Ianadmin

Domtar announces closing of sale of Ottawa/Gatineau hydro assets

Domtar Corporation has confirmed the November 20 closing of its previously announced Definitive Purchase and Sale Agreement ("the agreement") signed by its Canadian subsidiary, Domtar Inc., for the sale of its hydro assets inOttawa, Ontario and Gatineau, Québec. The purchaser is Chaudière Hydro L.P. ("Chaudière Hydro"), the newly-created affiliate of Energy Ottawa Inc.

Domtar Corporation has confirmed the November 20 closing of its previously announced Definitive Purchase and Sale Agreement ("the agreement") signed by its Canadian subsidiary, Domtar Inc., for the sale of its hydro assets inOttawa, Ontario and Gatineau, Québec. The purchaser is Chaudière Hydro L.P. ("Chaudière Hydro"), the newly-created affiliate of Energy Ottawa Inc.

The approximately $46 million transaction, after closing adjustments, includes Domtar's three power stations (21 MW of installed capacity), Domtar's water rights in the area, as well as the company's equity stake in the Chaudière Water Power Inc. (CWPI) ring dam consortium. With the closing of the agreement, the 12 workers currently operating the three power stations become employees of Chaudière Hydro.

SOURCE DOMTAR CORPORATION

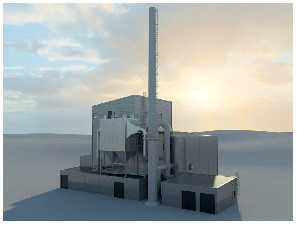

Metso to supply biomass power plant for Värnamo Energi for doubling green electricity production

Metso will supply Värnamo Energi AB with a biomass power plant for combined heat and power production in Värnamo in Sweden. The start-up of the plant is scheduled for autumn 2014. The value of the order is approximately EUR 17 million.

Metso will supply Värnamo Energi AB with a biomass power plant for combined heat and power production in Värnamo in Sweden. The start-up of the plant is scheduled for autumn 2014. The value of the order is approximately EUR 17 million.

Metso's delivery will include a complete power plant, including installation, training and commissioning. The plant will have a thermal output of 13.4 MWth for district heating and an electrical output of 3.6 MWe. The plant will use local forest residues such as bark and wood chips as fuel.

"This is an important investment in the future of Värnamo and in the environment," says Gunnar Crona, Chairman of Värnamo Energi. "After this investment 100 % of the area's district heating will be produced with biomass. In addition, we will produce approximately 20 GWh of electricity annually, which means a doubling of locally produced green electricity."

"We are pleased to be entrusted with the supply of this power plant to Värnamo Energi," says Anders Steen, Managing Director of the Metso unit in charge of the project, MW Power AB. "It is also proof that the solutions we supply are at the forefront of the technological and environmental performance."

"We feel confident in Metso as a supplier," says Göran Hansson, CEO of Värnamo Energi. "This is Värnamo Energi's largest investment ever and with it we can ensure that our customers will continue to be supplied with heating at a competitive cost. Also, Värnamo community will get a modern, well-performing district heating production facility that will be able to fulfill its task for many years."

The order is included in Metso's Pulp, Paper and Power fourth quarter 2012 orders received.

Värnamo Energi AB's main function is to provide energy and IT communications through a well developed infrastructure. Värnamo Energi is wholly owned by Värnamo community. The company has more than 14,000 clients, a turnover of approximately EUR 35 million and the number of employees is forty.

Billerud receives award for best IR

Billerud was commended for its work on investor relations in IR Nordic Markets Sweden 2012. For the second year in a row, Billerud was presented with the Best Mid Cap Company award and the award for Best IRO at a Mid Cap, which was awarded to Billerud’s IR manager Sophie Arnius.

Billerud was commended for its work on investor relations in IR Nordic Markets Sweden 2012. For the second year in a row, Billerud was presented with the Best Mid Cap Company award and the award for Best IRO at a Mid Cap, which was awarded to Billerud’s IR manager Sophie Arnius.

IR Nordic Markets is the biggest study of IR in the Nordic region and was carried out by Regi for the 15th year in a row. In the study presented yesterday at IR Nordic Markets Awards Sweden 2012, assessments from analysts in the Nordic region and Europe formed the basis of the analysis of the financial communication of listed companies.

“I’m delighted with these two awards,” said Sophie Arnius, IR manager. “They’re proof that we’ve managed to maintain a high standard in our communication with the capital market, which is particularly pleasing because 2012 has been an intense year for Billerud on the acquisitions front.”

Resolute Forest Products to Build Wood Pellet Plant

Resolute Forest Products has announced plans to build an industrial wood pellet plant that will convert a currently underutilized residual material into a reliable source of renewable energy. Construction of the plant is expected to begin shortly and is scheduled for completion in 2014. The Company has signed a ten-year agreement to supply Ontario Power Generation with 45,000 metric tons of pellets annually.

Resolute Forest Products has announced plans to build an industrial wood pellet plant that will convert a currently underutilized residual material into a reliable source of renewable energy. Construction of the plant is expected to begin shortly and is scheduled for completion in 2014. The Company has signed a ten-year agreement to supply Ontario Power Generation with 45,000 metric tons of pellets annually.

The plant will be built adjacent to the Company's sawmill in Thunder Bay, Ontario, creating approximately 24 new jobs when fully operational and improving the long-term viability of the sawmill and the approximately 350 jobs that it supports.

"Wood pellets are a clean, renewable energy source, and together with other biofuel opportunities, a natural diversification target for Resolute," said Richard Garneau, President and Chief Executive Officer. "This project provides the opportunity to enhance the use of our existing asset base to produce biofuel for a strategic, committed consumer and allows the Company to gain valuable manufacturing experience in commercial biomass production."

Resolute will invest approximately C$10 million in the construction of the plant, adding to the investments of approximately C$120 million the Company has announced for its Ontario operations since 2011.

SOURCE: RESOLUTE FOREST PRODUCTS INC.

Transparent communication about nanomaterials

BASF’s Dialog Forum Nano is presenting its final report for the dialog phase 2011/2012 today, November 22, in Berlin. The aim of the regular dialog with representatives from research institutes, labor unions, commerce, industry, churches as well as environmental and consumer organizations was to generate joint recommendations for improving transparency in communication about nanomaterials from manufacturers to consumers. “The Dialog Forum Nano is a good example of how BASF is innovative not only in using new technologies to develop new products, but also in communication about these technologies,” said Wolfgang Weber, Vice President Communications & Government Relations BASF Group. “Our positive experience shows that we are on the right track. We will therefore continue the dialog series in future.”

BASF’s Dialog Forum Nano is presenting its final report for the dialog phase 2011/2012 today, November 22, in Berlin. The aim of the regular dialog with representatives from research institutes, labor unions, commerce, industry, churches as well as environmental and consumer organizations was to generate joint recommendations for improving transparency in communication about nanomaterials from manufacturers to consumers. “The Dialog Forum Nano is a good example of how BASF is innovative not only in using new technologies to develop new products, but also in communication about these technologies,” said Wolfgang Weber, Vice President Communications & Government Relations BASF Group. “Our positive experience shows that we are on the right track. We will therefore continue the dialog series in future.”

BASF has conducted the Dialog Forum Nano since 2008, making it the only company in Germany to pursue a regular dialog on the topic of nanotechnology. “It is very important for us that a trusting and constructive cooperation has developed over the years. We have entered into many – sometimes difficult – discussions and have reviewed our own positions,” explained the organizer Carolin Kranz, Senior Manager Communications & Government Relations. Participant Rolf Buschmann of the North Rhine-Westphalia Consumer Advice Center stated: “The Dialog Forum Nano represents an innovative and successful approach to stakeholder communication which has been decisively shaped by the special commitment and willingness of the participants from many different areas of business and society to engage in discussions.” The Dialog Forum Nano was developed and moderated by the organization “Dialog Basis”.

Over several months the dialog partners discussed which scientific information is available, where knowledge gaps exist and how information can be usefully presented to consumers. The topics were partially based on specific consumer inquiries and numerous expert assessments. Using the examples of dirt-repellent and antimicrobial textiles as well as paints and coatings, the joint final report contains recommendations on how information can be gathered within the companies along the supply chain in order to facilitate communication with consumers. At today’s event in Berlin, the results of the dialog phase 2011/2012 will be presented and discussed with Ulrike Höfken, Minister for Environment, Agriculture, Food, Wine Growing and Forestry of the Federal State of Rhineland Palatinate, and others.

The final report and other information on the topic of nanotechnology can be found on http://nanotechnology.basf.com. The website contains information on new products and research projects as well as the results of BASF’s safety research on nanotechnology. There is also an opportunity to enter into dialog with the company through asking questions and exchanging viewpoints.

New anionic surface sizing agent Basoplast® 450 P

Since its invention by BASF, polymeric surface sizing agents (PSA) have seen many developments to reach their current performance levels. Recently, research, development and application specialists at BASF jointly completed their work on a new product for this established technology that allows papermakers to significantly improve on sizing costs. Traditionally, PSA for the liner segment used cationic polymers. This however limited the coloration to certain product ranges.

Since its invention by BASF, polymeric surface sizing agents (PSA) have seen many developments to reach their current performance levels. Recently, research, development and application specialists at BASF jointly completed their work on a new product for this established technology that allows papermakers to significantly improve on sizing costs. Traditionally, PSA for the liner segment used cationic polymers. This however limited the coloration to certain product ranges.

With Basoplast® 450 P, BASF introduces a new and highly cost- efficient PSA for the packaging segment. The product is suited for linerboard grades and complements BASF’s offer of anionic PSA in the graphical paper market. By replacing cationic PSA in packaging with Basoplast® 450 P, paper manufacturers now canadjust the desired coloration in the surface with direct dyes, which can provide a more cost-efficient solution than incumbent systems. Developing cost-efficient systems and solutions is built on the strengths of BASF’s expanded portfolio after the acquisition of legacy Ciba. Direct dyes are sourced from BASF’s new plant in Ankleshwar, India.

In addition to the new opportunities for cost-efficient coloration, BASF’s new anionic PSA Basoplast® 450 P agent shows no foaming tendency or sensitivity to pH or starch type and can be used in both, size or film-press. It further has received food contact approval (BfR XXXVI, FDA 176.170, 176.180).

“With Basoplast® 450 P we offer the first anionic polymeric sizing agent able to compete against cationic polymeric surface sizing agents traditionally used in liner and board. We recently had various mill trials throughout Europe and in consequence are able to promptly launch the product in the market. But, this invention also required cross-divisional support through the know-how- and production Verbund of BASF, especially the Petrochemicals Division. It shows that BASF can be very successful if we act as onecompany,” says Dr. Frank Höfer, Vice President, Marketing Paper Chemicals Europe.

“Our consistency in research & development work, also on established product lines, has made this new market opportunity available. This example shows very clearly that even in mature applications, with lots of creativity and enthusiasm, our development specialists are able to find new and successful products with which we can help our customers to achieve their targets in performance and cost reductions," adds Dr. Thomas Stährfeldt, Vice President, Innovation Paper Chemicals.

Sappi Fine Paper Europe goes to the root of the matter with its 4th Employee-led Tree-Planting

On the 16th of November, employees from Sappi Fine Paper Europe’s Headquarters in Brussels headed out to the Forêt de Soignes, armed with 2750 saplings, ready to be planted. Sustainability is an everyday reality at Sappi, and this initiative is ‘real’ example of how Sappi people can, and do, embrace sustainability on a day to day basis.

Employee-led tree-planting started at Sappi in Spring 2010. Since then, over 8000 trees have been planted by employees in conjunction with the ANB (Agentschap voor Natuur en Bos), the equivalent of the Department of Forestry. This organisation is responsible for the planting of approximately 30,000 trees in the Forêt de Soignes every year as part of the National Forest Management Plan (Belgium). Over 50 people from the company volunteered to take part in the very physical team building exercise, and the result brought great satisfaction to the group.

Sophie de Guignard, responsible for coordinating the group said, “We‘re looking forward to next year when we will plant our 10,000th tree. It will be a significant milestone, and a great reason to inspire others to share the same experience, and understand how to make sustainability real.”

Sappi’s tree planting initiative belongs to a series of sustainability driven initiatives at Sappi all with the objective of demonstrating that sustainability is at the heart of everything that Sappi does. Sappi cares, and wants to engage with others to care together. In September, the Treehouse was launched (www.the-treehouse.be). The Treehouse partnership is both a physical and virtual platform, for like-minded individuals and companies to come together to find ways to embrace sustainability in their daily activities. Sappi’s new sustainability website - We Care (www.sappipositivity.com) - is similarly focused on sharing knowledge and inspiring others to join and build momentum.

Incada a packaging competition winner

Incada, which is made by Iggesund Paperboard in Workington, England, featured in two winning entries when the Pro Carton/ ECMA annual packaging awards were presented recently.

Incada, which is made by Iggesund Paperboard in Workington, England, featured in two winning entries when the Pro Carton/ ECMA annual packaging awards were presented recently.

The folding box board Incada was the surface material – the one visible to customers – in the packaging which won Carton of the Year, “Rose” by champagne producer Taittinger. Incada was also used in the winner of the Beauty & Cosmetics category, Nivea Mini Treats.

“This clearly demonstrates that Iggesund has two strong brands in its portfolio,” comments Guy Mallinson, business director of European sales at Iggesund Paperboard. “Customers who want outstanding quality in folding box board choose Incada, and if they need the properties offered by a solid bleached board then they choose our Invercote.”

Taittinger’s Rose carton was converted by Van Genechten of Angoulême, France, which also created the structural design. Incada Exel was used to cover and add elegance to a base structure made of recycled-fibre material from Meyer Melnhof. The Nivea Mini Treats carton was converted by Clondalkin Pharma & Healthcare, which also created the structural design commissioned by Beiersdorf UK.

Incada was used to give Taittinger’s elegant Rose carton the elegance and élan which captures the consumer’s attention on the retail shelves.

Metsä Group’s tissue and cooking paper business area ends statutory negotiations in Finland

Metsä Tissue, Metsä Group’s tissue and cooking paper business has finished the statutory negotiations commenced in September in its Finnish units. The negotiations were part of Metsä Tissue’s on-going company-wide organisational restructuring targeted to improve profitability. As a result of the statutory negotiations the reduction of personnel will be 19 people. Metsä Tissue’s Finnish operations are based in Espoo and Mänttä and it employs approximately 480 people in Finland.

Metsä Tissue, Metsä Group’s tissue and cooking paper business has finished the statutory negotiations commenced in September in its Finnish units. The negotiations were part of Metsä Tissue’s on-going company-wide organisational restructuring targeted to improve profitability. As a result of the statutory negotiations the reduction of personnel will be 19 people. Metsä Tissue’s Finnish operations are based in Espoo and Mänttä and it employs approximately 480 people in Finland.

“By restructuring and reorganising our operations, we aim to secure our future competitiveness on the growing tissue and cooking paper market,” says Metsä Tissue’s CEO Mika Joukio.

ANDRITZ to supply film press to Brigl & Bergmeister, Slovenia

International technology Group ANDRITZ has received an order from Brigl & Bergmeister, one of the world’s leading producers of specialty papers for labels and flexible packaging, to supply a PrimeCoat film press, including an infrared drying system, for Papirnica Vevče, Slovenia. Start-up is scheduled for 2013.

International technology Group ANDRITZ has received an order from Brigl & Bergmeister, one of the world’s leading producers of specialty papers for labels and flexible packaging, to supply a PrimeCoat film press, including an infrared drying system, for Papirnica Vevče, Slovenia. Start-up is scheduled for 2013.

With the PrimeCoat film press, different pre-coatings are possible and coat weights can be applied to each side of the paper web, also at higher machine speed. In addition to the improved pre-coating quality for a wide range of coating applications, the ANDRITZ technology increases the annual output by 20,000 t to reach 110,000 t.