Ianadmin

South Korean company SsangYong C&B Inc invests in new Toscotec tissue machine

SsangYong C&B Inc., a South Korean company headquartered in Jochiwon-eup, Seong ,Korea has closed the purchase of a new tissue machine with a production capacity of 91 tpd from Toscotec. The machine will be installed in Jochiwon plant and is expected to come on stream within the end of 2013.

Ssangyong C&B Inc. produces and markets paper and tissues, such as facial, bath, kitchen towels, adult diapers, and household products. The company was founded in 1980 and is owned by Mr. David Kim. Ssangyong C&B Inc. operates as a subsidiary of Monalisa Co. Ltd. Today is one of the biggest tissue producer and converter in South Korea with a strong popular brand in the country. The meaning of Ssangyong is “two dragons” while C&B states for “clean and best”

The group owns three tissue plants in different cities: one tissue production and converting plant located in Jochiwon, one tissue and converting plant situated in Jeonju and a converting plant located in Daejon.

Today the total production capacity is 130.000 tons/year, reached with seven tissue machines: four of them are located in Jochiwon plant, while three other ones are in Jeonju plant.

The new Toscotec AHEAD 1.5S tissue machine is a crescent former with single-layer headbox, double press configuration, a Steel Yankee Dryer TT SYD-12FT and a Reel section TT Reel-P.

The scope of supply includes also high efficiency gas fired hood, steam & condensate system and a steam recovery boiler fed by hood exhaust air provided by Toscotec associate Milltech. A shaft puller for expandable shafts is also included in the supply.

The machine operating speed is 1700 mpm with a net web width of 2730 mm.

The project will be managed by Toscotec and Milltech including also engineering and overall services and will be focused on energy saving concepts.

Tissue and hygiene in South Korea recorded retail value growth in 2011 due to growing demand for premium products with specialized functionality, antibiotic ingredients and better quality raw materials. This rise in demand for higher priced brands boosted overall retail value growth. The new investment from SsangYong C&B Inc. with state of the art Toscotec technology will help the Company to maintain its leading position in this growing and challenging market.

Volga and Turinskiy pulpmills increased sales

Volga and Turinskiy pulpmills increased sales, but lowered net profit in January-September 2012

Volga and Turinskiy pulpmills increased sales, but lowered net profit in January-September 2012

Large Russian forest industry companies continue to publish quarterly reports. Turinskiy pulpmill (Sverdlovsk region) reported growth of sales by 2.7% year-on-year to 863.6 million Rubles (€21.6 million).

Net profit, however, declined by 41.2% down to 20.65 million Rubles (€0.51 million).

Sales of Volga newsprint mill (Nizhniy Novgorod region) amounted to 7.88 billion Rubles (€197 million), which is 10.8% higher year-on-year. Mill’s net profit, however, also fell (2.6 times down to 21.19 million Rubles – €0.53 million).

Log export from Russia declined by 21% to 12.5 million

Log export from Russia declined by 21% to 12.5 million cu m in 9 months of 2012 – WhatWood Analytics

Log export from Russia declined by 21% to 12.5 million cu m in 9 months of 2012 – WhatWood Analytics

Moscow, November 29. Physical volume of roundwood export from Russia declined by 21% in January-September 2012 year-on-year down to 12.5 million cu m, as said in the report published by WhatWood analytic service. Export cost declined by 27.3% on-year down to $1.1 billion.

Negative growth of log export from Russia was due to falling deliveries to three key markets, namely China (-26%), Finland (-9.6%) and Japan (-28.4%). Share of these three countries in total export amounts to 90%.

"Falling demand was also affected by decrease in harvesting volume (-2.3% in January-September 2012 year-on-year) and new export delivery terms after Russia’s WTO accession. Many Russian exporters came across difficulties in getting their licenses", as said in WhatWood Analytics report.

To read full 40-page version of WhatWood’s analytic report please contact our analysts at This email address is being protected from spambots. You need JavaScript enabled to view it..

Sonoco Recycling and Richland County Accepting Additional Materials

Sonoco Recycling, LLC, a unit of Sonoco, has invested $4 million in its Columbia, S.C., materials recovery facility (MRF), allowing the facility to accept additional types of materials. Because of this, Richland County residents will now be able to recycle more of their household materials such as composite cans, glass, magazines and other types of plastics.

Sonoco Recycling, LLC, a unit of Sonoco, has invested $4 million in its Columbia, S.C., materials recovery facility (MRF), allowing the facility to accept additional types of materials. Because of this, Richland County residents will now be able to recycle more of their household materials such as composite cans, glass, magazines and other types of plastics.

Sonoco Recycling has added three sorting screens for corrugated cardboard and paper sorting, an optical sorter to retrieve plastic, and a new glass crusher that allows the facility to collect whole and broken glass bottles, jugs and jars.

"Sonoco has always prided itself on 'closing the loop,'" said Ray Howard, general manager, Sonoco Recycling. "We use recycled materials in our products, which are then recycled by the consumer and come back to us for processing. With this upgrade, we're now able to recycle even more of the packaging produced by Sonoco, in addition to the other items we collect that aren't produced by us."

Derek Trader, division marketing manager, Global Rigid Paper and Closures, agreed, "Sonoco is one of the largest providers of composite can packaging in the world for products such as coffee or Pringles® potato crisps. The ability to both produce and recycle this item is exciting for us and further demonstrates the Company's commitment to sustainable business practices."

New items accepted:

- Composite cans – cardboard containers with metal bottoms, such as coffee or Pringles containers

- Paper – office paper, junk mail, magazines, chipboard, wet-pack boxes and gable-top cartons

- Plastics – most plastics #1-7, including plastic bottles, jugs, jars and containers like yogurt cups and margarine tubes, milk crates, curbside recycling bins and carts, laundry baskets, plastic lawn furniture and toys, and five-gallon buckets

- Glass – whole and broken glass bottles, jugs and jars

The facility is still unable to accept tissue paper, paper plates and cups, waxed cardboard, plastic bags and films, containers that have held toxic substances, metal lids on glass or plastic items, glass cups or plates, window glass or ceramics.

A recycling leader with 50 locations and expertise worldwide, Sonoco Recycling annually collects approximately 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers.

Sonoco Recycling currently operates six material recovery facilities (MRFs) and serves nearly 150 communities in which curbside-collected residential and commercial materials are processed. The Company also provides recycling programs which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the U.S.

Two weeks until the opening of IPX India

Adforum and Inter Ads-Brooks welcome you to the new meeting platform for the Indian Pulp and Paper industry. Taking place in the Bombay Convention and Exhibition Centre on December 13-15, 2012, IPX India is an exhibition and conference focusing on the fastest growing pulp and paper industry in the world today! At IPX India you will meet Indian and International suppliers of machinery, equipment, accessories and raw material for the pulp, paper and allied industries.

The conference will be held on a stage in the middle of the exhibition floor making the conference available to everyone visiting IPX India, meaning no more conference fees and an easier way for all participants to meet. Business related seminars and social activities will make sure that you, as a visitor, will get the most out of your IPX India experience.

The main theme of the two day long technical conference, Paper Industry – a world of opportunities, will focus on the possibilities and challenges facing the current and future Indian pulp and paper industry. Key note speaker of the event is Mr. Timo Suhonen, Poyry Management Consulting OY, Finland. Other international speakers include names like Mikael Åbacka and Mikael Svedman from Finland and Dr. Martin Ragnar from Sweden. Through lectures, panel discussions and case studies, renowned Indian and International experts and senior industry professionals will give their views on different themes within the main focus area. For full updated conference programme, please click here.

To pre-register your visit and read more about the event, please visit www.ipxindia.com. For questions, welcome to contact This email address is being protected from spambots. You need JavaScript enabled to view it.

The combination between Billerud and Korsnäs is now completed and BillerudKorsnäs is formed

The combination of Billerud and Korsnäs was completed today 29th Nov 2012. The new company BillerudKorsnäs will be a leading player in primary fibre-based packaging material and solutions. In connection with the combination, the Board of Directors of BillerudKorsnäs has decided upon new financial targets.

The combination of Billerud and Korsnäs was completed today 29th Nov 2012. The new company BillerudKorsnäs will be a leading player in primary fibre-based packaging material and solutions. In connection with the combination, the Board of Directors of BillerudKorsnäs has decided upon new financial targets.

As previously announced, Billerud entered into an agreement with Kinnevik on 19 June 2012 to acquire all shares in Korsnäs. The conditions of the acquisition has now been met and the combination between Billerud and Korsnäs was completed today by Billerud acquiring all shares in Korsnäs. In connection with the combination, the Board of Directors of BillerudKorsnäs have decided, with the authorisation of the extraordinary general meeting on 14 September 2012, to execute a share issue with preferential right for the shareholders. Information about terms and conditions regarding the rights issue will be announced in a separate press release, sent immediately following this press release.

Consideration

The consideration for the acquired shares shall according to the combination agreement consist of newly issued shares in BillerudKorsnäs corresponding to an ownership share of 25.1% [1] of the votes in the company, cash payment which, at the date of the agreement, was estimated to SEK 3 200 million and the assumption by BillerudKorsnäs of the existing external net debt of Korsnäs which, at the date of the agreement, was estimated to SEK 5 650 million.

At the day of completion an issue to Kinnevik of 34 551 592 shares has been implemented corresponding to an ownership for Kinnevik of 25.1% of the votes and an increase in BillerudKorsnäs’ share capital in the amount of SEK 255 153 438. The cash payment has been subject to a preliminary adjustment based on estimated levels of external net debt, working capital, and investments as of the date of the completion of the combination. The cash consideration was adjusted to SEK 3 253 million [2], as estimated external net debt in Korsnäs as of 29 November 2012 amounts to SEK 5 799 million [3], a deviation of SEK 149 million (compared to the calculated level of net debt on the day of signing of the combination agreement of SEK 5 650 million) and as estimated working capital in Korsnäs as of 29 November is SEK 202 million higher than an agreed, normalised level. The total consideration amounts to SEK 11 358 million (on a debt free basis and based on Billerud’s closing share price on 28 November 2012). Further adjustment regarding the cash payment may occur depending on actual levels of external net debt, working capital and investments as of the transaction’s completion date.

Of the cash payment SEK 500 million has been paid in the form of a vendor note to Kinnevik that will be used to subscribe for shares in the rights issue announced by the Board of Directors today (please see separate press release).

Change of company name

The change of company name from Billerud Aktiebolag (publ) to BillerudKorsnäs Aktiebolag (publ) is, as a result of Billerud acquiring the shares in Korsnäs, now effective.

New Board of Directors

In accordance with the resolution by the extraordinary general meeting on 14 September 2012, the changes regarding the Board of Directors are effective as a result of the completion. BillerudKorsnäs’ new Board of Directors as of today, until the next annual general meeting, consists of Hannu Ryöppönen (Chairman), Mia Brunell Livfors, Lennart Holm, Jan Homan, Gunilla Jönson, Michael M.F. Kaufmann, Wilhelm Klingspor and Mikael Larsson as well as the employee representatives Helén Gustavsson and Kjell Olsson (with deputies Kurt Lindvall and Tobias Söderholm).

The new Board of Directors has at its statutory meeting resolved, among other things, to appoint Mikael Larsson (Chairman), Lennart Holm and Jan Homan as members of the Audit Committee. The Remuneration Committee consists of Hannu Ryöppönen (Chairman), Mia Brunell Livfors and Michael M.F. Kaufmann. Lennart Holm (Chairman) and Hannu Ryöppönen have been appointed as members of the Integration Committee, a committee formed specifically for the integration between Billerud and Korsnäs.

Senior management

The new Board of Directors has at its statutory meeting resolved Per Lindberg as President and CEO, and appointed Christer Simrén as executive vice president and COO of BillerudKorsnäs. For further information about other changes to senior management, please visit www.billerudkorsnas.com.

[1] Kinnevik’s owner share will amount to 25% if the dilution from Billerud's long-term incentive programs (LTIP) is included in the calculation of the number of Shares.

[2] In addition Billerud has paid SEK 2 579 million in compensation for Korsnäs’ receivable on Kinnevik of the equivalent amount, which has been settled in conjunction with completion of the Transaction.

[3] Excluding MSEK 60 in dividend received from Bergvik Skog.

Financial targets for BillerudKorsnäs

The Board of Directors of BillerudKorsnäs has decided today, on the following financial targets for the company:

|

Target |

Description |

|

Operating margin |

Over a business cycle, the operating margin should on average exceed 10%.BillerudKorsnäs operates in an industry that historically has tracked a cyclical pattern, with corresponding variations in earning capacity. |

|

Return on capital employed |

Over a business cycle, the return on capital employed (ROCE) should on average exceed 13%.BillerudKorsnäs shall ensure a return corresponding to the shareholders’ return expectations while the cost for the company’s debt is covered with a margin. |

|

Net debt/equity ratio |

The net debt/equity ratio should be below 0.9.BillerudKorsnäs’ business is influenced to a large extent by the general economic climate, which means that the operating risk is considerable. Strengthening the financial position in good years is therefore essential in order to sustain the group in bad years. |

|

Dividend policy |

Over a business cycle, the dividend should on average amount to 50% of net profit.The dividend paid to shareholders will be dependent on, among other factors, BillerudKorsnäs’ profit level, financial position and future development opportunities. |

2013 financial calendar

BillerudKorsnäs financial reporting dates during 2013 are as follows:

Year-end report for 2012 8 February 2013

Interim report January-March 2013 23 April 2013

Interim report January-June 2013 18 July 2013

Interim report January-September 2013 30 October 2013

Annual general meeting 7 May 2013

Nomination committee for the annual general meeting 2013

The nomination committee for the annual general meeting 2013 in BillerudKorsnäs consists of the following members:

Mia Brunell Livfors, Investment AB Kinnevik, chairman

Michael M.F. Kaufmann, Frapag Beteiligungsholding AG

Frank Larsson, Handelsbanken fonder

Björn Franzon, Swedbank Robur fonder

The information is such that Billerud AB (publ) is obligated to publish under the Swedish Securities Market Act. Submitted for publication at 15.00 CET, 29 November 2012.

BillerudKorsnäs in brief

BillerudKorsnäs offers primary fibre-based packaging materials and smart solutions for the packaging needs of today and tomorrow. The overall goal is to generate profitable growth. BillerudKorsnäs has the customers in focus using high quality materials, knowledge of the whole processing chain and a global network enabling accessibility. BillerudKorsnäs has a leading position within several segments, in primary fibre-based materials for consumer packaging as well as for industrial appliances. The purpose of the company is to create value that strengthen customer brands and competitiveness, thus ensure the company’s position as the natural partner in smarter packaging. Approximately 75% of sales in BillerudKorsnäs are consumer related, Food & Beverages is the largest segment. Europe is currently the most important market to BillerudKorsnäs. The company’s annual turnover is approximately SEK 20 billion.

Three business areas

The Packaging Paper business area offers customers technically advanced primary fibre-based kraft and sack paper, as well as smart solutions in function, design and material choice. All grades are strong and have excellent printability and runability which contributes to increased conversion process productivity for the customers.

The Consumer Board business area develops and sells high-quality board made from primary fibre to several segments, including beverages and consumer goods, which demand efficient, attractive and functional packaging. The business area also offers delivery service and application expertise solutions to customers.

The Containerboard business area offers containerboard made from primary fibre that meets stringent demands on strength, hygiene and printing. The strong material contributes with lighter packaging resulting in lower emissions during transports. Advice on packaging optimisation helps brand owners identify the right packaging for items and logistics chains.

Approximately 4 400 employees

On 30 September 2012 Billerud had 2 490 employees and Korsnäs 1 883 employees. Consequently BillerudKorsnäs has approximately 4 400 employees in total.

Eight production units

Paper and board production takes place at eight production units – Gävle, Gruvön, Frövi/Rockhammar, Skärblacka and Karlsborg in Sweden, Pietarsaari and Tervasaari in Finland and Beetham in the UK.

The total production capacity is approximately 2 900 ktonnes annually.

For further information visit: www.billerudkorsnas.com

For further information, please contact:

Per Lindberg, president and CEO, +46 (0)8 553 335 00

Christer Simrén, vice president and COO, +46 (0)26 15 10 00

Sophie Arnius, IRO, +46 (0)8 553 335 24, +46 (0) 70 590 80 72

BTG Instruments opens new Service Center in India

BTG Instruments officially opened a Service Center in Hyderabad's Begumpet on November 21, 2012 to fully support customers in the growing Indian paper industry. The opening ceremony was conducted according to Indian tradition with a puja ritual for deity Ganesh with garlands, lighting the lamp, incense stick, coconut breaking, and food offerings for blessings.

This occasion also marked the start for a first service training in the facility which will further offer accredited repair, maintenance, upgrade and calibration of BTG sensors, laboratory devices and analyzers.

A laboratory is available for sample testing and user training.

The Indian center is staffed by experienced BTG service engineers handling inside and outside service, spare part requests and all application and sales inquiries.

The paper industry in India has a bright future and BTG is growing with it.

BTG Instruments India is a division of Spectris group, India; the Hyderabad office is also home for another Spectris company PANalytical.

For more information please contact

---------------------------------------------------

BTG Instruments

Office 417, 4th Floor

Block –III, White House,

Begumpet

Hyderabad-500016, India

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

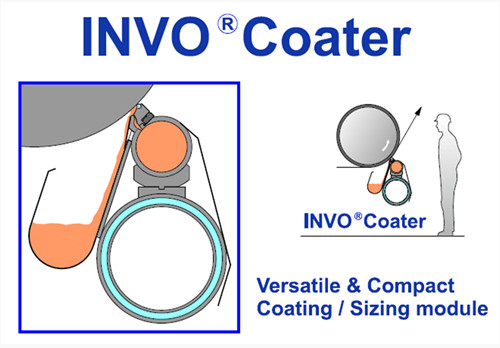

The New INVO® Coater from UMV

One of the latest UMV inventions is the INVO® Coater. Customers often have very limited space for rebuild and upgrades of existing coating units. Capital Expenditure constraints are also a common part of the reality for the lion part of our customers.

UMV has therefore designed and launched the compact and versatile INVO® Coater module.

“-Our guideline in this New Product Development has been that Minor Capex should give Major Effects, says Håkan Karlsson, Vice President Operations of UMV.

This short dwell application unit can be installed in pre-metering position or to meter directly on the web.

INVO® Coaters can run with grooved or smooth rod and of course with INVO® Tip, UMVs own patented and award winning metering element.

INVO® Coaters come with a jet applicator that has UMV’s unique chamber design, ensuring uniform MD and CD distribution. The jet applicator rests on a support beam with special features assuring exact positioning and stability.

INVO® Coaters can also be equipped with a profiling system.

The Black Box Project - Next Stop Moscow

At an event in Moscow in December a seventh box will be presented, this time by the Swedish photographer and filmmaker Jens Assur.

For almost two years Iggesund Paperboard has been running the Black Box Project, with exhibitions in cities like Paris, London, Amsterdam, Hamburg, Milan and New York. Iggesund has challenged a number of well-known international designers and design companies to fill a black box of a specified format with contents which in some way test the limits of Iggesund’s Invercote paperboard. Six designers have taken part in the project so far. When the doors open on 6 December to an exhibition at the Flacon Club in Moscow, a new box will be unveiled with contents created by the Swedish photographer and film director Jens Assur.

Assur began his career as a photographer for the daily press. In the 1990s he became Sweden’s most award-winning photojournalist. He gradually left the press world and began focusing on filmmaking. His films such as The Last Dog in Rwanda and Killing the Chickens to Scare the Monkeys have won multiple international awards. Partly as a result of this recognition, at the beginning of 2012 he was the first Scandinavian to win the Sundance/NHK International Filmmaker Award, the Sundance Festival’s prize for promising filmmakers.

“When I was asked to take part in the Black Box Project I didn’t hesitate a second,” he says enthusiastically. “As a creative artist, it’s rare that I have the opportunity to work so freely and at such a high artistic level in projects developed by customers. But in this case we could do so on both a conceptual and intellectual level.”

Carlo Einarsson, Director Market Communications at Iggesund Paperboard, is very pleased with Assur’s participation in the project.

“We’re looking for creative individuals who really push the limits of what can be done with Invercote,” he explains. ”But the project is also a tribute to all the designers who have chosen over the years to make fantastic creations using Invercote as their starting point. We’re especially pleased by the great interest our exhibitions have received from designers and the graphic industry in many parts of the world.”

Einarsson says that the Black Box Project is not a traditional advertising campaign in which the client expresses detailed wishes and closely supervises the project’s execution. The participating designers have great freedom – the only stipulations are that they must work with Invercote and create something that reflects their own distinctiveness and Invercote’s possibilities.

“The degree of freedom combined with the opportunity to create something extraordinary has made it easy to find interested participants,” he says. “A number of designers have contacted us and asked to be part of the project. We’re very satisfied with the response so far, both to our exhibitions and to our web pages about the project.

“In a world where the choice of materials is unfortunately often a matter of habit, it’s important for us to showcase the extra possibilities which Invercote offers designers to fully realise their creative ambitions.” Last November the Black Box Project presented a fifth designer’s work in Hamburg. The newcomer was designer and illustrator Sebastian Onufszak, based in Augsburg, Germany, but with all of Europe as his workplace. His contribution to the exhibition was unveiled at an event at the Prototyp Museum in Hamburg. This spring saw the addition of a work by the Japanese-American paper sculptor Jeff Nishinaka of Los Angeles in conjunction with a Black Box exhibition in Milan.

The other exhibitors are the Dutch firm of van Heertum Design, who are technical magicians who delight in combining printing techniques, use more than 30 inks and varnishes, and then add extra finishing touches, to the joy of printing aficionados and the despair of production economists. Landor, Paris elegantly demonstrates how designers break through all boundaries established by their clients. Brunazzi & Associati from Turin have created a survival kit for pasta lovers with both pasta tongs and a colander, all made of paperboard. And New York-based Frenchman Marc Benhamou presents his concept of beauty in a new interpretation of the Tarot’s 22 Major Arcana cards.

Sebastian Onufszak’s creation will now join this series of challenges. His contribution is a film about life as a closed loop system. The film is played on a video player integrated into the paperboard box.

“This project is an adventure and we don’t really know where it will all end,” Carlo Einarsson concludes. “But Invercote is one of the strongest brands on the European paperboard market, and with that as a secure foundation we can dare to try new channels of communication.”

The next Black Box, by photographer and filmmaker Jens Assur, will be presented at the beginning of December in Moscow.

UPM ceases production at Heinola further processing mill, offers support for employees

The glue lam panel production at UPM Heinola further processing mill in Finland will cease by mid-December. UPM announced in June 2012 the decision to close down the mill by the end of the year.

UPM has started the “From Job to Job” programme in Heinola in order to alleviate the effects caused by staff reductions in relation to the closing of the mill. The programme, which UPM implements in co-operation with the authorities and partner companies, includes active measures that promote employment and re-training.

Heinola further processing mill employs 27 people. The decision announced today is part of the plan published on 29 June 2012, including restructuring of UPM’s sawmill and further processing operations and renewal of business strategy in Finland.