Owens Corning, a leader in global building and industrial materials, has commissioned Voith to supply production machinery, Papermaking 4.0 solutions as well as components for its site in Fort Smith, Arkansas, U.S.A. The new 50,000-square-meter manufacturing facility will produce mat for roofing shingles and further innovative nonwoven products on what will be the widest and fastest glass mat machine in the world.

- The full-line supplier Voith receives the order for the forming, binding and drying sections of a new glass mat production line from Owens Corning.

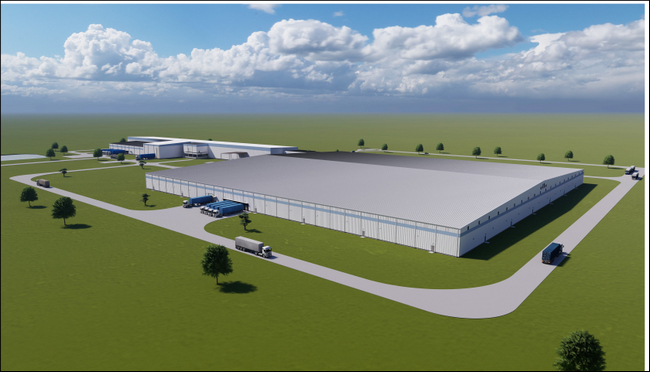

- Owens Corning’s new 50,000-square-meter manufacturing facility will sit adjacent to their existing Fort Smith site.

- Technological highlights include the world’s largest inclined wire former, the HydroFormer, and the glass mat dryer, the FiberDry, as well as a comprehensive Papermaking 4.0 and automation package to increase efficiency, product quality and machine availability.

“Owens Corning is investing in the growth of the Composites business,” states Nicolas Del Monaco, Senior Vice President at Owens Corning. “As a strategic partner to our customers, we continue to invest in state-of-the-art technology. Our new facility will allow us to serve fast growing markets and address the current and new needs of our customers.”

Highly specialized supplier for glass mat production

The centerpiece of the most powerful nonwovens machine in the world is the more-than five meters wide HydroFormer. This inclined wire former enables an outstanding homogenous formation of long glass fibers up to 40 mm with very low stock consistencies. Essential to the expansion project is the Voith FiberDry, an innovative glass mat dryer that has a flexible modular design.

“As a full-line supplier, Voith delivers the inclined wire formers and, in addition, high-performance dryers customized for glass mat production according to the specific requirements and high standards of Owens Corning,” states Oliver Crasser, Sales Manager at Voith Paper.

For Owens Corning, sustainability and efficiency were key factors when deciding on the individual components. Following the Process Line Package (PLP) concept approach, Voith will supply two IntensaPulper machines that set industry standards in pulping with their energy-efficient technology. In addition, a comprehensive Papermaking 4.0 and automation package is designed to increase efficiency, product quality and machine availability and integrates all third-party suppliers into the Voith control and condition monitoring systems.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.