Displaying items by tag: sulzer

Sulzer to establish new clean technology research and development center in Singapore for Asia Pacific

Sulzer has signed an agreement with JTC Corporation, the master planner and developer of Singapore’s industrial infrastructure, to build and operate a new research center for its separation technology solutions. The new facility will be located at the Jurong Innovation District’s CleanTech Park, Singapore’s first eco-business park specifically designed to support clean and sustainable manufacturing and urban solutions. Sulzer will focus its research activities on chemical separation processes for circular operations such as polymer recycling and bio-based fuel and polymer production.

Sulzer and JTC Corporation signed a tenancy agreement last week at the site location in CleanTech Park to mark the start of construction. Designed as a self-sustaining ecosystem, CleanTech Park supports the growth of clean technologies and advanced manufacturing by offering large-scale ‘living laboratories’ to test new solutions in real-world conditions. The new Sulzer Chemtech facility will focus on driving development of innovative separation solutions for customer applications in the Asia Pacific region. The test center will start commissioning in Q4/2023 and will be fully operational in Q2/2024.

Executive Chairwoman of Sulzer Suzanne Thoma said: “This investment in a new research and development center for Asia Pacific is a significant expansion to Sulzer’s global footprint and supports our strategic goals of progress, and the development of sustainable solutions. It also shows our commitment to innovation through continuous, significant spending in R&D.”

Executive Chairwoman of Sulzer Suzanne Thoma said: “This investment in a new research and development center for Asia Pacific is a significant expansion to Sulzer’s global footprint and supports our strategic goals of progress, and the development of sustainable solutions. It also shows our commitment to innovation through continuous, significant spending in R&D.”

Uwe Boltersdorf, Sulzer Chemtech division president, added: “Several Sulzer Chemtech separation technologies are enabling the transition towards more eco-conscious, circular operations. With our clean technology R&D center in Singapore we continue to anticipate and address market needs and enable sustainable manufacturing in the region.”

Lim Junwei, Director of Urban Solutions & Construction Cluster, JTC, said: "We welcome Sulzer to the growing ecosystem for advanced manufacturing, clean technologies and urban solutions at CleanTech Park. Sulzer's investment in CleanTech 3 to develop sustainable separation technologies dovetails with JTC’s vision of pushing the boundary for green manufacturing at CleanTech Park and the larger Jurong Innovation District. CleanTech Park provides a conducive environment for Sulzer’s research into new and sustainable separation solutions and we look forward to growing our partnership."

Sulzer is a global leader in fluid engineering and chemical processing applications. We specialize in energy-efficient pumping, agitation, mixing, separation, purification, crystallization and polymerization technologies for fluids of all types. Our solutions enable carbon emission reductions, development of polymers from biological sources, recycling of plastic waste and textiles, and efficient power storage. Our customers benefit from our commitment to innovation, performance and quality through our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2022, our 12’900 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Sulzer gains 2023 Top Employer recognition in multiple countries

Sulzer has been named a 2023 Top Employer in Brazil, China, Switzerland, the UK and the USA, demonstrating its commitment to best HR policy and people practices globally. The Top Employers Institute surveyed five key countries for Sulzer, also rating and independently auditing them against an international standard. Sulzer scored an average of 85% across the board, with an exemplary 95% in Sustainability.

Designed to positively impact the global employee experience at work, Top Employers Institute rates applicant companies in a number of HR domains. These cover topics such as People Strategy, Work Environment, Learning, Wellbeing, Sustainability, Diversity & Inclusion and more. Following extensive assessments, Sulzer achieved a remarkable average score of 85% across its five certified country locations. In the area of Sustainability, the company’s strategic commitment to enabling sustainable practices is notably reflected in its exemplary score of 95%.

“We strive to make a difference at Sulzer, and we empower our employees to do so,” said Executive President Suzanne Thoma. “We are committed to do everything we can to offer our employees a safe, inclusive and meaningful work environment in which we can thrive.”

“We strive to make a difference at Sulzer, and we empower our employees to do so,” said Executive President Suzanne Thoma. “We are committed to do everything we can to offer our employees a safe, inclusive and meaningful work environment in which we can thrive.”

Issued by the Top Employers Institute, Top Employer recipients are surveyed, rated and independently audited against an international standard. Sulzer scored an average of 85% across the board, with an exemplary 95% in Sustainability.

Top Employers Institute CEO David Plink says: “This year’s Top Employers have shown that they care for the development and well-being of their people. By doing so, they collectively enrich the world of work. We are proud to announce and celebrate this year’s group of leading people-oriented employers: the Top Employers 2023.”

Sulzer is a global leader in fluid engineering and chemical processing applications. We specialize in pumping, agitation, mixing, separation, purification, crystallization and polymerization technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of over 180 world-class manufacturing facilities, engineering and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Sulzer to write off assets in Russia and Poland

Following the Board’s decision to initiate the process of exiting the Russian market and the closing of the Polish businesses, the company has decided to write off most of its assets in both countries. After careful analysis of all options, Sulzer expects a one-time impact in the range of CHF 125m to CHF 135m at current foreign exchange rates. CHF 125m will be recognized in H1 of 2022.

Following the Board’s decision to initiate the process of exiting the Russian market and the closing of the Polish businesses, the company has decided to write off most of its assets in both countries. After careful analysis of all options, Sulzer expects a one-time impact in the range of CHF 125m to CHF 135m at current foreign exchange rates. CHF 125m will be recognized in H1 of 2022.

The one-time asset write-offs will have no significant impact on Sulzer’s operational results, however on Net Income, which was CHF 86m for H1 2021 and CHF 141m for the full year, respectively. Sulzer will report its H1 results on July 29, 2022.

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Investor Relations: Christoph Ladner, Head of Investor Relations

Phone +41 52 262 30 22, This email address is being protected from spambots. You need JavaScript enabled to view it.

AHLSTAR peak pumping performance

Responding to our customers’ needs, we have developed additional features for the AHSTAR A pump series, and new options are also now available for demanding industries.

In the new ASTM A395 60-40-18 construction, the volute case and case cover of the pump are made of ductile iron. AHLSTAR A pumps in ductile iron have a maximum working pressure of 16 bars, with a temperature limit of 180°C.

Furthermore, a heating jacket option is available. The concept consists of a heating jacket and a jacketed case cover. The heating jacket is easy to install and maintain, providing evenly distributed heating across the entire pump. The solution is cost-effective because a standard AHLSTAR A pump can be used, and the same spare parts as for other AHLSTAR A pumps in the mill will fit. Proper temperature of the pumped liquid prevents undesired sedimentation, crystal growth, or solidification of the fluid handled.

Moreover, a case cover with internal recirculation has been developed for AHLSTAR pumps. In this design, an internal recirculation flushing fluid channel is integrated inside the case cover, enabling seal flushing without external piping.

Along with the new features, our AHLSTAR pumps have been assigned the Food Contact Materials Certificate (EC) 1935/2004. Food contact materials (FCMs) are widely used in food transfer equipment, packaging, etc. AHLSTAR pumps compliant with this regulation are the ideal solution for various food and beverage applications, from raw material production to processing and packaging.

Read more about the AHLSTAR A peak performance process pumps and their new features in our brochure. Learn more about the smart, cost-competitive and safe heating jacket in our flyer.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centres across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Flow Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Sulzer to exit the Russian market

The Sulzer Board of Directors has decided to initiate the process of exiting the Russian market. The sales process will begin with immediate effect and follows Sulzer’s announcement earlier in the year that it had already significantly reduced business activities in Russia.

The Sulzer Board of Directors has decided to initiate the process of exiting the Russian market. The sales process will begin with immediate effect and follows Sulzer’s announcement earlier in the year that it had already significantly reduced business activities in Russia.

The Board regrets the necessity of this decision after decades of operations in Russia, but after careful review of the possible options, concludes that it is the best solution for all the stakeholders.

Sulzer expresses its gratitude to all employees globally for their outstanding engagement in these challenging times and is fully committed to continue supporting its 300 employees in Russia through the process.

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

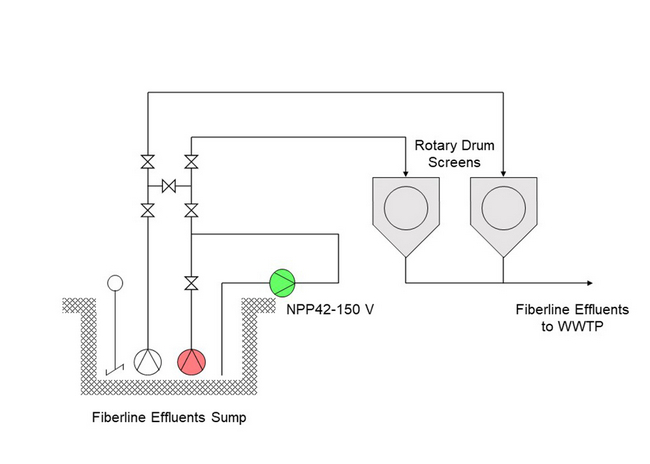

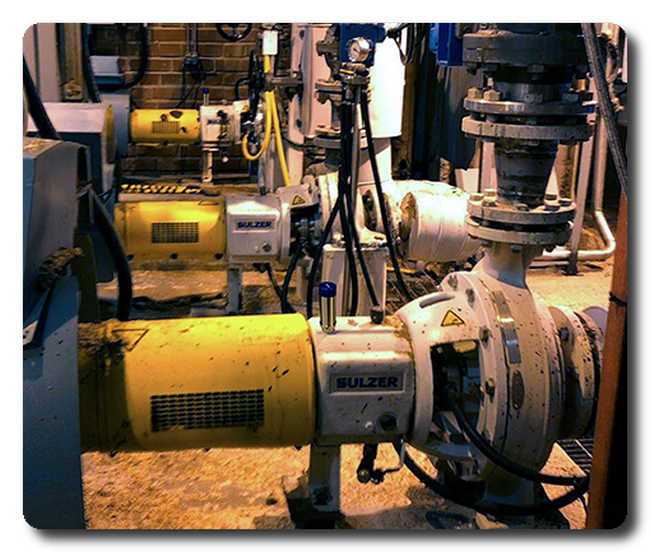

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill

A cardboard mill customer suffered from regular pump breakdowns in the fiber line effluent sump. Sulzer replaced the two existing submersible pumps by one non-clogging AHLSTAR NPP42-150 pump equipped with a Sulzer Ejector. After more than two years in operation, there has been no disturbance.

The challenge

This European mill produces 240’000 tons of cardboard from wastepaper per year. The cardboard is used to make plasterboard and for packaging. Various effluents from the mill are collected in different steps of the process and then treated in a modern, integrated wastewater treatment plant.

The main effluents from the fiber line process are collected in a large, 2.5 m deep sump prior to being pumped further through rotary drum screens and sent to the wastewater treatment plant. The liquids in the sump have varying char- acteristics and can be highly polluted with all kinds of solid particles (fibers, clips, tapes, ropes, etc.).

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill.

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill.

The initially installed sump pumps failed frequently. The two non-Sulzer submersible pumps were regularly clogged, disturbing the whole process and generating high repair costs. The customer decided to look for a more reliable pumping system and asked Sulzer for help.

The solution

After thorough discussions, the client and Sulzer agreed on a radical alternative: one dry-installed process pump with a complete priming system. An AHLSTAR NPP42-150 non-clogging pump unit with ejector soon replaced the fail- ing submersible pumps. The installation was fast and easy, and only minor piping modifications were needed.

The NPP42-150 pump unit is located above the liquid level in the sump. At each pump start, a fully automated priming is done in a few seconds with the Sulzer Ejector package. The NPP42-150 pump has been running smoothly for more than two years now, without any blockage. One of the initial submersible pumps was removed from the sump and the other one is kept as standby, only being used from time to time in parallel with the NPP42-150, when a maximum drainage flow is required.

Customer benefit

The AHLSTAR non-clogging NPP42-150 with vortex impeller is the right pump for sump applications where liquids are heavily polluted with debris and other big solid particles.

The previously installed submersible pumps were of cast iron, whereas all the wetted parts of the NPP42-150 pump are of duplex stainless steel. This material is ideal for liquids which can be both corrosive and abrasive. It ensures a much longer pump service life with minimum wear of parts.

The NPP42-150 pump unit is above the sump liquid level, and this makes all maintenance operations rapid and safe. Several other AHLSTAR process pumps are installed in the cardboard mill. The inventory control of spares is therefore easy.

Sump pumping diagram.

Sump pumping diagram.

The Sulzer Ejector is an inexpensive and simple device powered by compressed air from the mill network. It allows full priming of the inlet pipe and pump in a few seconds. After priming, the ejector is stopped, and the NPP42-150 pump starts running. No compressed air is required during normal pumping operation.

The Sulzer Ejector was delivered with an automation package that makes the whole priming operation extremely simple

“The AHLSTAR pump with a Sulzer Ejector is the prime solution!” - Fabrice Martin, Business Development Manager

Product data

AHLSTAR non-clogging pump unit for wastewater sump (pit depth 2.5 m)

| Flow | 350 m³/h |

| Head | 20 m |

| Speed | 1’000 rpm |

| Motor power | 55 kW |

| Impeller | Vortex – 340 mm |

| Max. solids passage | 80 mm |

| NPSHr | 5 mcL |

Complete Sulzer Ejector package including:

- Ejector

- Valves with actuators for motive air and ejection suction pipe

- Level control switch

- Control box with logic

Read our ejector brochure for further information.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Flow Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Sulzer’s business in Poland impacted by local sanctions

Sulzer has to temporarily suspend the activities of its two legal entities in Poland due to sanctions levied by the Polish government. The Polish sanctions apply to Sulzer’s minority shareholder, Viktor Vekselberg, and have been expanded over Sulzer’s two Polish entities, even though Mr. Vekselberg has no control or ownership of any Sulzer entity and is deprived of all his economic rights at Sulzer. The company is not sanctioned in any other country or legal entity and is consequently able to continue to develop its business globally. The potential impact on sales, if the suspension were to last, is limited to CHF 21m, representing 0.6% of Sulzer's total sales in 2021.

It is Sulzer’s firm belief that the sanctions against its two entities in Poland are erroneous. Sulzer therefore continues to petition for urgent removal of its entities Sulzer Pumps Wastewater Poland and Sulzer Turbo Services Poland from the Polish sanctions list. Interactions with the Polish government are ongoing, with the support of representatives of the Swiss government administration.

It is Sulzer’s firm belief that the sanctions against its two entities in Poland are erroneous. Sulzer therefore continues to petition for urgent removal of its entities Sulzer Pumps Wastewater Poland and Sulzer Turbo Services Poland from the Polish sanctions list. Interactions with the Polish government are ongoing, with the support of representatives of the Swiss government administration.

Based on an OFAC (Office of Foreign Assets Control) license granted in 2018, Sulzer is free to operate globally, independent of its sanctioned minority shareholder.

Sulzer has a total of 192 employees in Poland, all of whom are unfortunately affected by the Polish sanctions. We deeply regret this devastating situation, and the wide-ranging effects that the suspension is having on our employees and their families, as well as on the network of trusted customers, suppliers and partners that we have built up over many years of business in Poland.

Sulzer will continue to do everything in its power to petition for a removal from the sanctions list, while fully complying with the sanctions currently levied against the two entities. Sulzer Group continues to provide support to the families impacted by the local Polish sanctions.

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Sulzer launches the world’s biggest medium-consistency pump

Sulzer announces the launch of the world’s biggest medium-consistency pump, the MCE93-400. The new MCETM pump size is Sulzer’s answer to the customers’ demand for bigger production rates in pulp mills.

The MCETM pump is being tested at Sulzer’s full-scale R&D center in Kotka, Finland.Pumping of liquids with a high dry solids content, referred to as medium consistency (MC), is essential for the processes in the pulp and paper industry. The proven MCE™ pumps from Sulzer achieve a unique and reliable performance level when it comes to the capacity range as well as to the temperature and pressure of the pumped medium.

The MCETM pump is being tested at Sulzer’s full-scale R&D center in Kotka, Finland.Pumping of liquids with a high dry solids content, referred to as medium consistency (MC), is essential for the processes in the pulp and paper industry. The proven MCE™ pumps from Sulzer achieve a unique and reliable performance level when it comes to the capacity range as well as to the temperature and pressure of the pumped medium.

In recent years, the production rates of the industry have increased remarkably. Sulzer developed the biggest MCETM pump size for a customer project with record-breaking values. The capacity of the pump reaches up to 10’000 ADMT/d (air dry metric tons per day), the flow up to 940 l/s and the head up to 180 m. The MCETM pump is designed for the common consistency range of 10-12% and a pressure rating of 25 bar.

“The new MCE93-400 medium-consistency pump size is an excellent addition to Sulzer’s MC equipment offering. It has been designed to operate very efficiently, thus saving energy, water, and chemical costs in the pulp and paper mill processes. The unique and innovative design features of the pump minimize its life cycle costs,” says Jussi Heinonen, Product Manager for MC equipment at Sulzer.

Sulzer’s reliable MCE™ centrifugal pumps are suitable for the most demanding process applications to pump medium-consistency fibrous suspensions, slurries with a high dry solid content, and media with a high gas content. They cover all medium-consistency applications for pulp, paper, and board as well as related biomass and biofuel applications.

The MCE93-400 pumps are manufactured at Sulzer’s factory in Kotka, Finland. The first big MCE™ pumps have been dispatched to a major pulp manufacturer in South America.

Read more about the Sulzer MCE™ pump range on our website

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

The Flow Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Pioneer in plastic-free packaging one of the first to install Sulzer’s wireless condition monitoring

Kotkamills is a forest products company based in Kotka, Finland. The company specializes in consumer boards, laminating paper, and sawn products – and is an innovative pioneer in introducing new technologies. Kotkamills actively accelerates the adoption of plastic-free options in convenience packaging. The Sense condition monitoring system has been employed at Kotkamills from July 2019, ever since the first stages of the solution.

The system monitors the condition of the pumps in the pulp production line.

The system monitors the condition of the pumps in the pulp production line.

The challenge

Kotkamills was one of the first customers to use Sulzer Sense in their process after it was launched in 2019. The system monitors the condition of five process pumps and one medium-consistency (MC) pump in the pulp production line.

The system consists of one gateway designed for industrial conditions, located in the process area, and six sensors installed in the bearings of the monitored equipment. The devices are battery-powered and operate in a wireless mesh network.

Sulzer Sense measures vibration and temperature every 30 minutes. The gateway is connected to the Internet / Sulzer’s cloud service via a cellular connection. The monitored devices are within a radius of about 10 meters from each other. This allows for an excellent network and the use of a single gateway.

The solution

The sensors are installed in the bearings of the monitored pumps.The commissioning of the condition monitoring system was quick, easy and effortless and did not require special skills from the installer. The mobile app provided by Sulzer for the deployment of the system is unambiguous and easy to use.

The sensors are installed in the bearings of the monitored pumps.The commissioning of the condition monitoring system was quick, easy and effortless and did not require special skills from the installer. The mobile app provided by Sulzer for the deployment of the system is unambiguous and easy to use.

The Sulzer Sense monitoring device measures machine vibrations and temperature to detect possible imbalance, misalignment, looseness, and bearing wear. It helps to identify changes in equipment condition parameters and indicates potential faults at an early stage, thus supporting predictive maintenance.

The cloud service provides the customer with easy access to device information. Through the cloud service, the customer can monitor the condition of the devices and view hardware trend information anywhere and anytime.

Customer benefit

- In addition to the advantages of continuous monitoring, one of the most significant benefits to the customer is access to detailed equipment information such as spare parts lists and product documentation through the service. For maintenance and repair work, there is no need to look in the archive for instructions and drawings.

- Sulzer Sense is suitable for all pumps, agitators, mixers and motors regardless of the type or brand in all industries.

"The system has worked reliably, and the measurement results are in line with our own reference measurements." Harri Carling, Supervisor, Condition Monitoring and Reliability at Kotkamills.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2019, our 16’500 employees delivered revenues of CHF 3.7 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Pumps Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Building success together

Businesses in Brazil benefit from Sulzer engineering solutions

Since 1948 Sulzer has established a network of technically advanced repair and maintenance facilities. Today, service centers specializing in the repair and maintenance of all types of rotating equipment support local industry.

Brazilian service centers can deliver retrofit projects that re-engineer pumps to perform more efficiently

Brazilian service centers can deliver retrofit projects that re-engineer pumps to perform more efficiently

The Brazilian service centers are positioned to deliver quality equipment and maintenance services using high-precision instruments and machine tools. The experienced and dedicated teams of engineers provide flexible, round-the-clock support to customers in many industrial sectors.

Sulzer provides tailored engineering solutions to key businesses in the area, such as water, pulp and paper, refineries, hydrocarbon processing, fertilizers, power generation and more general industry. Every day, the teams take on the challenges posed by customers to deliver the best quality repairs that offer improved reliability and productivity.

To see how Sulzer can support the region watch the latest overview video:

Sulzer supports Brazilian customers with high quality pumping solutions as well as its rotating equipment services for all industries. Specialist designers can deliver retrofit projects that re-engineer large pumps to perform more efficiently and offer better productivity.

Marcelo Alves, President South America – Rotating Equipment Services and Managing Director at Sulzer in Brazil says “We have experience in working on gas turbines, industrial compressors, large scale pumping installations as well as motors and generators. From installing new equipment to repairing and maintaining existing assets, we have the skills and expertise to support the Brazilian industry.

“Whatever the project, our engineers have the support of the wider Sulzer organization, which has extensive knowledge and resources that offer cutting-edge solutions. In all of Sulzer’s facilities, customers are welcomed to discuss challenges and inspect on-going work, keeping communication at the heart of every project.”

Sulzer’s global network of 180 production and service sites distributed across more than 50 countries, including Argentina, Chile, Colombia and Venezuela, makes it possible for the company to support Brazil’s global competitiveness in its key sectors with state-of-the-art engineering solutions. Brazilian businesses can benefit from a wide range of services to boost operational efficiency while minimizing their downtime.