Super User

Mondi first to offer extensive portfolio of Cradle to Cradle Certified® uncoated fine papers from its European mills

Mondi, a global leader in packaging and paper, received the Cradle to Cradle certification at Bronze level for its uncoated fine papers produced in its mills in Austria, Slovakia and Russia. Mondi is thus the first to offer an extensive uncoated fine paper portfolio as Cradle to Cradle Certified® meeting the high standards and demanding requirements of this certification scheme which marks the step from a linear to a circular economy. This includes Mondi´s well-known professional printing brands Color Copy and PERGRAPHICA®, as well as its range of NAUTILUS® branded recycled papers, and a wide office paper portfolio.

“We are proud to kick off the year with this strong sustainability achievement underlining our Mondi Action Plan 2030 (MAP2030) commitment to create circular-driven solutions. For many years, Mondi has been a leader, and often a pioneer, in the sustainability of its uncoated fine papers. For example, Color Copy became the world´s first FSCTM certified colour laser paper in 2005. Thanks to our new Cradle to Cradle certification our customers have a uniquely wide choice of products to support the environment and contribute to the circular economy without sacrificing on quality or price,” says Devan Naidoo, Marketing and Sales Director at Mondi Uncoated Fine Paper.

The Cradle to Cradle Certified® Products Program is a globally recognised standard for safe, responsible materials and products made for the circular economy. The holistic approach follows nature´s principle of keeping materials and resources in circulation and eliminating waste. The Cradle to Cradle certification is awarded by the Cradle to Cradle Products Innovation Institute dedicated to powering the circular economy through products that have a positive impact on people and planet. The programme assesses five categories of sustainability performance: material health, product circularity, clean air and climate protection, water and soil stewardship, and social fairness. Mondi´s uncoated fine paper portfolio has been assessed across all five categories, reaching levels from Gold to Bronze, thereby being Bronze the overall level of the final certification.

Cradle to Cradle Certified® is a registered trademark of the Cradle to Cradle Products Innovation Institute.

About Mondi Uncoated Fine Paper

Uncoated Fine Paper is a business unit of Mondi Group. In six operating sites in Austria, Slovakia, Russia, and South Africa, Mondi Uncoated Fine Paper produces pulp and environmentally sound office and professional printing papers tailored to the latest professional digital and offset print technologies. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC™ or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, PERGRAPHICA®, NAUTILUS®, NEUJET®, IQ, MAESTRO®, BIO TOP 3®, DNS®, Snegurochka or ROTATRIM are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication. Converters appreciate the excellent printability and smooth handling of Mondi’s professional printing papers.

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is integrated across the value chain – from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer-centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2020, Mondi had revenues of €6.66 billion and underlying EBITDA of €1.35 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

Lucart has chosen Enel X to proceed on the path to decarbonisation

Enel's innovative business line will support Lucart on the path to increasing energy efficiency by installing a photovoltaic system that will produce over 3 GWh of renewable energy a year

A new synergy for creating an industrial development model that is sustainable in economic and environmental terms. This is the partnership between Enel X, the innovative global business line of Enel Group, and Lucart, one of Europe's leading paper manufacturers, known for its Tenderly, Grazie Natural and Tutto Pannocarta brands, among others, which has chosen to embark on an ambitious project to reduce the climate-changing emissions of its production plants. The first step will be the installation of a 3 MWp photovoltaic plant in the Diecimo factory, in the province of Lucca, which will generate over 3 GWh of green energy a year achieving a reduction of CO2 emissions into the atmosphere equal to 1,160 tonnes per year.

“The agreement with Lucart demonstrates once again how important it is for Enel X to provide cutting-edge technologies to the country's most important companies to make their production sites more cost-effective and sustainable", said Augusto Raggi, Head of Enel X Italy. "This partnership is only the first step of a long-term project that we are sure will become the benchmark for the entire paper industry, which is a pride for our country and a strategic sector for our business”.

“The agreement with Lucart demonstrates once again how important it is for Enel X to provide cutting-edge technologies to the country's most important companies to make their production sites more cost-effective and sustainable", said Augusto Raggi, Head of Enel X Italy. "This partnership is only the first step of a long-term project that we are sure will become the benchmark for the entire paper industry, which is a pride for our country and a strategic sector for our business”.

“We have always been very mindful of how we produce the electricity and heat we need to manufacture and convert paper into the hygiene products that we use every day at home and at work. This is why we sought out a top-level partner such as Enel X to work alongside us in all our plants to find the best technological solutions and successfully proceed on our path to decarbonisation," said Massimo Pasquini, CEO of the Lucart Group. "The photovoltaic plant we are going to build in Diecimo will be one of the largest private-owned ones ever installed in Tuscany and will be a further reason of pride for our company”.

Enel X will operate at the Lucart plants on several aspects of the company's production chain, which in the future will include the installation of additional renewable energy plants. Integrated solutions dedicated to the paper industry and its supply chain are also being studied, covering distributed generation, flexibility, energy efficiency, decarbonisation and sustainable mobility.

Order execution in record time – Successful start-up of Sun Paper's XcelLine PM 2 in Beihai

Asian paper producer Sun Paper recently successfully started up PM 2 at its site in Beihai in Southeast China. The new line in visionary industrial design now produces high-quality white folding boxboard with a basis weight of 170 to 350 gsm and a wire width of 8,900 mm. With a design speed of 1,400 m/min, the planned annual capacity is over 1 million tons of paper. Thanks to the very successful cooperation between Sun Paper and Voith, the entire project from initial contracting to start-up in December took only 18 months – a new world record for a high-speed line of this type. This is the third paper machine that Voith has started up for Sun Paper in the last 12 months. In total, Voith has already delivered 12 XcelLine paper machines to Sun Paper.

- Voith sets a new world record for high-speed board machines with a project execution of only 18 months

- With a design speed of 1,400 m/min, the new PM 2 produces over one million tons of folding boxboard per year

- Voith and Sun Paper have a long and successful partnership

"Sun Paper and Voith are trustful partners,” said Li Lu, Chairman of Sun Holding Group. “From Laos PM 2’s 1-hour and 46-minute start-up to today’s Beihai PM 2, the fastest project execution at 18 months, we have created many world records together."

"We are very pleased that the paper machine started up smoothly thanks to the joint efforts of Voith and Sun Paper," said Ying Guangdong, Vice General Manager and Chief Engineer of Sun Paper. "The line produces the best board quality currently available on the market."

Start-up in record time

There was only seven and a half months between the start of installation and the successful machine start-up, even with the major challenges presented by COVID-19. To ensure the on-time arrival of all components, Voith stabilized all upstream global supply chains. Voith's excellent supply chain management and project management, as well as close coordination, high degree of flexibility and additional shifts, made it possible to meet the ambitious schedule.

"The high-speed plant uses the latest technologies," said Dr. Michael Trefz, President Projects at Voith Paper. "In combination with the visionary industrial design, the plant sets the highest standards in terms of efficiency, safety and sustainability. The start-up is another milestone in the successful and long-standing partnership between Voith and Sun Paper."

As a full-line supplier, Voith supplied the entire XcelLine paper machine in the new industrial design. The tailor-made concept focuses in particular on the efficiency and robustness of the individual components. For example, a DuoFormer ensures excellent formation and strength properties even at very high speeds. Automatic dewatering of the three shoe presses reduces thermal drying and thus saves significant energy costs. For an optimized paper surface, a SpeedSizer is used as well as four DynaCoaters, which apply the film evenly during sizing and coating. Furthermore, the CombiDuoRun dryer section with EvoDry steel dryer cylinder ensures maximum runnability and energy efficiency. In addition, two VariFlex high-performance winders ensure smooth production. Due to the visionary Voith industrial design of the entire line, optimized accessibility for maintenance work and improved occupational safety are also achieved.

Sun Paper also benefits from Voith's leading expertise in digitalization and automation for additional efficiency gains and cost reductions. The intelligent quality control system QCS as well as the solutions DCS and MCS enable complete control over the entire production line. In addition, Sun Paper relies on solutions from the Papermaking 4.0 portfolio with OnCare.Health. Thanks to a wide range of interfaces, the intelligent maintenance tool detects the smallest faults at an early stage and automatically assigns them to the affected points.

About Sun Paper

Founded in 1982, Shandong Sun Holdings Group is a global advanced integrated multinational paper group, a leader in the Chinese paper industry, ranked 306th among China's 500 largest companies and among the world's 30 largest paper manufacturers.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Valmet to supply an extensive recycled fiber line and paper machine grade conversion rebuild to Model Paper Eilenburg in Germany

Valmet will supply an extensive paper machine grade conversion rebuild with an automation package to Model Paper Eilenburg in Germany. In the project, the paper machine, which currently produces newsprint grades, will be rebuilt to produce lightweight, recycled containerboard grades. The start-up is scheduled for the beginning of 2024.

The order is included in Valmet's orders received of the fourth quarter 2021. The value of the order will not be disclosed. The total value of an order of this type and delivery scope is typically around EUR 90–100 million.

“The converted machine will focus on the production of lighter grammages and will therefore meet the customers’ demands in the future. The containerboard production volume of Model Group will be more than doubled after the successful conversion. We trust Valmet’s technology to fulfil our goals,” says Jürgen Lemke, COO, Paper Unit of Model Group.

“The converted machine will focus on the production of lighter grammages and will therefore meet the customers’ demands in the future. The containerboard production volume of Model Group will be more than doubled after the successful conversion. We trust Valmet’s technology to fulfil our goals,” says Jürgen Lemke, COO, Paper Unit of Model Group.

“This is again a very interesting project for Valmet in Europe. The technology and references we presented to Model Group were well-suited. The production line has many technical highlights: a new linear double shoe press to improve machine runnability and end-product quality, and the extremely high-capacity winder and Valmet DNA Automation system for the whole machine line will ensure that the delivery meets Model’s goals,” says Tobias Hain, Senior Sales Manager at Valmet.

Technical information about the delivery

Valmet’s grade conversion delivery will include a rebuild of the DIP (deinked pulp) line and OCC (Old Corrugated Container) line, updates to stock preparation, and a rebuild of the board machine.

The OCC line will be featured with upgrades to HC cleaning, coarse screening, and LC cleaning to increase the capacity and the handling of brown fiber. Fiber fractionation and long fiber fine screening maximize the efficient stickies removal. Underneath the machine, a new broke collection minimizes the consistency variations, and machine screening ensures the final fiber quality.

The delivery for the board machine rebuild will include a shoe and blade technology upgrade in the forming section and a new OptiPress Linear press section. The drying section will be updated into OptiRun Single. The delivery will also include an OptiAir Hood high-humidity hood, OptiAir Recovery heat recovery system, and other runnability, dryer and air system equipment to improve the drying efficiency and runnability and to enhance draw control. After the drying section, a new OptiSizer Film sizer with a supply system, an OptiReel Linear reel, and a very high-capacity OptiWin Pro winder will be included. The delivery will also include a paper machine clothing package as well as maintenance master data to ensure an efficient and disturbance-free production.

The delivery will be complemented with the latest generation Valmet DNA Automation System, including built-in process control, machine control, sectional drive control, quality control, and condition monitoring. Additionally, Valmet IQ Quality Control System (QCS), Valmet Paper Lab, IQ Web Inspection System, IQ Dilution Profiler, IQ Steam Profiler, and IQ Moisturizer will be included in the delivery. Valmet Wet End Analyzer and Valmet Retention Measurement will provide valuable information on the process.

The board machine with a 10,050-mm-wide fabric will produce fluting and testliner grades with a basis weight range of 70 –120 g/m2. The design speed of the new parts will be 2,000 m/min with a daily capacity of approximately 2,000 tonnes.

About the customer Model Group

Model Group develops, produces, and supplies intelligent, innovative, and high-quality display and packaging solutions made of solid and corrugated cardboard. Model Group employs around 4,600 people in 15 European locations. Model Holding AG is the holding and management company of the group and one hundred percent owned by the Model family. The company's headquarters are in Weinfelden, Switzerland.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

ANDRITZ to supply third OCC line to Nine Dragons, China

International technology group ANDRITZ has received a repeat order – now the third order within the past 12 months – from Nine Dragons Paper Industries to supply a complete OCC line to China. Start-up is scheduled for the third quarter of 2023.

The highly energy-saving stock preparation system will have a design capacity of 2,000 bdmt/d and will process 100% LOCC (Local Old Corrugated Container) for the production of high-quality packaging paper.

The ANDRITZ equipment will enable highest production performance and conservation of resources. These ambitious goals will be achieved with a well-developed line setup, a highly efficient drum pulping system and a range of Prime stock preparation products.

An ANDRITZ FibreFlow drum pulping system will ensure premium accept quality, gentle slushing, and efficient removal of contaminants at minimum fiber loss. Energy-saving and maintenance friendly PrimeScreen F screens and PrimeFilter D disc filters, as well as an ultra-high dispersing system that enables at a consistency of up to 40%, will achieve substantial savings in steam consumption and superior fiber strength development.

FibreFlow drum pulping system as part of the third OCC line ordered by Nine Dragons © ANDRITZ

FibreFlow drum pulping system as part of the third OCC line ordered by Nine Dragons © ANDRITZ

With the delivery of this FibreFlow drum pulper, ANDRITZ will have supplied more than 30 drum pulpers to Nine Dragons.

Nine Dragons Paper is part of the Nine Dragons Paper Group, an important global player in the pulp and paper industry with mills in China, Vietnam, Malaysia, and the United States. The group primarily produces linerboard, high-performance corrugating medium, coated duplex board, and printing and writing paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

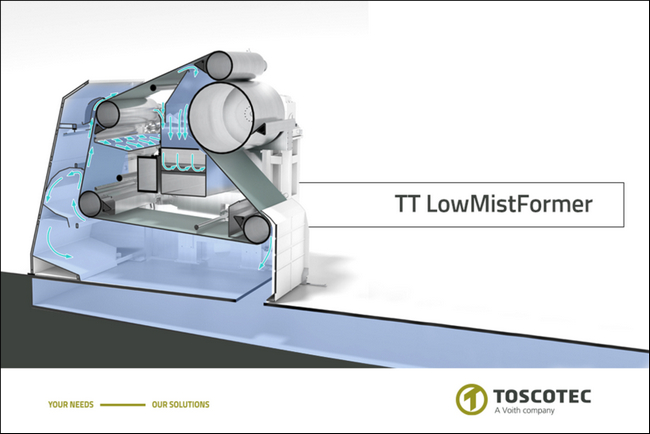

Toscotec introduces energy-efficient innovation for Crescent Former.

Toscotec has successfully introduced TT LowMistFormer, the latest innovation of the wire section of Crescent Former tissue machines. Originally designed by Voith, the system has been integrated into Toscotec’s design as part of the efficient know-how exchange between Voith and Toscotec following the acquisition. TT LowMistFormer technology has been applied on several AHEAD tissue machines manufactured by Toscotec.

Enrico Raffanti, Toscotec Deputy CTO, says: “TT LowMistFormer improves the runnability of the machine in the key section of paper formation, leading to higher process stability. This new concept is perfectly in line with our mission as manufacturers of advanced technology: developing innovative solutions to boost production efficiency while reducing energy consumption, in order to increase sustainability in paper production.”

Significant mist reduction with zero energy

By creating a screened area in the wire section with an optimized combination of fixed elements, TT LowMistFormer delivers remarkable air, water, and mist flows performance. The contained mist is captured and swiftly carried away through the Venturi effect generated by the jet speed of TT Headbox. The system ensures both a substantial reduction of mist expansion in the environment and its fast removal with zero energy consumption. With TT LowMistFormer the installation of a mist removal system in the forming section becomes unnecessary. This results in the elimination of more than half of the total installed power of a mist removal system, which saves a significant amount of energy.

A key tool to reduce maintenance and improve the working environment

TT LowMistFormer ensures a cleaner and healthier environment around the wire section, which normally produces the highest concentration of mist of the entire tissue line. The system also delivers a significant reduction of dirt build-up on the machine, which leads to a reduction of cleaning and maintenance operations on the production line and on the building. A cleaner environment is also reflected in the increase of machine efficiency and the improvement of working conditions for machine operators.

ANDRITZ to supply Ash ReCrystallization plant to Suzano, Brazil

International technology group ANDRITZ has received an order from the Brazilian pulp and paper company Suzano to deliver an energy-efficient Ash ReCrystallization (ARC) plant for the recovery boilers at its eucalyptus kraft pulp mill in Barra do Riacho, Brazil. The estimated start-up date for the ARC plant is the first half of 2022.

3D rendering of the Ash ReCrystallization (ARC) plantThe ANDRITZ ARC plant removes the harmful chloride and potassium from the ElectroStatic Precipitator (ESP) ash and returns valuable chemicals to the chemical recovery cycle. The plant to be supplied is designed to handle 550 tons of ESP ash daily.

3D rendering of the Ash ReCrystallization (ARC) plantThe ANDRITZ ARC plant removes the harmful chloride and potassium from the ElectroStatic Precipitator (ESP) ash and returns valuable chemicals to the chemical recovery cycle. The plant to be supplied is designed to handle 550 tons of ESP ash daily.

Featuring the new energy recovery technology, the ARC plant will optimize energy efficiency significantly. This technology is also based on an enhanced evaporative crystallization concept that will improve the recovery process. With this order, ANDRITZ is demonstrating its strong global position in the supply of state-of-the-art and environmentally friendly ARC plants.

Suzano is the largest pulp and paper company in Latin America and a leader in the paperboard market. The company is also the largest producer of eucalyptus pulp in the world. This proven process technology from ANDRITZ will help Suzano achieve their financial and sustainability goals.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ABB launches fastest paper machine moisture sensor on the market, taking 5,000 measurements per second

ABB has released its High-Performance Infrared-Reflection (HPIR-R) moisture sensor, which provides the fastest, most precise moisture monitoring available on the market today. Taking up to 5,000 measurements per second, the sensor delivers precise, high-resolution measurement that enables mills to increase throughput while reducing operating costs.

- ABB’s new patented technology offers unprecedented speed and accuracy of moisture measurements, even in difficult locations

- Accurate measurement can lead to significant cost savings; a ~1% change in moisture can generate up to $400K in energy savings

- Precise measurement helps reduce drying costs and emissions for more sustainable operations

This advanced, patented technology will help pulp, paper and board producers to always know the precise moisture levels, giving them confidence to raise moisture targets and improve their CD profiles, enhancing end product quality with fewer rejects as a result.

Being able to measure and control the moisture levels as the sheet moves through the paper machine is critical to reducing energy requirements. This leads to optimized drying, decreased steam usage, significant energy savings in dryer sections and reduced carbon emissions. In fact, changing the steam pressure to create a moisture change of just 1% can equate to $400K in energy savings.

The small spot of infrared energy used in the sensor provides excellent streak resolution and accurate edge-to-edge sheet measurement, even in the most difficult environments. Measurement while scanning is continuous, with no beam chopping or filter wheels ensuring optimum signal-to-noise ratio and maximum measurement rate.

ABB’s new HPIR-R moisture measurement, which also has a built-in sheet temperature sensor, is designed to be fully air-cooled and field repairable. That, coupled with its insensitivity to dust and disturbances enables high uptime and lower total cost of ownership than similar solutions.

“Unlike competitive offerings, ABB’s HPIR-R moisture sensor provides the highest frequency measurements possible, which helps customers to improve quality, reduce downtime, decrease costs and increase yields,” said Andy Broomfield, Product Line Manager at ABB. “It has been designed for papermakers looking for accurate and precise moisture measurement in hot, difficult machine environments.”

While it can be placed in any location, the highest impact application for this reflection moisture sensor is before a size press, where better precision and accuracy let you raise the moisture target, giving optimized starch/sizing pickup and reduced drying energy demand. This also applies to pre-coat locations.

Another high-value application is placing it after the wet press section, enabling operators to adjust press loadings to improve the moisture profile and increase sheet dryness going into the dryers. In addition to energy savings, this also gives higher sheet strength in that sensitive area of the machine, meaning improved runnability and sheet break recovery.

Part of the ABB Ability™ Quality Management System, the sensor is fully digital with high-speed measurements provided alongside a rich set of diagnostic data which is ideal for analytics to inform on-site or corporate-level decision-making. It is applicable for all network platform types and can be used to measure publication grades, graphic papers, board, tissue, packaging, specialist and recycled grades.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation

AFT refining with IoT integration at BillerudKorsäs Skärblacka

AFT recently had another successful refiner start-up with the BillerudKorsnäs group, world leader in packaging grades. Our new pulp mill reject refiner started-up in December at the 460 000 t/d Skärblacka mill in Sweden, designed to defiberize knots, shives and fiber bundles coming from pulp screening. Combined with Finebar® technology, AFT refiners deliver optimized performance and energy savings which will help support BillerudKorsnäs’ sustainability goals through resource-efficient production.

AFT refining at BK Skarblacka

AFT refining at BK Skarblacka

The Skärblacka installation also includes an AFTLinx integration unit for monitoring refiner performance remotely. Our optional IoT gateway collects equipment-specific operating data to address customer needs for remote product support and service. The data access allows AFT specialists to assist with start-ups, conduct comprehensive real-time machine diagnostics, and provide advice for optimized refiner operation.

About AFT:

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application, and the end-product being produced in order to optimize their return on investment.

For more on AFT refining products and services, contact us at http://ow.ly/6u4m50HtSAb

PulPac files patent for tool that further improves functionality and efficiency for Dry Molded Fiber

PulPac has just announced the filing of an additional patent application, further refining its pioneering cellulose forming technology for competitive fiber-based packaging and single-use products.

The new patent application comprises a hybrid tool that uses the pressing force to work in mould parts both in a pressing direction and in a lateral direction. The hybrid tool efficiently uses one pressing stroke for manufacturing a product having a general form in the pressing direction and a special feature such as for example undercut in the lateral direction. This is especially advantageous when manufacturing products like lids and other applications where e.g. stacking and denesting features are important. The hybrid tool also brings possibility of enhanced surface quality and improved tool life.

“Innovation is a core function at PulPac. It is at our heart and how we drive change for a sustainable future together with our clients. This patent application is a good example on how we continuously can refine and make Dry Molded Fiber even more effective or adapt it to specific demands or product applications” says Peter Ekwall, IP Manager at PulPac

Dry Molded Fiber is a fiber forming technology that can replace single-use plastic with sustainable fiber-based alternatives at low cost.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. www.pulpac.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy – using renewable pulp and cellulose resources to produce low cost, high performance, fiber-based packaging, and single-use products. Dry Molded Fiber gives up to 80-90% lower CO2 footprint at similar cost as plastic. It is up to ten times as efficient as conventional fiber molding invented over 100 years ago. The dry process also saves massive amounts of valuable water resources. In addition, energy savings are significant - as the molded products need no drying.