Ianadmin

J.Vilaseca, three centuries of innovation and internationalization

J. Vilaseca’s story goes back 300 years to the arrival of the Vilaseca family to Capellades, then epicenter of the Spanish paper industry. What started as a family project to group together various paper mills in the municipality - the oldest named Cal Mata was founded in 1714 - has evolved over time into the current corporation, which now has two production plants in Capellades, one in Vallbona d' Anoia and the headquarters in the center of Barcelona.

The values that govern J.Vilaseca’s strategy remain as they were on the first day, 300 years ago: it is a socially committed family business, dedicated to excellent customer service, continuous technological innovation and a sustainable approach to ensure maximum respect for the environment.

The company’s investment culture has facilitated modernization parallel with technological developments. Thus, J.Vilaseca boasts state of the art equipment and facilities that allow an annual production capacity of 63,000 tons per year. The company is thus prepared to quickly and effectively fulfill the demand of an increasingly specialized global market that looks for a high level of added value.

In the past 50 years J.Vilaseca has transformed its business model from manufacturing security and writing papers to producing all kinds of high-end papers: specialty papers and industrial base papers, security papers, printing and writing papers, Poster papers and wine labels, embossed and pearly papers and recycled papers. Specialization in niche markets, adaptability, flexibility and continuous investment to create new families of products are some of the company’s strengths.

J.Vilaseca is after all, a three hundred year old company that looks to the future committed to quality, sustainability and innovation, but without losing its original ethos.

Warm Water Innovation Challenge

The Paper Province has arranged an Innovation Challenge to find solutions of what can be done with the warm water from the pulp and paper mills. The winning contribution was announced on May 22nd and it came from Vegafish! It was their contribution Cultivation of prawn in pulp and paper mills warm wastewater that was selected by the jury.

By growing prawns by the pulp and paper mills we have the possibility of an eco-friendly, tasty and locally produced seafood. The prawns are otherwise imported from environmentally damaging crops in tropical countries.

- It's great to win the Innovation Challenge. It gives a clear indication that we are on the right track! The prize means that we can take another step forward towards realization, says Matilda Olstorpe, CEO of Vegafish.

The competition was open to everyone and in total there were 19 contributions. Warm Water Innovation Challenge was arranged by The Paper Province in cooperation with BillerudKorsnäs, Nordic Paper, Rottneros, Stora Enso, Inova, ALMI, Wipab, Åmotfors Energy and Karlstad´s University.

The jury said "With a high environmental profile, the winning contribution has a unique solution to something that normally cannot be done in our northern climate. Additionally there is a clear market and a major societal economic value. The solution is also easy to scale up."

The competition was financed by VINNOVA, the Swedish Innovation Agency.

Algae biomass produced in a unique pilot plant!

On May 27th Bäckhammars Algbruk was inaugurated by Kenneth Johansson, Governor of Värmland County. It is a unique facility where microalgae are grown at a pulp and paper mill.

- It´s a unique project that can give us some insights of how a future biobased society can look like, say Magnus Persson Innovation Advisor at The Paper Province.

Green microalgae are grown with sunlight as energy source. The algae fix carbon dioxide from the flue gas of the mill. Excess heat from the water treatment plant is used to keep the cultivation at a suitable temperature.Algae also need water and nutrients. The bio sludge from the mill and other nutrient sources are tested for this purpose. The project goal is to produce algae biomass in a sustainable way with the help of resources from the pulp and paper mill at Nordic Paper Bäckhammar and to extract bio oil for analysis of usability. The bio oil can later be refined into biodiesel, plasticizers, bioplastics and lubricants.

Theoretically 8 kg of algae per m2 and year can be produced in Sweden. The resources at Nordic Paper Bäckhammar are enough for 500 tons of algae or 150 tons of oil yearly, based on phosphorus as the limiting nutrient. That requires 10 ha of cultivation area. Algae produce much more oil per hectar than other crops.

The project is part of a 3-year research project led by SP Technical Research Institute of Sweden with the help of The Paper Province, Nordic Paper Bäckhammar and 11 other partners from industry, academy and society. The project is financed by Vinnova, Å-Forsk and Region Värmland.

The Global Timber and Forest Industry This Quarter - Wood Resource Quarterly

Global Timber Markets

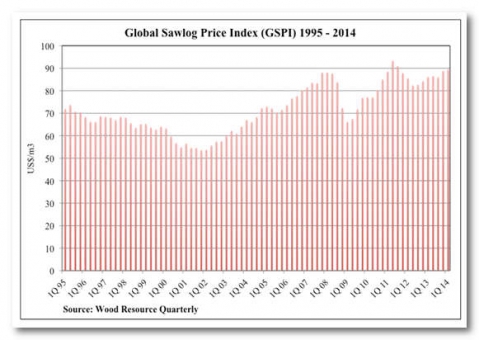

- With improved lumber markets in many regions around the world in early 2014, sawlog consumption was higher and sawlog prices were moving upward in a majority of the 20 regions covered by WRQ. The Global Sawlog Price Index (GSPI) rose by 0.8% from the 4Q/13 to US$89.45/m3 in the 1Q/14.

- During the 1Q/14, trade of logs was up in all major markets of the world as compared to the 1Q/13. For the four largest exporting countries, the increase was 17%, with the biggest rise in shipments coming out of Russia.

Global Pulpwood Prices

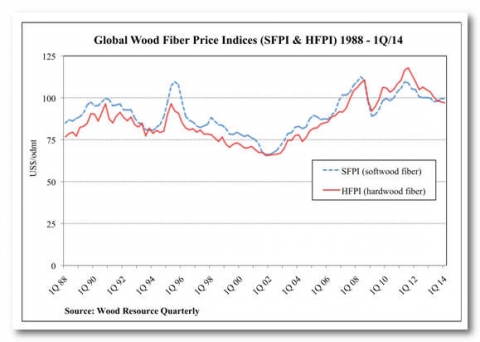

- Lower wood fiber prices in local currencies and a strengthening US dollar resulted in declines in both the Softwood and Hardwood Fiber Price Indices (SFPI and HFPI), which are the price indices that track wood costs for the global pulp industry.

- The SFPI fell from $99.51/odmt in the 4Q/13 to $99.43/odmt in the 1Q/14, with the biggest price reductions occurring in Canada, Russia, Australia and Brazil.

- The prices for hardwood pulplogs have trended downward in many markets for more than two years, which is reflected in an HFPI Index that has constantly fallen each quarter since its peak in the 3Q/11. In the 1Q/14, the HFPI was $97.01/odmt, down from $97.59/odmt in the previous quarter. Prices fell the most in Russia, Eastern Canada, Western US and Brazil.

Global Pulp Markets

- Production of market pulp fell in two of the three major pulp-producing regions in the world in early 2014. Production was down 5.2% in N. America and 4.2% in Europe. In Latin America, production was up 2.6% mainly because of higher exports to China and Europe.

- Prices for NBSK pulp have been holding up better than those for HBKP this year. With the recent opposing price trends for softwood and hardwood pulp, the price discrepancy between the two major pulp grades has widened to a two-year record.

Global Lumber Markets

- Lumber imports to Japan slowed down in the 1Q/14, with volumes being four percent lower than the first quarter of 2013 and, in fact, representing the lowest 1Q import levels since 2010.

- A slowdown in the Chinese economy has impacted the construction sector, resulting in a decline in lumber imports during the first four months of 2014. The biggest drop has been in lumber shipments from Canada, while Russian sawmills have kept up deliveries fairly well.

- The sawmilling sector in the US has been in a steady comeback mode ever since the global financial crisis struck in 2008. From 2009 to 2013, production has gone up every year, and the total production increased 28 % over this four-year period. In early 2014, production fell slightly.

- Lumber exports from Canada in the 1Q/14 fell to all markets except the US. The biggest decline from the previous quarter was in lumber headed to China (-22%) and to Japan (-32%).

- The Finnish sawmilling industry had a good year last year with total production reaching over ten million m3, the highest level in five years. This positive trend continued in 2014, with production in the 1Q being up 5% thanks to higher shipments to France, Germany and Algeria.

Global Biomass Markets

- With no slowdown in sight, North American wood pellet exporting companies keep building new facilities to manufacture pellets for the European market. Export volumes hit a new record high in the 4Q/13 and the total shipments for 2013 were up almost 50% from the previous year.

- South Korea has increased importation of pellets dramatically the past two years with Vietnam and Canada being the major suppliers

Catalyst Paper named to best 50 Canadian corporate citizens list for eighth consecutive year

Catalyst Paper (TSX:CYT) is pleased to accept - on behalf of its 1,600 employees - the honour of being named one of Corporate Knights' Best 50 Canadian Corporate Citizens for the eighth year running.

Catalyst Paper (TSX:CYT) is pleased to accept - on behalf of its 1,600 employees - the honour of being named one of Corporate Knights' Best 50 Canadian Corporate Citizens for the eighth year running.

Corporate Knights, an award-winning quarterly publication for clean capitalism, gave start to its magazine andBest 50 list in 2002 to raise awareness of sustainability issues. Catalyst was one of 144 companies considered by Corporate Knights for its Best 50 list, and evaluated across twelve key performance indicators covering resource, employee and financial management synchronized with the Global 100 Index from information that was disclosed voluntarily in Catalyst's public reports such as financial filings and sustainability reports.

"Earning this title for the eighth year is an honour and significant achievement - something that all Catalyst employees had a hand in realizing," said Joe Nemeth, President and CEO. "This recognition reaffirms that our continual vigilance to raising the bar on sustainability, environmental stewardship and social responsibility is more than just the right thing to do - it's good for business."

The honour reflects Catalyst's ongoing commitment and engagement with partners and organizations to drive forward sustainability and capacity-building initiatives. Our partners include the World Wildlife Fund, the Forest Stewardship Council, the Canadian Business for Social Responsibility, SmartWay, a program of the US Environmental Protection Agency, GreenBlue, the Coast Forest Conservation Initiative, ForestEthics, Greenpeace Canada, and Sierra Club BC.

Catalyst Paper manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With three mills, located in British Columbia, Catalyst has a combined annual production capacity of 1.5 million tonnes. The company is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE: Catalyst Paper Corporation

Lebanese Ministers Tour INDEVCO Industrial Complex in Halat: UNIPAK & UNIPAK Tissue Mill

UNIPAK and UNIPAK Tissue Mill (UTM) held an eco-industrial tour inside the Halat, Lebanon complex of the multinational manufacturing group, INDEVCO. The event hosted key Lebanese ministers including Minister of Energy & Water, Arthur Nazarian; Minister of Economy & Trade, Dr. Alain Hakim; Minister of Environment, Mohammad Machnouk; and Minister of Industry, Dr. Hussein El Hajj Hassan.

Industrial delegations and prominent civil society representatives also took part in the tour, which shed light on INDEVCO Group’s latest energy demand management and renewable energy promotion initiatives.

Guests visited different production units to examine the latest energy management and self-sufficiency technologies adopted by UNIPAK and UTM: fuel quality control; energy recovery from exhausts and radiator waste for steam production; fuel separators and filters capturing over 90% of particles; a biomass boiler that feeds on olive husks, energy-saving cooling processes and newly introduced photovoltaic plan and LED lighting.

In his welcome, Neemat Frem, INDEVCO Group President & CEO, acknowledged the presence of the ministers and officials as a sign of strong support for Lebanese industry and UNIPAK’s journey, which dates back to 1967. He highlighted the importance of close collaboration between the Lebanese industrial sector and the various ministries, which are striving to overcome obstacles and preserve industrial prosperity.

Frem added, “It is thanks to a deep faith in the excellence and creativity of the Lebanese citizen that national industry is able today to achieve growth and expansion.”

Minister of Industry El Hajj Hassan also delivered a speech, in which he announced that the Ministry will impose new import restrictions in light of an inability to create an Energy Support Fund.

“We should promote and protect industry and agriculture and adopt a national economic policy that reflects positively on all sectors” El Hajj Hassan concluded.

Mediapak, INDEVCO Group’s advertising and marketing agency, organized the ministerial eco-industrial tour to UNIPAK and UNIPAK Tissue Mill.

Minerals Technologies Inc. Signs Agreement to Build a Satellite PCC Plant for Coated Packaging Paper in China with Zhejiang Zhengda Paper Group Co. Ltd.

Facility will Produce 50,000 Metric Tons per Year of Coating-Grade PCC at a Paper Mill in Zhejiang Province; MTI's First Dedicated Satellite Plant for Packaging Market

Minerals Technologies Inc. (NYSE: MTX) has announced that it has signed an agreement with the Zhejiang Zhengda Paper Group Co. Ltd. for a 50,000 metric ton per year satellite precipitated calcium carbonate (PCC) plant that will produce coating grade PCC for packaging in Zhejiang Province, China. The plant should be operational in the fourth quarter of 2015.

Minerals Technologies Inc. (NYSE: MTX) has announced that it has signed an agreement with the Zhejiang Zhengda Paper Group Co. Ltd. for a 50,000 metric ton per year satellite precipitated calcium carbonate (PCC) plant that will produce coating grade PCC for packaging in Zhejiang Province, China. The plant should be operational in the fourth quarter of 2015.

"This agreement with the Zhengda Paper Group is important in that it is Minerals Technologies' first on-site satellite plant to produce PCC for the coated packaging market," said Joseph C. Muscari, chairman and chief executive officer. "We are very pleased to be working with a high-caliber paper company like Zhengda Paper to help them reduce costs, upgrade quality, and improve the performance of its coated cartonboard in the market. We look forward to a long, mutually rewarding relationship with this fine company."

Minerals Technologies (MTI) will manufacture OPACARB® Coating PCC specifically tailored for the Chinese packaging market at the satellite plant. This will allow Zhengda Paper to reduce the use of other expensive raw materials such as imported clay, latex, optical brighteners and expensive finely ground GCC. The Zhengda paper mill in Fuyang City, Zhejiang Province, China, produces 600,000 metric tons per year of coated, bleached cartonboard for packaging.

International Paper Appoints Mark S. Sutton President and Chief Operating Officer

International Paper (NYSE: IP) Chairman and Chief Executive Officer John Faraci has announced that Mark S. Sutton has been promoted to president and chief operating officer and elected a member of the company's board of directors effective immediately. In this new role Sutton will immediately assume responsibility for the operations of the company and will continue to report to Faraci. Most recently, Sutton served as International Paper senior vice president, industrial packaging.

![]()

"Mark has been a key member of our leadership team and has played an instrumental role in the transformation of International Paper over the last decade," Faraci said. "He has done an excellent job integrating the acquisition of Temple Inland, and with 30 years of proven success at International Paper in a variety of assignments, I'm confident Mark will continue to make International Paper a stronger, better company."

Sutton has been with International Paper his entire 30-year career. He joined the company in 1984 as an engineer at the Pineville, La., mill. In 1994, he was named mill manager at the Thilmany, Wisc., mill which at the time was part of International Paper's industrial papers business. In 2000, Sutton relocated to Europe to serve as director of European corrugated packaging operations and was promoted to vice president and general manager responsible for all corrugated packaging operations across the EMEA region (Europe, the Middle East and Africa) in 2002. In 2005, he was named vice president of corporate strategic planning and relocated to Memphis. He was named senior vice president, global supply chain, in 2007 and in 2009 became senior vice president, printing and communications papers – the Americas. In 2011, Sutton was appointed senior vice president, industrial packaging.

Sutton holds a Bachelor of Science degree in electrical engineering from Louisiana State University.

SOURCE International Paper

Cascades Fine Papers Group Joins Two Sides

Cascades Fine Papers Group, a leader in the manufacturing of ecological fine papers and security papers in Canada, has joined Two Sides, the rapidly growing non-profit organization that promotes the responsible production, use and sustainability of print and paper.

Cascades Fine Papers Group, a leader in the manufacturing of ecological fine papers and security papers in Canada, has joined Two Sides, the rapidly growing non-profit organization that promotes the responsible production, use and sustainability of print and paper.

"We're very excited to have Cascades Fine Papers Group join us. They have been a North American leader in producing fine papers with a low environmental footprint and are a great addition to our network as Two Sides begins exploring a Canadian presence. We look forward to working with them to spread the great environmental story of print and paper," says Two Sides President Phil Riebel.

"We are proud to produce paper. It is a beautiful, useful, recyclable and renewable tool, and we make it in a sustainable way. It is a pleasure for us to support an organisation that explains why people shouldn't shy away from paper and promotes the strengths and benefits of this great resource." says Julie Loyer, communications and sustainable development, Cascades Fine Papers Group.

Xerium Launches Redesigned Website

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced the launch of its newly redesigned website, www.xerium.com.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced the launch of its newly redesigned website, www.xerium.com.

The refreshed website delivers a modern user experience sharply focused on Xerium's worldwide customer base in all served markets. The site builds upon the company's efforts to unify its worldwide legacy brands of Stowe Woodward, Huyck.Wangner, and Weavexx under the single Xerium global brand. Additionally, xerium.com now supports mobile devices of all screen sizes to further enhance the user experience and functionality across all major platforms.

"We are excited about the revitalized Xerium website," said Mr. Harold Bevis, President and CEO of Xerium. "It now clearly communicates our company's unique value proposition based on our innovative product technology, cutting-edge mechanical services, unsurpassed technical expertise, and ValueResults platform. Using our skills and know-how, Xerium is providing millions in total savings to our customers around the world."