Ianadmin

Mitsubishi HiTec Paper invests in Bielefeld

As announced in the autumn of 2013, Mitsubishi HiTec Paper continues to invest in the optimization of the Bielefeld site. Five large recooling plants and two high efficient speed controlled screw chillers are currently being installed as part of a new process refrigeration system for two coating machines, and are expected to start up in July. Further investments will follow.

The five large recooling plants - the two largest are over 12m long - arrived in Bielefeld on schedule. They are part of a new process refrigeration unit for two of the speciality paper manufacturer’s coating machines. The two new chillers are needed to cool the process water in the system circuits. Supported by the large free coolers they effectively achieve maximum energy efficiencies.

The concept was developed together with the firm Redeker-Kältetechnik. The plant will start operating as soon as July. Energy Manager Gerd Finkenhofer is looking forward to future electricity savings of about 1 million kilowatt hours per year, which is roughly equivalent to the annual consumption of 200 single family homes. "This is only the first step of a consistent system optimization here at the site," says Gerd Finkenhofer. "A further 800,000 EUR will be invested in 20 decentralized climate and refrigeration units immediately after this. This will bring a further electricity saving of 500,000 kWh per year. "

In addition to investing in climate and environmental technology, Mitsubishi HiTec Paper is focusing on the optimization of production technology in Bielefeld. "Later this summer we will invest a further 3.2 million EUR in our state of the art coating machine No. 3, which is the fastest production machine in the thermal paper sector in the world today," says Managing Director Gerhard Schoon. "Objectives of the investment are, in addition to quality and productivity improvements, a more flexible use of the highly modern coating system with different product ranges."

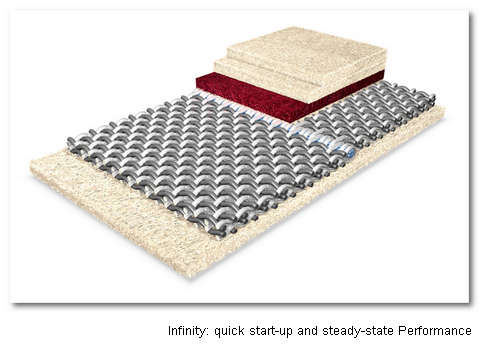

Infinity: Voith’s newly developed press fabric with high dewatering Performance

With Infinity, Voith has developed a completely new generation of endless and seam press fabrics containing a base structure that ensures the fabric will resist compaction during operation. The dewatering performance therefore remains consistently high while maintaining high paper quality.

The high-quality base fabric of Infinity is woven in an especially uniform method. Additionally, the laminated structure retains its open volume during the entire running time due to a high level of compressibility and better rebound behaviour in comparison to conventional press fabrics. These characteristics increase the dewatering performance and reduce dirt deposits and fiber loss. Infinity rapidly achieves optimal saturation, so the desired machine speed is quickly reached. The high number of contact points of the base fabric provides for uniform pressure distribution, increasing the dry content and the quality of the paper sheet.

The paper manufacturer has the choice of several designs due to the modular concept of Infinity. Infinity can be tailored to the specific needs of the application to provide immediate benefit to paper machine operation. The new press fabric is also available with seams: the seam loops have an identical loop length, roundness and spacing, which makes the installation of the fabrics faster, simpler and safer.

More information about press fabrics

Pankaboard invests in new headbox and sheeter to enhance product quality and customer service

Pankaboard continues their planned investment program for development of quality and service of their uncoated speciality boards from BM3.

In June 2014 Pankaboard will install a new dilution head box on BM3.

The new head box will provide better formation and improved thickness profile for all BM3 products. Resulting improved product consistency and uniformity will offer better runnability and efficiency in customer processing. Bellmer and TasoWheel will make the installation during the annual maintenance shutdown during midsummer.

In September 2014 Pankaboard will install a full-width sheet cutter for BM3.

The new sheeting line will increase the sheeting capacity for all uncoated speciality products from BM3 at Pankaboard. This investment will benefit customers by improving lead times for uncoated sheeted products by up to 2 weeks compared to today, as well as improving quality and consistency of sheeting.

Ari Vouti, CEO, commented, “It gives me great pleasure to announce these investments to our valued customers and to confirm our commitment to providing the best quality and service possible. These investments develop our market offer and strengthen our position as the leading producer of uncoated speciality boards and high substance coated folding boxboard”.

BM3 board machine produces a wide range of high quality uncoated speciality boards which will be enhanced by these investments. The end-use areas / products that will benefit include:

• Food service: PankaPlex

• Packaging applications: PankaStar

• Laminated display board: PankaSilk and PankaMax

• Capseals: PankaSeal

• Beer-matt/Coasters: PankaDisc

• Picture frames: PankaSilk and PankaFrame

All products are made of 100% natural virgin fibres, certified for direct food contact and available from a mill with PEFC & FSC certified chain of custody accreditation.

Commercial step for DuraPulp

In collaboration with UK based James Cropper PLC, the speciality paper and advanced materials group, Södra is taking the first commercial step into the international market for bio-composite material DuraPulp.

The collaboration brings together the respective core competences of each organisation and the creation of cross-functional expert teams with the aim to develop DuraPulp solutions for a wide potential range of applications.

"James Cropper's extensive technical competence and global market reach will mean that we will be able to speed up the commercialisation of DuraPulp," said Anna Altner, Södra's Project Manager for DuraPulp.

"Initially, the collaboration will involve niche and high end packaging related applications but we do see wide potential opportunities, including the horticulture market," explained Jacqueline Redman, Strategic Marketing and Innovation Manager at James Cropper.

James Cropper plc has 2 business divisions - the paper division includes the speciality and luxury paper manufacturing and converting business and the non-woven division, Technical Fibre Products which has a holds a niche and leading position in the aerospace, energy, medical, automotive and other sectors.

James Cropper Speciality Papers is one of the world's leading producers of bespoke coloured paper; in the last six months alone it has won two awards for innovative sustainable luxury packaging, most recently in Shanghai.

"We will be exploring these markets to establish if our unique product can offer useful solutions," noted Urban Blomster, Business Development Manager for DuraPulp.

Södra is already involved in technical collaboration with Swt Paper, a privately-owned business development company in Varberg specialising in bespoke paper and cardboard products. This collaboration is making it possible to produce wet-formed DuraPulp demonstrators that showcase the material's potential in bespoke packaging and containers.

DuraPulp is a bio-composite material that consists of specially-selected pulp from Södra Cell and a renewable biopolymer. After additional processing, these two components take on special properties, such as moisture resistance, strength and rigidity.

James Cropper PLC is an advanced materials group with more than 500 employees and turnover in the region of 80 million GBP.

Södra invests to increase pulp production at Mörrum

Södra's Board has decided to invest approximately SEK 700 million to increase pulp production at Södra Cell Mörrum. A new wood-chip plant will be constructed and one of the mill's two pulp lines will be upgraded.

In February of this year, Södra's Board decided to invest just over SEK 4 billion to increase capacity at the Värö pulp mill. Investments are now also being made in the Mörrum pulp mill, where Södra currently operates two parallel pulp lines for the production of softwood pulp and textile pulp (dissolving pulp).

"This is another investment that strengthens our market position and competitiveness for market pulp. The expansion of pulp production is a key part of our Group strategy and a crucial feature of our efforts to develop our operation," said Lars Idermark, CEO of Södra.

The existing facility at Mörrum currently produces a total of 380,000 tonnes annually. The investment is expected to increase production to about 425,000 tpy.

"The investment will enable us to meet the growing demands of our customers for softwood pulp and the increasingly popular textile pulp. It will enhance our energy efficiency, result in even higher quality pulp and improve the work environment," commented Gunilla Saltin, President of the Södra Cell business area.

The project includes a new wood-chip plant with two separate wood lines, one for softwood-chip and one for hardwood-chip production, in addition to a refit of the softwood line, where the existing washing equipment will be replaced.

The first phase of the project is scheduled to be carried out in 2014-15 with completion expected March 2016.

Södra Cell Mörrum currently produces high-quality pulp and is the only Södra mill to produce textile pulp, for which demand is growing rapidly. Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö.

Tieto provides Cham Paper Group Schweiz AG with a Web Trim cloud solution

Tieto provides Swiss paper specialist Cham Paper Group Schweiz AG a cost efficient and easily managed cloud solution for creating and optimizing cutting plans for the pulp and paper industry. Web Trim’s Software as a Service solution allows Cham to focus on its core business without any local installations or need to maintain its own IT infra.

Tieto provides Swiss paper specialist Cham Paper Group Schweiz AG a cost efficient and easily managed cloud solution for creating and optimizing cutting plans for the pulp and paper industry. Web Trim’s Software as a Service solution allows Cham to focus on its core business without any local installations or need to maintain its own IT infra.

Trim is an optimization module of Tieto Integrated Paper Solution TIPS, which is the leading sales, logistics and manufacturing execution system for the pulp and paper industry.

Cham and Tieto have been working together for more than 15 years. Cham had the need to update its old release of TIPS Trim to the newest Trim application. Tieto suggested that Cham start using Web Trim as Software as a Service, which allows the company to concentrate on its core business while Tieto takes care of the IT infrastructure.

“With this solution, we do not have to invest in our own software and hardware. We can focus on our core business and reduce our IT costs significantly. The collaboration with Tieto has been very constructive and efficient. The support after the implementation has been excellent,” says Markus Keiser, Head of Operations at Cham.

With Web Trim’s Software as a Service solution, the application will always be up to date without any upgrade projects or installations.

“This additional delivery confirms our assumption that there is an increasing demand for cloud applications in the paper industry as well,” says Stefanie Richter, Continuous Service Manager at Tieto Germany GmbH.

Metso’s new laboratory analyzer, Metso Fractionator, provides deeper insight into fiber furnish characteristics

New applications increase productivity and profitability through better raw material utilization, improve sustainability and lower production costs

The Metso Fractionator is a new, automated laboratory analyzer that classifies and measures fiber furnish characteristics to optimize paper, board or tissue production. It opens new windows to increase productivity and profitability through better raw material utilization, improve sustainability and lower production costs. The highly repeatable results can significantly reduce trial times and simplify furnish or process troubleshooting.

The new Metso Fractionator automates the tedious Bauer-McNett laboratory fractionation, improving the understanding of the effectiveness of different retention chemicals and allowing to optimize your pulp mixes. It is also possible to separately measure fibers and free ink particles in recycled pulp to evaluate the quality of slushing and deinking processes

The new analyzer replaces time-consuming and laborious laboratory Bauer-McNett analyses and makes it possible to separately measure fibers and free ink particles in recycled pulp to evaluate the quality of slushing and deinking processes. By separating fibers and fillers, the analyzer also improves the understanding of the effectiveness of different retention chemicals. A typical measurement takes only four minutes, with no need for special sample preparation.

Tube flow fractionation utilized

Unlike Metso's other automatic fiber or pulp quality measurements, the new solution utilizes tube flow fractionation to sort furnish particles according to dimension and specific surface area before the measurements.

Tube flow fractionation technology is based on controlling the flow profile, where the flow rate is higher in the center of the tube than near the tube walls. Particles with larger dimensions and specific surface area are captured by the faster moving middle zone of the flow, whereas particles with a relatively small diameter and specific surface area tend to move towards the slower moving zones in the flow. An image analysis at the end of the tube first sees the larger vessel fragments, then fibers, followed by fillers and fines. Additional measurements with optional ink and high-definition fiber cameras are available.

Complementing Metso's fiber analyzer offering

The Metso Fractionator joins three other Metso devices in Metso's growing arsenal of fiber analyzers: the recently introduced and very successful laboratory fiber analyzer Metso FS5, the Metso MAP online furnish analyzer, and the automatic pulp testing analyzer Metso Pulp Expert.

Metso has the world's widest scope of automation solutions and services for the pulp and paper industry - from fiber to print and from single measurements to mill-wide turnkey automation projects. It is the market leader in quality control systems and analyzers as well as in control and on-off valves for this industry sector. Metso's system-independent solutions help customers lower their operating and maintenance costs, and keep their assets' operating value as high as possible.

Metso signs EUR 500 million revolving credit facility

Metso Corporation has signed a new EUR 500 million multi-currency revolving credit facility with a syndicate of 10 relationship banks. The new facility is a refinancing of the Group's existing EUR 500 million facility and will be used for general corporate purposes. The facility has a tenor of 5 years, with two 1-year extension options dependent on the approval of the banks concerned.

Metso Corporation has signed a new EUR 500 million multi-currency revolving credit facility with a syndicate of 10 relationship banks. The new facility is a refinancing of the Group's existing EUR 500 million facility and will be used for general corporate purposes. The facility has a tenor of 5 years, with two 1-year extension options dependent on the approval of the banks concerned.

Commerzbank, Danske Bank and Nordea Bank acted as Coordinating Mandated Lead Arrangers and Bookrunners. The Mandated Lead Arrangers were BNP Paribas, Citigroup, Commerzbank, Danske Bank, HSBC Bank, Nordea Bank, Pohjola Bank and Standard Chartered Bank. Lead Arrangers were Banco Bilbao Vizcaya Argentaria and Svenska Handelsbanken.

Valmet to supply part of a pulp mill capacity upgrade at Portucel Soporcel's Cacia mill in Portugal

Valmet will supply Portucel Soporcel with upgrades for its Cacia mill in Portugal. Valmet's delivery will secure high pulp quality at the new increased production level. The start-up of the renewed plant is planned for the summer 2015. The order is included in Valmet's second quarter 2014 orders received and the value of the order will not be disclosed.

Valmet will supply Portucel Soporcel with upgrades for its Cacia mill in Portugal. Valmet's delivery will secure high pulp quality at the new increased production level. The start-up of the renewed plant is planned for the summer 2015. The order is included in Valmet's second quarter 2014 orders received and the value of the order will not be disclosed.

"This order is a continuation of a long-lasting relationship between Portucel and Valmet. The new lime kiln will support the increased demand for lime, as Cacia mill increases its pulp production," says Stefan Mattsson, Vice President, Fiber Processing Business Unit, from Valmet.

Technical details of Valmet's delivery

Valmet's delivery includes batch cooking, screening, bleaching and a new lime kiln with a capacity of 110 metric tons per day (MTPD). The bleach plant rebuild includes a new TwinRoll press, which replaces two drum filters. The new lime kiln with flash dryer and electro static precipitator (ESP) will be able to burn both heavy fuel oil (HFO) and natural gas.

About Portucel Soporcel Group

The Portucel Soporcel group is Portugal's second largest exporter. The group operates paper and pulp mills in Setúbal, Figueira da Foz and Cacia. The group is a leading European manufacturer of uncoated woodfree (UWF) printing and writing paper and Europe's top producer of BEKP (Bleached Eucalyptus Kraft Pulp). The Cacia mill is located in central Portugal at the heart of the country's largest area of eucalyptus forest. The Cacia pulp mill produces currently 285 thousand tons a year of pulp designed for special applications.

Södra to expand in Falköping

Södra has invested in a new rail terminal in Falköping. This investment is the biggest ever made by Södra in a terminal. It has the capacity to handle around 300,000 m3sub of timber per year which will mainly be transported to Värö and Mönsterås.

Södra has invested in a new rail terminal in Falköping. This investment is the biggest ever made by Södra in a terminal. It has the capacity to handle around 300,000 m3sub of timber per year which will mainly be transported to Värö and Mönsterås.

"We have been working on this project for two years and now we are ready to inaugurate," commented Björn Karlsson, the manager heading up the project at Södra.

Falköping is in a strategic location in Västra Götaland, close to the members' timber which will serve the expansion at the pulp mill in Värö. Rail distribution permits fast, efficient transport providing both environmental and financial benefits.

The Södra rail terminal is located in Marjarp and covers an area of six hectares - the same as twelve football pitches - and the company has established its own timber terminals there. There is also a 24-hour photometering station.

The terminal is sited in a completely new logistics area covering around 70 hectares, and the municipality of Falköping has also established a modern, cost-effective intermodal terminal known as Dryport Skaraborg. This will pave the way for expansion of the Falköpingspendeln container shuttle service between Gothenburg Harbour and Falköping/Skaraborg.

The municipality of Falköping's initiative involves a number of benefits, with access to shared service facilities, including fuelling stations.