Super User

Valmet receives a tissue line order for Metsä Tissue’s new Future Mill project in Mariestad, Sweden

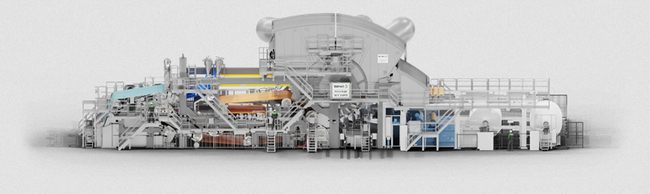

Valmet will supply a new tissue production line with the latest technology to Metsä Tissue’s mill in Mariestad, Sweden. The delivery also includes an extensive package of stock preparation, automation and service solutions. The order is part of Metsä Tissue’s development program ”Future Mill”, aiming for world class environmental and technological performance in tissue production.

The order is included in Valmet’s orders received of the first quarter 2023. The value of the order will not be disclosed.

Valmet and Metsä Tissue have a long history of cooperation. Recently the PM 10 machine at the customer’s Mänttä mill in Finland was successfully rebuilt. In the past few years Valmet has also supplied a series of energy saving and efficiency upgrades to Metsä Tissue’s other mills, including Advantage ReDry energy saving solutions, Advantage ViscoNip presses, refiners and automation controls.

The new Valmet tissue machine is equipped with the latest technology to reduce energy and water consumption and CO2 emissions.

The new Valmet tissue machine is equipped with the latest technology to reduce energy and water consumption and CO2 emissions.

“With the new tissue machine, we will increase the offering of locally produced sustainable virgin fiber-based tissue paper to the Scandinavian market. It enables reliable local deliveries of high-quality tissue to the consumers. The new technology brings big environmental benefits. In addition to the energy savings, we can reduce the process water in the paper making process by 50 percent,” says Esa Paavolainen, Vice President projects, Metsä Tissue.

”It’s a pleasure to get the opportunity to contribute to the establishment of a completely new tissue mill in Sweden. We are honored to be trusted in delivering a tissue line with the latest technology to Metsä Tissue in Mariestad. Our long history of collaboration is an excellent foundation for a successful project execution,” says Jari Vähäpesola, President, Paper business line, Valmet.

Technical information

The new tissue machine will have a design speed of 2,200 m/min and is optimized for low energy consumption and enhanced quality of the final product.

Valmet’s scope of delivery will comprise a complete tissue production line featuring full stock preparation with bale handling and a Valmet Advantage DCT 200 TS tissue machine with latest technology for high efficiency, low energy and water consumption and reduced CO2 emissions.

Furthermore, the delivery will include Valmet quality control and monitoring system, complete engineering, installation supervision, training, start-up, and commissioning. Valmet will also supply start-up clothing as well as master maintenance data services and remote support from Valmet’s Performance Center.

The new line will add 70,000 tons of tissue made from virgin fiber to the mill’s current production. The mill’s total annual capacity will increase to 145,000 tons.

Information about Metsä Tissue

Metsä Tissue creates a cleaner everyday life. It is one of the leading tissue paper suppliers to households and professionals in Europe and one of the leading greaseproof paper suppliers globally. Their brands are Lambi, Serla, Mola, Tento, Katrin and SAGA. With production units in five countries, it employs around 2,450 people. In 2022, their sales totaled EUR 1.2 billion. Metsä Tissue is part of Metsä Group.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Voith grows capacity for refurbishment services in Europe

At the end of January, Voith inaugurated its new refurbishment workshop in Karlstad, Sweden, alongside its customers, business partners, employees and media representatives. The new workshop and office space significantly increase capacity for refurbishment services of screw presses and screens in the Karlstad region, Scandinavia, and for all of Europe. It also presents the opportunity to refurbish other equipment, such as rotary valves, vacuum pumps and rolls.

- New workshop and office in Karlstad, Sweden, increase capacity for refurbishment services in Scandinavia and all over Europe

- State-of-the-art equipment ensures highest level and wide range of technology services for customers

“Our new location in Karlstad is a clear investment in the future of Voith Paper in Sweden,” says Jan Haraldsson, Operations Manager at Voith Paper Fabrics Högsjö AB. “Our customers now benefit from state-of-the-art equipment, a higher capacity and an even wider range of refurbishment services than before.”

During the event, members of the Voith Paper Products & Services leadership teams from Sweden and Germany alongside BTG and representatives of longstanding customers, including Holmen Braviken, learned about Voith Paper’s presence in Scandinavia and its efforts and achievements in sustainability and digitalization.

Wider range of refurbishment services

With the new location in Karlstad, Voith replaces the previous site of its Products & Services Division, doubles capacity for screw press refurbishments and meets increasing customer demands in this area. The largest screw presses can now be overhauled at the Voith site, allowing customers to significantly reduce downtime due to screw press refurbishments at their plant. Additionally, the new facility is equipped with a larger overhead crane capacity.

“The expanded crane capacity enables us to serve our customers with a wider range of refurbishment services,” says Krister Nygard, Service Center Director Scandinavia at Voith Paper Fabrics Högsjö AB. “We can refurbish rotary valves, vacuum pumps, rolls and other components.”

Clear focus on sustainability and efficiency

The expansion in Sweden goes hand in hand with Voith’s commitment to sustainable and efficient paper production. Refurbishment services allow for the economical use of raw materials and an increase in efficiency while utilizing existing resources. With the new location, Voith additionally sets a clear focus to serve its customers with efficient and sustainable services using state-of-the-art technology and expertise. In the course of the inauguration, Voith celebrates 10 years of its Products & Services Division in Sweden and takes the next step to further strengthen its business operations in northern Europe.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Corporate responsibility: Voith publishes Sustainability Report 2021/2022

The Voith Group has published the 13th edition of its annual Sustainability Report for fiscal year 2021/22. The focus is on the sustainability strategy, resource efficiency and employee safety in the company's own activities. In addition, the Sustainability Report shows how Voith products and services help customers worldwide achieve their sustainability goals. "We want to make a measurable contribution to the sustainable development of the economy and society," explains Dr. Toralf Haag, CEO Voith Group. "To this end, we make our actions transparent and comprehensible through comprehensive reporting."

In the paper industry, Voith Paper sets the standards in the area of resource-saving paper production. As part of its Papermaking for Life sustainability program, the leading full-line supplier has set ambitious targets for 2030 to significantly improve its customers' carbon footprint:

- 100 percent CO2-neutral paper production thanks to energy-optimized products, digital solutions, disruptive concepts and the efficient use of renewable energies

- 90 percent fresh water savings thanks to a completely new papermaking process

- 90 percent recycling rate thanks to the development of new fiber streams

In total, Voith Paper invests around 100 million euros per year in the development of efficient and sustainable innovations. To drive decarbonization forward, Voith Paper is focusing on four areas in its research and development work: Voith Paper is continuously optimizing its existing product portfolio to reduce energy consumption. One example here is the newly developed InduraClean (IDC) product family. Depending on requirements, the focus of the modular cleaning technology can be placed on significantly increased production, energy reduction of up to 50 percent or vastly improved separation efficiency. On the other hand, digital solutions ensure improved process efficiency with reduced shutdowns, which also reduces CO2 emissions. In order to realize CO2-neutral paper production by 2030, Voith Paper is also working with partners on disruptive concepts that have the potential to reduce CO2 emissions by further 50 percent. The fourth R&D area focuses on using renewable energies as efficiently as possible and identifying suitable storage options.

Strong focus on sustainability also in own activities

As a family-owned company, Voith also feels a particular responsibility to avoid environmental risks and to use resources responsibly in its own operations. The company’s commitment was confirmed by the independent rating agency ISS ESG, which again awarded Voith a premium rating of B- last year. This makes Voith one of the world's top companies in plant and mechanical engineering.

Over the past 10 years (2011/12 - 2021/22), Voith sites have been able to reduce energy consumption by 34 percent, water consumption by 44 percent and waste volume by 38 percent in relation to sales. In addition, all Voith locations worldwide have been climate-neutral since the beginning of 2022. Energy-saving and more efficient solutions were installed for this purpose. Voith also increased the share of renewable energies in the overall electricity mix from 38 percent in the previous year to currently 80 percent. In the same period, the company's own photovoltaic and hydroelectric power plants helped to generate 8.3 GWh of electricity themselves. As a result, the Voith Group was able to reduce greenhouse gas (GHG) emissions by 40 percent in fiscal 2021/22 and voluntarily compensated for the remaining emissions. By 2049/2050, emissions that are currently unavoidable are also to be reduced to a minimum.

In addition to ecological sustainability, social responsibility is a top priority at Voith. Closely related to this are occupational safety and health protection for Voith employees. With the help of safe workplaces and processes, accidents and work-related illnesses are to be avoided to the greatest extent possible. Thanks to a comprehensive occupational safety program, the number of workplace accidents in fiscal 2021/22 was reduced from 79 to 61 compared to the previous year. The frequency rate is therefore 1.6 (= number of occupational accidents per million hours worked). Voith is strongly focused on further reducing the number of occupational accidents to a minimum.

The Voith Sustainability Report 2022 contains many other examples, research and development areas, and projects examples that illustrate Voith's commitment to sustainability. The Voith Sustainability Report is now available for download on the Voith website. In addition, you can find more information about Voith Paper's sustainability program Papermaking for Life here.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Metsä Group and Kemira are intensifying their sustainability cooperation with the goal of a new product or raw material

Metsä Group and Kemira have agreed to jointly develop a new renewable product or raw material related to the forest industry by 2027. As large industrial players, the companies have good opportunities to reduce the environmental impacts of the forest industry's value chain.

"One of Metsä Group's strategic sustainability targets until 2030 is that no fossil emissions are generated in our production and our products are completely fossil-free by 2030. The fossil-free raw material or product to be developed with Kemira is an excellent complement to our existing development projects," says Jari Voutilainen, SVP, Sourcing and Logistics, from Metsä Group.

"This cooperation supports the strategic goals of both companies and makes the entire value chain more sustainable. It's important for us to help our customers reach their own environmental goals and at the same time develop our own renewable product portfolio," says Kemira Pulp&Paper’s SVP, EMEA Sales Harri Eronen.

Metsä Group and Kemira have established a joint working group to develop the new product or raw material.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 7 billion, and we have around 9,500 employees in around 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by over 90,000 forest owners.

A.Celli to supply six paper rewinders to Shanying Paper (Suzhou)

Shanying Paper decided to rely once again on A.Celli solutions and know-how to equip five of their PM (71-75) in the Suzhou subsidiary with six E-WIND® P100H paper rewinders.

An order that represent a milestone, since it includes the widest paper rewinders ever built by A.Celli, designed to process jumbo rolls of fluting paper with a width of 8770 mm at a design speed of 2600 mpm.

Furthermore, the P100H paper rewinders will be enhanced by numerous optionals, also making them among the most technologically advanced machines ever manufactured by A.Celli. Among these optionals we can find the automatic end tail gluing system, parking stations for the master rolls and shuttles for their transfer, under-machine pulpers and the possibility to interface the machines with the customer’s MES system for data and parameters interchange.

The delivery of the paper rewinders will take place in 2024, from April to October.

SHANYING PAPER (SUZHOU) CO. LTD. – COMPANY PROFILE

Shanying Paper (Suzhou) is an established subsidiary of Shanying Paper, a company founded in 1957 and part of Shanying International Holding. The company has several productions that use domestic and foreign recycled fibers to manufacture packaging paper and newspaper, including high-strength fluting paper and white coated white top testliner.

Stora Enso completes the divestment of its Maxau paper site to Schwarz Produktion

Stora Enso has completed the divestment of its Maxau paper production site in Germany, and all related assets to Schwarz Produktion, part of Schwarz Group. The divestment announced on 13 September 2022 was completed today after regulatory approvals. The enterprise value of the transaction is approximately EUR 210 million.

The transaction will reduce Stora Enso’s annual SC (supercalendered) paper capacity by 530,000 tonnes. Based on the 2022 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 385 million. Subject to closing date adjustments, Stora Enso will book a one-time disposal gain of approximately EUR 55 million in its IFRS operating profit in the first quarter of 2023, considered as an item affecting comparability.

The transaction will reduce Stora Enso’s annual SC (supercalendered) paper capacity by 530,000 tonnes. Based on the 2022 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 385 million. Subject to closing date adjustments, Stora Enso will book a one-time disposal gain of approximately EUR 55 million in its IFRS operating profit in the first quarter of 2023, considered as an item affecting comparability.

This transaction is part of the earlier announced plan to divest four of Stora Enso’s five paper production sites. The plan was concluded earlier this year when Stora Enso signed an agreement to divest its paper production site in Hylte and discontinued the Anjala site divestment process. The divestment of the Nymölla paper site in Sweden was completed on 2 January with ownership transferred to Sylvamo. In line with its strategy, Stora Enso’s focus is on long-term growth potential for its renewable products in packaging, building solutions and biomaterials innovations.

About Schwarz Produktion

Schwarz Produktion is the umbrella brand for the production companies of Schwarz Group. In total, more than 4,500 employees in the Schwarz Produktion companies produce high-quality food as well as sustainable packaging and materials for the retail companies Lidl and Kaufland. In addition to mineral water and soft drinks, the Schwarz Produktion companies also produce chocolate, dried fruit, baked goods, coffee and ice cream. In addition, three plastic and recycling plants are a central component of a unique PET materials cycle. Further information about Schwarz Group here: gruppe.schwarz/en.

Recent releases about Stora Enso’s paper assets:

27 January 2023: Stora Enso signs an agreement to divest its Hylte paper site and will discontinue the Anjala site divestment process

2 January 2023: Stora Enso completes the divestment of its Nymölla paper site to Sylvamo

13 September 2022: Stora Enso has signed an agreement to divest its Maxau paper site to Schwarz Produktion

29 March 2022: Stora Enso plans to divest four paper sites to focus on strategic growth areas

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Toscotec’s TT Headbox-SL starts up on BiOrigin Specialty Product’s MG machine in USA

BiOrigin Specialty Products started up PM2 at its Menominee site in Michigan after the successful completion of a wet section rebuild supplied by Toscotec on a turnkey basis. PM2 is a MG (Machine Glazed) machine producing specialty papers including MG grades and flexible packaging products.

A fully customized design

The project started with an onsite survey by Toscotec’s technical team who identified the primary targets of the new design, in particular moisture profile and CD bone dry profile. BiOrigin Specialty Products (or ‘BSP’) selected Toscotec’s design solution, valuing the importance of a fully customized technical offer based on the analysis of the machine’s operating data.

Target achieved

The rebuild achieved its targets of remarkable enhancement of cross direction (CD) profiles of the paper sheet. In particular, the new TT Headbox-SL’s dilution control allowed to improve the bone-dry profile; an optimized jet distribution and jet landing led to the improvement of the moisture and basis weight (BW) profiles.

The installation of dewatering elements with angle and height adjustable blades in the Fourdrinier section increased wire dewatering.

As a result, the rebuild improved the machine runnability, delivered definite potential for future production increase and improved sheet formation on all produced grades both in absolute terms and across the machine width.

A turnkey rebuild

Toscotec supplied the approach flow system, a hydraulic TT Headbox-SL fitted with dilution control to ensure optimal profile control, and an upgrade of the Fourdrinier section. The turnkey supply of the rebuild included a complete service package with erection, erection supervision, commissioning, and start-up assistance.

Steve Michalko, BSP’s Vice President Technical Service, says, “The entire project went smoothly from inception to successful completion without any significant concerns. The start-up curve was literally hours, and we continue to see intended and unanticipated improvements. The solutions provided by Toscotec have eliminated previous operational constraints and positioned BiOrigin Specialty Products to improve both capability and productivity moving forward.”

Luca Ghelli, R&D Director at Toscotec, says, “Since the beginning of this project, BiOrigin Specialty Products and Toscotec’s teams have been working in sync toward a common goal with a strong feeling of reciprocal respect. This kind of approach is in itself a recipe for success. The very positive outcome of the rebuild is of course the icing on the cake.”

About BiOrigin Specialty Products

With a focus on eco-friendly specialty paper, packaging, and tissue, BiOrigin Specialty Products is a trusted wholesale paper supplier, continuing to thrive, grow, and manufacture some of the finest sustainable paper and tissue products in North America.

Contact

Fabrizio Charrier

Sales Manager, Paper & Board division Toscotec

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ to supply resource efficient debarking line to Smurfit Kappa in Colombia

International technology group ANDRITZ has received an order from Smurfit Kappa to deliver a new energy-efficient debarking line for its paper mill in Yumbo, Colombia. Start-up is scheduled for the fourth quarter of 2024.

- ANDRITZ sustainable technologies support Smurfit Kappa to achieve its net zero emissions goals

- ANDRITZ debarking line provides exceptional high wood-usage-rate to fuel Smurfit Kappa’s new energy supply system effectively

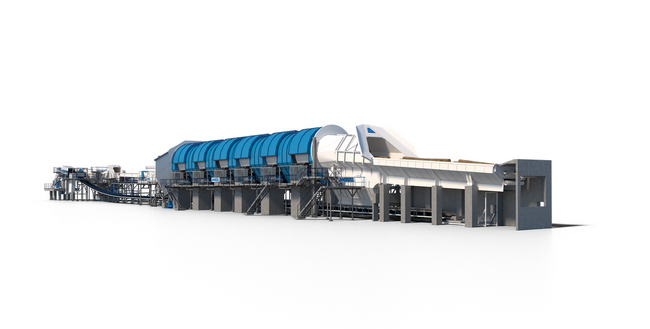

The order is part of Smurfit Kappa´s project to replace the fossil fuels currently used with different types of organic waste to generate cleaner energy at its paper mill in Yumbo. The installation is another step towards Smurfit Kappa’s ambitious goals of achieving net zero CO2 emissions by 2050. The organic waste, processed in the ANDRITZ debarking line, will be comprised of pine and eucalyptus bark from the company’s own forestry plantations and waste from its wood treatment plant, among other materials.

ANDRITZ rubber tire supported debarking drum provides excellent debarking results. “Photo: ANDRITZ”.

ANDRITZ rubber tire supported debarking drum provides excellent debarking results. “Photo: ANDRITZ”.

The scope of supply, on an EPS (Engineering, Procurement, Supervision) basis, includes a new debarking line with rubber tire supported debarking drum which provides excellent debarking results with very low wood losses. The capacities of the new line are 333 m3 hardwood and 370 m3 softwood solid-over-bark per hour. The scope also includes chip screening equipment and a bark handling system with ANDRITZ BioCrusher BSX.

Smurfit Kappa is one of the leading providers of paper-based packaging in the world, with operations in 23 European countries and 13 countries in the Americas.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Metsä Board updates its strategic 2030 sustainability targets

Metsä Board, a leading supplier of fresh fibre paperboards and part of Metsä Group, has updated its strategic 2030 sustainability targets. The new targets highlight its commitment to safeguarding natural biodiversity, mitigating climate change, promoting the sustainable use of natural resources, healthy workplace communities and ethical operations. The sustainability targets are categorised according to the ESG perspectives.

Natural biodiversity is safeguarded in wood sourcing through measures that increase the diversity of tree species and the amount of decaying wood, and by preserving valuable habitats. The 2030 targets are monitored with a comprehensive, more than doubled set of indicators. Also climate-positive actions in forests have been increased.

Metsä Board’s target regarding climate change is unchanged. To mitigate climate change Metsä Board is aiming for 100% fossil free production and products by the end of the year 2030. This target includes both emissions from the company’s own energy production (scope 1) as well as purchased energy (scope 2). Currently, 87% of the energy used at Metsä Board mills is fossil free.

For water use, Metsä Board has set an even stricter target of 35% (previously 30%) reduction in process water use per product tonne and continues to aim at a minimum of a 10% energy efficiency improvement by the end of the year 2030 compared to the 2018 level.

Several indicators related to ethical operations and well-being at work have been added in target setting. Metsä Board will monitor job satisfaction, the implementation of anonymous recruitment processes, and the share of women in leadership positions.

Indicators related to society and supply chain sustainability include the share of certified wood, supplier surveys and audits, and shared sustainability targets with key partners.

Metsä Board’s sustainability targets are in line with the strategic sustainability 2030 objectives of Metsä Group. The sustainability target updates are based on materiality analysis based on discussions with various stakeholder groups. The analysis was carried out in the autumn 2022.

More information about Metsä Board’s sustainability and all new sustainability targets for 2030 can be found at the company’s website.

Metsä Board

metsagroup.com/metsaboard

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable and recyclable resource, that can be traced back to sustainably managed northern forests. We are a forerunner in sustainability, and we aim to have completely fossil free mills and raw materials by the end of 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2022 our sales totaled EUR 2.5 billion, and we have around 2,250 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 7 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by over 90,000 forest owners.

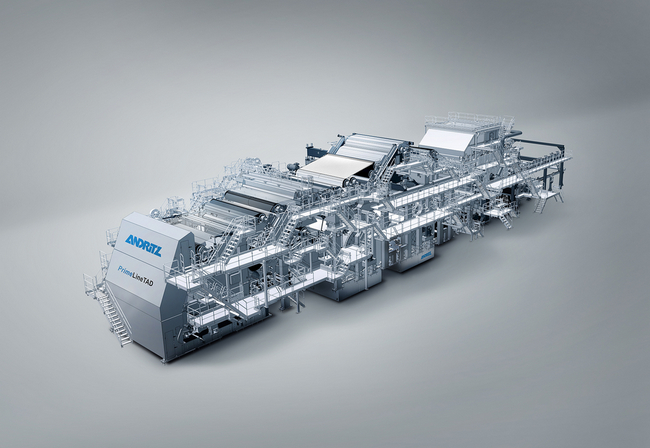

ANDRITZ to supply TAD tissue machine to Procter & Gamble, Box Elder, Utah mill, USA

International technology group ANDRITZ has received an order from Procter & Gamble (P&G) to supply a PrimeLineTAD (Through-Air Dried) tissue machine for its Family Care plant in Box Elder, Utah, USA. Start-up is scheduled for 2024.

The new PrimeLineTAD machine will be supplied with state-of-the-art energy efficient process equipment to meet P&G’s demanding sustainability targets.

ANDRITZ and Procter & Gamble have been strong business partners for many years. In 2007, ANDRITZ supplied and started up a TAD tissue/towel machine at Procter and Gamble’s Green Bay, Wisconsin, USA site that fully met P&G’s expectations. This was followed by another TAD tissue/towel machine at Procter and Gamble’s Box Elder facility, which started up successfully in 2011.

Rendering of an ANDRITZ PrimeLineTAD tissue machine © ANDRITZ

Rendering of an ANDRITZ PrimeLineTAD tissue machine © ANDRITZ

Procter and Gamble, one of the largest manufacturers of premium consumer bath tissues and paper towels in North America, produces the brands of Charmin, Puffs, and Bounty.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.