Displaying items by tag: voith

Indian customers rely on the Voith Paper Webshop for a quick and easy ordering process

Customers worldwide order products and services in real-time in the Voith Paper Webshop. In addition, to spare and wear parts, fabrics can also be purchased via the application with just one click for over a year now. Chandpur Enterprises Ltd. has been benefiting from the expansion of the product portfolio in the Voith Paper Webshop since March. "With the help of the personalized menu and the order history, we can now quickly identify our fabrics, order them and track the delivery status around the clock," says Mr Devesh K. Singhal, Technical Director of Chandpur Enterprises Ltd. "We are very satisfied with the Voith Paper Webshop and the cooperation with the Voith experts, who have been flexible to our requirements."

- Worldwide, the Voith Paper Webshop is already used by 180 customers

- Chandpur Enterprises Ltd. and other India customers have now also opted for the Voith Paper Webshop

- A fast, simple and personalized ordering process was the main reason for the decision.

In addition to Chandpur Enterprises, other Indian customers have already integrated the Voith Paper Webshop into their ordering process. In total, more than 180 customers already rely on digital applications. In the personalized "My Shop" section, the paper manufacturers can find all the necessary information from the original and current condition of the equipment as well as the order and quotation history, drawings, manuals and contracts.

F.l.t.r.: Praveen Batra (Head of Sales & Services FRS, Voith India), Devesh K. Singhal (Technical Director, Chandpur Enterprises Ltd.), Gaurav Singh (Senior Executive, Sales & Services FRS, Voith India) and Harsh Bakshi (Deputy Manager, Sales & Services FRS, Voith India).

F.l.t.r.: Praveen Batra (Head of Sales & Services FRS, Voith India), Devesh K. Singhal (Technical Director, Chandpur Enterprises Ltd.), Gaurav Singh (Senior Executive, Sales & Services FRS, Voith India) and Harsh Bakshi (Deputy Manager, Sales & Services FRS, Voith India).

Mr Devesh K. Singhal confirms the advantages: "Initially, we were not sure whether we should convert our previous ordering processes to the webshop and digitize them. However, we then decided in favour of the Voith Paper Webshop, because we were completely convinced by the functionality as well as the very clear user guidance. In addition, the onboarding process and subsequent registration of the individual users went smoothly. We are glad to have taken this step."

The Voith Paper Webshop is characterized by the highest data security standards. Different options can be booked depending on customer requirements. "Our goal is to enable our customers to optimize production with minimized downtimes," sums up Mr Gaurav Singh, Senior Executive Sales & Service India at Voith Paper. "One building block for this is the quick and easy ordering of fabrics. We offer customer-specific solution packages, which we are continuously developing further on a region-specific basis. The integration of the Webshop can be done smoothly for any customer worldwide."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Big savings of starch with the help of Voith's Papermaking 4.0 solutions – successful digitalization project with Saica

The results are clear: Just a few months after Voith's comprehensive digitalization solutions were commissioned at PM 9 in El Burgo, Saica Group's investment in the Papermaking 4.0 package has already paid off. The Spanish paper manufacturer produces around 430,000 tons of paper per year at the facility, located around 25 kilometers from Zaragoza. At the end of 2020, the company decided to digitalize production. After a thoroughly positive experience with the digitalization of PM 4 in Venizel, France, Voith was awarded the contract to implement the project for PM 9, which includes OnCumulus applications and the two solution packages OnView.MassBalance and OnEfficiency.Strength.

- Comprehensive Papermaking 4.0 package for PM 9 in El Burgo

- OnCumulus, OnView.MassBalance and OnEfficiency.Strength enable significant resource savings

- Saica plans to expand its digitalization strategy

"Voith has been a great partner along the digitalization journey in our mills," says Fernando Carroquino, Industrial Director at Saica Group. "Our perception of Voith Paper as one of the main digital solutions provider is reaffirmed every day, and we are very glad with the cooperation with Voith over the last years. We have the full commitment of both companies, which makes us look forward to the next successful cases."

The main goal of OnEfficiency.Strength on a paper machine for container board is to reduce the consumption of starch without negatively affecting the strength properties of the paper. The solution uses virtual sensors as a basis on which innovative advanced process control is built. OnEfficiency.Strength has already proven a high benefit in several references and significantly reduced the product cost. At PM 9, too, the high potential of digitalization became apparent shortly after commissioning.

Fernando Vicente, Production Manager at PM 9 El Burgo, says: "Although the plant has been continuously optimized in recent years, we have now been able to significantly reduce our starch usage in the first few weeks with the help of OnEfficiency.Strength. The tool is very easy to use, and the operators are very motivated to integrate it into their daily work. We are confident that, in the future, savings can be increased even further. Now it is much easier to sustainably achieve the targeted quality at the lowest possible cost."

OnView.MassBalance starts at an earlier point in paper production. The app's data maps the current stock flows in a diagram and depicts deviations from the standard. As soon as a defined threshold is exceeded, the application automatically highlights the relevant area in the diagram and recommends suitable courses of action to avoid fiber losses. In this way, OnView.MassBalance leads to targeted process optimization in stock preparation and provides the operating team with all relevant information if a different process setting is required. Both applications are integrated on Voith's OnCumulus platform. The platform provides users with an overview of all important process parameters, includes several industry-specific applications and also acts as a reliable and secure data repository. Building on the initial positive results, regular meetings are held between the Saica and Voith teams to jointly discuss progress, results and schedules. The goal is to further push the optimization of the system.

Juan Luis Mendoza, Digital Process Officer at Saica, explains how the new solutions have already opened up a whole new perspective: "The integration of OnEfficiency.Strength into the existing automation technology of PM 9 was seamless. This is now reflected in our very positive results. The digital tools support us in achieving our ambitious targets in an intelligent way." For Mendoza, there is no doubt that the company will also implement Voith's Papermaking 4.0 solution on other machines in the coming years.

From Voith’s perspective as the technology partner, the balance of the project is thoroughly positive: "The solution we offered has proven itself and leads to resource important savings with qualitatively consistent results," sums up Renan Fusco, Head of Digital Solutions Sales at Voith Paper. "Voith has clearly positioned itself as a reliable partner on the path to digitalization. This confirms our commitment to continuously advance our products in order to continue to be an innovation driver in paper production."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Digital maintenance solutions OnCare.Asset and OnCare.Health successfully in operation: Grupo Gondi reports positive results

Since the beginning of 2021, Grupo Gondi has been producing light recycled corrugated base paper with its PM 7 at the new Papel y Empaques mill in Monterrey. As a full-line supplier, Voith supplied the entire production line, including the BlueLine stock preparation system; the XcelLine paper machine; and MCS, DCS and QCS automation solutions. For the green field project Grupo Gondi also relied on the OnCare.Health and OnCare.Asset digital maintenance solutions from Voith's Papermaking 4.0 portfolio. The intelligent maintenance management system started at the same time as production and has since then provided intelligent maintenance support in daily operations. In addition, Grupo Gondi uses the Voith Paper Webshop to order new spare and wear parts.

- Grupo Gondi successfully uses the OnCare.Asset maintenance management system and partly OnCare.Health condition monitoring solution at PM 7 in the Papel y Empaques mill in Mexico

- Installation of the user-friendly systems was fast and smooth

- Digital solutions from the Papermaking 4.0 portfolio provide support in daily operations and ensure more efficient processes and minimal downtimes

After one year, Grupo Gondi is now taking stock: The company is very satisfied with the successes achieved, the current status and the partnership with Voith. "We saw the new plant as an opportunity to integrate leading digital technologies from Voith," says Victor Alcantar Lara, Corporate Manager Projects & Maintenance at Grupo Gondi. "After looking at all the benefits of Voith's digital solution package, we were convinced by the smart applications. With the help of the digital products, we get a direct link to Industry 4.0. Voith is always at our side with valuable expert knowledge and pursues the highest quality standards in every project. We are therefore very happy about the trusting and good partnership with Voith."

At the beginning of the project, Voith harmonized all data sources together with Grupo Gondi. For a seamless material management process, the Voith experts connected OnCare.Asset to Grupo Gondi's ERP system via a bi-directional interface. The integration of the systems took only a few weeks and went smoothly. Since then, the condition monitoring solution OnCare.Health has partly analyzed machine data at the Mexican plant, targeting reduction of unplanned and planned downtime. In addition, the OnCare.Asset digital maintenance management system forecasts the appropriate maintenance measures on a preventive basis. To increase predictability the systems will be fully interfaced in the first quarter of 2022. In addition, the maintenance personnel benefit from quick and easy identification and ordering of spare and wear parts via the Voith Paper Webshop. Thus, the digital solutions significantly increase the productivity, maintenance efficiency and process stability of PM 7.

At the beginning of the project, Voith harmonized all data sources together with Grupo Gondi. For a seamless material management process, the Voith experts connected OnCare.Asset to Grupo Gondi's ERP system via a bi-directional interface. The integration of the systems took only a few weeks and went smoothly. Since then, the condition monitoring solution OnCare.Health has partly analyzed machine data at the Mexican plant, targeting reduction of unplanned and planned downtime. In addition, the OnCare.Asset digital maintenance management system forecasts the appropriate maintenance measures on a preventive basis. To increase predictability the systems will be fully interfaced in the first quarter of 2022. In addition, the maintenance personnel benefit from quick and easy identification and ordering of spare and wear parts via the Voith Paper Webshop. Thus, the digital solutions significantly increase the productivity, maintenance efficiency and process stability of PM 7.

"Through intensive teamwork, coaching and training, all team members in Monterrey were quickly trained and qualified to operate the digital solutions," says Francisco Javier Lozano Hernandez, Manager Planning & Scheduling Monterrey at Grupo Gondi. "OnCare.Health now partly monitors the current condition of the plant at all times, registers even the smallest anomalies, sends warning signals to the operators and independently develops optimization options. Combined with OnCare.Asset intelligent maintenance management, the solutions will increase and maintain our world-class machine availability."

"We use the maintenance system every day and can now also use it to document and track current statuses," adds Victor Alcantar Lara. "Thanks to the user-friendly operation and the continuously growing data collection, the operators have a comprehensive overview of the maintenance status and can react proactively and efficiently. The digital solutions can also be controlled flawlessly from a distance."

With the campaign "PAPER IS ON," Voith highlights the following focus topics of the Papermaking 4.0 digital product portfolio: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more and visit our homepage: voith.com/PaperIsOn.

About Grupo Gondi

Grupo Gondi is a leading paper packaging company with 66 years of experience in the Mexican market. The company currently employs over 7,800 people. A total of 14 converting plants and 7 recycled paper machines are in operation. The company specializes in the production of recycled paper, corrugated boxes, pre-printed corrugated boxes and solid fiber containers, folding containers, micro-corrugated boxes and digital boxes, as well as services to support the production of these products. In total, Grupo Gondi produces more than 1.1 million tons of paper per year.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

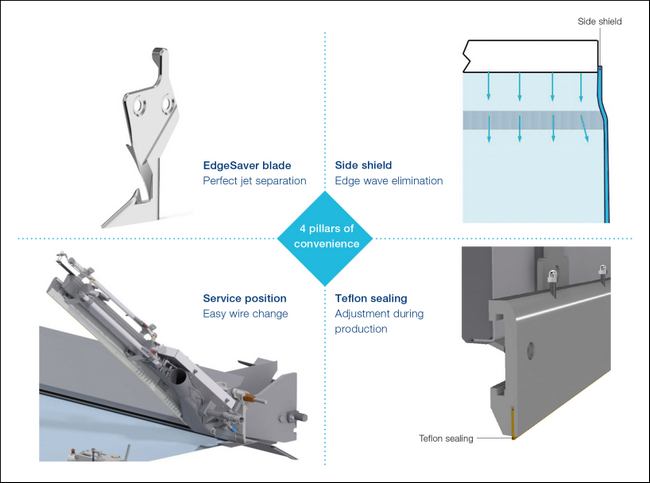

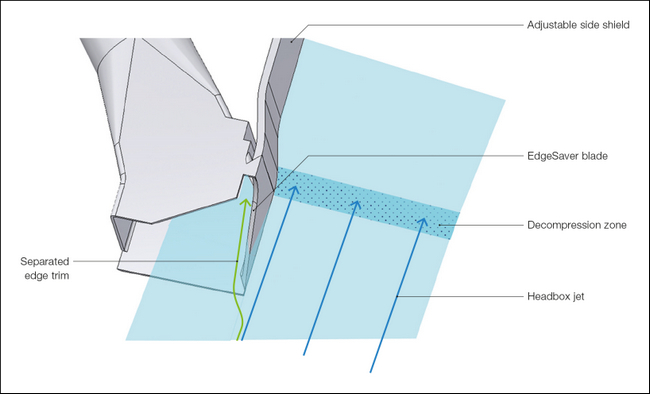

Voith’s new edge trim concept EdgeSaver achieves significant savings in valuable virgin fibers

With the new EdgeSaver edge trim concept, Voith is effectively improving its range of products for stabilizing the web edge in the headbox area. The innovative system trims the web edge in the stock jet exiting the headbox. As a result, paper manufacturers not only save valuable raw materials like virgin fibers but also reduce the energy consumption for paper production.

- EdgeSaver trims the web edge in the stock jet as it exits the headbox

- Saves valuable virgin fibers and reduces energy requirement

- Web width can already be adjusted to individual customer requirements in the wet end

In conventional systems, the edge cut on multi-ply machines is only done after couching, so that the mixed trim residues can only be returned to the lower quality stock cycle. By contrast, the innovative design of the EdgeSaver blade offers a simple and energy-efficient solution for adjusting the web edge directly in the headbox jet. Fibers that exceed the required paper web width are not lost in the couch pit, as they are discharged before the suspension reaches the wire. The discharged stock suspension can thus be returned directly to the primary fiber stock cycle in a single-sort process. In addition, the web width can be adjusted to specific customer requirements in the wet end, which offers crucial advantages, above all when producing various paper grades with different run-out widths. As a result, EdgeSaver helps to significantly reduce raw material costs and thus ensures a smaller carbon footprint.

“By using the Voith EdgeSaver we consume less energy and therefore reduce our carbon footprint, because the product allows high-quality fibers to be retained,” says Oliver Kern, Plant Manager at Papier- und Kartonfabrik Varel. “This means, we not only produce more sustainably, but also more cost-efficiently.”

The EdgeSaver also offers an impressive improvement in paper quality. Thanks to its specially manufactured side shield with a patented, adjustable S-shape, edge waves are minimized. This improves edge stability and also facilitates the successful threading of the web into the press section. The Teflon seal on the underside of the side shield provides an optimal seal to the wire. For the first time, the seal can be adjusted with the machine running.

The EdgeSaver can be mounted to the standard headboxes of all manufacturers. It can be easily installed on both sides of the web in just a few hours during a shutdown. Changing the forming fabric is also not a problem, as the ingenious swivel device enables it to be replaced easily without having to restore the optimized settings on the EdgeSaver afterwards.

“The EdgeSaver enables us to variably adjust the paper web width without major rebuild measures. Even with changing production parameters, we are able to produce without restrictions, thus reducing breaks and production losses due to defects in the edge area,” says Andreas Jaeger, Plant Manager at MM Neuss GmbH.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Smurfit Kappa relies on Voith’s advanced process control system OnEfficiency.Strength to reduce starch consumption

Voith’s digital solution package OnEfficiency.Strength, installed at Smurfit Kappa's Hoya mill in Lower Saxony in 2021, is showing very positive results from the first day. With virtual sensors and predictive control, OnEfficiency.Strength reduces the amount of starch applied while maintaining defined quality standards – a step that is leading to significantly lower costs and more sustainable paper production. The Hoya project is representative of how the two companies Voith and Smurfit Kappa are working together to drive digital transformation in the paper industry.

- The advanced process control system OnEfficiency.Strength has now been put into operation at the Hoya, Germany, site after a short installation period

- The solution from the Papermaking 4.0 portfolio ensures lower starch consumption, leading to significant cost savings and more stable paper quality

- The successful installation is a result of the strong cooperation between Voith and Smurfit Kappa and another important step towards more sustainable and efficient paper production with digital applications

"We chose Voith's digital solution approach because it offers significant cost savings with the latest technologies and pays for itself in less than a year," says Gerold Buck, Manager Operations at Smurfit Kappa Hoya. "With the implementation of OnEfficiency.Strength, we are successfully continuing our innovation and digitalization strategy while paying towards our sustainability goals."

In the first step, Voith had conducted a value-add assessment that identified optimization potential and significant cost reductions for production with the help of digital technologies. Subsequently, Voith experts analyzed all relevant process, laboratory and production data from the last few months, checked for anomalies and defined a control concept based on this. For smooth data exchange and efficient commissioning, the plant was also connected to the Voith OnCumulus Cloud. In addition, the personnel received training at an early stage in order to operate the application optimally. After the quick installation and start-up, OnEfficiency.Strength immediately showed potential savings in starch application.

In the first step, Voith had conducted a value-add assessment that identified optimization potential and significant cost reductions for production with the help of digital technologies. Subsequently, Voith experts analyzed all relevant process, laboratory and production data from the last few months, checked for anomalies and defined a control concept based on this. For smooth data exchange and efficient commissioning, the plant was also connected to the Voith OnCumulus Cloud. In addition, the personnel received training at an early stage in order to operate the application optimally. After the quick installation and start-up, OnEfficiency.Strength immediately showed potential savings in starch application.

"Due to rising raw material prices and highly competitive pressure, paper manufacturers are increasingly looking for ways to further optimize their production facilities and save costs - digital solutions can make a valuable contribution here," says Maria Knauer, Global Product Manager Efficiency Solutions at Voith. "OnEfficiency.Strength continuously monitors all relevant quality parameters during the manufacturing process and automatically regulates the appropriate settings. Smurfit Kappa thus saves costs and resources in production every day in a simple and automated way. We see great potential to integrate OnEfficiency.Strength at many more plants worldwide." Smurfit Kappa is also considering installing the digital solution from the Papermaking 4.0 portfolio at other sites based on the results of OnEfficiency.Strength at Hoya.

With the "PAPER IS ON" campaign, Voith highlights the focus topics of the Papermaking 4.0 digital product portfolio: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more and visit our homepage: voith.com/PaperIsOn.

About Smurfit Kappa

Smurfit Kappa, a FTSE 100 company, is one of the leading providers of paper-based packaging solutions in the world, with approximately 46,000 employees in over 350 production sites across 36 countries and with revenue of €8.5 billion in 2020. The company is located in 23 countries in Europe, and 13 in the Americas. Smurfit Kappa's products are produced from 100% renewable energy, improving customers' environmental footprint.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Order execution in record time – Successful start-up of Sun Paper's XcelLine PM 2 in Beihai

Asian paper producer Sun Paper recently successfully started up PM 2 at its site in Beihai in Southeast China. The new line in visionary industrial design now produces high-quality white folding boxboard with a basis weight of 170 to 350 gsm and a wire width of 8,900 mm. With a design speed of 1,400 m/min, the planned annual capacity is over 1 million tons of paper. Thanks to the very successful cooperation between Sun Paper and Voith, the entire project from initial contracting to start-up in December took only 18 months – a new world record for a high-speed line of this type. This is the third paper machine that Voith has started up for Sun Paper in the last 12 months. In total, Voith has already delivered 12 XcelLine paper machines to Sun Paper.

- Voith sets a new world record for high-speed board machines with a project execution of only 18 months

- With a design speed of 1,400 m/min, the new PM 2 produces over one million tons of folding boxboard per year

- Voith and Sun Paper have a long and successful partnership

"Sun Paper and Voith are trustful partners,” said Li Lu, Chairman of Sun Holding Group. “From Laos PM 2’s 1-hour and 46-minute start-up to today’s Beihai PM 2, the fastest project execution at 18 months, we have created many world records together."

"We are very pleased that the paper machine started up smoothly thanks to the joint efforts of Voith and Sun Paper," said Ying Guangdong, Vice General Manager and Chief Engineer of Sun Paper. "The line produces the best board quality currently available on the market."

Start-up in record time

There was only seven and a half months between the start of installation and the successful machine start-up, even with the major challenges presented by COVID-19. To ensure the on-time arrival of all components, Voith stabilized all upstream global supply chains. Voith's excellent supply chain management and project management, as well as close coordination, high degree of flexibility and additional shifts, made it possible to meet the ambitious schedule.

"The high-speed plant uses the latest technologies," said Dr. Michael Trefz, President Projects at Voith Paper. "In combination with the visionary industrial design, the plant sets the highest standards in terms of efficiency, safety and sustainability. The start-up is another milestone in the successful and long-standing partnership between Voith and Sun Paper."

As a full-line supplier, Voith supplied the entire XcelLine paper machine in the new industrial design. The tailor-made concept focuses in particular on the efficiency and robustness of the individual components. For example, a DuoFormer ensures excellent formation and strength properties even at very high speeds. Automatic dewatering of the three shoe presses reduces thermal drying and thus saves significant energy costs. For an optimized paper surface, a SpeedSizer is used as well as four DynaCoaters, which apply the film evenly during sizing and coating. Furthermore, the CombiDuoRun dryer section with EvoDry steel dryer cylinder ensures maximum runnability and energy efficiency. In addition, two VariFlex high-performance winders ensure smooth production. Due to the visionary Voith industrial design of the entire line, optimized accessibility for maintenance work and improved occupational safety are also achieved.

Sun Paper also benefits from Voith's leading expertise in digitalization and automation for additional efficiency gains and cost reductions. The intelligent quality control system QCS as well as the solutions DCS and MCS enable complete control over the entire production line. In addition, Sun Paper relies on solutions from the Papermaking 4.0 portfolio with OnCare.Health. Thanks to a wide range of interfaces, the intelligent maintenance tool detects the smallest faults at an early stage and automatically assigns them to the affected points.

About Sun Paper

Founded in 1982, Shandong Sun Holdings Group is a global advanced integrated multinational paper group, a leader in the Chinese paper industry, ranked 306th among China's 500 largest companies and among the world's 30 largest paper manufacturers.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Sustainability milestone reached: Voith will be operating climate neutrally at all its sites as of January 1, 2022

Voith has achieved an ambitious sustainability goal: As of the beginning of 2022, Voith has successfully reduced the CO2 emissions at all its sites to “net zero.” Therefore, the Group’s operations will be climate neutral from January onwards.

- Climate neutral production confirms Voith’s role at the forefront of industry

- Voith products contribute to reducing carbon footprint

- Independent rating agency ISS ESG gives Voith an excellent sustainability performance rating

This success confirms Voith’s pioneering role in the decarbonization of industrial production. All Voith sites worldwide undertook enormous efforts to achieve this major accomplishment. Increased energy efficiency and the comprehensive use of renewable energy sources were key factors in reaching the Group’s CO2 reduction goals.

This success confirms Voith’s pioneering role in the decarbonization of industrial production. All Voith sites worldwide undertook enormous efforts to achieve this major accomplishment. Increased energy efficiency and the comprehensive use of renewable energy sources were key factors in reaching the Group’s CO2 reduction goals.

Enhanced energy efficiency and energy from renewable sources

Since fiscal 2011/12, Voith has successfully reduced its energy consumption by 28 percent. In addition, the Group relies on energy from renewable sources. Until the beginning of fiscal 2021/22, the proportion of renewable energies in the Voith-wide electricity mix could be increased from 44 percent in the previous year to 87 percent. In addition, the Voith sites are generating more and more energy from solar and hydropower – currently approximately 6 GWh/a. CO2 emissions, which are still unavoidable at the moment, are voluntarily mitigated through carbon offsets.

Sustainable Voith technologies contribute to the decarbonization of industry

Voith also supports its customers in reducing their carbon footprint and achieving their sustainability and climate protection goals. “Developing sustainable technologies for future generations is at the core of Voith’s DNA. We have already achieved our goal of climate neutral production today. This clearly demonstrates the Voith team’s strong implementation skills,” emphasized Voith Group CEO Dr. Toralf Haag. “Our customers can also rely on this strength. We combine our expertise to support them in meeting their climate protection goals.”

Voith products are already saving more CO2 emissions than they produce. This is confirmed by a TÜV-verified analysis of the Voith products launched in 2019/20 and their potential deployment. According to the report, Voith products achieve annual CO2 savings of almost 3 million tons compared to 2.2 million tons produced. The Group is continuously striving to further reduce the carbon footprint of its products during their service life at customer sites.

Independent rating confirms leadership position

Sustainability is a core element of Voith’s corporate strategy. This includes various measures for the improvement of companies, society and the environment. Their success is monitored and controlled at regular intervals. In 2021, the independent rating agency ISS ESG rated Voith’s sustainability contribution a B minus for the first time. Voith is thus among the three best companies in its industry worldwide and continues to maintain the “Prime Status.”

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of plants, products, services, and digital applications, Voith sets standards in the markets for energy, paper, raw materials, and transport & automotive. Founded in 1867, Voith today has around 20,000 employees and earns 4.3 billion euros in sales. It has locations in more than 60 countries and is one of Europe's major family-owned companies.

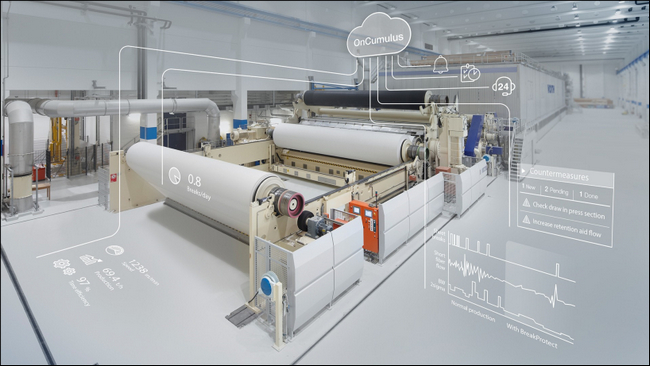

Voith expands Papermaking 4.0 portfolio with three new apps for higher process stability and efficiency in paper production

Customers worldwide rely on Voith's modular Papermaking 4.0 portfolio to individually optimize their production with the leading digital industrial applications. Based on extensive expertise, Voith is introducing OnEfficiency.BreakProtect, OnView.VirtualSensorBuilder and OnView.MassBalance, three new apps on the IIoT platform OnCumulus. The new digitalization solutions feature the highest safety standards, are quick to install and easy to use. The technologies are already successfully implemented in several plants worldwide. Due to the process optimizations and lower resource consumption, the applications often pay off in less than a year and pave the way to the digital paper mill.

- OnEfficiency.BreakProtect: Detect, understand and prevent paper break causes

- OnView.VirtualSensorBuilder: Quickly and easily calculate and visualize relevant quality parameters in real time

- OnView.MassBalance: Visualize raw material losses in stock preparation and increase yields

OnEfficiency.BreakProtect: Detect, understand and prevent paper break causes

The IIoT platform OnCumulus has already established itself as a central hub for data from multiple sources for numerous paper manufacturers. OnEfficiency.BreakProtect uses artificial intelligence to analyze the process data bundled in OnCumulus. Thereby, the innovative solution automatically detects various critical process conditions that can lead to breaks. This allows the development of specific countermeasures and the reliable prevention of tear-offs.

"I am always fascinated by the correlations that artificial intelligence can recognize," says Jürgen Käser, Director Process Applications at Voith. "Among other things, we were able to use OnEfficiency.BreakProtect to identify increased dirt and starch agglomerate loads – for which there is no measurement data at all – at the SpeedSizer pulper. In the past, these had repeatedly led to break-off series. A small mechanical rebuild, which prevents starch from entering the pulper in larger quantities, has permanently solved the previously undetected problem."

OnView.VirtualSensorBuilder: Calculate and visualize quality parameters quickly and easily using virtual sensors

Virtual sensors, also called soft sensors, have proven themselves in the process industry for many years. With the help of data models, the sensors calculate various quality parameters and thus reliably supplement laboratory tests. Until now, the use of virtual sensors required considerable time and, above all, data analysis skills. With OnView.VirtualSensorBuilder, Voith introduces a user-friendly app that allows paper manufacturers to quickly and easily create the virtual sensors themselves with just a few mouse clicks.

"With OnView.VirtualSensorBuilder, it only takes a few hours for a new soft sensor to be ready for use," says Maria Knauer, Global Product Manager Efficiency Solutions at Voith. "Previously, this required a time-consuming and costly process of several weeks."

Once installed, operators can use OnView.VirtualSensorBuilder to continuously calculate, visualize and control relevant quality values, such as strength values, in real time. Combined with OnCumulus.Suite, the digital application identifies critical values and provides preventive warnings, allowing personnel to make immediate improvement adjustments. The solution thus increases process stability, enables compliance with desired quality standards, reduces raw material costs and minimizes waste.

OnView.MassBalance: Visualize and reduce fiber losses in stock preparation

OnView.MassBalance maps the current stock flows in an intuitive Sankey diagram and provides information on deviations that are no longer within the standard range. If a defined warning threshold is exceeded, the application automatically highlights the relevant area in the diagram and recommends suitable action to avoid fiber losses. OnView.MassBalance thus leads to targeted process optimization in stock preparation and also enables centralized knowledge management.

With the help of OnView.DigitalEye, the accuracy of OnView.MassBalance can be increased even further. The innovation makes it possible for the first time to analyze recovered paper quality even before stock preparation with the help of artificial intelligence. The award-winning AI application OnView.DigitalEye is currently undergoing final testing as part of pilot installations at national and international customer sites and is expected to be available starting next year. Another application that will be launched in 2022 is OnView.Energy from Voith. The app visualizes and analyzes energy consumption and CO2 emissions in production. This enables significant savings potential to be identified, leading to lower energy costs, improved sustainability and competitiveness.

This release is part of the current "PAPER IS ON" campaign, in which Voith highlights the focus topics of the digital Papermaking 4.0 portfolio: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more at voith.com/PaperIsOn. For more information on the solutions from the OnCumulus, OnView and OnEfficiency family as part of Voith's Papermaking 4.0 portfolio, please visit https://voith.com/corp-en/products-services/automation-digital-solutions/onefficiency.html. In addition, read more about OnView.DigitalEye receiving the AI Champions Award: https://voith.com/corp-en/news-room/press-releases/voith-wins-ai-champions-award-2021.html.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Leading paper manufacturers rely on Voith expertise for resource-efficient rebuilds and optimization projects to boost competitiveness

With its full-line supplier approach, Voith Paper strengthens position as partner of choice for extensive rebuilds and customized optimization projects. Shifting consumer demands, tougher environmental regulations and ongoing supply chain issues with raw materials have combined to create a perfect storm in the paper industry. To remain competitive in unprecedented conditions, leading papermakers around the globe are relying on Voith to modernize their existing paper production lines, undertake comprehensive grade conversions or upgrade their current assets in the market. As a full-line supplier, Voith realizes every type of rebuild to give paper machines a second life. In the process, Voith expertise, innovative components and advanced digital tools ensure customers achieve their efficiency and productivity targets with a lower capital investment.

Extensive grade conversion in Indonesia

In September 2021, Voith kicked off the grade conversion of Mojokerto MSE-PM2 for PT Mega Surya Eratama. The extensive rebuild will transform the former newsprint paper machine, which is currently out of service, to a state-of-the-art packaging production line at the company’s Mojokerto paper mill in East Java, Indonesia.

As is the case with every rebuild, Voith is placing a special focus on high machine availability, technological efficiency, process stability and sustainability with the lowest possible energy balance for the plant. After conversion, the PM 2 will produce high-quality containerboard grades between 70 g/m² and 180 g/m², with a design speed of 1,400 m/min and 6,660 mm paper width at reel. After start-up, the XcelLine paper machine will have an annual production capacity of 450,000 tons, and, as a result, the PM 2 will be one of the most powerful paper machines of this grade in Indonesia. The Voith scope of supply includes a forming section rebuild into a DuoFormer CBh with shoe-blade technology, a new DuoCentri NipcoFlex Press and SpeedSizer AT film sizer for starch application. The order also includes a complete BlueLine stock preparation and approach flow line. The start-up after conversion is scheduled for the end of 2023.

As is the case with every rebuild, Voith is placing a special focus on high machine availability, technological efficiency, process stability and sustainability with the lowest possible energy balance for the plant. After conversion, the PM 2 will produce high-quality containerboard grades between 70 g/m² and 180 g/m², with a design speed of 1,400 m/min and 6,660 mm paper width at reel. After start-up, the XcelLine paper machine will have an annual production capacity of 450,000 tons, and, as a result, the PM 2 will be one of the most powerful paper machines of this grade in Indonesia. The Voith scope of supply includes a forming section rebuild into a DuoFormer CBh with shoe-blade technology, a new DuoCentri NipcoFlex Press and SpeedSizer AT film sizer for starch application. The order also includes a complete BlueLine stock preparation and approach flow line. The start-up after conversion is scheduled for the end of 2023.

“We were convinced by Voith’s capability as a full-line supplier to meet our highest benchmark and sustainability requirements for this strategic grade conversion,” says Eric Saputra, General Manager at PT Mega Surya Eratama. “Given their extensive experience and innovative equipment, Voith is ideally positioned to bring out the full potential of the PM 2 production line. We rely on Voith to support us in producing the highest paper quality on a machine with the best operational reliability.”

Record-breaking 30th shoe press rebuild

This year, Voith marked the 30th successful rapid shoe press rebuild in a row in China, with five more underway. The most recent was completed for the Sun Paper Group. As it took a mere seven days from shutdown to paper on reel, the project set a record for the fastest shoe press rebuild in the region, saving the customer valuable production time as a result. The centerpiece is a new NipcoFlex shoe press for the existing press section. In addition, the scope of delivery included a PLC control system for NFP, erection and start-up service as well as spare part and wear part packages. Previously, in December 2020, Voith successfully completed the rebuild and smooth start-up of the NipcoFlex shoe press on PM 9 for JiangXi WuXing, a leading paper manufacturer based in Jiujiang City.

Large-scale Voith rebuilds spread across the globe

Voith successfully provides full-line supplier support for large-scale rebuilds around the world, all of which have ambitious efficiency targets and productivity goals. In Spain, for instance, PAPRESA, the leading southern European manufacturer of newsprint, commissioned Voith for the resource-efficient grade conversion of PM 5 from newsprint paper to testliner and corrugating medium at the company’s Rentería mill. Papermaking 4.0 tools supports the company’s ambitious efficiency and sustainability goals. Other notable projects in Europe include the PM 2 rebuild for Schumacher Packaging, a corrugated board producer and full-range supplier of paper-based packaging solutions. The rebuild at the company’s Myszków site in Poland involves a forming section upgrade to DuoFormer D, a new headbox MasterJet Pro and DuoShake DG 800, which will ensure the necessary dewatering capacity and final paper quality. While in North America, Domtar, a leading U.S. paper manufacturer, has entrusted Voith to support the company’s entry into the containerboard market and set higher industry standards. At the company’s Kingsport mill in Tennessee, Voith is to install a BlueLine stock preparation line and perform the grade conversion of its production line.

“Drawing on our full-line supplier expertise, we provide the know-how and technology for rebuilds of every kind. Whatever the ultimate business and sustainability goals of an optimization project, our comprehensive approach ensures we are in a leading position to fully exploit the potential of existing paper production lines,” states Martin Jauch, Senior Vice President Global Rebuilds at Voith.

To discover more insights and updates on Voith solutions for rebuilds and optimizations projects, visit our website: https://voith.com/corp-en/industry-solutions/papermaking/rebuilds-and-optimization.html

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Over 300 global installations of digital solutions confirm the success of Voith's Papermaking 4.0 portfolio

With its digitalization and automation portfolio Papermaking 4.0, Voith Paper is an international pioneer and innovation driver in paper production. The technology company now has more than 300 digital installations worldwide. The numerous references prove how digitalization continuously optimizes the production process in terms of efficiency, sustainability and quality.

"For more than five years, customers worldwide have been relying on our digital solutions. The areas of application are very different – with our individual industrial application, we offer customized solution packages," says Dr. Jürgen Abraham, President Products & Services and Digital Business Officer at Voith Paper. "Based on our expertise in digitalization, automation and artificial intelligence, we are continuously developing new possibilities for the paper production of the future."

With concrete approaches, Voith experts and the OnPerformance.Lab advise, accompany and support customers on their way to a digitalized paper mill. The IIoT platform OnCumulus, which provides fast and reliable access to data from machines and systems, serves as the basis. Using the collected and evaluated data, the applications lead to performance improvements along the entire process chain. The robust digital solutions feature the highest security standards, are implemented in the shortest possible time and show continuous production improvements from day one. In addition to long-term efficiency gains, Papermaking 4.0 solutions enable significantly more sustainable production.

"Digitalization is an important lever to support the improvement of all performance areas of the operation: customer service, efficiency and flexibility," says Mario Naldini, COO BU Paper & Security at Fedrigoni. "The OnEfficiency solution implemented in Fabriano by Voith represents a fundamental milestone in our digital transformation. With a payback period of less than one year, the economic benefits are significant."

"With the help of Voith's leading technologies, we can improve the sustainability of our production," says Dr. Thomas Welt, CEO at Laakirchen Papier AG. "In addition to the diverse references, Voith's decades of expertise in sustainable papermaking and extensive research and development activities convinced us. Innovations from the Papermaking 4.0 portfolio, including OnEfficiency.Strength, are already being used successfully at our PM 10. In addition, we are a pilot customer for the new OnEfficiency.BreakProtect and OnView.Energy solutions."

Voith’s bundled know-how and specially-focused innovation on the paper industry are unique in the market. For each initial situation, Voith offers paper manufacturers customized complete solutions consisting of digitalization, automation and expert knowledge. In line with the full-liner approach, Voith develops specific sensor technology, for example, and supports implementation throughout the entire process for the best result.

Grupo Gondi also implemented MCS, DCS and QCS automation solutions as well as Voith's OnCare.Health and OnCare.Asset digital condition monitoring and maintenance solutions on PM 7 at the Papel y Empaques mill. "Through intensive team work, coaching and training, all team members in Monterrey were quickly trained and up to speed," says Francisco Javier Lozano Hernandez, Maintenance Planning Manager at Grupo Gondi. "OnCare.Health now monitors the current condition of the plant at all times, registers even the smallest anomalies, sends warning signals to the operators and independently develops optimization options. Combined with the intelligent maintenance management OnCare.Asset, the solutions will increase and sustain a world class machine availability."

In order to continue to provide impetus in the digitalization and automation environment, Voith Paper relies on agile, customer-centric development processes. One result of this approach is OnView.DigitalEye, which won this year's AI Champions Award. With the help of the digital analysis tool, recovered paper quality can be precisely determined for the first time even before stock preparation.

"New innovative solutions like OnView.DigitalEye are important components of Papermaking 4.0 and autonomous paper production," explains Dr. Jürgen Abraham. "In the future, digitalization and automation will grow ever closer together. We also recently presented an innovative operating concept as part of our Papermaking Vision. With the help of intelligent algorithms and an intuitive design, this will ensure maximized user-friendliness, production capacity and efficiency in the future."

With the campaign "PAPER IS ON", Voith will be highlighting the focus topics of the digital product portfolio Papermaking 4.0 in the near future: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more and visit our homepage: voith.com/PaperIsOn.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.