Ianadmin

Need To Spend Your Budget Before Year End? Honeywell Has Test and Measurement Sensor Solutions For You

advertorial:

As 2012 comes to a close, you may find that you have some extra budget dollars to spend before year end - i.e., spend it or lose it.

If you have been putting off buying sensors for your test and measurement needs, now is the time to give Honeywell a call to discuss your application requirements.

If you have been putting off buying sensors for your test and measurement needs, now is the time to give Honeywell a call to discuss your application requirements.

For more than 50 years, customers worldwide have relied on Honeywell for innovative, high quality, and extremely reliable test and measurement sensing solutions. Our products include:

• Load Cells

• Pressure Sensors

• Torque Transducers

• Accelerometers (Vibration)

• Displacement (LVDTs)

• Instruments

Need a modification or a customized solution?

We work with customers every day to find just the right solutions for their applications.

Online: http://measurementsensors.honeywell.com

Call Us: (800) 848-6564 (U.S.) or +1 614-850-5000

Fax: +1 614-850-1111

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Ashland Inc. names Luis Fernandez-Moreno as new president of Ashland Water Technologies

Ashland Inc. has announced that it has hired Luis Fernandez-Moreno to serve as vice president of the company and president of Ashland Water Technologies, the global leader in specialty papermaking chemicals and a commercial unit of Ashland. He reports to John Panichella, Ashland senior vice president and group operating officer.

Ashland Inc. has announced that it has hired Luis Fernandez-Moreno to serve as vice president of the company and president of Ashland Water Technologies, the global leader in specialty papermaking chemicals and a commercial unit of Ashland. He reports to John Panichella, Ashland senior vice president and group operating officer.

Fernandez-Moreno, 50, brings nearly 30 years of chemical industry leadership experience to this role. He most recently served as executive vice president of Arch Chemicals, Inc., where he was responsible for the wood protection and HTH water products businesses, with combined annual sales of approximately $900 million. Arch was acquired by Lonza Group Ltd., a leading supplier to the life sciences industry, in October 2011. Prior to that, Fernandez-Moreno served as business group vice president, Dow Coating Materials, a $3 billion unit that was formed after Dow Chemical Co. (NYSE: DOW) acquired Rohm & Haas Co. in 2009. He previously spent more than 25 years with Rohm & Haas in a series of leadership roles spanning across Europe, Latin America and the United States. The businesses he directed ranged from paint and coating materials to plastic additives and printing technologies.

"Luis is a talented leader with significant experience in driving profitable growth and execution across global business lines," said Panichella. "Throughout his career, Luis has proved adept at forging close relationships with customers, establishing clear strategic goals and holding his teams accountable for performance. We are pleased to have someone with his experience in the specialty chemical industry assume the leadership of Water Technologies and we are confident in his ability to position the business for future sales and earnings growth."

Fernandez-Moreno earned a Bachelor of Science degree in chemical engineering from Universidad Iberoamericana in Mexico City. He also completed the Wharton Management Program at The Wharton School at the University of Pennsylvania.

The combination between Billerud and Korsnäs is planned to take place on 29 November 2012

Relevant competition authorities have approved the combination between Billerud and Korsnäs. All conditions for the combination are consequently fulfilled. Accordingly, completion of the combination is planned to take place on 29 November 2012.

Relevant competition authorities have approved the combination between Billerud and Korsnäs. All conditions for the combination are consequently fulfilled. Accordingly, completion of the combination is planned to take place on 29 November 2012.

As previously announced, Billerud AB (publ) has on 19 June 2012 entered into an agreement with Investment AB Kinnevik to combine Billerud and Korsnäs AB. The combination was conditional upon, among other conditions, the approval from Billerud's shareholders and approval from relevant competition authorities.

The condition regarding approval from the shareholders was fulfilled at the extraordinary general meeting that was held on 14 September 2012. In addition, all relevant competition authorities have now approved the combination. Accordingly, the conditions for the combination are fulfilled.

"As a result of the combination with Korsnäs, we will become a leading player in the packaging paper business with a strengthened offer and a strong platform for future growth. The new company BillerudKorsnäs will be able to offer customers a better and wider range of products and solution. We will now, with full force, work with the integration and create a world leading company ", says Per Lindberg, President and CEO of Billerud.

The European Commission's decision to approve the combination is conditional upon the divestment of a paper machine located at the production facility in Gävle (PM 2). The sales of white kraft and sack paper products manufactured at PM 2 amounted to approximately 2 percent of the new Group's total combined sales volume for the year 2011. Furthermore, BillerudKorsnäs will for a period of time offer to deliver certain supply inputs such as pulp, steam and electricity to the paper machine.

"The condition for the European Commission's decision concerns a limited part of the new group's business operations and does not have a significant impact on the business logic or the expected synergies of the combination" says Per Lindberg, President and CEO of Billerud.

Completion of the combination is planned to take place on 29 November 2012 and the Board will, in immediate connection with it, making use of the authorisation granted to the Board from the extraordinary general meeting, resolve on, and announce the terms of, a new issue of shares with preferential rights for the shareholders. Further information on the new issue of shares will be available in the prospectus which will be published in connection with the Board's resolution.

Ahlstrom updates 2012 outlook following the EGM approval to demerge the Label and Processing business

![]() Ahlstrom, a global high performance fiber-based materials company, updates its 2012 outlook for net sales and operating profit excluding non-recurring items after the Extraordinary General Meeting of the company approved the demerger of the Label and Processing business area.

Ahlstrom, a global high performance fiber-based materials company, updates its 2012 outlook for net sales and operating profit excluding non-recurring items after the Extraordinary General Meeting of the company approved the demerger of the Label and Processing business area.

Ahlstrom's Extraordinary General Meeting of the Shareholders today resolved to approve the demergers of the Label and Processing business in Europe and the Coated Specialties business in Brazil according to the respective demerger plans. Consequently, the Label and Processing business area will be classified as an asset held for distribution to owners and reported separately as discontinued operations in the Financial Statements Bulletin 2012.

Ahlstrom's view of the market environment remains unchanged. However, the outlook is only adjusted to reflect the resolution by the EGM to approve the demerger of the Label and Processing business area.

Ahlstrom now expects net sales from continuing operations to be EUR 960 -1,040 million and operating profit excluding non-recurring items from continuing operations to be EUR 22 - 32 million in 2012. Ahlstrom had previously estimated, including the Label and Processing business area, net sales to be EUR 1,550 - 1,630 million and operating profit excluding non-recurring items to be EUR 48 - 58 million.

The cost structure of the continuing operations has been adjusted with the costs historically allocated to the discontinued businesses to the extent such costs will remain with Ahlstrom after the demergers.

Earlier this month, Ahlstrom announced that the company intends to rightsize its cost base to reflect the future size and scope of the company following the closing of the Label and Processing transaction. The company aims to achieve a total of EUR 15 million in cost savings within one year after the closing of the transaction.

Decisions taken by Ahlstrom Corporation's Extraordinary General Meeting of Shareholders

![]() Ahlstrom Corporation's Extraordinary General Meeting of Shareholders (EGM) was held today on November 27, 2012.

Ahlstrom Corporation's Extraordinary General Meeting of Shareholders (EGM) was held today on November 27, 2012.

Demerger of the Label and Processing business in Europe

The EGM resolved to approve the demerger concerning the Ahlstrom Group's Label and Processing business in Europe ('LP Europe Demerger') in accordance with the demerger plan.

Upon the execution of the demerger concerning the Label and Processing business in Europe, the shareholders of Ahlstrom Corporation will receive as demerger consideration 0.25 new shares in Munksjö Oyj for each share owned in Ahlstrom Corporation (i.e. the exchange ratio is 4:1). In case the number of shares received by a shareholder of the company as demerger consideration would be a fractional number, the fractions will be rounded down to the nearest whole number. No demerger consideration will be paid on the basis of own shares held by Ahlstrom Corporation.

The completion of the demerger is subject to, among other things, approvals of the competition authorities.

Demerger of the Label and Processing business in Brazil

The EGM resolved to approve the demerger concerning the Ahlstrom Group's Label and Processing business in Brazil ('Coated Specialties Demerger') in accordance with the demerger plan.

Upon execution of the demerger concerning the Label and Processing business in Brazil, the shareholders of Ahlstrom Corporation will receive as demerger consideration 0.265 new shares in Munksjö Oyj for each share owned in Ahlstrom Corporation. In case the number of shares received by a shareholder of the company as demerger consideration would be a fractional number, the fractions will be rounded down to the nearest whole number. No demerger consideration will be paid on the basis of own shares held by Ahlstrom Corporation.

The completion of the demerger is subject to, among other things, certain regulatory approvals in Brazil, including the approval of the Brazilian competition authority (CADE).

Sustainable Brands Conference in London: BASF makes sustainability tangible

- Carmel McQuaid, climate change manager at Marks and Spencer

- Dr. Christoph Günther, head of SET – applied sustainability, Europe, BASF

- Vidar Gundersen, sustainability manager at BioMar

World records after start-up of Zhanjiang Chenming greenfield pulp mill in China

The greenfield pulp mill of Zhanjiang Chenming Pulp & Paper Co., Ltd reached its nominal production capacity of 700,000 t/a in world record time – only 121 days from start-up. It has also produced 100% of design capacity during the first full operating year, establishing another world record. All key production technologies and start-up supervision were provided by international technology Group ANDRITZ. Zhanjiang Chenming Pulp & Paper is a subsidiary of Shandong Chenming Paper, one of the largest pulp and paper producers in China.

The greenfield pulp mill of Zhanjiang Chenming Pulp & Paper Co., Ltd reached its nominal production capacity of 700,000 t/a in world record time – only 121 days from start-up. It has also produced 100% of design capacity during the first full operating year, establishing another world record. All key production technologies and start-up supervision were provided by international technology Group ANDRITZ. Zhanjiang Chenming Pulp & Paper is a subsidiary of Shandong Chenming Paper, one of the largest pulp and paper producers in China.

In 2009, ANDRITZ PULP & PAPER was awarded the contract to deliver all process technologies for the bleached hardwood kraft pulp mill located in GuangdongProvince. The mill was started up in September 2011 and reached its nominal average production capacity only four months later (measured as a 30-day moving average). This represents a new “world record” based upon officially available figures of greenfield pulp mills, eclipsing the record set by another ANDRITZ customer in South America. This extremely fast start-up has an important economic element in that it greatly enhances a mill’s return on investment.

ANDRITZ’s scope of supply included the wood handling system, the fiberline (cooking, washing, screening, bleaching, pulp dryer, and bale finishing), and the recovery island (evaporation, recovery boiler, and white liquor plant). In addition, ANDRITZ was entrusted with the delivery of the stock preparation systems for the mill’s new paper machines.

Reliable and maintenance free break detection in the toughest conditions

KPM, a member of the ABB Group, recently announced new KB2 Fibre-Optic Sheet Break Detector – a new generation sheet break detector with the latest RGB / IR LED technology.

Many customers have already noticed the KB2‘s extremely reliable break detection in demanding applications, including open draws, against the felt or dryer can, in misty or foggy conditions and even in the press section of the paper machine. The reliability is achieved with fibre optic technology which eliminates electronics and light source from the extremely hot environment inside the paper machine hood. The sensor has built-in redundancy and self-diagnostics to eliminate false breaks effectively.

This new KB2 model is versatile, with both RGB and IR light sources it is suitable for all applications in paper and board machines. Start-up is very fast and easy due to the simple setup and calibration procedures. The built-in air purge system keeps the sensor head clean from dust and other impurities in the paper machine, and guarantees 100% accurate break detection.

This new KB2 model is versatile, with both RGB and IR light sources it is suitable for all applications in paper and board machines. Start-up is very fast and easy due to the simple setup and calibration procedures. The built-in air purge system keeps the sensor head clean from dust and other impurities in the paper machine, and guarantees 100% accurate break detection.

KB2 and its predecessor KB have already hundreds of installations worldwide, with excellent references from satisfied customers declaring that KB2 is the best break detector in the market.

Info from the Board of Directors of Rottneros AB (publ) regarding Arctic Paper’s bid for the company

On 7 November 2012 Arctic Paper S.A. announced its public offer to buy all of the shares in Rottneros AB. On the same day the Board of Directors of Rottneros recommended that the shareholders should accept the offer, subject to the conditions specified.

The Board of Directors of Rottneros has now been informed in writing by shareholders (including Skagen Vekst and Peter Gyllenhammar via companies, who taken together control more than 10 per cent of the capital and voting power in Rottneros), that these owners will not accept the bid announced by Arctic Paper.

In light of the above-mentioned new information - which means that Arctic Paper’s offer will not be accepted to such an extent that Arctic Paper would obtain over 90 percent and thereby be able to request the compulsory redemption of outstanding shares and consequently that a merger cannot be implemented - the Board of Directors of Rottneros makes the following comments.

The primary reason for the position adopted by the Board of Directors as referred to above is that a merger of the two companies may be expected to generate synergies of approximately SEK 80 million and also that, from the perspective of both results and cash flow, a merger would balance out the two companies' very strong dependency on fluctuations in pulp prices. A precondition for realising a substantial proportion of these synergies is that the companies are completely amalgamated and that one head office and one management group be phased out. In addition, synergies have been identified on the financial side, though this also presupposes that the companies join together. The other significant synergy comprises the optimisation of transport costs, which would probably be considerably more difficult to achieve if the companies continue to operate as autonomous businesses.

The Board of Directors’ recommendation remains unchanged, that is to say that the companies merge to enable these synergies to be realised. The fact that two major owners controlling more than 10 per cent of the capital and voting power have given notice that they will not accept the bid means in that event that a merger cannot be effected and that it would thus not be possible to secure most of these synergies.

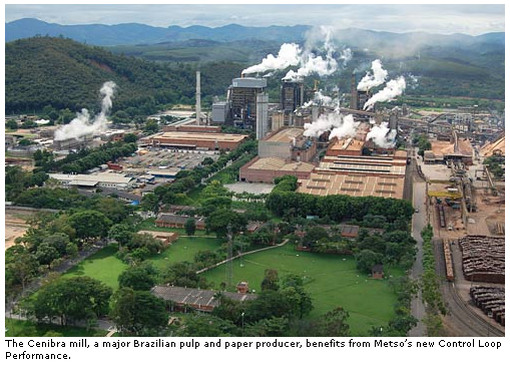

Cenibra improves its competitive edge by using Metso’s new Control Loop Performance Solution

Cenibra, a major Brazilian pulp and paper producer, has reached significant improvements in process efficiency and in end-product quality by using Metso’s new Control Loop Performance solution at their mill – with annual 1.2 million tonnes capacity in two lines. ‘’Partnership with Metso in implementing this new solution has proved to be great asset for us in fighting rising costs and finding more ways to stay strong in a highly competitive environment,’’ says Cenibra’s IT director Ronaldo Ribeiro

Being a cost-competitive pulp producer in Brazil doesn’t depend only on the good climate that helps trees to grow faster but also requires constant investments in new solutions to improve processes and reduce production expenses. This was Cenibra’s objective when it accepted a proposal from Metso to implement and test new Control Loop Performance Solution at their mill.

“We were curious to see how this new system would work, as we already had Metso’s Field Device Performance solution and Valve Health Predict service which could help us identify issues with valves, but we wanted to be able to see more,” comments Cenibra’s maintenance manager José Antônio de Oliveira.

Multiple benefits

Metso’s Control Loop Performance solution is designed to ensure that the control loops are working optimally throughout the plant. A key factor for better production management, properly tuned control loops, will improve process efficiency and end-product quality.

Metso has had a control loop monitoring service available for many years. Earlier it was designed to be used with Metso's own DNA automation system. Now the new Metso Loop Monitoring system can be used with any automation suppliers' DCS system. The system is also able to connect with the Field Device Performance solution.

The benefits that the new solution offers to our customers are many. Manager Jani Honga explains: “The new system can also be connected with Field Device Performance component. By combining the components together, the accuracy of monitoring results will be significantly improved and more value generated. Control Loop Performance gives broader view from the point of process controls and Field Device Performance gives deeper insight to device performance.”

Results right from the beginning

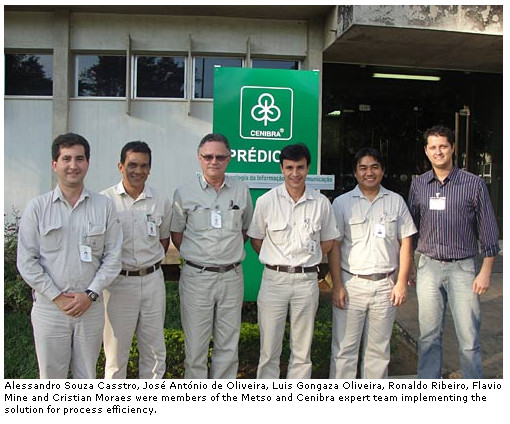

At the Cenibra mill, the new Control Loop Performance solution showed its ability and effectiveness already in the first steps of the project. ‘’Integration to other suppliers’ DCS system was solved quickly, and in the second week of work we were already collecting data,” explains Metso’s services coordinator Cristian Moraes who worked on the project full time.

“We identified a process problem the root cause of which was not clear. With the new solution the problem could be identified and with the Field Device Performance solution we were able to detect a critical valve which was showing abnormal behavior. The valve was checked and the finding was that the supply air pipe to the positioner was slightly broken, and there was a leakage which caused the device not to perform optimally,” Moraes says.

According to Cenibra’s engineering and investment coordinator Luis Gonzaga Oliveira the project implementation went smoothly and Metso was able to easily integrate its systems with those from other suppliers installed at the mill.

Matter of trust

Engaging a customer in a field test is a matter of trust. Cenibra’s team commented that making the decision to accept the proposal for testing the new solution was not problematic, as the company had a good relationship with Metso and knew that the project would be conducted by qualified experts.

Metso’s Service engineer Matti Mustonen spent some months during the pilot period at Cenibra’s site.

“It was great to see the benefit of the new technology for the customer when I stayed at Cenibra’s site,” Mustonen tells.

‘’Being close to the customer doesn’t only mean seeing the customer’s daily actions but also a possibility to understand and observe the customer’s needs and wants better than ever before. The possibility to discuss face to face with the customer offers a first-class opportunity to embrace their needs and especially to fulfill those as well as possible,” says Mustonen.

Celulose Nipo-Brasileira S.A. (CENIBRA) is Brazilian pulp and paper producer. Cenibra’s first pulp line was started up in 1977 and the second in 1995.

For more info please contact:

|

Metso Automation Inc. |

|

Lentokentänkatu 11 PO Box 237 |

|

33101 Tampere, Finland |

|

Mobile: +358 40 5551637 |

|

This email address is being protected from spambots. You need JavaScript enabled to view it. |