Ianadmin

KapStone Reports Ongoing Progress In Meeting 2020 Sustainability Goals

KapStone Paper and Packaging Corporation (NYSE: KS) announces the recent release of its fourth annual sustainability report which shows ongoing progress towards meeting its 2020 sustainability goals. The report details accomplishments along with areas for improvement necessary to meet those goals.

The baseline for this report is company performance as reported in 2010 and conforms to the Global Reporting Initiative's (GRI) G4 rigid and voluntary standards.

The baseline for this report is company performance as reported in 2010 and conforms to the Global Reporting Initiative's (GRI) G4 rigid and voluntary standards.

KapStone Paper and Packaging Corporation President, Matt Kaplan, states: "We have set aggressive environmental, health and safety goals that are of importance to our employees, our customers and the communities where we operate. These goals are key to our guiding principles. We think big and act small. We take care of our partners. We do business the right way. With our commitment to these guiding principles, we are committed to meeting our 2020 sustainability goals."

The 2015 Sustainability Report details six areas of 2020 Sustainability goals, our progress toward meeting those goals, and a Management Plan for further progress. In the environmental impact area, we made good progress in reducing energy use, greenhouse gas and criteria air emissions. We are working hard to minimize our environmental footprint in the areas where we operate. We believe we are on track to meet all of our performance targets. Our People and Communities area highlights "Safety First, Last and Always" for employees as a core value at KapStone as well as community involvement and open communications. The report concludes with an overview of KapStone Paper and Packaging Corporation.

KapStone's 2015 Sustainability Report provides a detailed update reporting on progress and the continued commitment to achieving its 2020 Sustainability Goals.

For additional information visit sustainability.kapstonepaper.com

About KapStone

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company has four paper mills, 21 converting plants and 65 distribution centers. The business has approximately 6,300 employees

Voith wins order to install a VariFlex winder at Stora Enso in Imatra

Stora Enso has commissioned Voith to install a fully automated VariFlex winder on the BM1 board machine at its Kaukopää mill in Imatra, Finland. The winder’s innovative concept increases processing capacity and makes production safer and more reliable.

![]() The Voith VariFlex has proven to be effective in a large number of facilities. It impresses with fast swap-over times for format and roll changes and consistently good roll quality. Other outstanding features are the excellent start and end sheet gluing using the Gecko OneStep gluing device and the high productivity and machine safety due to the automated perforating units for parent reel and finished rolls.

The Voith VariFlex has proven to be effective in a large number of facilities. It impresses with fast swap-over times for format and roll changes and consistently good roll quality. Other outstanding features are the excellent start and end sheet gluing using the Gecko OneStep gluing device and the high productivity and machine safety due to the automated perforating units for parent reel and finished rolls.

For Stora Enso, the short installation time was one of the key factors in awarding the contract to Voith: The rebuild is scheduled to take place in January 2017 and should be completed within a maximum of ten days. Voith was able to demonstrate that this is possible through its past rebuild projects.

The BM1 in Imatra Mills produces food service boards for drinking cups and other food service and food packaging applications. The winder is designed with a width of 4,600 mm and a speed of up to 2,500 m/min. In future, the diameter of the finished roll can be increased to up to 2,100 mm.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Imatra Mills situates around 250 km east of Helsinki. Imatra Mills consist of two production units, Kaukopää and Tainionkoski. The mills produce about a million metric tons a year of liquid and food service board as well as high-quality packaging papers and graphical board for book covers, cards and luxury packaging.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Valmet to supply a biomass-fired boiler plant to Segezha Pulp and Paper Mill in Russia

Valmet will deliver a biomass-fired boiler plant and related automation and environmental systems to Segezha Pulp and Paper Mill (Segezha PPM) in the Republic of Karelia, Russia. The boiler will produce steam for the mill's production processes and enables the mill to use wood residues and sludge as fuel and thus reduce the use of heavy fuel oil and lower its emissions and environmental impact. Valmet's delivery is scheduled for 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed.

"We selected Valmet's multi-fuel boiler after comparing a number of supplier offers. We took into account the reliability of the equipment and its operation, and the price/quality ratio. The decisive criteria that determined our decision were the technological factors and successful boiler references in numbers of industry enterprises. We see that a modern multi-fuel boiler can efficiently burn waste from wood processing with high and variable humidity, as well as sludge from our effluent treatment," comments Sergei Pondar, Vice President of Production for Segezha Group.

The new order strengthens Valmet's position as the leading supplier of bubbling fluidized bed (BFB) boilers with electrostatic precipitator based flue gas cleaning on the Russian market. This is the third boiler delivery featuring Valmet's bubbling fluidized bed (BFB) technology to Russia in the past three years.

"Over decades Valmet has delivered numerous biomass-fired boilers as well as chemical recovery boilers to Russia. We have an established supplier network in Russia and significant part of the delivery for Segezha will be manufactured in Russia. We look forward to delivering our competitive technology to Russia's market also in the future," remarks Nikolay Doroshenko, Director of Energy Sales and Services Operations, Russia and CIS, Valmet.

Technical information about Valmet's delivery

Valmet's delivery includes a 90 MW HYBEX boiler utilizing BFB combustion technology, Valmet electrostatic precipitator based flue gas cleaning equipment, electrification and a Valmet DNA automation system to control and operate the plant.

The HYBEX boiler developed by Valmet features wide fuel flexibility, high combustion efficiency, high reliability, excellent controllability and low emissions. Its main advantage is the possibility to use fuels with high moisture content and a low thermal value.

Information about the customer Segezha Pulp and Paper Mill

Segezha Pulp and Paper Mill is part of Segezha Group, a vertically integrated international forest industry holding company that comprises Russian and European enterprises in the forest, wood processing and pulp and paper industries as well as paper packaging manufacturing enterprises. Segezha Group has assets in 13 countries and employs around 13,000 people.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Strategic foundation based on investment, innovation and close customer relationships

Long-term strategy focuses on optimizing growth rather than growing sales

Xerium Technologies, Inc. is one of the paper industry's leading global suppliers of paper machine clothing and roll covers. Its corporate strategy for the next five years is to optimize growth instead of aiming to generate higher sales. The strategy will be based mainly on investments targeting growth markets, a high innovation rate for game changing product technologies in the Huyck.Wangner (PMC) and Stowe Woodward (rolls covers and spreader rolls) divisions, together with the group's traditional strong customer focus, which will be further expanded by adding new offices and sales organizations. In the EMEA region, Xerium has also been able to further expand its market share over the past few quarters, and was selected as the supplier for countless paper machine expansion projects.

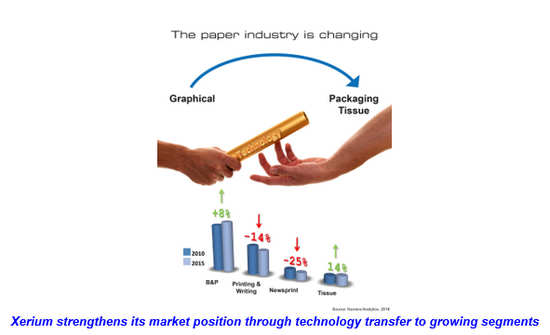

The unrelenting transformation of the paper industry, with significant declines in the newsprint and graphic papers segments, presents suppliers with ever greater challenges. Since 2010, production in these important Xerium target segments has shrunk by twenty-five and fourteen percent respectively. This market situation, together with currency exchange factors, is reflected in Xerium's 2015 earnings. Overall revenues were down about four percent year over year, coming in at 477 million US dollar. Having foreseen these developments, the company launched strategic initiatives, and was able to not only hold its EBITDA percentage steady, but even boost it slightly.

In contrast, tissue and packaging papers continued to be reliable businesses marked by steady growth. Tissue paper production rose fourteen percent from 2010 to 2015, while the packaging papers segment was up eight percent. Industry associations are forecasting growth for packaging papers in the EMEA region of 5.6 million tons between now and 2020.

Overall, it is estimated that 65 percent of EMEA paper production is on a growth track. Xerium's priority is therefore to boost its market share in these markets and at the same time limit declines in the newsprint and graphic paper sectors as much as possible.

Investment focus on strategically important market and growth segments

Xerium has initiated a long-term investment program focused on strategically important market growth segments. The plan is supported by the resources the company has made available for new offices, factories and product development. A strong customer focus and solid advisory services play as great a role as does the enhancement of key technologies in all product segments. The company's new sites in Kunshan, China, and Çorlu, Turkey have successfully started operations. But the strategic aim is clear: Europe is to manufacture for Europe, or the EMEA region, and China for Asia and Australia. This will guarantee close proximity to customers and faster service, as well as greater flexibility, shorter lead times, lower logistics costs and efficient supply chain management.

The European factories in Reutlingen and Gloggnitz were a high priority and here the company invested heavily: 12 million US dollar in 2015/16 for new seaming technologies, four new looms, a new needling machine and an additional finishing machine. This not only boosts capacity and manufacturing, but also reinforces the company's claim that it is able to quickly and flexibly deliver all products in line with customary European top-quality standards. In parallel, a number of operational continuous improvement projects were rolled out, including in the area of process systems, procurement management, data collection and the all-important employee development.

Basic research – valuable asset and competitive advantage

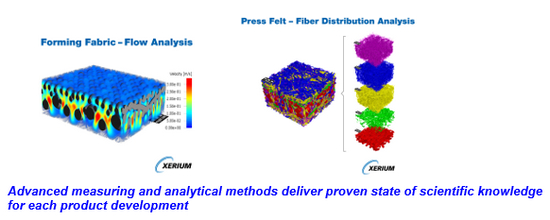

The strong capital spending for basic research is a testament to the importance that Xerium attaches to this corporate asset. It impacts both enhancement of its core competencies, as well as key technologies and new product concepts. For example, in 2014 alone, Xerium's spending on R&D projects for innovative analysis and simulation tools totaled close to 1 million US dollar. The entire product portfolio of every segment has been revamped over the past three years. The rate of innovation has never been this high: twenty-five new patented products introduced to market, often including groundbreaking new material or design concepts.

Products form the foundation. If this foundation is not solid, products will not work properly on a paper machine. In the past, the successful launch of a product was based to a large extent on the experience and specialized knowledge of the engineers and those responsible for the product, in addition to risky empirical half-knowledge.

In order to determine whether current performance parameters are still valid, Xerium examines every application to see if efficiency could potentially be improved by changing one or more criteria. It is how the company ensures that Xerium products successfully run on paper machines. Designers also use unique digital measuring and analytic processes developed in-house in order to clearly and understandably present to customers the pros and cons of the structural and performance attributes of various applications.

Expanding market share by pacesetting innovations

Xerium can easily justify its claim to being the pioneer and technology leader when it comes to paper machine clothing. The company aims to meld its technical knowledge with more than 200 years of market experience since its founding. Since 2014, patent applications have been submitted for 100 developments and 65 inventions have been announced – a clear indicator of the rising pace of innovation. Thanks to this research and development drive, the company has set new benchmarks: the SSB and EDC technologies, the QS and Booster technologies and the SMART® technology for roll covers to name just a few. These patented developments not only testimonialize Xerium's expertise, but are also the basis for developing various products, adapting and enhancing them, and introducing new performance features, all in accordance with customer and market requirements.

Exclusively from Xerium: Game changing paper machine clothing and roll cover technologies

Key technologies and innovative product solutions secure sustainable growth

This approach fundamentally differentiates Xerium from the competition. New, future-proof forming fabrics and felt technologies, combined with unique material and design concepts – especially for tissue and packaging applications in proven growth markets, as well as for the nonwovens/industrial textile product range – offer significant value added: exclusively from Xerium. At the same time, it reinforces the company's high demands of not only providing customers with products that function flawlessly, but also working with them in close partnership to supply individually tailored product solutions, which in turn enables papermakers to develop the right strategies for the future, seize new market opportunities and ensure long-term success.

Furthermore, the decision to continue to conduct research and development on basic technologies for its core competencies at its European locations and to supply products to customers in the EMEA region from there is an added plus. It means that the company is obliged to continue to offer the paper industry top-quality innovative products.

Xerium Technologies Inc. at a glance:

Xerium Technologies Inc. is located in the United States in Youngsville, North Carolina, and incorporates the leading paper industry brands Huyck.Wangner, Weavexx, Stowe Woodward and Mount Hope. In 2015, the company generated consolidated sales of about 477 million US dollars. About 64% was attributable to paper machine clothing and 36% to rolls. Xerium has approximately 3,000 employees at 30 manufacturing facilities in 13 different countries. Its established technology leadership is reflected in intensive research and development work, as well as hundreds of patented, registered product inventions, all of which serve to improve customers' papermaking processes.

The Xerium Podium:

• Ernst Kerschhofer, Vice President Sales & Marketing Xerium Europe

• Oliver Baumann, Global Vice President Machine Clothing Technology

• DI Dr. Robert Marchhart, Global Product Manager

Stora Enso evaluates expansion of Gruvön Mill

Stora Enso has decided to commence a study in order to assess the feasibility of building a cross laminated timber (CLT) production unit in connection with its Gruvön Mill in Sweden. The expansion would add a total annual capacity of approximately 75 000 m3CLT.

The feasibility study will evaluate the profitability of the possible expansion, as well as integration benefits and design criteria for the plant. The investment under study would be cost competitive and would have synergies with the existing mill in Gruvön. The findings of a recently completed pre-feasibility study supported continuation of the process. The feasibility study is expected to be completed by the end of 2016.

The feasibility study will evaluate the profitability of the possible expansion, as well as integration benefits and design criteria for the plant. The investment under study would be cost competitive and would have synergies with the existing mill in Gruvön. The findings of a recently completed pre-feasibility study supported continuation of the process. The feasibility study is expected to be completed by the end of 2016.

If the investment is approved following the feasibility study, the capital expenditure for the expansion is estimated to be in the range of EUR 30−34 million, which falls within the group’s long term capital expenditure policy of keeping capital expenditure into fixed assets approximately at the same level as depreciation. In addition to fixed asset investments, Stora Enso invests approximately EUR 100 million annually in biological assets.

“Our target is to grow cost competitive CLT capacity located favourably in relation to target markets. The existing Gruvön Mill has been selected due to its favourable logistics and secured raw material supply. By utilising our new competitive building materials, we aim to capture market share from competing materials in the construction sector. The decision regarding a possible expansion of Gruvön Mill will be made once the feasibility study has been completed,” says Jari Suominen, EVP Division Wood Products.

Currently, Stora Enso has an annual capacity of 130 000 m3CLT at its Bad St. Leonhard and Ybbs mills in Austria. Gruvön Mill has an annual capacity of 370 000 m3sawn timber of which 150 000 m3are further processed wood products. The mill also produces 100 000 tonnes of pellets annually. Gruvön Mill employs 115 people.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 26 000 people in more than 35 countries, and our sales in 2015 were EUR 10.0 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY) on the International OTCQX over-the-counter market. storaenso.com

Holmen: Sale of Newsprint Mill in Spain Completed

As previously announced Holmen (STO:HOLMB) (STO:HOLMA) has signed an agreement to sell its newsprint mill in Madrid, Spain. The transaction is now closed.

![]() The buyer, International Paper, will convert the mill into recycled containerboard production. International Paper will continue to produce newsprint at the mill until the second half of 2017 when it is scheduled to be converted into recycled containerboard. During this period, Holmen will sell the newsprint produced at the mill and continue to serve its customers.

The buyer, International Paper, will convert the mill into recycled containerboard production. International Paper will continue to produce newsprint at the mill until the second half of 2017 when it is scheduled to be converted into recycled containerboard. During this period, Holmen will sell the newsprint produced at the mill and continue to serve its customers.

- During this period we will maintain our service and deliveries of todays products. Our customers will not be affected, says Nils Ringborg, CEO Holmen Paper.

Included in the transaction is also the recycled paper collector Cartón y Papel Reciclado S.A. (Carpa) and Holmen´s 50 per cent shareholding in the energy producer Peninsular Cogeneración S.A.

Holmen is a forest industry group that manufactures paperboard, printing paper and sawn timber and runs forestry and energy production operations. In 2015 Holmen’s net sales were SEK 16 billion and the group has approx. 3,300 employees. Holmen’s shares are listed on Nasdaq Stockholm, Large Cap. For more information, visit www.holmen.com

Procemex Machine Vision Technology Highlighted in International Quality Congress

The theme of the 60th International Quality Congress arranged in Helsinki in June was ‘Quality Enables Growth and Competitiveness’. In its Sino-Euro Forum, the Finnish Procemex Oy Ltd’s web inspection and monitoring systems were highlighted in a case study which described a small technology company’s remarkable influence in the quality of paper production in China.

Mr. Pekka Hemmi, CEO of Nordic Ventures Group, a panelist and speaker in the Sino-Euro Forum described the path of PROCEMEX in 15 years from innovative start-up to world market leader in paper and printing industry machine vision systems. The highest market share has been obtained in Europe and China, where the industry is setting the toughest technology requirements to suppliers, according to Hemmi.

The key of success has been continuous development of camera sensors, optical imaging and image processing solutions, and close cooperation with leading customers in Europe. The tailor-made imaging systems help to secure quality and reduce down time in paper production. By developing ever faster and higher resolution cameras with matching lighting solutions and low angle inspection, Procemex can today inspect wider range of surface quality parameters on-line. With their patented pinhole cameras, Procemex has also been first to detect problems reliably in the harsh wet end conditions of the paper machine where most quality problems root from.

In conclusion, Mr. Hemmi noted that the Chinese industry would benefit even more if it would learn to utilize the know-how of the leading edge suppliers like Procemex rather than just buying equipment. Instead of listing sanctions purchase agreements should also encourage suppliers to achieve excellent results. One way to improve quality and profitability in highly competitive paper industry is to make partnership agreements with this type of pioneering technology suppliers.

Neil Lovell confirmed as The Printing Charity’s Chief Executive

The Printing Charity has confirmed Neil Lovell’s appointment as the charity’s permanent Chief Executive and Secretary. He was appointed to the role on an interim basis in February this year.

During his time as interim Chief Executive, his focus has been on meeting people in the print industry and the charity’s partners, as well as getting to know the staff and trustees, and looking at the direction of the charity.

During his time as interim Chief Executive, his focus has been on meeting people in the print industry and the charity’s partners, as well as getting to know the staff and trustees, and looking at the direction of the charity.

Neil Lovell says: “The Printing Charity has a proud heritage and very clear aims of promoting independence and furthering education. I have been looking at how we can make it easier for individuals needing our support, and the industry we represent to connect with us. It’s clear we cannot do everything on our own but we have great potential to build strong partnerships with the industry and other bodies with similar aims to ours.”

He has 27 years’ experience in senior communications, marketing, fundraising, and management roles. He began his career in a traditional ad agency off Fleet Street, followed by commercial roles at T-Mobile and RAC plc. He joined the not-for-profit sector in 2009 and prior to joining The Printing Charity he was CEO of the Jamie Oliver Food Foundation. He is a supporter of the education and skills sector and is a trustee of the Further Education Trust for Leadership, an independent Further Education (FE) and skills sector think tank and grant-awarding charity.

Jon Wright, The Printing Charity’s Chairman, says: “Neil brings a wealth of experience from the commercial and not-for-profit sectors to the Chief Executive’s role to drive the charity forward and has the full support of the trustees as he works with us to refocus our work and deliver greater impact.”

About The Printing Charity:

The Printing Charity is proud of its heritage and has been supporting people of all ages working in printing, packaging and publishing since 1827. Its charitable aims include promoting independence, protecting dignity and furthering education. It meets the needs of those it helps through one-off and regular grants, and working strategically with industry partners to attract and retain future talent in the industry. Please see www.theprintingcharity.org.uk for more information.

Catalyst Paper Corporation's Principal Securityholders and KGI Enter Into a Support Agreement for a Potential Acquisition of Catalyst Paper

Catalyst Paper Corporation (TSX:CYT) ("Catalyst" or the "Company") has just announced that it has been advised that the four largest shareholders of the Company holding or controlling approximately 79% of the Company's outstanding common shares, that include Mudrick Capital Management, L.P., Cyrus Capital Partners, LP, Oaktree Capital Management, LP and Stonehill Capital Management LLC (collectively, the "Principal Securityholders") have entered into a support agreement with Kejriwal Group International ("KGI"). The Principal Securityholders have filed Schedule 13D with the United States Securities and Exchange Commission setting out the details of the support agreement.

The support agreement has been entered into between KGI and the Principal Securityholders following previously disclosed discussions. The Company is not a party to the support agreement, nor has it been a party to the discussions that led to it.

The support agreement has been entered into between KGI and the Principal Securityholders following previously disclosed discussions. The Company is not a party to the support agreement, nor has it been a party to the discussions that led to it.

The Principal Securityholders have committed to support and vote in favour of a transaction to be implemented by way of a plan of arrangement under the Canada Business Corporations Act, the terms of which would include:

- common shares held by minority shareholders would be acquired for C$6.00 per share, subject to a maximum aggregate payment of C$18 million;

- common shares held by the Principal Securityholders would be exchanged for interests in a new junior convertible term loan;

- existing PIK toggle senior secured notes due 2017 would be exchanged for interests in a new 5-year US$260.5 million term loan;

- existing credit facilities, including the Company's ABL Facility, would have their maturities extended, or be refinanced; and

- trade and other obligations remaining unaffected.

The support agreement among KGI and the Principal Securityholders includes material conditions and other provisions including satisfactory due diligence by KGI to occur over a period of up to 75 days, the refinancing or maturity extensions of the existing credit facilities of Catalyst, securityholder, regulatory and court approvals, and funding at closing. The support agreement contemplates an outside date to complete the transaction of November 30, 2016, subject to extension.

The Board of Directors has not yet entered into any discussions regarding the potential transaction with KGI or agreed to the contemplated process and timeline set forth in the support agreement. The Board of Directors is encouraged by KGI's proposal and will be pleased to review and evaluate the proposed transaction and the process contemplated by the support agreement with the assistance of legal and financial advisors.

There can be no assurance that any agreement to implement the transaction will be entered into between KGI and Catalyst, and on what terms, that any of the material conditions to the transaction will be satisfied, or that this or any other transaction will be approved or consummated.

The Company does not undertake any obligation to provide any updates with respect to this or any other transaction, except as required under applicable law. Interested stakeholders may access the Principal Stakeholders' filings, including the support agreement, from time to time with the U.S. Securities and Exchange Commission by visiting EDGAR on the SEC website at www.sec.gov/edgar.shtml.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and has been ranked by Corporate Knights magazine for 10 consecutive years as one of the 50 Best Corporate Citizens in Canada.

4 tissue rewinders for Lee & Man Paper.

A.Celli Paper has recently concluded an important agreement with the Chinese group Lee & Man Paper Manufacturing Limited (“Lee & Man Paper”).

The Porcari-based company will supply four tissue rewinders to the Asian customer that has grown quickly in the course of the last twenty years, changing its status and going from a small company (founded in 1994) to a structured group listed in the stock exchange, with five facilities in China and some factories in Vietnam.

The order from Italy entails the supply of 4 tissue rewinders model AC882, in a paper width 5620 mm and a speed of 1000 metres per minute, two equipped with calendar. Two rewinders are designated for the Jiangxi Jiujiang facility, while the other two for the Dongguan Guangdong plant. Delivery date is scheduled for the end of the year.

The supply of these four machines will assure Lee & Man Paper an increment in performance and in the level of reliability. The Asian group, that has established itself as one of the most dynamic and farsighted players in the field, focuses on a continuous renewal process and one of constant growth capable of guaranteeing further business development and the pursuit of new goals. Scale economies, verticalisation and process integration together with the collaboration of excellent partners in terms of technology and innovation have allowed Lee & Man Paper to become what it is today.