Ianadmin

Paper industry on EU Waste Directive guidance and End-of-Waste

Verso Paper Corp. Announces Discussions with Holders of First-Lien Notes of NewPage Corporation

Verso Paper Corp. has announced that it has held discussions with certain holders of the 11.375% first-lien senior secured notes of NewPage Corporation in an effort to achieve a potential business combination involving Verso and NewPage as part of a consensual plan of reorganization in NewPage's Chapter 11 bankruptcy proceedings.

The terms of Verso's proposed transaction would provide NewPage's first-lien noteholders with $1.425 billion of value, consisting of $1.075 billion of new Verso first-lien notes, $150 million of Verso common stock, and $200 million of cash. In addition, the proposed transaction would include a 100% recovery in cash to repay NewPage's debtor-in-possession financing, a 100% recovery in cash for the allowed priority and administrative claims in the bankruptcy proceedings, a to-be-determined amount of Verso common stock for the holders of NewPage's second-lien notes, and a to-be-determined recovery for NewPage's unsecured creditors. To facilitate the transaction, a $200 million cash equity investment in Verso was contemplated. The proposed transaction would be subject to customary conditions, including the satisfactory completion of due diligence and the completion of antitrust review.

Verso believes that a combination with NewPage would create a stronger business in the global coated and supercalendered paper industry because of the material cost savings that would be achieved. Verso also believes that a combination with NewPage would provide a compelling option for a restructuring in that it would afford NewPage's first-lien noteholders a very attractive recovery, while at the same time treating fairly the other NewPage constituencies, including its employees, other creditor classes, and customers. Despite these advantages, Verso has been disappointed with the lack of progress in advancing its discussions with the first-lien noteholders. Verso continues to believe that its proposed transaction is the most sensible.

The terms of Verso's proposal to NewPage's first-lien noteholders regarding the proposed transaction are included in the June 18, 2012 discussion materials attached as an exhibit to the current report on Form 8-K that Verso is filing with the Securities and Exchange Commission. Verso provided advance notice to NewPage of its presentation to the first-lien noteholders and delivered its presentation to the first-lien noteholders for discussion purposes only. Verso also is including a withdrawn May 30, 2012 term sheet previously presented to the first-lien noteholders as an exhibit to the current report on Form 8-K. This May 30 term sheet was superseded in its entirety by the term sheet included in the June 18, 2012 presentation, which was revised to reflect NewPage's updated earnings and cash balance. This press release is not a solicitation to any party to accept or support any Chapter 11 plan of reorganization.

Source: Verso Paper Corp.

Rottneros: Production record at Vallvik Mill

Vallvik Mill, which forms part of the Rottneros Group, produced well over 20,000 tonnes of chemical sulphate pulp in June. This is the highest ever monthly production at the mill and is well over the old record. Furthermore, a new daily record of 740 tonnes was achieved.

"It is very pleasing that several years of goal-oriented work has yielded such tangible results," says Robert Jensen, MD of Vallvik Mill. "Furthermore, we have an excellent outcome in terms of quality – we have managed to achieve our environmental objectives and are delivering to our customers according to plan. All of our employees have good reason to look forward to a well-deserved holiday."

Rottneros has invested over a quarter of a billion Swedish kronor in Vallvik Mill in recent years in order to satisfy the environmental requirements imposed on the mill, while annual capacity increases from 200,000 tonnes to 240,000 tonnes. The Environmental Court is considering a permit application to temporarily increase production from 220,000 to 242,000 tonnes, and a decision is expected during the third quarter of 2012. The company is preparing a permit application to enable it to permanently increase production up to 300,000 tonnes.

Domtar unveils 2020 sustainabilty indicator framework

Domtar Corporation has released its 2011 Sustainable Growth Report, unveiling 35 key performance indicators that will shape the company's sustainability efforts out to 2020. This sustainability framework builds on years of industry leadership in forestry certification, mill-level environmental performance and longstanding ENGO collaborations.

This year also marks the first time Domtar is issuing a level-checked "B" Global Reporting Initiative (GRI) report, as well as the first time that outside perspective from sustainability experts in the private sector and civil society is being featured.

"The release of a key performance indicator framework is an important milestone in our long-term sustainability strategy," noted John D. Williams, DomtarPresident and Chief Executive Officer. "By addressing sustainability in a systematic way we are making this company more resilient, better able to seize opportunities for innovation and growth, as well as more open to constructive input from our shareholders, customers, suppliers, and environmental partners. All of this supports our evolution from papermaker to fiber innovator that positions us for success over the long term."

For more information please visit the Sustainability section of www.domtar.com

Weaker pulp markets have resulted in lower wood chip and pulplogs prices worldwide

Weaker pulp markets have resulted in lower wood chip and pulplogs prices worldwide, reports the Wood Resource Quarterly

Wood fiber costs, which can account for up to 70 percent of the production costs for a pulpmill, fell in many markets during the 1Q/12, according to the Wood Resource Quarterly. The biggest declines were seen in Western Canada, Europe and Brazil, while Chile, Australia and New Zealand experienced some minor price increases for pulplogs and chips during the quarter.

International Paper Completes Mill Divestitures

International Paper has announced that it has finalized the sale of its Ontario and Oxnard, California containerboard mills to New-Indy Containerboard LLC, along with its New Johnsonville, Tennessee containerboard mill to Hood Container Corporation. By completing these transactions, the company satisfies its divestiture obligations under its February 2012 settlement agreement with the U.S. Department of Justice. The settlement agreement, in which the company agreed to divest the three mills, was entered into in connection with the company's acquisition of Temple-Inland.

About International Paper

International Paper (NYSE: IP) is a global paper and packaging company with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include uncoated papers and industrial and consumer packaging, complemented by xpedx, the company's North American distribution company. Headquartered in Memphis, Tenn., the company employs approximately 70,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2011 were $26 billion. Temple-Inland Inc., which was acquired in February 2012, had 2011 net sales of $4 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

SOURCE International Paper

Xerium Technologies Announces Operational Realignments in Argentina and France

Xerium Technologies, Inc. a leading global manufacturer of clothing and roll covers used primarily in the paper production process, today announced a voluntary redundancy program at its press felt facility in Buenos Aires, Argentina in connection with the relocation of its Huyck.Wangner press felt capacity and initiated consultation proceedings with its works’ council at its rolls cover facility in Meyzieu,France regarding a proposal to cease operations there. In Argentina, the production of press felts and fiber cement felts would be transferred to the Company’s facilities in Brazil and the roll cover production of its facility in France would be transferred to the Company’s rolls facilities in Germany and Italy. The actions are expected to be completed over the next several months.

Commenting on the action, Stephen R. Light, the Company’s Chairman, President and Chief Executive Officer said, “Any action of this nature is taken only after much deliberation. This action helps align our rolls and press felt capacity with current and future market demands. With these actions, Xerium will maintain its leadership position in the global paper industry with state of the art facilities strategically located in North and South America, Europe and Asia.”

Although the final costs will not be known until the actions are complete, the Company estimates it will incur approximately $10.1 million in restructuring charges, including $2.8 million of non-cash impairment charges, beginning in the third quarter of 2012 through the planned completion of shutdown activities in the fourth quarter of 2012. The Company estimates it will make approximately $5.8 million in net cash payments related to various personnel, facility and capital expenditure costs associated with these plans, which are net of proceeds on the sale of certain assets. The Company estimates these actions will result in future annual pre-tax savings of $2.6 million.

Source: Xerium Technologies, Inc.

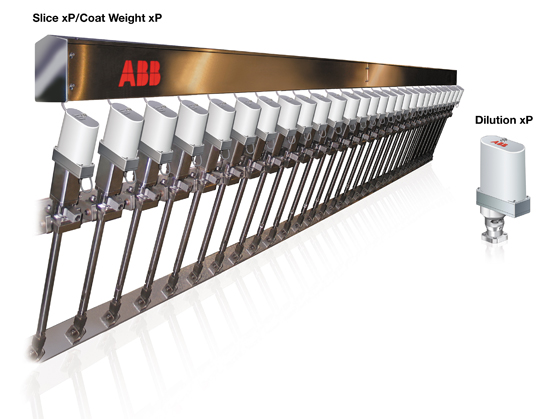

New ABB Weight xP Actuators at Zellcheming

Leading-edge technology reduces variability, minimizes sheet breaks and improves product quality

ABB, the leading power and automation technology group, recently launched new Weight xP extended profiling actuators with high-speed positioning that guarantee optimal reliability. The actuators provide faster grade changes and faster recovery from process upsets, keeping mill productivity levels high.

The state-of-the-art Weight xP technology eliminates dependence on a physical position sensor, so the actuators can shift into new positions in one swift, continuous movement. This reduces control action time and increases precision. The patented and patent-pending technology also helps mills meet even the most exacting product specifications.

“Papermakers can achieve the lowest possible Cross Direction variability, improve product quality and reduce their costs with the new Weight xP actuators,” says Steven St. Jarre, Head of Sales & Marketing for ABB Quality Control Systems.

A patented power management scheme allows the actuators to move simultaneously at all times, including flush cycles, global setpoint changes or the failure of one power supply, ensuring reliability even in extreme conditions.

The new Weight xP actuators are the latest generation of ABB’s popular xP profilers. The Weight xP family includes the Slice xP, Dilution xP and Coat Weight xP systems, which are designed drawing on ABB’s experience in applying actuators on the headboxes and coaters of more than 25 different manufacturers.

Slice xP, Coat Weight xP and Dilution xP each offer advanced diagnostics for easy troubleshooting and increased system availability, as well as built-in monitoring of over 60 different parameters, to predict an impending actuator failure long before it occurs.

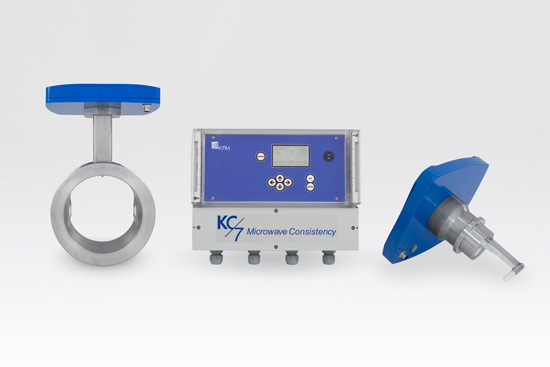

New solution for accurate consistency control

KPM, a member of the ABB Group, announces its KC/7 Microwave Consistency Transmitter – a transmitter that measures total consistency of mixed pulps, different quality pulps, and pulps with fillers. With the reliable and well tested microwave true-phase measurement technology, it offers excellent measurement accuracy. Additionally the transmitter's straightforward design, with no moving parts, guarantees high uptime without maintenance.

The transmitter is unaffected by variations in pulp grade (fiber length, freeness, kappa, brightness, color and shives) unlike other transmitters based on optical and shear force technologies. It is applicable close to the paper machine, after the mixing chest and machine chest, and it is especially recommended at paper machines for mixed furnishes and fillers. In pulp production it is applicable before first bleaching stage, after bleaching before drying machine, at mixed pulps and fillers, broke and recycled pulps. Further, the KC/7 Microwave Consistency Transmitter is resistant to changes in process conditions such as flow rate, pressure, temperature, and turbulence.

"We have the knowledge, products and experience to help customers achieve measurement objectives, and this new microwave consistency transmitter is a further support to our customer", says Urpo Heikkinen, Managing Director KPM.

Tensile testing from tissue to the strongest board

Lorentzen & Wettre, a member of the ABB Group, announces the L&W Tensile Tester – its fourth generation horizontal tensile tester. It measures according to all established paper testing standards. Basic tensile properties such as tensile strength, stretch at break, TEA and tensile stiffness are measured. In addition, eight other industry standard properties can be calculated and reported. It is sensitive, with precision to measure on tissue, and strong enough to measure on packaging board.

The L&W Tensile Tester is designed with attention to ergonomics and efficiency. A large table area makes it easy to manage test-pieces, the start button is placed near the test-piece input, and the easy-to-use color touch-screen has intuitive and easy accessible menus and buttons. The instrument has a well-proven clamp design – recommended by the ISO and TAPPI standards – with a cylindrical clamp holding the test-piece in place, and guides on each clamp that ensure the alignment of the test-piece. The clamps are also totally backlash-free, for precision measurements.

This new tensile tester is the perfect choice for automatic dry and wet tensile testing of tissue paper. With the fracture toughness setup, the L&W Tensile Tester can predict fracture strength and fracture strain for a two meter long and one meter wide paper web with a 10 millimeter edge cut, only by measuring on small standard test-pieces. This large paper geometry can be used for predicting and ranking of the fracture properties of paper materials.

“With L&W Tensile Tester we have made traditional quality testing very easy, but still with high precision and trust in result”, says Mr. Thomas Fürst, Product Manager, Lorentzen & Wettre.