Ianadmin

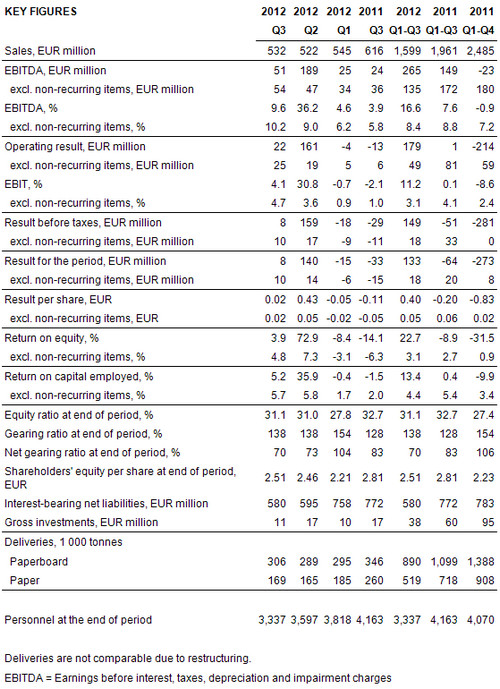

Metsä Board Corporation’s operating result excluding non-recurring items

Metsä Board Corporation Interim Report 1 January–30 September 2012, 1 November 2012 at 12 noon

Result for January–September 2012

- Sales were EUR 1,599 million (Q1–Q3/2011: 1,961).

- The operating result excluding non-recurring items was EUR 49 million (81). The operating result including non-recurring items was EUR 179 million (1).

- The result before taxes excluding non-recurring items was EUR 18 million (33). The result before taxes including non-recurring items was EUR 149 million (-51).

- Earnings per share excluding non-recurring items were EUR 0.05 (0.06) and including non-recurring items EUR 0.40 (-0.20).

Result for the third quarter of 2012

- Sales were EUR 532 million (Q2/2012: 522).

- The operating result excluding non-recurring items was EUR 25 million (19). The operating result including non-recurring items was EUR 22 million (161).

- The result before taxes excluding non-recurring items was EUR 10 million (17). The result before taxes including non-recurring items was EUR 8 million (159).

- Earnings per share excluding non-recurring items were EUR 0.02 (0.05) and including non-recurring items EUR 0.02 (0.43).

Events in the third quarter of 2012

- Delivery volumes of paperboard and coated paper increased.

- Delivery volumes of uncoated paper and pulp decreased.

- There were no material changes in paper and paperboard prices. The market price of pulp decreased.

Events after the period

- The biopower plant owned by Pohjolan Voima and Leppäkosken Sähkö was inaugurated at the Kyro mill.

“Our profitability improved further in the third quarter. Favourable development in the paperboard business continued, and delivery volumes increased as expected. Despite the extensive maintenance shutdown at the Husum mill, the operating result of the paper and pulp business remained at the second quarter level.

The paper and paperboard order books and operating rates are currently at a normal level. Folding boxboard order inflows have in recent weeks slowed down somewhat, but the price situation is stable. Paperboard delivery volumes are estimated to be slightly lower in the fourth quarter than in the third quarter, due to seasonal factors. Market prices of pulp are expected to increase in the fourth quarter, but it is estimated that the average price of deliveries will be slightly lower than in the third quarter. The overall situation in the global economy is currently uncertain, which makes business forecasting more difficult than in normal conditions.

We completed the Paperboard business area’s investment programme as planned with the inauguration of the biopower plant at the Kyro mill. Our production machinery is now top class in the world, and our folding boxboard capacity, which was expanded by 150,000 annual tonnes, will be fully available from the beginning of 2013. New capacity is necessary in order for us to ensure the availability of board for our customers in all situations.”

Mikko Helander, CEO

Near-term outlook

The situation in the global economy is currently uncertain, which makes business forecasting more difficult than in normal conditions.

Folding boxboard order books and operating rates are currently at a normal level, but the order inflows have recently slowed down somewhat. The average prices of folding boxboard are not expected to change materially in the coming months.

Linerboard order books and operating rates are at a strong level. Prices of linerboard will be slightly higher in the fourth quarter than in the third quarter, as a result of the price increase implemented in September.

It is estimated that in the fourth quarter the delivery volume of folding boxboard and linerboard will be slightly lower than in the third quarter, due to the seasonally weaker December. The slight increase in the price of linerboard is, however, not estimated to be sufficient to completely cover the negative result impact of the seasonally lower delivery volumes in the fourth quarter in the Paperboard business area.

The delivery volumes of paper and pulp are in the fourth quarter expected to be at least at the third quarter level. No material changes are on the horizon in paper prices. The USD denominated market price of long fibre pulp is estimated to increase somewhat during the fourth quarter. All in all, the average price of Metsä Board’s pulp deliveries in the fourth quarter is however estimated to be slightly lower than in the third quarter.

Production costs are not estimated to change materially in the coming months.

Metsä Board’s operating result in the fourth quarter of 2012, excluding non-recurring items, is expected to be roughly at the third quarter of 2012 level.

Disclosure procedure

Metsä Board Corporation follows the disclosure procedure enabled by Standard 5.2b published by the Finnish Financial Supervision Authority and hereby publishes its Interim Report for January-September 2012 enclosed to this stock exchange release. Metsä Board's complete Interim Report is attached to this release in pdf-format and is also available on the company's web site at www.metsaboard.com.

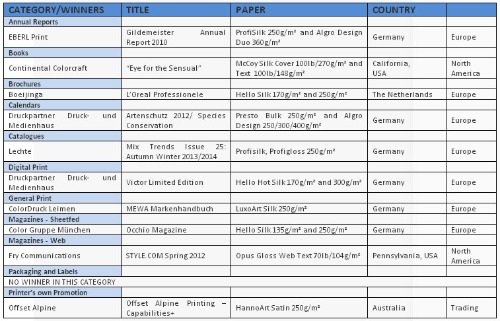

Europe excels in 2012 Sappi International Printers of the Year Awards

Metso valves for Sappi's Ngodwana fiberline expansion

The long-term relationship between Sappi Ngodwana and Metso is strengthened by a new contract for automated valves and services to increase the mill's efficiency.

Metso will deliver all the automated process valves required for Sappi's fiberline expansion in the Ngodwana mill in South Africa. In this project, called Go-Cell, the existing fiberline is being expanded to produce chemical (specialised) cellulose, also known as dissolving pulp. In total, over 700 automated valves will be delivered during the final quarter of 2012, and the mill start-up is scheduled for early 2013.

Metso will deliver all the automated process valves required for Sappi's fiberline expansion in the Ngodwana mill in South Africa. In this project, called Go-Cell, the existing fiberline is being expanded to produce chemical (specialised) cellulose, also known as dissolving pulp. In total, over 700 automated valves will be delivered during the final quarter of 2012, and the mill start-up is scheduled for early 2013.

Metso was chosen as a supplier because of the proven quality and reliability of its solutions in similar applications worldwide. The existing, large installed valve base in the mill makes it beneficial for Sappi to select Neles products once again, as this will facilitate the successful management of shutdowns, inventories and spare parts. The decision to choose Metso was further reinforced by the long relationship between the organisations and the excellent service support provided to the mill.

Metso will supply all the automated on-off and control valves with intelligent Profibus positioners for the new fiberline, and for upgraded process areas in evaporation, recausticising and ash leaching. The delivery includes valves in stainless steel, duplex stainless steel, titanium, SMO and ceramic material in sizes from DN25 to DN500. All valves are equipped with pneumatic cylinder actuators and intelligent positioners or limit switches. The delivery also comprises Neles metal-seated ball valves, segment and triple eccentric Neldisc butterfly valves as well as Jamesbury soft-seated ball valves.

In addition to typical process valves, Metso will also supply specially designed high-consistency valves for the fiberline as well as capping and discharge valves for six batch digesters for the cooking plant. All these high-performance solutions will support the mill's goals of increased efficiency and reduced energy consumption.

The expanded fiberline will produce 210, 000 tonnes per annum of chemical (specialised) cellulose, which is widely used in the textile, pharmaceutical and food industries. Sappi is the global leader in chemical (specialised) cellulose production.

Experienced in valves

Metso is the leading provider of valve solutions and services. Metso's Flow Control solutions include control valves, automated on/off and emergency shut-down valves, as well as smart positioners and condition monitoring technology. Metso's world-leading brands include Neles, Jamesbury and Mapag.

Due to Metso's strong position in advanced valves technology, services are a major part of their offering. Several of their service centers are located close to major production facilities in order to support customers. For valve customers, Metso already has 32 service centers around the globe, and a new supply and service center was opened in India last spring.

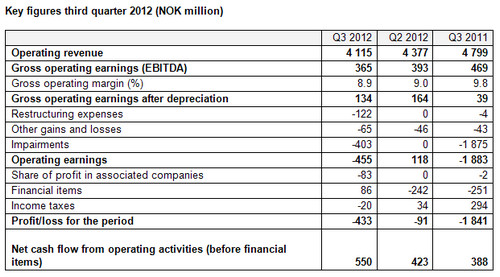

Norske Skog, Third quarter 2012: Good cash flow and lower debt

Good capacity utilisation, with high export levels and lower costs, counteracted the effects of the weak market development in Europe and Australia. The significant reduction in debt was a result of strong cash flow.

Good capacity utilisation, with high export levels and lower costs, counteracted the effects of the weak market development in Europe and Australia. The significant reduction in debt was a result of strong cash flow.

Gross operating earnings in the third quarter were NOK 365 million, compared to NOK 393 million in the previous quarter. The weak markets in Europe and Australasia were offset by lower variable- and fixed costs and effective production adjustments.

- Despite very challenging markets, we have been able to implement effective production adjustments, considerable cost reductions and a significant debt reduction this year, says President and CEO in Norske Skog, Sven Ombudstvedt.

Cash flow from operating activities (before financial items) was NOK 550 million, an improvement of NOK 162 million from the same quarter last year. The good cash flow for the period was a result of an effective realisation of trade receivables and reduction of inventories. Net interest-bearing debt during the quarter decreased from NOK 6.9 billion to NOK 6.3 billion, and has decreased by NOK 1.6 billion this year, primarily due to cash flow from operating activities and asset sales.

- We have had a significant decrease in debt of NOK 1.6 billion so far this year. This helps to strengthen our financial position going forward, says Ombudstvedt.

The net loss for the period was NOK 433 million, compared with a loss of NOK 1 841 in the corresponding quarter last year. Operating revenue was NOK 4 115 million, compared with NOK 4 799 million in the same quarter last year. The decrease was due to reduced production capacity after the divestment of Bio Bio and the closure of Follum, combined with lower sales volumes in a weak market.

The sale of the Parenco mill to H2 Equity Partners in the Netherlands was completed on 2 October.

During the quarter, Norske Skog announced the closure of a newsprint machine at the Tasman mill in New Zealand, and conversion of a newsprint machine to magazine paper production at the Boyer mill in Australia. This will result in a total closure of around 250 000 tonnes of newsprint capacity in Australasia.

Norske Skog expects relatively stable volumes and margins for the rest of the year, when the Parenco transaction is taken into account. The company will actively adapt production to match market demand and will continue its efforts to reduce fixed costs and net interest-bearing debt.

Paper mill Frohnleiten will be closed in 2013

Over-capacities on the European paper market and intensified international competition no longer allow cost-effective production in Frohnleiten

The paper mill Frohnleiten in Styria has to be closed-down in the course of the next year. This was communicated to its staff today by the owner’s company management, the W. Hamburger GmbH, in the course of a works meeting. After taking over the plant in the year 2010, W. Hamburger GmbH tried everything to achieve economic efficiency of the paper mill by means of synergies with the Hamburger plant in Pitten/Lower Austria, as well as through investments and reorganisation. Due to over-capacities on the European paper market and the intensified international competitive context, the company did not succeed in breaking the 15-months lasting period of loss in Frohnleiten. Closing down the paper machine is planned on 30 April, 2013. For the 100 employees of the plant, a comprehensive social-compensation plan with a work foundation will be elaborated.

The paper mill Frohnleiten in Styria has to be closed-down in the course of the next year. This was communicated to its staff today by the owner’s company management, the W. Hamburger GmbH, in the course of a works meeting. After taking over the plant in the year 2010, W. Hamburger GmbH tried everything to achieve economic efficiency of the paper mill by means of synergies with the Hamburger plant in Pitten/Lower Austria, as well as through investments and reorganisation. Due to over-capacities on the European paper market and the intensified international competitive context, the company did not succeed in breaking the 15-months lasting period of loss in Frohnleiten. Closing down the paper machine is planned on 30 April, 2013. For the 100 employees of the plant, a comprehensive social-compensation plan with a work foundation will be elaborated.

Liability towards employees

“Being obliged to close-down a traditional company like Frohnleiten, in which generations have been employed, and which, as an important employer, has revitalised and helped to form the region, is a very difficult task for us”, explains Harald Ganster, managing director of W. Hamburger GmbH today, after the employees had been informed that the machines definitely will have to be turned off in six month. “We will of course be committed to our employees in the course of the plant closure, in order to make the change into a new period of their life easier.” A social-compensation plan with a work foundation will be negotiated within the next weeks with the workers’ council.

Lack of orders due to over-capacities on the market

The main reason for this close down is the intensified international competitive context due to over-capacities, mainly on the European market. The specific equipment in Frohnleiten with a total capacity of 170,000 tons, produced on two small paper machines with only 2.5 m working width, is not able to compensate long term cost disadvantages on the market. In Great Britain and Poland, two new paper machines with a capacity of 450,000 tonnes, respectively, and a working width of 7.5 m, go into operation within a few months. Moreover, the current situation in the business sector does not give reason to expect a turnaround: Overseas markets cannot be supplied cost-effectively because of the euro-/dollar-exchange rate. The same applies to exports to Russia and Turkey.

"We have fought for two years – by means of investments, product innovations and a reorganisation of the plant. After an extensive analysis of all options we now had to realise that closing down the plant due to market development, with a comprehensive cushioning of social hardship for our employees, is the only realistic step", says Harald Ganster.

Gradual closedown

The first paper machine will be turned off on November 1st, 2012, the second remains in operation until the definite close-down of the plant on 30 April, 2013. Together with announcing the close-down today, the W. Hamburger GmbH has started talks with the workers’ council. "It is our defined goal to negotiate a social-compensation plan with a work foundation with the workers’ council, in order to limit the consequences of the plant closure for long-term employees as much as possible", Ganster explains.

Prinzhorn Group well positioned

The W. Hamburger GmbH is a company of the Prinzhorn Group. Besides the paper mill in Frohnleiten, the group operates plants in Pitten/Lower Austria, Spremberg and Trostberg in Germany as well as Dunaujvaros in Hungary. These sites are optimally positioned for the hard market conditions. With the plants in Spremberg and Trostberg Hamburger is the market leader for the high-quality coated and uncoated white top testliner.

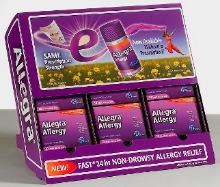

Sonoco Display and Packaging Receives Top Awards for Marketing to Seniors at Retail

Sonoco, one of the largest diversified global packaging and services companies, today announced that its retail point-of-purchase display and packaging business won two of the top awards at the inaugural Retail Innovation Fair presented by the Wake Forest University Center for Retail Innovation.

Sonoco, one of the largest diversified global packaging and services companies, today announced that its retail point-of-purchase display and packaging business won two of the top awards at the inaugural Retail Innovation Fair presented by the Wake Forest University Center for Retail Innovation.

Sonoco received the Best Consumer Engagement Award and the People's Choice Award at the CVS Caremark-sponsored event, which was themed, Marketing to an Aging Population. The event showcased the latest retail marketing ideas for engaging today's senior shoppers and attracted exhibitors, sponsors and attendees representing many of the best-known names in retail.

"There's a silver tsunami coming as the Baby Boomer population become seniors," said Professor Roger Beahm, executive director of the Center for Retail Innovation. "As the size of this demographic grows, so do the retail marketing opportunities."

Sonoco presented its award-winning exhibit in a "total store solution" format, integrating a mix of in-store promotional packaging and merchandising displays to highlight industry best practices for marketing to seniors. The CVS Caremark Best Consumer Engagement Award was chosen by a panel of CVS executives, while the People's Choice Award was voted on by event attendees.

"Our retail display and packaging team does an outstanding job helping our customers maximize their in-store branding and sales opportunities," said Jeff Tomaszewski, division vice president and general manager, Sonoco Display and Packaging. "To receive further validation for our expertise in marketing to seniors in particular is extremely gratifying."

SOURCE Sonoco

Walki Brings Higher Output and a Cleaner Production Environment to Polyurethane Soft Foam Producers

Finding ways to save money and the environment is important for polyurethane manufacturers. Using Walki®Peel Foam or Walki®Cover Foam protection materials helps producers of PUR foam blocks to cut down on costly chemical consumption, while at the same time reduce waste in manufacturing.

Walki Group, a leading global supplier of carrier material for the foaming industry, has spent many years developing its well-established paper-based Walki-Foam products.

Peelable Walki®Peel Foam and conventional Walki®Cover Foam materials are used to cover all of the inner walls of the foaming line on which the polyurethane is injected and where it expands. This brings various benefits to manufacturers, including stable production quality and good chemical hold out, which ultimately leads to cost savings and higher profits.

Peelable Walki®Peel Foam and conventional Walki®Cover Foam materials are used to cover all of the inner walls of the foaming line on which the polyurethane is injected and where it expands. This brings various benefits to manufacturers, including stable production quality and good chemical hold out, which ultimately leads to cost savings and higher profits.

Less chemicals; lower production costs

With chemicals expenses accounting for as much as 97% of production costs in polyurethane manufacturing, there is no room for wastage in the foaming process. Using Walki-Foam products is estimated to reduce raw material costs by some three per cent.

- The high and even quality of our Walki-Foam materials also helps to ensure trouble free foam production, makes it easier to keep foaming lines clean, and runs easily on a PUR-line compared with standard polyethylene films and conventional processing paper, says Kari Salminen, Business Line Manager at Walki’s Technical Products -division.

- Moreover, we offer reasonably short lead times, of two to three weeks, for most of our process liner materials.

Multiple uses and benefits

Walki’s peelable protection material can be used as a top, side, and bottom layer in the PUR-foaming process, while Walki®Cover Foam is a universal carrier in the foaming process.

Walki’s peelable protection material can be used as a top, side, and bottom layer in the PUR-foaming process, while Walki®Cover Foam is a universal carrier in the foaming process.

- Both products combine high-quality and recyclable kraft paper with very thin polymer layer that is specially developed for the foam industry to ease up the foam production process and protect the ready PUR block against excessive moisture, dirt, and harmful effects of UV-light, says Salminen.

The paper layer is peeled off when the foam block comes off the line for curing. Meanwhile, the PE layer stays in place around the block forming a protective barrier around the final product.

- The PE layer also prevents the paper from flex cracking during production, ensuring less machine stops and cleaning procedures and avoiding longer set-up times.

Recyclable material creates less waste/Transforming manufacturing waste into profit

An additional advantage from using Walki’s foam carrier materials is the recyclability of the kraft paper.

- Standard polyethylene films used by some manufacturers are very thick adding to the environmental burden. Our paper-based products help to create significantly less waste in manufacturing. The kraft paper can be recycled, or even sold forward for an additional profit, Salminen says. /ins

Metso-supplied tissue line efficiently started up at Xiamen Xinyang Paper in China

Xiamen Xinyang Paper’s new Metso-supplied tissue machine came on stream one week ahead of schedule on September 10, 2012, in Xiamen City, Fujian Province, China. Only nine days later, after five days of continuous operation, the machine reached the operating speed of 1,900 m/min.

Xiamen Xinyang Paper’s new Metso-supplied tissue machine came on stream one week ahead of schedule on September 10, 2012, in Xiamen City, Fujian Province, China. Only nine days later, after five days of continuous operation, the machine reached the operating speed of 1,900 m/min.

“We are very satisfied with the new record we have set on the process of commissioning, start-up and speed-up,” says Chen Qi, Chairman of Xinyang Paper Corporation.

“This record fast start-up process is the result of very good cooperation and efficient team work between Xiamen Xinyang Paper and Metso’s personnel. It also proves that our technology is optimized for customer needs, efficient installation and highly efficient production,” says Stefan Ziegel, Project Manager, Metso.

Metso’s delivery comprised a complete production line with stock preparation equipment and an Advantage DCT 200 HS tissue machine including an OptiFlo II TIS multi-layer headbox, a Metso Yankee cylinder, an Advantage AirCap hood, an Advantage WetDust dust management system and an Advantage SoftReel reel. The delivery also featured Metso’s patented AdvantageViscoNip pressing technology and BlackBelt shoe press belt. The production line will be optimized to enhance final product quality and save energy.

The delivery also comprised an extensive automation package including Metso DNA machine, process and integrated drive controls, and a Metso IQ quality control system with a Metso IQ Scanner and a Metso IQ Fiber sensor.

With a width of 5.6 m and a maximum operating speed of 2,000 m/min, the new production line will produce 60,000 tonnes a year of high-quality facial, toilet and towel grades. The raw material for the new line will be virgin pulp.

Xiamen Xinyang Paper Co., Ltd. was established in 2009 by four state-owned companies based in Fujian Province, China: Xiamen Shun-Cheng Asset Management Co., Ltd, Xiamen Haicang Investment Group Co., Ltd, Nanping Paper Co., Ltd and Xiamen Construction & Development Group Co., Ltd. The first phase in the company’s investment plan is a tissue mill for producing 60,000 tonnes a year of facial, toilet and towel grades.

Outotec recognized again in Carbon Disclosure Leadership Index

Outotec recognized again in Carbon Disclosure Leadership Index

For the fourth consecutive year Outotec is included in the Nordic Carbon Disclosure Leadership Index, which highlights companies with the most professional approach to climate change disclosure practices. Outotec received 87 out of 100 points and was ranked among the top 10 percent of the 260 companies in CDP's annual Nordic Report.

For the fourth consecutive year Outotec is included in the Nordic Carbon Disclosure Leadership Index, which highlights companies with the most professional approach to climate change disclosure practices. Outotec received 87 out of 100 points and was ranked among the top 10 percent of the 260 companies in CDP's annual Nordic Report.

CDP's analysis is based on greenhouse gas emissions, emission reduction targets as well as understanding of risks and opportunities associated with climate change. High scores indicate good internal data management and understanding of climate change related issues affecting the company. The index provides an evaluation tool for institutional investors and other stakeholders.

"We are again proud of this recognition in the CDP Leadership Index and the fact that we were able to improve our score. Commitment to sustainability is our core value and guides us in striving for good governance, responsible business practices and transparency. As a global technology provider we can make a significant impact in mitigating climate change by improving the eco-efficiency of our customers' production processes. Through continuous R&D we further improve our proprietary, benchmark technologies enabling sustainable use of natural resources", says Pertti Korhonen, CEO of Outotec.

The Nordic 260 Report including companies featured in the Carbon Disclosure Leadership Index can be found at www.cdproject.net.

Ahlstrom announces price increases for its filtration materials worldwide

![]() Ahlstrom, a global leader in high performance materials, announces price increases in the first quarter of 2013 for its filtration materials globally as a consequence of the continued high level of raw materials prices, such as specialty fibers, chemicals and energy.

Ahlstrom, a global leader in high performance materials, announces price increases in the first quarter of 2013 for its filtration materials globally as a consequence of the continued high level of raw materials prices, such as specialty fibers, chemicals and energy.

The price increase will affect filtration materials produced by Ahlstrom globally. The level and timing of the increase will depend on the markets served, the raw material content of the product and the agreements in place. The increase will be between 5-10 %. Specific details will be discussed with each customer individually by the appropriate sales teams in the coming days.