Displaying items by tag: voith

Voith and partners announce FOREST initiative: Research project aims to develop digital framework for optimizing energy and material flows in paper production

Voith, the leading global technology group for the paper industry, has launched a new research project called FOREST together with partners from industry and research. The goal of the project is to develop a fully comprehensive digital map for papermaking processes that can capture energy and material flows, as well as CO2 flows and footprints, down to the sub-process and sub-product level. The digital framework identifies multiple optimization opportunities that promote a targeted acceleration of the paper industry's transformation toward climate neutrality.

- FOREST research project launched in cooperation with renowned partners from industry and research

- Goal is to build a digital framework that will enable effective process optimization and predictive benefit assessment

- Project aims to support the paper industry's transformation towards climate neutrality

By visualizing the actual state of the production facilities, all stakeholders gain a deeper understanding of the processes. In particular, the innovative solution makes it possible to identify plant areas with high optimization potential during ongoing operation using current data. With the help of the digital framework, for example, the optimum settings for minimized CO2 emissions can be determined and the benefits of rebuild measures can be estimated in advance. In addition, the digital framework supports the definition of requirements for future developments. In this way, the influence of new framework conditions, such as changes in energy supply or costs, can be modeled.

After the first kick-off meeting, the project team is now working to define the requirements and interfaces for the framework and derive a requirements catalog. In addition to a physical basic model, this framework also includes specific, more detailed modeling of individual sub-processes, which are also being developed by Voith as part of the project. In the next step, Voith will test the digital framework together with the other research partners on various pilot installations.

The research project was approved by the project management organization Jülich as of April 1, 2023. The project involves cooperation between Voith and Modellfabrik Papier gGmbH, the Institute of Textile Technology at RWTH Aachen University (ITA), the NOWUM-Energy Institute at FH-Aachen University of Applied Sciences, the Chair of Wood Technology and Fiber Materials Technology at TU Dresden, the Paper Technology Foundation (PTS), ABB AG and associated partners such as Felix Schoeller GmbH & Co. KG, Sappi Ehingen GmbH, Schoellershammer GmbH and WEPA Group.

About the FOREST research project

FOREST stands for “Framework fOr Resource, Energy, Sustainability Treatment” in paper production. The work is funded by the German Federal Ministry of Economics and Climate Protection as part of the German government's 7th Energy Research Program. Further information can be found at: BMWK - Energy Research and Innovation.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Saica again relies on the leading digital solution OnEfficiency.Strength to save starch

Saica has selected the leading full-line supplier Voith to install the OnEfficiency.Strength digital solution. The innovative package for saving starch and consequently reduce CO2 emissions will be used at PM 10 at the El Burgo de Ebro site (Spain) as well as the PM 70 at Nogent-sur-Seine site (France). OnEfficiency.Strength is currently a unique solution on the market, developed specifically for paper production. The application is already successfully in operation worldwide. Especially after raw material costs have risen significantly, there is an increasing need for intelligent solutions that quickly reduce production costs.

Voith and Saica have already shared a very trusting and very good business relationship for a long time. The winning synergies combined with the technical know-how of Voith experts enable a best-in-class concept. Juan Luis Mendoza, Digital Officer at Saica, can also confirm this: "With Voith as one of our most important strategic partners, we are taking another step towards digitalization. The digital solution has already convinced us at other Saica sites. With the new installations in PM 10 and PM 70, we expect now to save significant amounts of starch at these plants and produce with less CO2 emissions. We look forward to improving Saica´s resource efficiency. We are sure it will quickly pay for itself."

Once installed at Saica, OnEfficiency.Strength will monitor key quality parameters and automatically adjusts starch application to the paper as well as other process and machine settings to customer requirements. Saica can thus save starch significantly. In addition, the solution increases the precision and reliability of the process, reduces manual handling and is easy to operate. Thanks to OnEfficiency.Strength, the current values for strength properties can be viewed in real time rather than only being available with manual sampling. In addition, the solution has the potential to reduce steam consumption and thus CO2 emissions as well as to ensure quality throughout the value chain.

"Voith's excellent reputation has been further reinforced with its strong focus on digitalization in the paper industry. I strongly believe that we offer by far the best added value to our partners, who are more than just customers," emphasizes Renan Fusco, Head of Digital Solutions Sales at Voith Paper. "By working with Saica, we are providing another important impulse for the paper industry in Europe."

More information on Voith's digitalization portfolio can be found here: https://voith.com/PaperIsOn.

About the Saica Group

The Saica Group is one of the leading companies in Europe in the manufacture of recycled paper for corrugated board, with a production capacity of 3.3 million tonnes. With over 10,000 employees and operations in Spain, France, Italy, Portugal, United Kingdom, Turkey, Luxembourg, Netherlands, Poland and United States, the Saica Group has four business lines: manufacture of recycled paper for corrugated card (Saica Paper), waste management and environmental services (Saica Natur), production of corrugated card for packaging (Saica Pack) and flexible packaging (Saica Flex). The Group’s turnover amounts to 4,394 million euros (consolidated turnover as of 31st December 2022). Saica.com

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Paper manufacturers increase energy efficiency through customized audits and process analysis from Voith

Voith Paper is helping paper manufacturers significantly increase their energy efficiency. Using customized auditing and process analysis methods, the leading full-line supplier offers innovative solutions to improve processes and increase efficiency. This allows paper manufacturers to understand the big picture of their energy consumption and find clear ways to reduce it.

- Energy audits performed by Voith Paper have achieved significant energy savings in areas such steam and condensate, air handling and vacuum systems

- Papermakers can choose from a variety of energy audits, including desktop audits, on-site overview audits and detailed on-site audits

- Customers are reporting a 10 to 20 percent savings on their total energy costs

"An on-site overview audit provides the customer with an up-to-date overview of the main energy saving measures and opportunities," says Eduardo Fernandes, Process Engineer Sustainability Audits at Voith Paper. "Using specially developed toolboxes and checklists covering 20 key areas, the energy savings are assessed, including a project list and an estimate of the investment budget and payback period. The results provide a valuable baseline and work list for the future. Typically, energy savings are in the range of 10 to 20 percent of current total energy costs. Especially in light of rising energy costs and sustainability requirements, an energy audit is a good choice."

Voith offers a range of services, including desktop audits, on-site overview audits and detailed on-site audits:

- Desktop audits use customer information such as equipment data and trends to provide an effective overview of energy consumption and identify ways to reduce it. The paper manufacturer receives a report with analysis, industry benchmarking, best available technologies and possible optimization projects. For example, with a successful energy audit for an Asian paper mill, Voith experts identified 34 projects that saved 20 percent in energy costs and reduced the carbon footprint by 35.7 percent.

- The on-site overview audit is designed to provide a comprehensive overview of energy consumption and a detailed analysis. This service solution includes, for example, collecting details from on-site systems, reviewing documents and assessing leakages and bottlenecks. A successful overview audit in Germany resulted in a reduction of more than 30 percent in gas consumption and savings of almost 18 percent in electrical energy. To achieve this, 28 individual projects were successfully implemented.

- A detailed on-site audit includes the collection of details from specific systems such as vacuum, steam, condensate and air treatment. With the help of special on-site measurement tools, a realistic operating scenario and a detailed study of the specific system are created. The report includes a calculation design as well as innovative ideas for process improvement and increased energy efficiency. Voith also offers support in the implementation of the projects. For example, thanks to a detailed audit at a paper mill, potential improvements in the vacuum system were identified. By making simple adjustments and without capital expenditure, energy savings of 21 percent were subsequently achieved.

Papermaking for Life sustainability program

As part of the "Papermaking for Life" innovation and development offensive, Voith Paper is presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: voith.com/papermaking-for-life/energy.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

#VoithCares funding program continues

The #VoithCares program was launched this fiscal year together with the Hanns Voith Foundation. Through the program, Voith financially supports the volunteer work of employees throughout the world. A total of 50,000 euros has been donated to nonprofits. For the next fiscal year, employee activities are being sought to receive funding.

- Funding of 50 social projects planned for the coming fiscal year

- Applications from Voith employees now open

- Impressive response in the first year

Social responsibility is more than just a buzzword for the global technology group Voith: the company directly funds education and training, science and research, and social, sports, and cultural activities worldwide. To support their socially involved Voithians, the company launched #VoithCares. Through active employee nominations, 50 organizations and their measures were selected and given financial support. Each of 26 projects in Europe and Africa received 1,000 euros. Among others, the Crailsheim child protection association, the Heidenheim wind orchestra, and an education initiative for children in Ghana were supported. Nine projects from nonprofit organizations in North America, nine in Asia and six projects in South America also received funding. The workforce response was overwhelming – almost 100 applications were received.

Due to its huge success, the initiative is now continuing for another round. Voith is inviting employees at all of its locations throughout the world to submit nonprofit projects.

“Social responsibility is important to us at Voith Paper, and I am proud of the exceptional response and commitment of our employees to the #VoithCares program,” says Andreas Endters, President & CEO Voith Paper. “In the upcoming fiscal year, we will support additional social projects worldwide to have a positive impact on education, social issues, and culture. Our employees are the key to our success.”

In fiscal 2023–24, 50 projects from all over the world will be selected and funded with a maximum 1,000 euros each by the Voith Group and the Hanns Voith Foundation within the scope of the program. Voith employees can submit applications until the end of September. The donations will then be made in the following fiscal year. Voith will report on the selected organizations and measures on a regular basis.

About #VoithCares

As part of the #VoithCares program, Voith and the Hanns Voith Foundation annually award financial support to a select number of employee-nominated projects and nonprofits, in which the employees also personally volunteer. Nominated projects must align with Voith’s DNA, “sustainable technologies for future generations," and fall into the categories of digitalization; technology, innovation and decarbonization; or social causes. Projects selected benefit children, youth, young adults or those who are disadvantaged. Through the #VoithCares program, the company supports both employees and nonprofits in the communities Voith serves around the world and encourages employees to volunteer in their local communities so we can make the world a little better – together.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

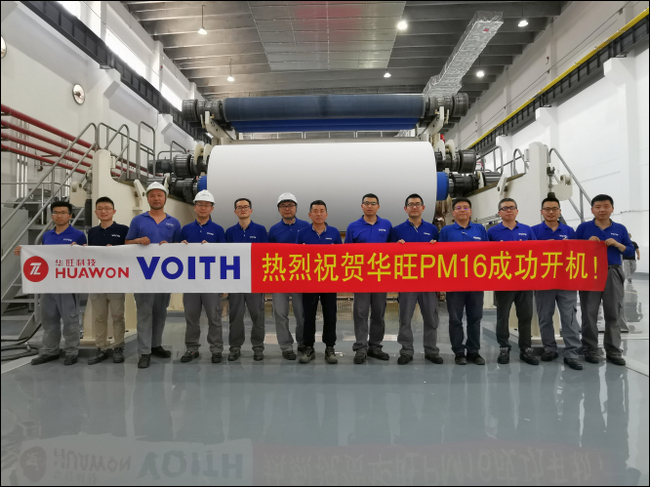

Voith and Huawon strengthen their cooperation with the successful start-up of PM 16 for production of high-quality décor base papers

In mid-June, PM 16 from Chinese paper manufacturer Huawon successfully started up at the Ma'anshan site, Anhui Province, with leading solutions from Voith. With the PM 16, Huawon will produce high-quality, environmentally friendly décor base paper and thus strengthen its market position at home and abroad.

- In mid-June, Huawon's PM 16 was successfully started up at the Ma'anshan site

- PM 16 is equipped with highly efficient Voith solutions and produces high-quality décor paper for premium customers at home and abroad

- Huawon's President Dou Zhengliang praises the reliable quality of the Voith system and emphasizes the successful cooperation

The solutions supplied by Voith include key components for the BlueLine stock preparation system for virgin fiber, WEP, headbox, DuoShake DG and calender. The PM 16 already represents Huawon's fifth follow-up order with Voith. Through the internal exchange of experience, valuable knowledge from the past could be transferred, further optimizing the design of the new paper machine and raising it to a higher level.

Dou Zhengliang, Chairman of Huawon, expressed his satisfaction with the successful start-up of PM 16: "The successful start-up of PM 16 has once again proven the reliable quality of Voith equipment and raises Huawon's production capacity and scale to a new level. I would like to thank the employees of both companies for their trustful cooperation. Voith is a global technical leader in the field of specialty papers and has a wealth of experience. We will deepen cooperation with Voith and jointly develop new markets for specialty papers."

"Huawon has achieved remarkable success in the field of décor papers with its outstanding innovation, excellent quality standards and first-class customer service," says Lin Carlos, Vice President Order Execution and Manufacturing at Voith Paper Asia. "I would like to thank all the professionals for their contribution to this endeavor. We are confident that we can achieve more great successes together in the future and help Huawon become a leading national brand for world-class décor base papers."

During the project, the Voith-Huawon team demonstrated deep mutual trust and shared expertise. Despite the challenges to global supply chains, the two companies coordinated flexibly and completed all tasks with dedication to enable the project to progress smoothly.

About Huawon

Despite market challenges, Huawon continued to develop against the trend in 2022, achieving sales volume of 227,400 tons of decorative paper, up 12.3 percent year over year. Huawon's operating profit reached RMB 3,436 billion, a year-over-year increase of 16.88 percent. Huawon has several production lines of décor paper with international leading standard. The company attaches great importance to technological progress. Its products are sold in all parts of the world and have successfully reached the global top field for décor paper. Adhering to the guiding principles of "professionalism, focus, consistency and development," Huawon is steadily moving towards greater goals.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

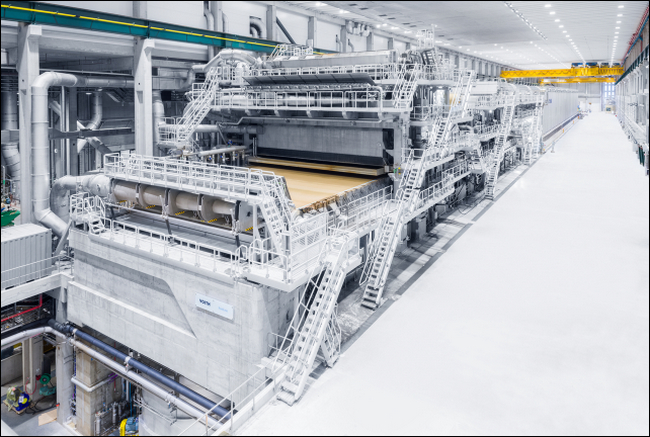

DS Smith commissions Voith to rebuild PM 4 at Viana to increase production capacity and efficiency

DS Smith, a leading global manufacturer of sustainable containerboard and specialty papers, has commissioned Voith to rebuild its PM 4 at the company’s Viana site in Northern Portugal. Producing around of 400,000 tons of kraftliner and high-performance top kraftliner per year, the mill is a market leader in Southern Europe. The extensive rebuild will increase production and improve overall efficiency. Production will expand to around 428,000 tons per year with a machine design speed of 1,100 m/min. The start-up of the project is scheduled for the fourth quarter of 2023.

“We are happy to realize this project together with DS Smith. Our customized solutions will lead to the desired production capacity, efficiency and quality,” says Marcos Garcia de la Torre, Managing Director Voith Paper Spain. “DS Smith benefits from Voith’s expertise, state-of-the-art technology and outstanding project efforts. The commission confirms that we, as the full-line supplier to the paper industry, are the trusted partner for rebuilds.”

The rebuild scope includes modifications to the forming section to increase capacity and performance of the paper machine. The press section will be completely renewed, including installation of a Tandem NipcoFlex press that will significantly increase the dry content after press and reduce specific steam consumption.

The rebuild scope includes modifications to the forming section to increase capacity and performance of the paper machine. The press section will be completely renewed, including installation of a Tandem NipcoFlex press that will significantly increase the dry content after press and reduce specific steam consumption.

The transfer between press and dryer sections will be modified with state-of-the-art web transfer and tail threading technology to provide the best runability for lightweight grades. In addition, smaller modifications and upgrades in the stock preparation and approach flow line are planned. Finally, the scope of delivery includes a comprehensive fabrics package for the PM 4 start-up and subsequent supply, as well as spare parts.

About DS Smith

DS Smith is a leading provider of sustainable fiber-based packaging worldwide, supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast-moving consumer goods and industrials.

Through its purpose of “Redefining Packaging for a Changing World” and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sit at the heart of this response.

Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

SCA relies on latest digitalization and lifecycle management solutions from Voith and BTG along the entire paper machine to save resources

SCA is successfully utilizing Voith's digital and automation solutions with the aim of optimizing the production efficiency of its new XcelLine PM 2. Last year, the leading full-line supplier Voith successfully commissioned the paper machine at its Obbola site. The high-performance machine produces 725,000 tons of kraftliner annually with basis weights between 100 and 200 gsm and has a design speed of 1,400 meters per minute.

- SCA uses digitalization and automation solutions from the Papermaking 4.0 portfolio of Voith and BTG across the entire paper machine

- In addition, Voith works closely with SCA after installation as part of an Efficiency Partnership

- Solutions lead to significant resource savings in paper production

“The journey for SCA and Voith together has only just begun,” says Gustaf Nygren, Mill Manager Obbola at SCA. “We have a long-term partnership in place with the target of reaching the common vision of PM 2 in Obbola becoming the new reference for safety, efficiency and digitalization.”

To achieve its goals, SCA is using more than 10 innovative digitalization and automation solutions across the entire paper machine from the Papermaking 4.0 portfolio of Voith and its subsidiary. For example, solutions from the OnEfficiency family help increase line efficiency and stabilize product and process quality. The increased efficiency also contributes to more sustainable and resource-saving paper production. SCA also uses applications from the OnCare family to monitor productivity and take optimization measures quickly.

Machine availability is further increased by digital services such as the OnCall.Video remote maintenance service. The Voith Paper Webshop enables fast ordering of spare and wear parts as well as services. The digital portfolio is made available on Voith’s IIoT dataPARC cloud platform, which is characterized by the highest security standards.

“With the PM 2, we will take our next steps in the digitalization journey. The applications provided by Voith will help us to monitor the process and make the right decisions,” confirms Niclas Ahnmark, Paper Mill Manager at SCA.

SCA has also signed a long-term service agreement with Voith subsidiary BTG for process control. BTG's Lifecycle program ensures optimal consistency accuracy and control by providing preventive maintenance services for the entire consistency sensors install base, including regular calibration and routine checks. BTG Field Service Engineers assist in the planning, implementation and coordination of the various maintenance services, maximizing machine uptime and stability while maintaining SCA's high safety standards.

The collaboration with SCA is long-term and is particularly evident through the Efficiency Partnership. Throughout the process, the teams work closely together to ensure that the solutions are used optimally. Stephan Sicking, Vice President Sales FRS EMEA at Voith Paper, explains, "As part of a digitalization roadmap, we have defined common goals and KPIs in a cross-functional team, developed a customized concept and are now providing support for successive installation and employee training. Already, the benefits from this collaborative approach are clearly demonstrated." Learn more on our Voith website: Containerboard mill Obbola PM 2 | Voith.

About SCA

The core of SCA’s business is the growing forest, Europe’s largest private forest holding. Around this unique resource, we have built a well-developed value chain based on renewable raw material from our own and others’ forests. We offer packaging paper, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. 2022 the forest products company SCA had approximately 3,300 employees and sales amounted to approximately SEK 21 bn. SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden. More information at http://www.sca.com.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith strengthens best-in-class mechanical roll service with sophisticated sensor technology and digital upgrades

With a worldwide network of 22 Mechanical Roll Service Centers, unrivalled domain expertise and sophisticated digital solutions, Voith is uniquely positioned as a full-line supplier to provide best-in-class customized roll maintenance to papermakers around the globe.

- A worldwide network of 22 Mechanical Roll Service Centers provides tailored support and short response time in state-of-the-art roll maintenance, repairs and digital upgrades

- Papermaking 4.0 portfolio supports data-driven decision-making to boost machine availability, production efficiency and sustainable papermaking

Voith’s individualized and transparent service solutions ensure maximum machine availability as well as highly reliable and sustainable production lines. Moreover, the benefits of Voith’s approach to mechanical roll service (MRS) extend beyond efficiency and sustainability gains.

“Expertly maintained rolls in paper machines are fundamental to efficient and sustainable papermaking. With the support of our experienced application specialists and state-of-the-art service tools, we are able to recommend if and when optimization or maintenance measures are required. And our global network of dedicated service centers ensures that timely roll maintenance is performed to schedule and to the highest of industry standards,” says Joerg Schauberger Global Product Manager MRS & Digital Products at Voith Paper.

SealView unlocks data-driven decision-making

With SealView, for instance, papermakers now have accurate, reliable, and real-time information on the wear status of sealing strips inside suction rolls. The sophisticated sensor system can be installed on any type or brand of suction roll at Voith MRS Centers. Notably, the SealView system provides insight on the condition of the seal strips in suction rolls and predicts the remaining seal lifetime. SealView can be accessed by machine operators at the customer site as well as remotely by dedicated Voith Service Centers.

Such precise information supports data-driven decision-making, increases safe roll run times and allows the stress-free and timely scheduling of roll change and service with the Voith MRS Centers. As seal strips are only ordered in time for the scheduled maintenance, capital expenditure is also reduced. What’s more, as SealView is based on a pneumatic system, with this innovative solution there is less risk of malfunction during use under wet conditions.

HydroSeal radically cuts lubrication water consumption

When SealView is combined with HydroSeal, further cost and resource savings are achieved. Unlike conventional seal strips that rely on water showers to cut down on friction during rotation, HydroSeal works with an innovative integrated lubrication system to ensure a constant, even and uniform lubrication over the complete width of the suction roll. Along with significant savings in lubrication water requirements, HydroSeal also increases the efficiency of drive operation, which reduces energy costs. Furthermore, rewetting is reduced and a more homogenous moisture profile across machine direction can be achieved, when running in optimum conditions.

At one plant in the U.S., installing HydroSeal led to an 82 percent reduction in water consumption for the lubrication of sealing strips each year, which translates into cost savings of more than US$30,000 for fresh water and wastewater.

“Our sophisticated sensor technology and advanced cloud-based analytics ensure decision-making around roll maintenance is fact-based, data-driven and impactful,” says Halim Takhedmit Digital Product Manager Fabric & Roll Systems at Voith Paper. “This digital upgrade is what customers need to turn their paper plants into ultraefficient and sustainable operations.”

Digitalized roll maintenance and inventory management

A transparent and easy to use inventory management system is crucial for optimizing maintenance scheduling and visualizing run times. This is provided by Voith’s OnCare.pmPortal, the powerful asset management tool for fabrics, rolls, roll covers and doctor blades. With the OnCare.pmPortal module “ID Tagging” critical products are tagged to support better tracking and inventory management. Depending on the product and machine environment, either a barcode, QR code or RFID/NFC technology is used. In all cases, a simple scan with a mobile device quickly reveals all the relevant information necessary for optimized predictive maintenance, including product history and run time since installation.

“By combining best-in-class roll maintenance service with future-oriented inventory management support, we are driving best practices in efficient and sustainable papermaking,” states Joerg Schauberger.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Fast and easy rebuild of existing cleaner systems: New AdaptClean technology ensures optimized cleaning process

Based on many years of experience in cleaner technology, Voith introduces the AdaptClean rebuild kit, the latest optimization option within its BlueLine product range. The AdaptClean technology enables a quick and easy conversion of existing low consistency cleaners from a diameter of 105 mm. The upgrade involves removing all parts below the headstock. A Voith cleaner cone and the Easy EcoMizer are then attached to the existing headpiece using an adapter. A dilution water line with pump makes the system ready for use again within a few hours.

- The new AdaptClean system leads to efficiency increases as well as significant fiber and energy savings for existing low consistency cleaner with a diameter of 105 mm or more

- The rebuild kit consists of an adapter, the tried and tested cones in various material designs, and the Easy EcoMizer

- The modernization is possible for most plants worldwide, regardless of manufacturer

"With the new AdaptClean system, we now offer an efficient and fast rebuild worldwide and independent of manufacturer for existing cleaner systems," explains Elmar Ott, Product & Service Manager at Voith Paper. "Due to the optimized service lives and higher plant efficiency, customers thus achieve cost savings every day through the modernization, even for originally non-Voith cleaners. The ROI of the AdaptClean system is therefore less than one year."

To realize the best cost-benefit combination, the new AdaptClean system is available in a wide range of cone materials. The proven Easy EcoMizer enables clog-free operation with optimal fiber backflushing, significantly reducing fiber losses compared to conventional systems. By reducing the amount of fiber, a significant increase in ash content in the rejects can be realized. In addition, increased inlet stock consistency achieves further energy savings.

Voith also supports its customers with suitable spare parts after the rebuild. In addition to the AdaptClean concept, Voith offers many additional services and individual measures to optimize processes and plant efficiency. Thanks to worldwide service locations and the OnPerformance.Lab remote service center, customers can receive competent support at any time and from any location. Find more information here.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith’s PapermakingAcademy contributes to successful start-up of SCA’s PM 2 in Obbola

Voith delivered effective commissioning trainings for the November 2022 start-up of the world’s largest kraftliner machine, SCA’s PM 2 in Obbola, Sweden. Thanks to Voith's PapermakingAcademy and comprehensive documentation, the SCA team was optimally prepared for operation of its new state-of-the-art facility.

- Effective commissioning training provided by the PapermakingAcademy to ensure successful start-up of SCA’s PM 2 in November 2022

- PapermakingAcademy bundles Voith’s training offerings along the entire life cycle of a plant

- Customers benefit from in-depth expert know-how and application-oriented training courses

“A key factor to the successful start-up here in Obbola has been the training given to the employees,” says Lisa Lundström Hämälä, Process Engineer at SCA. “Voith prepared extensive training materials, and Voith and SCA together made sure there were several occasions for each training so employees could attend while also running our old, now closed paper machine.”

Voith is a leading provider of comprehensive expert training for the papermaking industry. With the PapermakingAcademy, the company offers target group-specific training programs and courses that cover the entire life cycle of a paper machine and the plant’s components. The PapermakingAcademy enables customers to use and operate their paper machines to their optimal capacity. During commissioning, this results in a faster take-over. At the same time, Voith supports papermakers with in-depth expert knowledge to drive forward efficiency and lift their plants to the next level of performance.

Training offerings of the PapermakingAcademy cover the entire life cycle of a paper machine

“The new training modules include all sections of the paper machine and cover its entire life cycle,” says Zahida Sakic-Kramer, Director Design Main Sections at Voith Paper, describing an important aspect of the PapermakingAcademy. “This allows us to support customers precisely where and when they need it – and with the help of new, digital tools.”

“With the PapermakingAcademy, we are expanding the previous training offered by the Voith PaperSchool, which primarily covered service-related topics,” adds Stefanie Schmied, Concept Manager Digital Training at Voith Paper. “Voith Paper now offers a comprehensive course catalog – from basic training units on our new machines and commissioning to in-depth, application-oriented expert training of specific service activities.”

The PapermakingAcademy course catalog gives information about all courses, the respective learning objectives and the recommended target groups. This ensures that participants get the maximum benefit from training in homogeneous learning groups and that customers can make use of a comprehensive and unique training offering to educate their personnel in the best possible way.

For further information on the PapermakingAcademy and the current course catalog, please visit: www.voith.com/papermakingacademy

Visit our website to learn more about SCA’s PM 2 in Obbola: www.voith.com/corp-en/industry-solutions/papermaking/obbola-pm-2.html

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.