Displaying items by tag: xerium

Xerium Technologies Announces Review of Strategic Alternatives to Maximize Shareholder Value

Xerium Technologies, Inc. (NYSE: XRM), a leading manufacturer and supplier of machine clothing and roll covers for the paper and packaging industry, has just announced that its Board of Directors has initiated a review of strategic alternatives to maximize shareholder value. Alternatives could include a sale of the Company or of its divisions and selected assets in separate transactions, a strategic merger, a Reverse Morris Trust transaction, or other business combination. The Company has engaged TN Capital Advisors LLC (“True North”) as financial advisor and Latham & Watkins LLP as legal advisor to assist in the process.

James Wilson, Chairman of the Board, said, “Our markets are stable and our execution is strong and getting stronger. With an expected EBITDA to capital expenditure ratio of roughly 7 times, Xerium is on a path to increase shareholder value through debt reduction. However, the Company currently carries expensive debt that could be refinanced on more attractive terms by a buyer, and suffers from poor stock trading liquidity. After careful consideration, the Board has determined that there may be opportunities to accelerate value recognition or unlock additional value through strategic actions, and this is an appropriate time to identify and evaluate options for shareholders.”

James Wilson, Chairman of the Board, said, “Our markets are stable and our execution is strong and getting stronger. With an expected EBITDA to capital expenditure ratio of roughly 7 times, Xerium is on a path to increase shareholder value through debt reduction. However, the Company currently carries expensive debt that could be refinanced on more attractive terms by a buyer, and suffers from poor stock trading liquidity. After careful consideration, the Board has determined that there may be opportunities to accelerate value recognition or unlock additional value through strategic actions, and this is an appropriate time to identify and evaluate options for shareholders.”

Mark Staton, President and Chief Executive Officer, said, “Our people have done a great job of completing this complex asset restructuring. We are now a company with high quality assets in regions around the world poised for growth, with 75% of our product sales in markets for growing grades of paper and packaging.”

There can be no assurance that the Board’s strategic review will result in any transaction, or any assurance as to its outcome or timing.

The Company does not intend to disclose or comment on developments related to its review unless and until the Board has approved a specific transaction or otherwise determined that further disclosure is appropriate.

About Xerium Technologies

Xerium Technologies (NYSE:XRM) is a global leader in the design, engineering, manufacture and installation of machine clothing and roll covers for the world’s leading producers of paper and packaging. For more information about Xerium visit our website at www.xerium.com

Xerium Recognized as Participant Partner at N.C. State University’s Nonwovens Institute

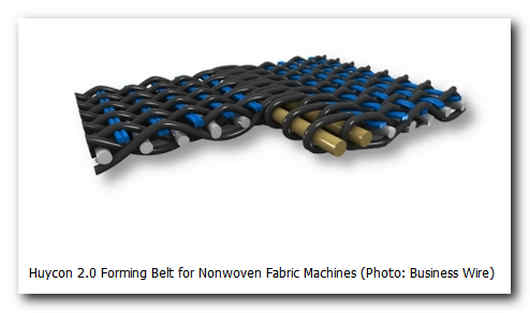

Huycon Forming Belts Selected for New Reicofil 4 Pilot Line

Xerium Technologies, Inc. (NYSE: XRM), a leading global provider of industrial consumable products and services, was recently presented an award for Participating Partner during the open house for The Nonwovens Institute (NWI) at North Carolina State University in Raleigh.

Randy Woodson - Chancellor N.C. State University (L), John Schauer - Global Product Manager - Nonwovens, Xerium (R) (Photo: Business Wire)The award was presented by N.C. State Chancellor Randy Woodson to Xerium’s John Schauer, Global Product Manager - Nonwovens.

Randy Woodson - Chancellor N.C. State University (L), John Schauer - Global Product Manager - Nonwovens, Xerium (R) (Photo: Business Wire)The award was presented by N.C. State Chancellor Randy Woodson to Xerium’s John Schauer, Global Product Manager - Nonwovens.

The May 22nd event and ribbon-cutting highlighted the NWI’s commissioning of its new world-class, 1 meter wide, Reicofil 4 bicomponent spunbond pilot machine.

Additionally, as a leading technical supplier of advanced forming belts for the global nonwoven fabric manufacturing industry, Xerium was also selected as supplier of choice for this new state-of-the-art pilot machine. The new machine will startup with Xerium’s Huycon line of products for spunmelt/meltblown production. In addition, Xerium will continue the advanced development of the Huycon forming belts portfolio utilizing the NWI’s vast research and development assets.

“We are truly honored to be such a close partner with The Nonwovens Institute”, said Bill Butterfield, EVP and CTO of Xerium. “We are also very proud to have been chosen as supplier of choice to run on the world’s newest and most advanced nonwoven pilot machine, and look forward to additional technical advancements from this partnership. This project would not have been possible without the guidance and leadership of Dr. Behnam Pourdeyhimi, Executive Director of The Nonwovens Institute, and I’d like to thank him publically for his support.”

The new Recofil R4 line consists of; Hills’ bicomponent and monofilament die packs, two unwinders, a thermobonding calendar from Andritz, two Perfojet hydroentanglement units, a kiss roll, through-air dryer and A.Celli winder and slitter.

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 28 manufacturing facilities in 13 countries around the world, Xerium has approximately 2,950 employees.

Source: Xerium Technologies, Inc.

Xerium Celebrates 1000th Press Felt Shipped From Its Kunshan, China Plant

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently celebrated the shipment of its 1000th press felt from its new state-of-the-art machine clothing plant located in Kunshan, China.

This world-class press felt plant was designed and built to exacting best-practice standards over a 3 year period by a team of industry veterans from Europe, North America and China. It is the newest press felt plant in the world and shipped its first press felt in Q3 2015.

Xerium is now routinely producing its press felt solutions locally for customers in China and the Asia-Pacific region. The company is proud to announce that the 1000th press felt was produced for Jiangsu Bohui Paper Machine 1. The Kunshan, China plant is equipped to serve the largest and most complicated pulp, paper, paperboard, and tissue machines in the world.

Kunshan produces leading products known as Flomaxx, Strata, Huyspeed, Impact, Huyperm, and Huystar. These premium products are known for exceptional performance in the tissue, paperboard, paper, and fiber cement industries and help manufacturers make higher quality products, with reduced operating costs, and longer product lives.

Xerium’s Kunshan plant is located in the heart of the Yangtze River paper-making region of China, at the very center of the largest papermaking region in the world. Prior to the Kunshan plant, Xerium served this region of the world mainly as an exporter of products made in Europe. Xerium has significantly increased its competitive position with this plant and is now closely partnering with customers in China and the rest of Asia. Xerium has a multi-year plan to continue expanding the scope of machine clothing production in Kunshan. It is underway right now with an expansion to make forming fabrics in Kunshan.

“We are delighted to celebrate this important milestone for the Kunshan plant. We have the right processes and a strong Six Sigma certified team. We are proud that our customers are having great success when they use these high-performance press felts on their machines. We use the latest designs, best materials, and most modern manufacturing processes in the world,” said Mr. Harold Bevis, President and Chief Executive Officer of Xerium. “Customers have really embraced Kunshan as a new local source of high-value press felts. They now depend on us every day to help them achieve their goals.”

About Xerium (NYSE:XRM)

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 30 manufacturing facilities in 13 countries, approximately 500 patents, and approximately 3,000 employees.

Xerium Announces the Promotion of Mr. Robert Burke to the Position of Xerium - President of Asia

Harold Bevis, the President and CEO of Xerium Technologies, Inc., a leading global provider of industrial consumable products and services, has just announced the promotion of Mr. Robert Burke to the position of Xerium - President of Asia.

Mr. Burke will be based in Xerium - Asia headquarters located in Kunshan, China. Mr. Burke will have full responsibility for the Asia region and be responsible for delivering Xerium-Asia’s long-term and short-term business plans while maintaining and strengthening customer relationships.

Mr. Burke will be based in Xerium - Asia headquarters located in Kunshan, China. Mr. Burke will have full responsibility for the Asia region and be responsible for delivering Xerium-Asia’s long-term and short-term business plans while maintaining and strengthening customer relationships.

Harold Bevis said “Xerium has a very successful and growing business in the Asia region and we have significantly increased our competitive position with our strategic initiatives over the past 3 years. We have even bigger plans over the next 3 years. We have a great team and are closely aligned with key customers throughout Asia. Bob will be taking over a great business for Xerium and taking it to the next level. He is a seasoned leader both within Xerium and in the industry with significant strengths and established relationships. He adds a lot to our Asian business and to our top executive team. Bob will shape the team under him, refine the company’s product offerings, expand our production capabilities, and deepen our go-to-market strategies.”

“Xerium is committed to leveraging its customer relationships, best practices and cost optimization across the globe and is an expert at creating value for our customers and we have an arsenal of patented solutions,” continued Mr. Bevis. “Asia is an extremely important market for Xerium and it is imperative that we continue to profitably grow, enhance our lead times and diversify our Asian business.”

Mr. Robert Burke said, “Xerium is a market leader in the region and we are committed to the continued growth of the business while further executing our strategic business plans. It is my goal to ensure alignment with the company’s long-term strategy, address future market demands and opportunities while further developing our strong relationships with critical regional customers.”

Mr. Robert Burke Background Highlights

- 30+ years of sales, operational, development, managerial and executive leadership experience within the industry.

- Seasoned international leader with 20+ years residing and operating in China and the USA.

- Joined Xerium as an Executive leader in 2009. Most recently held the position of Vice President of Sales and Marketing for Xerium – Asia.

- Many years of full P&L responsibility with functional leadership experiences including manufacturing, project management, business development, sales and marketing.

- Experience in establishing and maintain manufacturing and sales operations in China, Malaysia, India, Korea, Japan, Indonesia and Australia.

- Instrumental in the start-up and business development for our Kunshan, China Greenfield operation.

- BS in Industrial Engineering from the University of Massachusetts - Dartmouth

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 30 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Fabric Scanning Profiler – fabric under optimal control

Measurement technology for ensuring maximum fabric and machine efficiency

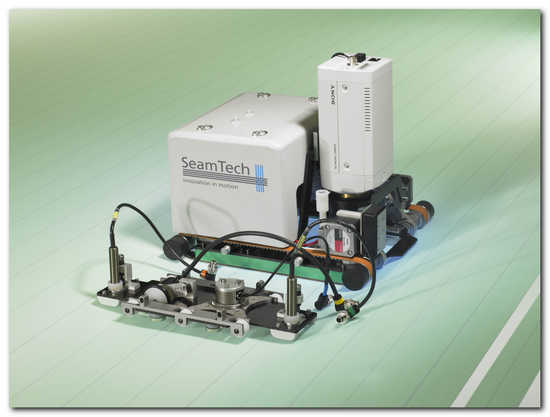

SeamTech, a division of the US technology corporation Xerium and its leading clothing division Huyck.Wangner, is providing forming fabric and paper manufacturers with unique measurement technology: the Fabric Scanning Profiler. It measures the fabric profiles during production and directly at the paper machine, thus providing important information for optimizing process stability.

The forming fabric plays a key role in perfect sheet forming and paper quality during paper production. The drainage and formation processes are largely determined by optimum clothing and thickness cross profiles as well as trouble-free running properties. The technicians at SeamTech have developed the Fabric Scanning Profiler in order to keep an eye on these important parameters and individually adjust them to the specific paper production as needed. The Xerium division SeamTech, which began developing the first fully automated seaming machines for continuous seams of forming fabrics 25 years ago, is now the worldwide leading supplier of fully automated seam machines SeamMaster as well as other machines and components for producing forming and dry fabrics.

With the Fabric Scanning Profiler (FSP), the technicians at SeamTech are now providing another instrument for keeping the fabrics under control and individually adjusting them to the specific paper production as needed. This uniquely configured measuring instrument records all relevant information and provides data on the most important parameters of the clothing by precisely presenting the main bases for the analysis in order to maintain top-level fabric quality and paper machine efficiency at all times.

Modular configuration for universal use

The Fabric Scanning Profiler is mobile and runs automatically, and can also be controlled and steered via remote control, making it useable in virtually any situation. The tension and fabric thickness measurement runs across the fabric can be made at an inclination of up to 45°. Control and data recording are conducted via W-LAN. This enables detailed, dependable analysis of the forming fabric or other clothing components with data output and storage directly on location – even if the paper machine is stopped briefly. The measuring instrument features a modular configuration and is offered for measuring clothing thickness and tension, and is available with an optional camera module for visual inspection of the fabric surface. The camera can be used to examine the forming fabric at targeted points, thus enabling continuous visual monitoring of the fabric surfaces (on the running side as well as the paper side).

W-LAN is used to control the Fabric Scanning Profiler precisely at the point to be examined.

Increase in productivity and paper quality

The measurement data recorded on the machine run’s effect on the fabric can immediately be analysed, processed and saved. The fabric can then be continuously adjusted quickly, precisely and in a traceable manner. And it offers many other advantages:

• exact, data-supported determination of the fabric’s clothing and cross profile

• simple monitoring of all important parameters,

• direct documentation and interpretation of the measurement results obtained to ensure quick and targeted analysis,

• recording of periodic profile faults via FFT analysis,

• visual inspection via camera module at any desired point on the fabric,

• reliable determination of the clothing’s remaining running time,

• maximum user-friendliness and

• high individual application possibilities thanks to the modular configuration.

Edgar Hofstetter, Head of SeamTech, sums up the extensive performance spectrum of FSP measurement technology as follows: “The advantages of ideal analysis and optimal forming fabric output are obvious to forming fabric and paper manufacturers. These benefits come together at the bottom line in outstanding drainage performance with increased production efficiency and top paper quality – an added value which pays off in hard cash.”

Whereas everyone had been developing and using their own measuring instruments in the past, all worldwide leading forming fabric manufacturers now use SeamTech’s patented Fabric Scanning Profiler – and with great success. So much so that the machine has conquered a firm place in the service portfolio for paper machines and quality optimization in production.

Xerium Completes Renovation Program at 4 Machine Clothing Plants, Further Optimizing Global Footprint, Cost Structure and Lead Times

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that it has completed the renovation program at four machine clothing plants that took over two years to design, construct, equip and commission. The Company is aggressively pursuing growth in its popular products, growing grades and regions that are outpacing global industry growth. This global renovation program, involving facilities in North America, South America, Europe and Asia reconfigures its 10-plant machine clothing footprint to serve its customers more effectively with better lead times and global availability of its innovative and rapidly-growing portfolio of patented technology. Key highlights of these projects:

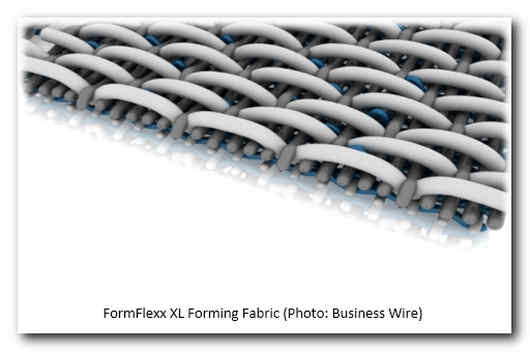

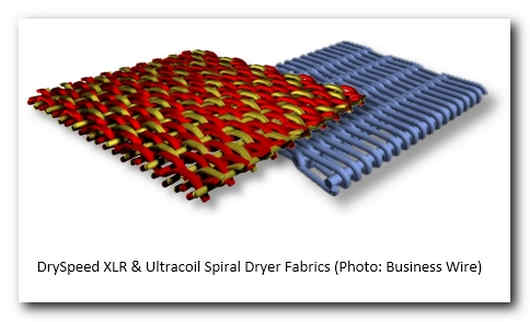

North America – the expansion of the Kentville, Canada forming fabric plant to manufacture woven dryer fabrics in North America for the first time in over a decade. The expansion transitions Xerium from a position of being competitively disadvantaged in dryer fabrics to improved responsiveness to customer quality and delivery expectations. The existing sales force can now leverage relationships in complementary products to accelerate penetration in this currently underserved market. The commissioning of this newly expanded facility and the installed assets was completed in Q3 2015.

South America – the renovation and expansion of the Piracicaba, Brazil plant to manufacture spiral dryer fabrics. Xerium previously manufactured spiral dryer fabrics at its smaller and higher cost Argentina plant. Upon closure of this facility, Xerium made the strategic decision to purchase all new production equipment and modernize its product technology. This initiative, the largest of the four, will enable Xerium to offer both higher quality products and shorter lead times, while operating under a significantly more advantageous cost structure and was fully operational in Q3 2015.

Europe – the expansion of the Gloggnitz, Austria plant to produce belts and fabrics for nonwoven fabrics machines. Xerium has installed special-purpose machines, which will more than double its global capacity for its nonwoven products portfolio. Concurrent with this expansion, Xerium enhanced its product technology to deliver higher levels of performance on the most modern nonwoven production lines and will provide global support for a variety of product types from this site. This expansion further leverages one of Xerium’s most cost competitive and high quality facilities. The expansion is on schedule to reach its full production rate capability by year-end 2015.

Asia – the expansion of the Asahi, Japan plant to produce Xerium’s most advanced forming fabrics for containerboard machines. Xerium has historically manufactured machine clothing for large containerboard machines in its European plants and shipped them to Asia. This investment enables Xerium to serve the Japanese and the entire Asian markets locally with shorter lead times, significantly lower shipping costs to the customer while delivering Xerium’s most modern product portfolio. The commissioning is underway and remains on schedule to reach its full production rate capability by year-end 2015.

Mr. Harold Bevis, President and CEO of Xerium, commented regarding these business transformation projects; “Xerium is committed to quantifiably increasing profits of its customers. These investments enable Xerium to strengthen our partnerships by being closer to its customers with transformative innovation, on-site product experts, and in-region short lead times. The pace of technical breakthrough requests from our customers continues to quicken. We must have shorter product life cycles and faster supply chains to compete and win. Our products and services make a difference for owners of sophisticated large machines, and these machines are dispersed globally. We are very optimistic that these machine clothing programs will be another successful step in our transformation to deliver better financial and operational results and continue to improve our growing stature of supplier of choice in the most attractive regional markets. We do not expect to achieve sales growth by waiting for, and then riding, a global GDP growth cycle. With uncertain global economic conditions, we are strategically deploying our people, innovation, and know-how into expected growth regions.”

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Xerium Announces New Business in China

Two Plants, New Headquarters, New Supply Chain, $60 million Investment

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that it has materially completed the $60 million successful restructuring of its business in China. The business is now in a position to locally serve customers in China, Asia, and also export certain products globally. The make-over of its China and Asian business has taken over 3 years to complete with a number of key aspects required for full implementation. Xerium has implemented an all-Asian business model and will now run its entire Asian business from Shanghai.

Kunshan, China Press Felt Plant (Photo: Business Wire)

Highlights of the repositioning of Xerium’s Asia business are as follows:

- Production has begun at Kunshan, China Press Felt Plant – Xerium completed a 2 year, multi-million dollar construction project to build and equip a brand-new press felt plant in Kunshan, China. This greenfield plant is located in the heart of the Yangtze River paper-making region, which is at the center of the largest paper-making region in the world - China. It took over 2 years to design, build, equip, and commission. Until this new plant began production, Xerium served this region mainly as an exporter of products made in Europe. Xerium has significantly increased its competitive position with this plant and will now be able to more closely partner with customers in China and the rest of the world.

For the first time ever, customers in China will receive locally provided and optimized state-of-the-art press felt solutions from Xerium. Xerium will conduct business in local currency and local languages. The Kunshan plant will be able to service the largest pulp, paper, paperboard, and tissue machines in the world, as the main machine in the plant is greater than 15 meters wide. This central machine and its foundation weighed almost 1 million pounds at installation, and is one of the largest of its type in the world. For some press felt designs, the company will be able to make 3 pieces simultaneously - a first for the company. The plant has state-of-the-art information systems and supply chain interfaces along with real time operational communication systems throughout the site. It is conducting business from a new Infor™ information technology platform. The company is moving a large portion of its press felt production to this plant in China. The plant has initiated production.

- Renovated Changzhou, China Rolls Plant – Xerium completed a 2 year, multi-million dollar investment program to completely renovate its rolls and mechanical service plant in Changzhou, China. This plant is located in the Yangtze River paper-making region. Until this renovation was completed, Xerium had served this region for many decades by exporting high-end working rolls from Europe. Xerium has now transferred all of its technology to this plant – SMART® Roll production cell, spreader roll production cell, polyurethane production cell, suction box production cell, upgraded extrusion and drilling equipment. The plant can now produce all of Xerium’s designs. The plant recently received ISO-9000 quality certification.

- Implemented new Asia Headquarters in Shanghai- Moved and reincorporated Xerium Asia headquarters into the Shanghai Free Trade Zone. This special Chinese government approval allows Xerium to import/export at the lowest possible cost, expedite customs processing, provide shorter lead times for materials transfer, enables maximum leverage of working capital for Xerium across Asia, and receive improved tax treatment as a local Chinese business entity. The entity is now in place.

- Implemented new Chinese Capital Structure – Implemented a local capital structure and banking relationship by moving a portion of the Xerium corporate debt structure to China. The company has implemented a multi-million RMB on-going loan in China with ICBC, the largest bank in the world. Xerium will now conduct local business in local currency (RMB), finance and fund its China business locally in RMB. This will also enable Xerium to both secure a natural business hedge and receive local entity tax treatment. The new loan and new ICBC financial relationship are complete and in place.

- Localized all Asian Leadership - Moved its Asia business leadership from the United States and Europe to China. The key top personnel moves were: moved President and CFO positions from the US to Shanghai, moved Sales leadership from Europe and Australia to Shanghai, moved technical leadership from Europe to Shanghai. All of these personnel moves are complete.

- Implemented Chinese IT structure - Moved its IT and data support from Europe to Shanghai. The company has completed its data center in Shanghai and is partnered with SAP as its provider for rolls plant information technology, and is partnered with Infor™ for machine clothing plant information technology. Both technology providers have huge businesses in China and are also located in Shanghai.

- Implemented Contemporary Asian Supply Chain - Moved its Asia supply chain and warehousing activities from in-house/locally provided into a global partnership with Panalpina. Panalpina is one of the world’s leading providers of end-to-end supply chain solutions. Xerium is connecting its internal systems with Panalpina to give its customers a seamless electronic supply chain. The supply chain moves are in place.

Changzhou, China Rolls & Mechanical Service Plant (Photo: Business Wire)

Mr. Harold Bevis, President and CEO of Xerium, made several comments regarding this business realignment. “Competing and winning in China and throughout Asia is central to Xerium’s corporate repositioning. Xerium’s legacy markets in North American and European newsprint, printing and writing are all under pressure. These market segments are going through permanent correction. Several years ago, the Board of Xerium decided to tackle this situation head-on and reposition its assets and commercial profile directly into growth markets globally.

“These China investments have taken a few years and a lot of money to implement. We are very happy that these new investments are coming on line now. The commercial objective is to provide machine optimization solutions with world-class technology and shorter lead times, at a local cost structure. Customers will immediately benefit from improved costs, better lead times, better technology, and better service. This new business start-up is a key part of Xerium’s investment strategy to realign its global business model and global factory locations to line up with growth markets in the world.

This business restructuring is an important part of the business strategy being deployed at Xerium – to reposition the company into growth markets. We are excited about our new future in Asia. This restructured business is now underway producing and selling machine clothing, performing on-machine service, and performing in-factory rolls and mechanical service.” added Mr. Bevis.

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,100 employees.

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,100 employees.