established on the market and has proven to enable cost- and energy-efficient production of high quality tissue products.

Technical information about the delivery

The new tissue machines will have a width of 5.6 m and a design speed of 2,000 m/min. Each machine will produce 60.000 tons of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

Valmet's scope of delivery will comprise complete tissue production lines featuring stock preparation systems and Advantage DCT 200HS tissue machines. The machines will be equipped with OptiFlo headbox and cast alloy Yankee cylinders. The machines will also be featured with the well proven Advantage tissue technology including ViscoNip press, steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The delivery will also include an automation package from Valmet with Valmet DCS and QCS process control system.

About the customer Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. The company's 6,500 employees are located at the company's five production sites in China. The company had a capacity of 7 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2014.

For further information, please contact:

Svenerik Olsson, Director, Tissue mills, China area, Valmet, Tel. +86 139 10171872

Krister Harnesk, Sales Manager, Tissue mills, Valmet, Tel. + 46 766 397543

In the Matter of Resolute v. United States Department of Agriculture

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) has announced that a U.S. federal court has ordered the U.S. Department of Agriculture (USDA) to try again to provide "a reasoned and coherent treatment" of its decision implementing an order to collect taxes on softwood lumber shipments in the United States. On September 9, 2015, the court granted part of Resolute's motion contesting the lawfulness of the USDA's "Softwood Lumber Checkoff" order imposing the tax. According to the court, the government's explanation of its decision to exclude certain softwood lumber manufacturers from paying or voting on the tax "strains credulity," and the USDA was either "hiding the ball" or else "ill informed" about the number of companies it had exempted. The court also reserved for another day Resolute's claims that the order violates the U.S. Constitution.

Resolute Forest Products Inc. (NYSE: RFP) (TSX: RFP) has announced that a U.S. federal court has ordered the U.S. Department of Agriculture (USDA) to try again to provide "a reasoned and coherent treatment" of its decision implementing an order to collect taxes on softwood lumber shipments in the United States. On September 9, 2015, the court granted part of Resolute's motion contesting the lawfulness of the USDA's "Softwood Lumber Checkoff" order imposing the tax. According to the court, the government's explanation of its decision to exclude certain softwood lumber manufacturers from paying or voting on the tax "strains credulity," and the USDA was either "hiding the ball" or else "ill informed" about the number of companies it had exempted. The court also reserved for another day Resolute's claims that the order violates the U.S. Constitution.

The USDA instituted a tax in 2012 on all shipments of softwood lumber in North America as part of a scheme proposed by the Binational Softwood Lumber Council, which was created under the now-expiring 2006 Softwood Lumber Agreement between Canada and the United States. Resolute objects to paying this tax, which it considers an unnecessary additional burden on international commerce.

A USDA Administrative Law Judge upheld the "Checkoff" tax initially, despite finding that materials prepared by the Blue Ribbon Commission to promote the Checkoff order in a referendum "contained statements that are wrong." Upon reviewing the Administrative Law Judge's decision, U.S. District Court Judge James Boasberg agreed with Resolute that the procedures creating the tax may have been defective, and remanded the agency's decision.

In reaching his decision, Judge Boasberg said that "Resolute is understandably upset by the agency's evasion" and that Defendants' interpretation of the law "is dubious for several reasons."

The USDA must now come up with answers to the questions posed by Judge Boasberg. Because the tax has been in place for years and is part of a complex administration, Judge Boasberg is permitting it to continue while waiting for answers. However, should USDA not come up with satisfactory answers, the court may be forced to terminate the tax, and require USDA to provide restitution to Resolute for all funds Resolute has been required to pay.

If Judge Boasberg finds the answers on possible statutory violations satisfactory, he then would have to address Resolute's complaint that the entire scheme is unconstitutional. Under U.S. practice, courts resolve statutory disputes before addressing constitutional claims. When complaining parties prevail in their statutory claims, the Court does not reach, and therefore does not rule on, constitutional claims. So far, Judge Boasberg has not addressed Resolute's claims that the entire tax scheme is unconstitutional because he agrees that it might be contrary to law.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including newsprint, specialty papers, market pulp and wood products. The company owns or operates some 40 pulp and paper mills and wood products facilities in the United States, Canada and South Korea, and power generation assets in Canada. Marketing its products in close to 80 countries, Resolute has third-party certified 100% of its managed woodlands to at least one of three internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute and other member companies of the Forest Products Association of Canada, as well as a number of environmental organizations, are partners in the Canadian Boreal Forest Agreement. The group works to identify solutions to conservation issues that meet the goal of balancing equally the three pillars of sustainability linked to human activities: environmental, social and economic.

Resolute is proud to be ranked by Corporate Knights as one of Canada's Best 50 Corporate Citizens for 2014. The company and Richard Garneau, president and chief executive officer, have been named to Canada's 2015 Clean50, and Resolute was also awarded The New Economy magazine's global Clean Tech Award for best forestry and paper solutions.

SOURCE Resolute Forest Products Inc.

Verso Announces Additions to Blazer Digital(R) Offering

Verso Expands Blazer Digital(R) Line to Meet Needs of Xerox(R) iGen(R) Series of Digital Presses

Verso Corporation (NYSE: VRS), a leading producer of digital coated papers, announces the expansion of its Blazer Digital® economy digital coated paper offering with 10 new sheet sizes specifically designed for the Xerox® iGen4™, Xerox® iGen® 150 and new Xerox® iGen® 5 digital presses.

Verso Corporation (NYSE: VRS), a leading producer of digital coated papers, announces the expansion of its Blazer Digital® economy digital coated paper offering with 10 new sheet sizes specifically designed for the Xerox® iGen4™, Xerox® iGen® 150 and new Xerox® iGen® 5 digital presses.

"Verso has been a leader in manufacturing digital papers since digital printing technology first emerged, with specialized expertise, dedicated production capacity and one of the broadest offerings of digital-specific products in the industry," states Mike Weinhold, Verso's Senior Vice President of Sales, Marketing and Product Development. "Every one of our digital products is designed specifically for digital printing."

Blazer Digital® is an economical, coated digital paper with weight and finish choices similar to conventional folio formats. Offered in gloss and satin, text and cover weights, it provides good performance on dry and liquid toner, production color laser printers and digital offset technologies.

Verso continues to focus on the digital print market and align its grade offering to better meet the needs of digital press owners. With the growth of the Xerox iGen series, Verso has added 14.33" x 26" stocking sizes in 80 lb. and 100 lb. gloss and satin text and 26" x 14.33" stocking sizes in 80 lb., 100 lb. and 110 lb. gloss and satin cover to its Blazer Digital® offering. These new sizes are stocked in our warehouses and are readily available.

"These additional sheet sizes allow customers to diversify the type and size of high-end color printed materials using one of the industry's largest digital sheet sizes," said Dennis Essary, Verso's Director for Digital Papers. "It's now possible to digitally print collateral such as six-panel 8.5" x 11" tri-fold brochures, postcards and greeting cards, or extra large book covers and jackets with Verso's new 14.33" x 26" sheet size."

Along with the Blazer Digital® economy product, Verso offers premium digital products such as Futura®, Sterling® Premium Digital and Sterling® Premium Digital for HP Indigo, each with pleasing optics, exceptional surface quality and budget-friendly pricing, and Productolith Pts. Digital® for heavier-weight packaging. Verso also produces award-winning TrueJet®, a specialized line of digital coated papers for production inkjet presses that not only optimizes quality but also is designed to deliver significant savings in ink costs. From Futura® to TrueJet®, Verso can meet your coated digital paper needs.

To learn more about Verso's entire product portfolio including digital, sheetfed, web and specialty papers, visit us at Booth 3667 from September 13 to16 at GRAPH EXPO 15, McCormick Place, Chicago, Illinois.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

Registrations for the 48th Pulp and Paper International Congress are already available

Papers presented by international and nationally renowned experts will be one of event highlights this year

Registrations for the 48th Pulp and Paper International Congress, promoted by ABTCP – Brazilian Pulp and Paper Technical Association – are already available at ABTCP website, www.abtcp2015.org.br, as well as information on values. The event will take place next October 06, 07 and 08, at the Transamérica Expo Center, in São Paulo.

By paying the registration, visitors assure, in advance, their attendance to the Congress, whose main subject this year will be Innovation focused on Economy, Energy and Bio-Inspired Materials, essential to the continuous improvement of all field players. For Francisco Valério, Congress president, such space is crucial to bring visibility to the presented papers, which highlight the latest trends in the industry.

“Besides, I believe there is an exchange of information occurring for the last two years, because people attending the Congress are skilled and have a lot of knowledge to share”, he comments. So, the event technical sessions will have special emphasis, with important works being presented by world-renowned researchers, from similarly renowned institutions.

Such is the case of the presentation of Luiz Ramos, Associate Professor in the Chemistry Department of the Federal University of Paraná (UFPR), which will focus on the production of cellulosic ethanol from eucalyptus wood chips with steam pretreatment methods (self-hydrolysis) followed or not by alkaline delignification.

“Aspects related to enzymatic hydrolysis under high total solids content will be presented, using the latest generation enzymes, and the conversion yields will be compared to those obtained from raw materials of agricultural origin, such as sugarcane bagasse. This approach will allow comparing these two models and will open a discussion on the feasibility of this initiative for the sector”, he highlights.

He still notes his lecture will be oriented towards the discussion of premises directing the implementation of bio-refinery activities and the perspectives such option could bring to the industry. For the academic, ABTCP is the main national forum for the discussion of state of the art and innovation in all processes involved in the manufacture of pulp and paper, including the evaluation of new market trends.

“And this extends to the search for new niches, based on sustainable technologies, for the production of chemical products, biofuels and biomaterials whose production is associated with the concept of bio-refineries. Therefore, it’s an essential event to establish contacts and expand horizons, the ideal condition for those wishing to keep up with information and updated with the major trends of a market in constant evolution”, Ramos stresses.

International Experiences

History and evolution of pulp and paper industry in Portugal, and particularly in the companies associated to the Portugal Paper Industry Association (CELPA), will be taught by Marta Souto Barreiros, Forest Engineer of the entity, with special emphasis on efficiency and sustainability in water use and its critical analysis.

The specialist believes the main challenge for the industry, on a worldwide basis, is the substantial reduction of consumption and improved utilization of water resources in the production of pulp for paper. “The companies associated to CELPA have made great efforts aiming at the partial or total closure of their circuits, with the intention of minimizing the use of water and, eventually, be able to operate with zero discharge”, she highlights.

According to Marta, in the last 100 years there has been a major progress in the European companies of the sector, which reduced their specific consumption from 300m3/ton to something between 20-30m3/ton. In her opinion, the Brazilian pulp and paper industry enjoys strong dynamism and international reputation. “An event of this nature will allow the dissemination and knowledge of new projects, technologies and the best that has been done in various areas of industry. It also brings the opportunity, for both Brazilian and other countries technicians, to exchange experiences and ideas”, she believes.

On his turn, Michael Paleologou, Canadian, a specialist in Chemical Analyses, Biomass, Industrial Paper and Product Development, from FP Innovations, will talk about the opportunities for chemicals recovery in Kraft pulp plants, based on the latest technologies developed by his company through the years. “Such technologies will be discussed with respect to their main features, as well as their technical feasibility, process integration and economy”, he says.

According to him, such resources can also be used in Brazil, recovering chemical products from waste or process flows, and may result in significant savings concerning chemicals or help to diversify the products portfolio in Kraft pulp mills. “Lignin can be used in several high value applications, such as: phenolic resins, thermoplastic polyurethane foams, and also as dispersers and flocculants”, explains the expert.

Paleologou highlights that the 48th Pulp and Paper International Congress offers a unique opportunity for learning new technologies and products, as well as a chance of meeting other industry professionals and discuss matters of common concern and interest.

The event will also offer papers presented by Nilda de Fátima Ferreira Soares, Dean of Viçosa Federal University; Giancarlo Pasquali, Researcher of Rio Grande do Sul Federal University (UFRGS); Jorge Luiz Colodette, Full Professor of Viçosa Federal University; Juan Carlos Villar Gutiérrez, Specialist in characterization of new cellulosic raw materials and biotechnology applied to the paper industry by INIA; in addition to Katsuyuki Kadota, Senior researcher at Oji Holdings Corporation.

To get to know all program content access www.abctp2015.org.br

About ABTCP 2015

ABTCP 2015 - 48th Pulp and Paper International Congress and Exhibition, arranged by ABTCP, will take place from October 06th to 08th this year, in São Paulo, SP, and is recognized as one of the major sector occurrences, bringing together professionals willing to exchange knowledge and experience on such productive chain, in the most diverse areas.

Such is its representativeness for the sector that this edition estimates to host over 400 experts and technicians of international reputation and over eight thousand visitors. The event happens in conjunction with the also traditional industry Manufacturers and Suppliers Exhibition.

Agenda:

Date: October 06th to 08th, 2015

Place: Transamérica Expo Center – São Paulo/SP

Hours: Congress – from 9:00 AM to 05:00 PM; Exhibition – from 01:00 PM to 08:00 PM.

Registrations, Congress program and additional information at the website: www.abtcp2015.org.br