Ian Melin-Jones

Metso to supply automation modernization and machinery rebuilds to Stora Enso Heinola mill

Metso will supply its modern Metso IQ control quality system to Stora Enso Heinola’s Fluting Mill. Metso was chosen for its’ single source expertise in automation and instrumentation coupled with its’ stock preparation, paper machine and paper finishing technologies.

The extensive rebuild and modernization work includes the replacement of aging QCS system, a retrodilution headbox rebuild, refiner, dilution water and short circulation screens, FoilForce tail threading, IQ Steam Profiler and Machine Control System (MCS) added with electrical and field instrumentation engineering, refiner area and headbox instrumentation.

The project is planned to be completed in September 2011.

Stora Enso’s Heinola Fluting Mill has produced high-quality fluting since 1961. Today, the mill produces 300,000 tpy of semi-chemical fluting. About 90 % of the mill’s production is being exported for fruit and vegetable packaging as well as for packaging of consumer electronics and machine parts.

Metso IQ quality control system

Metso IQ quality control system including high-level intelligent control applications optimizes the cross machine performance for papermaking processes. It integrates process quality management, measurements and profile controls resulting faster start-ups and grade changes, reduced dryer breaks and better runnability with stable short circulation improving uniformity of the wet sheet.

Metso IQ quality control systems chosen for three Sappi mills in Europe

Target for the investment is to further enhance end product quality and increase raw material savings which, among other benefits, will also have a positive environmental impact.

Target for the investment is to further enhance end product quality and increase raw material savings which, among other benefits, will also have a positive environmental impact.

Metso will supply four modern Metso IQ systems to replace four aging quality control systems in three separate Sappi mills in Europe. The delivery includes a total of twelve scanners for three paper machines in Stockstadt and Maastricht as well as one coater in Alfeld, the latter also including four Metso IQ Coating Profilers.

The replacements are planned for August, September and December 2011.

Sappi Fine Paper Europe is the leading producer of coated fine paper in Europe with an annual capacity of approximately 4 million tons of coated and uncoated paper brands.

Temple-Inland Provides Update on Bogalusa Paper Mill

Temple-Inland Inc. (NYSE: TIN) today provided an update on the shutdown of its Bogalusa, Louisiana paper mill following an operational issue at the mill and its waste-water treatment facility.

Predictive testing for Biochemical Oxygen Demand (BOD) indicated that the Bogalusa mill would exceed its maximum daily permit levels for discharge to the Pearl River from the mill's waste-water treatment facility. The Company believes that this exceedance may have depleted the oxygen level in part of the river below that necessary to sustain a healthy fish population and resulted in a fish kill.

On Saturday, August 13, 2011, upon receiving the results of predictive testing, Temple-Inland immediately shut down the mill. The Company promptly informed the Louisiana Department of Environmental Quality (DEQ) of the situation and began taking corrective actions to restore the water quality of the River.

Temple-Inland's Chairman and CEO Doyle R. Simons said, "The health of the Pearl River and surrounding communities are our utmost concerns. Temple-Inland has a strong environmental record and we sincerely regret this incident, which is contrary to our culture of good community stewardship as both an employer and a resident of Bogalusa and the State of Louisiana.

"We never lose sight that we are members and supporters of the Bogalusa area and apologize for the impact this issue at the mill has had on the Pearl River, its aqua culture and surrounding communities. We are working diligently and expeditiously to remove the fish kill and restore the quality of the River," Simons concluded.

KPM´s 10 year anniversary

On the 15th of August this year KPM celebrates their 10 year anniversary. The company was established in 2001 by founders with long and substantial industrial experience. The head office is located in Kajaani, Finland. In 2008 KPM was acquired by Lorentzen & Wettre and is an important part of Lorentzen & Wettre´s product portfolio.

After the startup in 2001 KPM acquired product technology for consistency measurement and then invested in redesigning this technology to introduce the most modern product portfolio in the field.

A distributor network was created to cover all important pulp and paper manufacturing countries. The product portfolio was constantly extended with own development and by networking with industrial partners like Toshiba and Cerlic.

Today KPM is a company with key competence concerning applications for consistency transmitters, samplers and sheet break detectors and the products represent the most progressive solutions of the field. Market proven products and application engineering expertise, combined with leading-edge design and manufacturing know-how, and being exceptional service-focused has placed KPM above other suppliers in delivering added value and cost efficiency to the customers.

"I have been a part of this company since day one and these ten years have been instructive and exciting. I am proud of what we have accomplished and look forward to new challenges", says Urpo Heikkinen, Managing Director of KPM.

Upgrading the KU 1 Pulp Drying Machine

The KU 1 pulp drying machine in Stora Enso's Kaukopää plant in Imatra is being upgraded, with the aim of improving the fibre balance in the production of the Imatra plant. The productive capacity of the drying machine will be increased by about 30% for all pulp types.

CTS Engtec is overseeing the planning of the upgrade process. The project includes process, plant, electric, automation, heating and ventilation, and structural design as well as the project management for the design stage.

The targets of the project include changes to pulp preparation and the wire and press sections, raising the steam pressure of the drying cabinet, the improvement of recirculation fans and ventilation, modification to the sheeter, upgrading of the wrapping machine, modification to the dropping device, updating of the automation system, improvement to the baling line, and upgrading of the bale management and bale storage systems.

The increased drying capacity in turn enables the Imatra chemical pulp mill to improve its overall capacity and minimize production and quality inconsistencies. A more uniform quality of chemical pulp contributes to the reduction of the grammage of the final product. An increase in chemical pulp production will improve the energy consumption of the whole company.

The upgraded pulp dryer will be in use at the end of 2011.

Mondi Syktyvkar launches Forest of the Future project

The project aims to keep Mondi’s Syktyvkar forestry operations in the leading position in the Russian forest industry

August 17, 2011 - Last month Mondi Syktyvkar launched the large-scale Forest of the Future project to further strengthen its forestry operations. The program is scheduled to close in 2013.

"The aim of the project is to bring our timber business to the next level by increasing the efficiency and profitability of our forestry operations," said Mondi Syktyvkar Managing Director Gerhard Kornfeld. According to Mr. Kornfeld, the Forest of the Future project will further the achievements made in mill’s sustainable forestry operations during the past three years and create a single competitive and balanced system that follows a distinctive strategy. The anticipated outcomes: improved efficiency and an integrated supply chain. Key pillars of this project are Lesnaya Kompaniya (logging), Ezhvatrans (transport) and Ezhvadorstroy (road construction).

The breadth of the project covers the entire wood supply system from Mondi Syktyvkar leased forests to the preparation of raw wood for the pulp flow. It will also include all forestry subsidiaries and associated companies of Mondi Syktyvkar.

"The project will help us to preserve our strategic advantage in Syktyvkar and ensure the sustainability of the forestry operations. In this case, we will focus on using up-to-date methods of forest management," said Klaus Peller, Mondi Syktyvkar member of the board responsible for forestry.

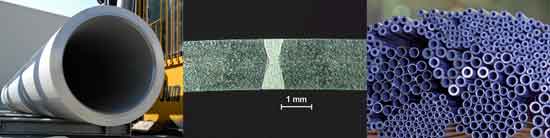

Seamless and welded pipes compared

Stainless steel pipes can be manufactured in either welded or seamless form.

The decision as to which manufacturing process should be used for a particular purpose depends mainly on the wall thickness/diameter ratio required and on the specified pipe tolerances.

In many cases, the benefits of the welded pipe predominate, and so this method is now generally used in western European industry.

For outside diameters of up to DN 100 with a diameter/wall thickness ratio of 5:1 or less, however, seamless pipes are usually better value. But wall thicknesses of less than 3 mm are not available for heat-formed seamless pipes. For welded pipes, the minimum diameter/wall thickness ratio is a constant 10:1, thus offering a wide range of possibilities.

The individual production of longitudinally welded pipes also enables an order for precise wall thicknesses – that is cost-effective and saves resources.

Due to the manufacturing process, differences in wall thicknesses and thus deviations from symmetry (eccentricity) may arise in seamless pipes. It is different with longitudinally welded pipes: The regularity of the coil or plate thickness means that here the wall thickness tolerance is the same across the entire pipe surface – there can be no eccentricity.

The number of alloys available for each group of materials is limited in the case of heat-formed seamless pipes, whereas coils and plates for the production of welded pipes are available without any problems in a wide variety of materials.

When manufacturing seamless pipes, the length manufactured depends on the weight per metre or pipe. In welded form you have a choice of up to 12 m or 18 m without circumferential welds.

The pipes welded on the basis of the valid calculations (AD-form 2000 / ANSI B 31.3 / ASME VIII) are of the same quality as seamless pipes, providing a 100 % weld check has been performed. Corrosion resistance in the weld seam area is maintained at a constant level by the use of higher-alloyed welding additives.

Would you like more information and comparison criteria? Then click here to be taken to our flyer on the subject.

BUTTING - Progress by Tradition

PMPoland to supply new pick-up roll installation to AB Klaipedos Kartonas paper mill in Lithuania!

PMPoland – member of PMP Group in September 2011 will deliver to AB Klaipedos Kartonas, Lithuania new Pick-up roll installation. Scope of supply includes pick-up suction roll, pick-up lift assembly, felt roll monting assembly, pick-up suction roll doctor. The contract was signed in November 2010. The paper machine in Klapieda produces testliner with basis grade of 90-180 gsm and fluting – 90-125 gsm. After modernization of the machine, headbox podsides will be equal to 4760 mm and operating speed will reach 650 mpm. The main goal of the AB Klaipedos Kartonas is to increase annual production as well as the quality of final product.

AB Klaipedos Kartonas is one of the oldest enterprise in Lithuania. The company is located in the West part of Lithuania in the city of Klaipeda. The company's operation is closely related to ecology - the whole production uses waste paper.

SCA helps customers reach sustainability

Kersti Strandqvist, senior vice president of sustainability at SCA, believes that four important trends will drive consumer behavior in the future – rapid  population growth, technological advances, social development and limited natural resources.

population growth, technological advances, social development and limited natural resources.

“For SCA, it’s a matter of developing products and innovations that fit these trends, with sustainability being a key part,” Strandqvist says.

“A critical issue is the supply of resources. We have to work constantly to develop product solutions that are as efficient as possible. In the short term, it’s a matter of making improvements based on existing technology. In the long term, it means working with new materials and technologies.”

Forest raw material

Many oil-based materials will need to be replaced soon by renewable ones as the oil supplies grow tight, driving oil prices too high. “SCA has a major advantage there because our operations are based on forest raw materials that we can expand on and use for a variety of different materials,” Strandqvist says.

It’s also important to look at the life cycles of products based on resource efficiency and reuse as much as possible. “Wood fiber can be reused up to seven times,” she says. “The most efficient solution is to recycle the fiber as many times as possible and then use it as energy.”

One trend that is becoming increasingly clear is that people are choosing brands that they can depend on and that represent sustainability. “By being resource-efficient, we’re helping people be sustainable in their consumption,” she says.

Fire in Mönsterås chip conveyor

Last Friday, a fire broke out in a chip conveyor at the pulp mill in Mönsterås. The cause of the fire is currently unknown. The prevailing wind caused the fire to spread rapidly to the three chip stacks at the mill. Firefighters have battled to contain the fire over the weekend, and the fire is now under control. The fire has not spread, but has been restricted to the chip stacks.

At present, putting out the fire is expected to take a few more days. It is difficult to say with any certainty when production will resume at the mill until the fire has been put out and it is possible to inspect the equipment. We are currently expecting the mill to resume operations within a few weeks. Nobody was injured in the fire.

The sawmill in Mönsterås was also closed due to the fire. Operations at the sawmill are expected to resume midweek.