Would you like to run your various print marking systems – inkjet, labelling and thermal transfer – automatically and reliably? Trace-it! is the solution.

As a manufacturing company, you must meet specific printing requirements which are increasingly restrictive. The efficiency of your supply chain depends on this and so does the satisfaction of your customers. An oversight or the wrong code on a product means you have a dissatisfied customer on your hands and can result in significant extra costs – transportation, credit notes and more.

The challenges

You need to have accurate information, available in real time, for each of your products. You want a seamless connection between your print marking tools and production management system in order to minimize the risk of mistakes.

Trace-it! unifies all marking data (GS1) in a single database management system. This means you access data in real time, securely, from any terminal

linked up to the system.

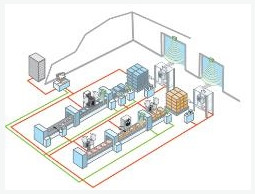

Trace-it! employs client-server technology and is a one-stop shop for managing the different elements of your marking system – databases (containing data

on the items being produced, work orders, printers etc.), labelling software, print drivers, label formats, users and packing lines.

Unlike the majority of software on the market today, with Trace-it! there is no need to acquire numerous software licences for each user station. Trace-it! print server management saves you time and money. Having variable data sent to your marking systems automatically means that you improve the overall output rate of your packing lines.

Your key questions

• Can I set the system up so that the right information is available at the right place, to the right person?

• Will I be able provide guarantees to my customers regarding compliance with their marking requirements?

• How can I make my EDI messages reliable?

Your solution

Production labelling and data management – Trace-it!, an “all-in-one” Avery Dennison software solution!

Trace-it! has many built-in features which can be set and adjusted to meet the needs of your customers – the running and supervision of printing systems, the real-time generation and printing of print masks in accordance with the GS1-128 standard, batch number and use-before date administration, manual and automatic updating of Trace-it! data using your company’s data (ERP, CAPM etc.).

Avery Dennison Trace-it!

The multi-brand one-stop shop for managing your supply chain

The efficiency of your supply chain depends on the standards and accuracy of printed data, in particular that of barcode data.

The Trace-it! server delegates functions to the different client stations in accordance with your requirements. The application’s flexibility allows you to customize the man-machine interface to suit your needs. In addition, the interface provides information to operators on the progress of a given works order in real time, at several points along the line. Trace-it! can communicate with and run virtually any printing software available on the market (Nice Label, Code Soft, Jet Mark, Bar Tender etc.).

Trace-it! can run in client/server mode or connect directly to your production management system. In the latter case, when a works order is triggered by your existing system, Trace-it! receives a file and processes it automatically by combining the data contained in a work order, product data and line

configuration data.

In addition to your existing print management system, or as a separate printing solution, Trace-it! is an essential tool for your supply chain.

Your benefits at a glance

• You save time and eliminate the risk of data-entry mistakes

• Ethernet network architecture

• Supply chain data reliability

• One solution runs all of your printing systems

• Customizable features and multilingual options are standard