Ianadmin

Cham Paper Group wins the Zug Innovation Prize with Barnamic®

The Cham Paper Group has won the Zug Innovation Prize 2012. The CHF 20,000 prize was awarded to the company today by the Mayor of Zug, Matthias Michel, to mark this year's Zug Innovation and Technology Day. The Jury selected the Cham Paper Group to receive the prize for the successful development of its ground-breaking speciality paper Barnamic®.

The Cham Paper Group has won the Zug Innovation Prize 2012. The CHF 20,000 prize was awarded to the company today by the Mayor of Zug, Matthias Michel, to mark this year's Zug Innovation and Technology Day. The Jury selected the Cham Paper Group to receive the prize for the successful development of its ground-breaking speciality paper Barnamic®.

Barnamic® is a product range of innovative speciality papers, which can be used on their own as packaging solutions for food products. Barnamic® provides the protection required for packaged food,

with barrier functions directly integrated into the paper, and can therefore replace complicated composites made out of various materials (such as plastic and aluminium).

Over the past few years, the Cham Paper Group has invested around 20 million francs in the innovative curtain coating technology, which now enables it to utilise a production technique that is currently unique to the paper industry. The development of innovative speciality paper and its coating is something held very dear at the Group’s traditional place of manufacture in Cham. Products such as Barnamic® form the basis for the establishment of the Cham Paper Group's innovation and technology centre. The prize money awarded to the company will be used to purchase laboratory test equipment that the Group requires to optimise and refine the Barnamic® product range.

UPM Shotton Paper Mill Scoops PPI Enviromental Strategy Award

UPM Shotton paper mill in north Wales has triumphed at the annual PPI Awards held in Brussels. The Award for Environmental Strategy of the Year for a Mill was given in recognition for UPM Shotton going the extra mile and implementing innovative environmental solutions.

UPM Shotton paper mill in north Wales has triumphed at the annual PPI Awards held in Brussels. The Award for Environmental Strategy of the Year for a Mill was given in recognition for UPM Shotton going the extra mile and implementing innovative environmental solutions.

The judges commented: “The importance of environmental issues keeps growing in the pulp and paper industry and this can be clearly seen in the entries we received. The judges felt the winner was a great example of resource efficiency combined with pragmatic strategic planning – securing valuable supply chains for the mill and adding value to the other waste fractions at the same time.”

The judges were looking for a showcase mill that takes all the elements of responsibility into consideration, from sourcing of raw material, minimising impacts, and water energy and resource efficiency.

“Resource scarcity will be a key future issue for everybody and one reason why UPM has focused on material and resource effectiveness – creating more with less is almost a mantra for the company's operations. We have developed innovative ways to reduce our own waste and reuse waste in new products, leading to highly sustainable use of resources. And one of the best examples of the company's thinking and resource effectiveness is the zero waste strategy at Shotton Paper Mill”, says John Sanderson, Director of Environmental Market Support, UPM.

Not only is UPM Shotton mill based on the use of recovered materials, but it aims to use every last bit of those recovered resources to produce products or energy, and to waste nothing. An estimated one million tonnes of renewable & recoverable materials from UK urban conurbations and forests are processed through UPM Shotton every year, and today UPM Shotton utilizes 99.5% of the incoming materials.

UPM’s Biofore vision and consistent work on corporate responsibility has recently gained recognition from different parties. UPM was listed as the only forestry and paper company worldwide in the Dow Jones Sustainability Indexes, and also recognized as the ‘Most Innovative Company’ at the 2012 Ethical Corporation Awards. In the Nordic Carbon Disclosure Leadership Index, UPM was ranked in shared first place with top scores. UPM is one of seven paper producers to receive an award from the WWF in the category of ‘Transparency’ during the 2012 WWF Environmental Paper Awards.

Discover what responsibility means to UPM. Learn more on www.upmresponsibility.com

Organized by RISI, the leading information provider for the global forest products industry, the PPI Awards program honors leadership, vision, innovation and strategic accomplishments within the pulp and paper industry. The PPI Awards are the only global awards dedicated to recognizing the achievements of companies, mills and individuals in the pulp and paper sector.

For more information about the awards, please go to PPI Awards’ web site.

Major wins for Mondi with three awards from PPI and two from WWF

Mondi’s contribution to industry standards in sustainable paper production, efficiency, and safety were recognized at the 2012 Pulp and Paper International (PPI) Awards on 12th November. The following day, WWF announced Mondi as the recipient of two Environmental Paper Awards in the categories "Transparency" and "Best Environmental Performance Paper Brands".

Mondi, the global paper and packaging manufacturer, received international accolades this week at the 2012 PPI Awards and by WWF, the world´s largest conservation organisation, who announced Mondi as one of the winners of the 2012 WWF Environmental Paper Awards in the category “Transparency”. Mondi also received the Best Environmental Performance Paper Brands Award for 100% recycled NAUTILUS® SuperWhite, which is listed in the WWF's Check Your Paper database, reaching 90% of achievable scores.

Mondi, the global paper and packaging manufacturer, received international accolades this week at the 2012 PPI Awards and by WWF, the world´s largest conservation organisation, who announced Mondi as one of the winners of the 2012 WWF Environmental Paper Awards in the category “Transparency”. Mondi also received the Best Environmental Performance Paper Brands Award for 100% recycled NAUTILUS® SuperWhite, which is listed in the WWF's Check Your Paper database, reaching 90% of achievable scores.

Emmanuelle Neyroumande, Manager of WWF International´s global pulp and paper work commented: "Mondi has been applauded by WWF for transparency on its environmental footprint, showing that the company takes their environmental and social responsibility seriously. We welcome that Mondi has published 92% of Mondi-branded uncoated fine papers on WWF's Check Your Paper database of eco-rated papers."

“This was a very exciting and gratifying week for Mondi, having had our efforts and achievements recognised by both PPI and WWF - major international organisations and stakeholders in the pulp and paper industry,” commented Peter Orisich, CEO Mondi Uncoated Fine Paper.

PPI awarded Mondi SCP mill in Slovakia the prize for Managing Risk and Safety in the company category as well as the Efficiency Improvements of the Year in the mill category with regard to machine performance. Mondi SCP is the producer of well–known Mondi uncoated fine papers such as MAESTRO® Print offset, DNS® performance and several IQ and MAESTRO® office grades. The success of Mondi Group was underlined by the award in the company category for Environmental Strategy of the Year (http://sd-report.mondigroup.com/2011/).

“Safety is a key concern in all of our Uncoated Fine Paper mills; therefore it is especially motivating to see Mondi SCP’s success in risk and safety management applauded on an international scale by PPI. We have also recently celebrated 2 million lost-time-injury free hours at the mill,” said Peter Orisich.

The PPI Awards are organised by RISI, one of the leading information providers about the global forest products industry. The awards aim at honouring leadership, vision, innovation and strategic accomplishments within the pulp and paper industry.

Lenzing Group: Second Best Nine-Month Results Despite Headwinds

In spite of economic headwinds, the Lenzing Group succeeded in achieving the second best business results in its history. However, as expected, the company could not match the record performance of the previous year. Fiber shipment volumes rose by 12% year-on-year, whereas average selling prices for Lenzing fibers fell by about 11%, as anticipated.

- New record fiber shipment volumes

- Lower average fiber selling prices as expected

- Guidance confirmed for the entire year 2012

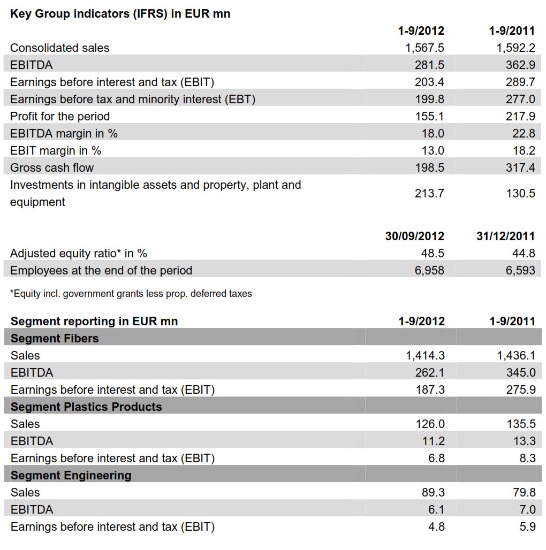

Consolidated sales of the Lenzing Group in the first nine months of 2012 amounted to EUR 1,567.5 mn, a drop of 1.5% from the prior-year level of EUR 1,592.2 mn. Consolidated EBITDA (earnings before interest, tax, depreciation and amortization) in the first three quarters was the second highest in the company’s history, totaling EUR 281.5 mn, down 22.4% from EUR 362.9 mn in Q1-3 2011. The EBITDA margin remained at an attractive double-digit level of 18.0% (Q1-3 2011: 22.8%). Earnings before interest and tax (EBIT) were also at a gratifying level of EUR 203.4 mn (Q13 2011: EUR 289.7 mn). This corresponded to an EBIT margin of 13.0% for the Lenzing Group in the first nine months of 2012, compared to 18.2% in the prior-year period.

“In spite of the difficult market conditions, we were able to achieve record sales of 590,000 tons of fibers in the first three quarters of 2012 against the backdrop of the full utilization of our production capacities. This underlines the world market leadership of the Lenzing Group based on quality, innovation, a global presence and optimal service“, says Lenzing’s Chief Executive Officer Peter Untersperger.

Adjusted Group equity totaled EUR 1,152.0 mn as at the end of September 2012, a rise of 9.9% from the comparable figure of EUR 1,048.1 mn at the end of 2011. The adjusted equity ratio was 48.5% as at September 30, 2012 (December 31, 2011: 44.8%). As a result of the lively investment activity within the Group, net financial debt increased to EUR 295.3 mn at the end of the third quarter (December 31, 2011: EUR 159.1 mn). Accordingly, net gearing continued to be a very low level of 25.6% (December 31, 2011: 15.2%).

(click picture to enlarge)

Outlook

Lenzing confirms its guidance for the entire year 2012, which was published as part of the half-year results. As a consequence, Lenzing is well on track to achieve the second best business results in the company’s history in 2012 as a whole. However, due to the current market developments, a decline of average fiber selling prices to about EUR 1.85 per kilogram is expected. Accordingly, Lenzing now expects that it will likely reach the lower end of the targeted range with respect to its performance indicators for the entire year 2012. This means consolidated sales are anticipated to be within a range of EUR 2.1-2.15 bn, whereas EBITDA will amount to EUR 350-400 mn and EBIT will total somewhere between EUR 240-290 mn. Capital expenditure for 2012 is budgeted to be about EUR 325 mn.

Long-term megatrends such as population growth, increasing per capita fiber consumption in the emerging markets and growing demand for resource-saving, environmentally compatible fibers remain intact, and are good arguments in favor of man-made cellulose fibers. However, this longterm growth trend does not exclude the possibility of repeated phases of delayed or accelerated economic growth. Lenzing remains committed to its long-term growth strategy.

Breakthrough: Metso Pulp Analyzer helps papermakers predict paper properties

The new Metso Pulp Analyzer (Metso MAP) features the first on-line measurement of micro-scale details of fiber properties. It provides pulp and papermakers a tool that helps to predict how fiber properties will affect final sheet strength properties. The new analyzer also enables precise furnish preparation and low consistency refining management resulting in better sheet runnability, higher machine efficiency and lower furnish costs.

Metso introduces the next generation's pulp analyzer (Metso MAP) that features a new high definition fiber imaging module. This module represents the first on-line measurement of micro-scale details of fiber properties, including fibrillation, vessel segments, flocs and other particles. The fibrillation measurement, combined with other fiber properties measured by the analyzer, can be processed in a modeling tool that helps to predict how fiber properties will affect final sheet strength properties.

Metso introduces the next generation's pulp analyzer (Metso MAP) that features a new high definition fiber imaging module. This module represents the first on-line measurement of micro-scale details of fiber properties, including fibrillation, vessel segments, flocs and other particles. The fibrillation measurement, combined with other fiber properties measured by the analyzer, can be processed in a modeling tool that helps to predict how fiber properties will affect final sheet strength properties.

This next generation's analyzer provides online measurement of fiber dimensions including kink, curl, size distribution and fractionation. The Metso MAP has established an excellent reputation for measurement accuracy and reliability in the pulp and paper industry.

Several advantages for pulp and paper makers

The new product is intended for managing fiber properties in papermaking furnish preparation as well as in mechanical, recycled fiber and kraft pulp mills. To provide the highest measurement application flexibility, the analyzer samples from up to 20 process fiber streams. This new analyzer also utilizes brand new manual sampling stations that can be located throughout the plant. To date, the product has been installed in paper, tissue and board mills.

With a freeness measurement module included in the same platform, the Metso MAP provides pulp and papermakers with a quickly updated and complete fiber and furnish measurement solution. More precise furnish preparation and low consistency refining management provides better sheet runnability, higher machine efficiency and lower furnish costs. Pulp mill operations will benefit from minimum shives in mechanical and chemical pulps, and reduced fiber quality variability. In addition to providing operators with an unprecedented window into pulp quality, these measurements are an integral part of pulping and refining controls.

Flexible and modular design

The Metso MAP builds upon a flexible and modular design. Already installed analyzers can be upgraded easily with the new high definition fiber analysis module. This underlines the original analyzer design philosophy which allows for upgrading the platform as new technology becomes available without making the original investment obsolete. The useful lifecycle of the product is thereby extended.

To ensure maximum uptime and process measurement performance, the Metso MAP analyzer has been designed with remote access and service support in mind. From anywhere in the world a Metso expert can access an analyzer - with permission and through a secure access port - and work out a solution to technical and process applications very quickly.

FITNIR Analyzers Collaborating with FPInnovations on New Developments

FITNIR Analyzers Inc. is pleased to announce its recently signed strategic research agreement with FPInnovations.The partners will jointly develop new measurement technologies, for both online and offline systems, focusing on the advantages of spectroscopy solutions.

“Strategically, we are very excited about our joint development agreement with FPInnovations,” said Thanh Trung, VP Technology. “Combining FITNIR’s technical capability in spectroscopy with FPInnovations highly qualified researchers and technical team will allow for expedited development, technology transfer to FPInnovations’ member companies, and eventual commercialization of innovative products.”

Today, the marketplace is lacking instrumentation that can provide rapid measurement of the physical and mechanical properties of pulp. The initial joint development projects will be based on the success of a benchtop Near Infrared (NIR) device for the measurement of pulp properties, including oven-dry content and physical and mechanical properties of High Yield Pulp (HYP). With the capability to provide critical HYP properties within minutes, pulp mills will have the ability to segregate their product by quality — a game changer for pulp producers in a competitive market that will drive focus quality assurance and customer satisfaction, all the while addressing value-chain optimization by reducing chemical and transportation costs.

“Strategic research alliances are a growing aspect of FPInnovations’ business model,” said Hervé Deschênes, Vice-president of Business Development, FPInnovations. “We are confident that our association with FITNIR will deliver significant benefits to our member companies in the short term, and lead to the successful commercialization of ground-breaking instrumentation for pulp producers.”

Xerium Technologies Continues European Cost Reductions

Xerium Technologies, Inc. (NYSE:XRM), a leading global manufacturer of clothing and roll covers used primarily in the paper production process, has announced that it has initiated consultation proceedings with the works council at its Huyck Wangner forming fabric facility in Reutlingen, Germany regarding a proposal to eliminate a significant number of positions in an effort to continue to address the Company’s cost structure. Due to the nature of the proceedings with the local works council, the Company is not able to provide an estimate of the anticipated restructuring expenses or costs savings at this time.

Commenting on the action, Harold Bevis, the Company’s President and Chief Executive Officer said, “This is an important element of the Company’s plan to rightsize our cost structure. Despite these anticipated workforce reductions, Huyck Wangner will continue to timely fulfill customer requirements and will maintain its leadership in producing high quality forming fabrics.”

Source: Xerium Technologies, Inc.

Tieto begins collaboration with FormPipe Software AB

Tieto has signed a partnership agreement with FormPipe Software. The collaboration entails Tieto building on its Enterprise Content Management (ECM) focus by offering sales, administration and further development of FormPipe's product suite for document and case management, workflow and archiving.

Tieto has signed a partnership agreement with FormPipe Software. The collaboration entails Tieto building on its Enterprise Content Management (ECM) focus by offering sales, administration and further development of FormPipe's product suite for document and case management, workflow and archiving.

FormPipe's products for document and case management, workflow and archiving have been devoted much attention in recent years and enjoyed a great deal of success in the market. For this reason, Tieto is now complementing and strengthening its product portfolio with FormPipe's products.

"The goal of the partnership is to be able to offer both the public and private sector an optimum product on the basis of each customer's needs and wishes," says Tony Forstén, ECM Manager at Tieto.

For FormPipe, the partnership means greater availability on the market, with a higher delivery capacity and level of competence.

"We see Tieto as a key strategic partner for continuing to grow in our main segments. Tieto has proved its worth as a very competent supplier of solutions for document and case management, workflow and archiving, which fortifies our position in our main markets," says Mauritz Wahlqvist, Partner & Sales Manager at FormPipe.

The partner agreement will run for two years and means that Tieto can secure its position as a leading supplier of solutions for document and case management.

Sappi’s talent for innovation awarded during 2012 Pulp and Paper International (PPI) Awards

Sappi Fine Paper Europe is very proud to have won one award in the 2012 Pulp & Paper International Awards, during a ceremony hosted on 12 November in Brussels. The awards are dedicated to recognising the achievements of companies, mills and individuals in the pulp and paper sector and are truly global in scale.

Our 2012 award is in the following categories:

- Advances in Innovation in Speciality Papers (Mill) : Alfeld, White liner for corrugated board production [Fusion]

Sappi’s Alfeld mill in Germany was the innovation centre for a new type of white liner developed for corrugated board production, focused on the creation of a new reverse side barrier coating. The result was Fusion, a product which is much more than a simple white top liner; it is a premiumwhite liner. The innovation came about as a result of Sappi’s accumulated competence in paper coatings, and its vast knowledge and experience in packaging materials in the Alfeld mill. With this new innovation Fusion can offer customers a very special appearance and associated print performance that other top liners simply can’t beat. Sappi is very proud of this new innovation.

Sappi was nominated in a further three categories this year. This in itself is testament to the company’s continued strong performance in the market and dedication to investing in future growth opportunities, as well as its commitment to creating valuable tools and resources for Sappi customers and partners. The additional category nominations were as follows:

-

Innovative Products- Graphic Papers (Jaz Silk, digital paper)

-

Promotional Campaign (Houston, the digital universe of paper and printing knowledge)

-

Advances in Innovation in Sustainable Packaging (Mill) (Alfeld / Innovia – Laminate Structure for Compostable Packaging [Algro Nature])

The PPI Awards

First launched in 2009, the global PPI Awards (organized by RISI, the leading information provider to the global forest products industry ) are dedicated to recognising the achievements of companies, mills and individuals in the pulp and paper sector. The PPI Awards are global, and proudly provide a platform that honours leadership, vision, innovation and strategic accomplishments within the industry. http://www.risiinfo.com/events/ppi_awards/2012_finalists.html

Our Nominations Sappi Fine Paper Europe was nominated in 4 separate award categories as follows:

· Innovative Products- Graphic Papers (Jaz Silk, digital paper)

Jaz™ silk is a high-quality coated paper specifically made for high speed digital inkjet web printing. In an era where speed and customisation are key differentiators in highly competitive markets, print quality no longer has to suffer. Jaz™ silk digital coated paper has full high-speed inkjet functionality, yet manages to combine the reassuring look and feel of offset paper with full colour personalisation options and flexibility. Key characteristics for this paper include the fact that no bonding agent or other treatments are required, print efficiency leading to time saving, and lower consumption of ink compared to offset paper. Jaz™ silk is first achievement from a very successful partnership between HP, the world’s leading printer and PC manufacturer, and Sappi Fine Paper Europe.

· Promotional Campaign (Houston, the digital universe of paper and printing knowledge)

Houston is Sappi Fine Paper Europe’s brand new online knowledge platform specifically developed as a support tool for professionals working in the paper and graphic industries. As well as easily accessible information on paper, printing and converting-related topics, live experts work with professionals to find solutions to issues in real time. Anything you need to know about paper or print; Houston will have the answer! www.sappi.com/houston .

The idea for Houston came from the desire to share our wide expertise and accumulated knowledge with our customers. The knowledge platform includes all types of information from the latest printing techniques and paper types, to market trends and specific topics via Web Seminars. The platform also hosts polls, market feedback and opinions, and is regularly updated with news about, and from, the broader industry environment. One of the most exciting features is the live support service which is offered free of charge, enabling users to chat directly with Sappi technical staff to ask questions and share ideas.

· Advances in Innovation in Speciality Papers (Mill) (Alfeld, White liner for corrugated board production [Fusion]

Fusion is a premium white topliner designed for lamination onto corrugated board. Using 100% bleached virgin fibres, to ensure it is a spotless paper Fusion has been engineered to bring out the highest levels of quality - regardless of the printing process - offset, flexo and digital. But what makes the grade stand out is its flexibility and suitability for a range of markets, from corrugators, litho laminators, display manufacturers and folding box converters to direct mailers, pre-printers, designers, agencies and co-packers.

By coating and calendering the paper, the Fusion surface offers a special quality and gloss much closer to the quality of content and display packaging therefore carrying a perception of higher-value-for money. A cost effective high quality result is therefore achievable for brand owners, retailers, agencies and converters. Key to this is its ability to produce unrivalled results on a lower grammage sheet, mirroring the market trend towards lightweighting.

Fusion is especially attractive for brand owners requiring high shelf impact for applications from displays to packaging for consumer electronics, bag in box and pet food.

· Advances in Innovation in Sustainable Packaging (Mill) (Alfeld / Innovia – Laminate Structure for Compostable Packaging [Algro Nature])

Algro Nature is the first completely bio-based, renewable, recyclable and compostable paper and bioplastic packaging that can be used for a wide variety of foods, beverages and pharmaceuticals. It can be composted at home or even used in anaerobic digestion plants to produce heat and energy, meaning lower greenhouse gas emissions and less waste. As end users become more aware of the availability of environmentally sustainable paper, it has become increasingly important for mills to continue to improve the sustainability position of their products, and Sappi has dedicated significant resources to this effort. Sappi and its Algro Nature has teamed up with Innovia Films and its NatureFlex™ range to demonstrate the potential of laminate structures suitable for end users in the food, confectionery and beverage industries. The result of this effort is a product that is technically functional and utilizing renewable resources that enhance compostability.

Reorganization drives Q3 profit for Catalyst Paper

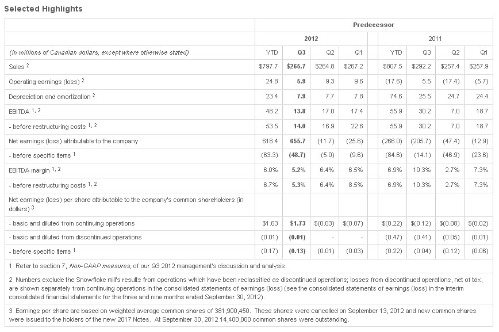

A significant one-time credit arising from reorganization gains and “fresh-start accounting” valuation adjustments resulted in third quarter net earnings of $655.7 million for Catalyst Paper. The company emerged from creditor protection on September 13, 2012 with significant debt and cost-structure improvements.

Net earnings this quarter contrast with a net loss of $11.7 million the quarter before. Sales were essentially unchanged at $265.7 million. The net after-tax restructuring-related credit was $688.1million. An after-tax foreign exchange gain on translation of U.S. dollar denominated debt of $25.2 million further supported Q3 earnings.

Before these and other specific items, Catalyst posted a net loss for the third quarter of $48.7 million, compared to a net loss of $5.0 million in the prior quarter. Earnings before interest, tax, depreciation and amortization (EBITDA) in the third quarter were $13.8 million and EBITDA before restructuring costs was $14.0 million, compared with EBITDA of $17.0 million and EBITDA before restructuring costs of $16.9 million in the second quarter.

“The third quarter marked a turning point for Catalyst as we exited creditor protection with a stronger balance sheet, lower interest costs and lower annual operating costs going forward,” said President and CEO Kevin J. Clarke. “This puts us on stronger operational footing to address ongoing market dynamics. And it means Catalyst can now take a much more active role in the transformation of the industry as a whole.”

Creditor Protection and Restructuring Process

After filing for creditor protection on January 31, 2012, Catalyst secured 99% approval from voting creditors for its second amended plan of arrangement under the CCAA on June 25, 2012. The plan subsequently received court sanction in British Columbia and was confirmed by the US Court in Delaware. A new asset-based loan (ABL) facility was in place on September 13, 2012, meeting the final pre-condition for implementation of the plan.

Previous secured note holders received shares and US $250 million of new senior secured notes due 2017 in exchange for their US$390 million of secured notes due 2016. In addition, we issued US$35 million of new exit notes under a secured exit financing facility on September 13, 2012, to pay restructuring costs and expenses and to manage other contingencies on exit from CCAA protection.

The restructuring has reduced Catalyst’s debt by $390 million, eliminated $80 million of accrued interest, and reduced annual interest expense and other cash costs by $70 million.

Catalyst’s operations are continuing in substantially the same form, and a new board of directors took office upon exit from CCAA. Previous secured note holders now own all of the 14.4 million new common shares that are presently issued and outstanding. An addition of approximately 135,000 common shares will be issued to unsecured creditors who made an equity election in respect of their claims under the plan. Additional shares may be issued under a new management incentive plan that may be adopted in future. An application has been submitted to the Toronto Stock Exchange for a public listing of the new common shares.

Fresh start accounting has been applied as of September 30, 2012, in accordance with U.S. Generally Accepted Accounting Principles. This involved use of independent financial advice to determine an enterprise value for the company and the fair value of Catalyst’s assets and liabilities.

Snowflake Closure

The previously announced permanent closure of the Snowflake mill in Arizona, which primarily manufactured recycled newsprint, was implemented on September 30, 2012. This will stem operating losses and reduce annualized selling, general and administrative expenses. A court-approved sales process for the mill and associated assets was announced on September 17, 2012.

The closure is expected to result in one-time cost of approximately $9.7 million ($8.7 million of which had been paid or accrued by quarter-end) and ongoing costs of approximately $0.6 million per month until disposition. These costs are expected to be largely recouped by sales proceeds.

Performance and Market Overview

Operating earnings of $5.9 million were up from the same quarter last year and on a year-to-date basis but lagged Q2 operating earnings of $9.3 million. They were negatively impacted by reduced pulp transaction prices, a stronger Canadian dollar, increased power costs, and a pulp inventory write-down. Offsetting factors included higher overall sales volumes, lower maintenance costs and lower labour costs – the final factor being an outcome of new collective agreements reached during the restructuring.

North American demand was down year-over-year across specialty paper product lines – most notably by 18.0% for uncoated grades and by 15.4% for directory. Benchmark prices were up moderately for coated grades from the second quarter, but unchanged for other specialty products. Sales volumes decreased while average sales revenue remained flat year-over-year.

North American newsprint demand saw a marginal 1.4% year-over-year increase, although the average benchmark price dropped from the second quarter due to marketplace inventory buildup. Sales volumes increased while average sales revenue was down year-over-year.

Markets for Northern Bleached Softwood Kraft pulp remained weak as a result of end-user inventory in China, and the benchmark price for that market dropped by 8.7% from the second quarter. There were year-over-year declines in both sales volumes and average sales revenue.

Liquidity

Quarter-end liquidity of $96.8 million was down from $125.9 million a year prior, but up from $71.8 million at the end of the second quarter due to a larger borrowing base under the new ABL facility. Cash on hand was down mainly due to payment of success fees of $6.9 million on emergence from creditor protection and debt issuance costs of $9.3 million.

(click picture to enlarge)

Outlook

The U.S. economic recovery in the first half of 2012 moderated somewhat though employment data, housing and financial markets held steady. The Canadian dollar remains near par and currency volatility is expected to ease somewhat through year-end and early 2013.

Specialty printing paper markets will be positively affected by seasonally strong demand in the fourth quarter. Producer and consumer inventories are relatively low with good industry operating rates for most specialty grades, especially coated and high gloss. Price increases for coated grades announced for October 1st are expected to be partially implemented though the Port Hawkesbury mill restart will make seasonally slow specialty markets even more challenging in the first quarter of 2013.

Newsprint demand is expected to decline modestly through the remainder of the year and exports are likely to remain sluggish. However, the Snowflake mill closure has tightened operating rates in the West and prices are expected to increase marginally in our freight-logical markets while remaining flat in Eastern markets.

Demand for NBSK pulp is expected to increase slightly in the fourth quarter driven primarily by China. Prices are expected to recover from the lows they reached in the third quarter. Further price appreciation is dependent on global demand and supply dynamics and growth in Chinese consumption.

On the operations side, price pressure is expected to ease on fibre and some chemicals. Maintenance costs are expected to increase with two boiler outages and a scheduled 12-day outage on one of our pulp lines and recovery boilers. Crofton No. 1 paper machine will continue to be indefinitely curtailed for the foreseeable future.

Capital spending in 2012 is forecasted to be approximately $25 million, and energy efficiency projects funded through the Federal Green Transformation Program are complete and on track to deliver EBITDA in excess of $5.0 million in 2012.

Further Quarterly Results Materials

This release, along with the full quarterly report (Management Discussion &Analysis, Financial Statements and accompanying notes) are available at www.catalystpaper.com/Investors. This material is also filed with SEDAR in Canada and EDGAR in the United States.

Kevin J. Clarke, president and CEO, and Brian Baarda, vice-president finance and CFO, will hold a conference call on Wednesday November 14, 2012, at 11 a.m. ET, 8 a.m. PT to present the company’s third quarter results. Financial analysts and institutional investors are invited to dial 1-888-231-8191 (North America) or 1-647-427-7450 (Toronto / International) reservation number 56717173#. Media and other interested people may join the live webcast in listen-only mode at www.catalystpaper.com