Leading-edge technology reduces variability, minimizes sheet breaks and improves product quality

ABB, the leading power and automation technology group, recently launched new Weight xP extended profiling actuators with high-speed positioning that guarantee optimal reliability. The actuators provide faster grade changes and faster recovery from process upsets, keeping mill productivity levels high.

The state-of-the-art Weight xP technology eliminates dependence on a physical position sensor, so the actuators can shift into new positions in one swift, continuous movement. This reduces control action time and increases precision. The patented and patent-pending technology also helps mills meet even the most exacting product specifications.

“Papermakers can achieve the lowest possible Cross Direction variability, improve product quality and reduce their costs with the new Weight xP actuators,” says Steven St. Jarre, Head of Sales & Marketing for ABB Quality Control Systems.

A patented power management scheme allows the actuators to move simultaneously at all times, including flush cycles, global setpoint changes or the failure of one power supply, ensuring reliability even in extreme conditions.

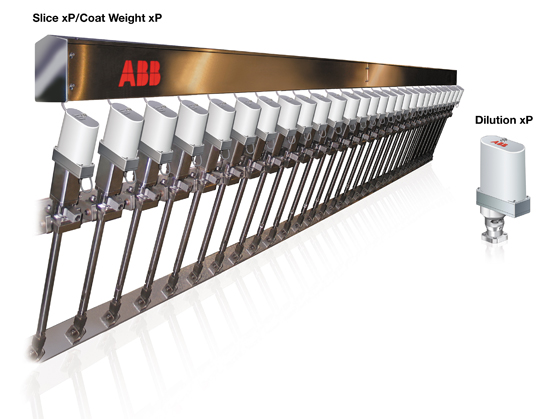

The new Weight xP actuators are the latest generation of ABB’s popular xP profilers. The Weight xP family includes the Slice xP, Dilution xP and Coat Weight xP systems, which are designed drawing on ABB’s experience in applying actuators on the headboxes and coaters of more than 25 different manufacturers.

Slice xP, Coat Weight xP and Dilution xP each offer advanced diagnostics for easy troubleshooting and increased system availability, as well as built-in monitoring of over 60 different parameters, to predict an impending actuator failure long before it occurs.