Displaying items by tag: AGE Industries

Tubes versus Boxes: Creating an Optimal Packaging Solution

Custom corrugated boxes and fiber tubes protect products and the environment and build brand image

By Cheryl Smith

The subject of packaging and shipping solutions has become an increasingly popular topic of conversation within businesses and among the public.

Before and during the pandemic, the rapid expansion of e-commerce has fueled demand for packaging, while labor shortages and shipping constraints have also made it harder to produce and deliver the containers used to ship and store everything from food and consumer goods to machine parts.

At the same time, consumers are increasingly aware of the need for more sustainable packaging. According to McKinsey & Company, 55% of US consumers are extremely or very concerned about the environmental impact of packaging. They are willing to pay more for eco-friendly products, and they express a desire to buy additional sustainably packaged products if more of them were available and better labeled to indicate green packaging.

As a result, businesses have responded in three important ways.

First, they have turned to suppliers that have a proven track record and ongoing capability of delivering packaging solutions when needed to ensure that the right shipping container is available when product comes off the production line.

Environmental Sustainability

Second, the demand for corrugated cardboard boxes and fiber tubes expands as consumers, government regulators, investors and employees push for environmentally friendly alternatives to plastics. Boxes and tubes are made from plant-based materials which can be sustainably harvested and replanted, and many boxes and tubes are manufactured from 100% recycled material.

The disposal of these paper-based packaging solutions is also far more sustainable. In 2021, 91.4% of corrugated cardboard was recycled compared to only 6% of the 40 million tons of plastic waste generated in the US. Moreover, the paper is biodegradable and does not contain any toxic chemicals or heavy metals, and therefore the small percentage of scrap or used boxes and tubes that do end up in a landfill will decompose without harming the environment. In fact, boxes and tubes buried in the earth will compost in a couple months, adding nutrients back into the soil.

Custom Packaging Solutions

The third reason for the increased interest in custom boxes and fiber tubes is their versatility and adaptability to perfectly fit the specific requirements of each application to achieve the optimal balance between the crush strength and weight/thickness to reduce the cost of materials and shipping.

Custom packaging comes in many shapes, sizes, and strengths to contain and protect products for storage or transport. The packaging should be designed to fit the product, rather than the other way around.

A perfect fit means eliminating the waste, reducing environmental impact and costs of producing, handling, and disposing of excess packaging and unnecessary void fill material — and of damaged product. The right fit also means higher packing density for more energy-efficient transport and more space-efficient storage.

Custom boxes and fiber tubes also enable important marketing advantages over stock packaging. Graphics and information can be printed on the interior and exterior surfaces to increase brand awareness and support point-of-purchase campaigns.

The two major categories of custom, sustainable packaging are corrugated boxes and fiber tubes. Both categories have the environmental benefits of fiber material, and both are extremely customizable to meet specific application requirements.

Custom Corrugated Boxes

Custom corrugated boxes can be designed in any desired size and in a wide range of board thickness. Designers utilize software to optimize the shape and size of the box to efficiently and safely package the product(s) contained within, and to ensure the boxes can be stacked securely on a pallet, without wasted space.

Boxes hold items wrapped with protective packaging or surrounded with void fill material for safe shipment. They can be sealed, closed, and stacked in a warehouse or shipping container. Some specialty boxes ship hazardous materials or insulate products from excessive heat or cold.

Box types include Die Cut, Full Overlap Slotted Container (FOL), Full Telescopic Design Container (FTD) and Overlap Slotted Container (OSC). A variety of wax and varnish coating options are available. Additional customizations include partitions, eyelets, transparent windows, and die cut foam inserts

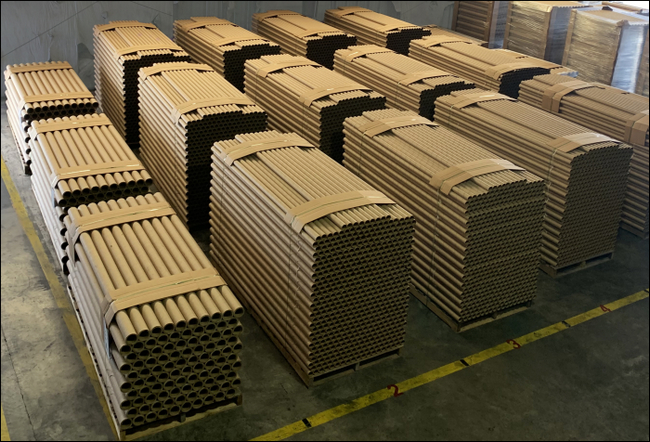

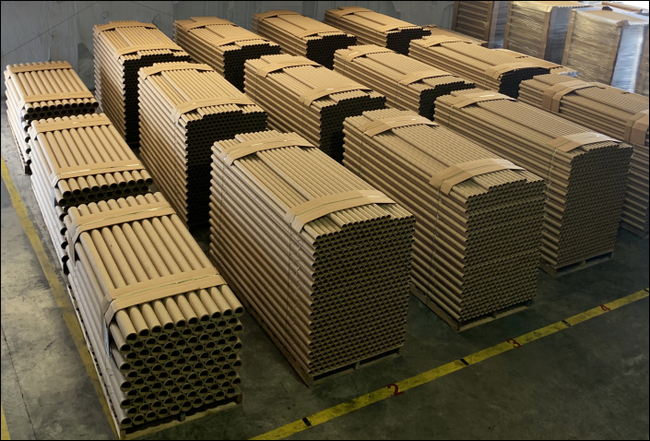

Fiber Tubes

Fiber wound tubes are also customized depending upon the specifications and requirements of each customer and applications. They are typically made of cardboard, but they can also be reinforced with other materials for added strength and resilience. Paper or paperboard sheet layers are wound together and bonded with an adhesive to form strong, hollow, and usually cylindrical shapes. Fiber wound tubes provide an excellent strength-to-weight ratio and are used in applications requiring high bend strength, crush resistance, and dynamic strength.

Tubes are available in various sizes; length, inside diameter, and wall thickness can be customized to fit specific products. The wall thickness of the tube can vary depending on the number of layers wrapped during manufacturing. The innermost layer or ply - the liner -, and the outermost layer - the wrap -, can consist of different materials (foil, film, etc.) or specialized paper. The specialized paper and materials can provide water resistance, graphics or labeling, or a specific color.

Tubes Serve as Containers and as Paper Cores

The high strength of fiber tubes makes them well-suited to two very different uses — as an exterior container for a very wide range of products or as the interior core around which sheets of material are wound.

As a container, tubes protect a wide variety of products during shipment, protecting them from damage, including long, heavy items such as pipes and baseball bats, and fragile items such as fishing poles. Tubes are often a good alternative to shipping items in a box with protective packaging or void fill. The range of applications is quite extensive, from small tubes with film barriers for potato chips to large tubes used to form concrete pilings.

Paper cores typically fall into two subcategories: In industrial applications, webs or sheets of flexible material (plastic film, paper, foil, textiles, etc.) are wound around paper cores with thick walls. These tubes function as a machine element and facilitate loading of the large rolls. The other subcategory is a thinner-walled variety of tube used for the packaging and dispensing of retail products, such as the core of aluminum foil, plastic wrap, paper towel and toilet paper rolls, as well as adhesive tape and labels.

Protect Products and the Environment

Custom boxes and tubes are more effective at protecting products than stock boxes, and they have far less impact on the environment compared to plastic packaging. A custom packaging solution means a perfect fit for your product, with less waste and more efficient packing and transport, resulting in cost savings, as well as a distinctive image that enhances brand image and supports marketing campaigns.

Tubes versus Boxes: Creating an Optimal Packaging Solution

Custom corrugated boxes and fiber tubes protect products and the environment and build brand image

By Cheryl Smith

The subject of packaging and shipping solutions has become an increasingly popular topic of conversation within businesses and among the public.

Before and during the pandemic, the rapid expansion of e-commerce has fueled demand for packaging, while labor shortages and shipping constraints have also made it harder to produce and deliver the containers used to ship and store everything from food and consumer goods to machine parts.

At the same time, consumers are increasingly aware of the need for more sustainable packaging. According to McKinsey & Company, 55% of US consumers are extremely or very concerned about the environmental impact of packaging. They are willing to pay more for eco-friendly products, and they express a desire to buy additional sustainably packaged products if more of them were available and better labeled to indicate green packaging.

As a result, businesses have responded in three important ways.

First, they have turned to suppliers that have a proven track record and ongoing capability of delivering packaging solutions when needed to ensure that the right shipping container is available when product comes off the production line.

Environmental Sustainability

Second, the demand for corrugated cardboard boxes and fiber tubes expands as consumers, government regulators, investors and employees push for environmentally friendly alternatives to plastics. Boxes and tubes are made from plant-based materials which can be sustainably harvested and replanted, and many boxes and tubes are manufactured from 100% recycled material.

The disposal of these paper-based packaging solutions is also far more sustainable. In 2021, 91.4% of corrugated cardboard was recycled compared to only 6% of the 40 million tons of plastic waste generated in the US. Moreover, the paper is biodegradable and does not contain any toxic chemicals or heavy metals, and therefore the small percentage of scrap or used boxes and tubes that do end up in a landfill will decompose without harming the environment. In fact, boxes and tubes buried in the earth will compost in a couple months, adding nutrients back into the soil.

Custom Packaging Solutions

The third reason for the increased interest in custom boxes and fiber tubes is their versatility and adaptability to perfectly fit the specific requirements of each application to achieve the optimal balance between the crush strength and weight/thickness to reduce the cost of materials and shipping.

Custom packaging comes in many shapes, sizes, and strengths to contain and protect products for storage or transport. The packaging should be designed to fit the product, rather than the other way around.

A perfect fit means eliminating the waste, reducing environmental impact and costs of producing, handling, and disposing of excess packaging and unnecessary void fill material — and of damaged product. The right fit also means higher packing density for more energy-efficient transport and more space-efficient storage.

Custom boxes and fiber tubes also enable important marketing advantages over stock packaging. Graphics and information can be printed on the interior and exterior surfaces to increase brand awareness and support point-of-purchase campaigns.

The two major categories of custom, sustainable packaging are corrugated boxes and fiber tubes. Both categories have the environmental benefits of fiber material, and both are extremely customizable to meet specific application requirements.

Custom Corrugated Boxes

Custom corrugated boxes can be designed in any desired size and in a wide range of board thickness. Designers utilize software to optimize the shape and size of the box to efficiently and safely package the product(s) contained within, and to ensure the boxes can be stacked securely on a pallet, without wasted space.

Boxes hold items wrapped with protective packaging or surrounded with void fill material for safe shipment. They can be sealed, closed, and stacked in a warehouse or shipping container. Some specialty boxes ship hazardous materials or insulate products from excessive heat or cold.

Box types include Die Cut, Full Overlap Slotted Container (FOL), Full Telescopic Design Container (FTD) and Overlap Slotted Container (OSC). A variety of wax and varnish coating options are available. Additional customizations include partitions, eyelets, transparent windows, and die cut foam inserts

Fiber Tubes

Fiber wound tubes are also customized depending upon the specifications and requirements of each customer and applications. They are typically made of cardboard, but they can also be reinforced with other materials for added strength and resilience. Paper or paperboard sheet layers are wound together and bonded with an adhesive to form strong, hollow, and usually cylindrical shapes. Fiber wound tubes provide an excellent strength-to-weight ratio and are used in applications requiring high bend strength, crush resistance, and dynamic strength.

Tubes are available in various sizes; length, inside diameter, and wall thickness can be customized to fit specific products. The wall thickness of the tube can vary depending on the number of layers wrapped during manufacturing. The innermost layer or ply - the liner -, and the outermost layer - the wrap -, can consist of different materials (foil, film, etc.) or specialized paper. The specialized paper and materials can provide water resistance, graphics or labeling, or a specific color.

Tubes Serve as Containers and as Paper Cores

The high strength of fiber tubes makes them well-suited to two very different uses — as an exterior container for a very wide range of products or as the interior core around which sheets of material are wound.

As a container, tubes protect a wide variety of products during shipment, protecting them from damage, including long, heavy items such as pipes and baseball bats, and fragile items such as fishing poles. Tubes are often a good alternative to shipping items in a box with protective packaging or void fill. The range of applications is quite extensive, from small tubes with film barriers for potato chips to large tubes used to form concrete pilings.

Paper cores typically fall into two subcategories: In industrial applications, webs or sheets of flexible material (plastic film, paper, foil, textiles, etc.) are wound around paper cores with thick walls. These tubes function as a machine element and facilitate loading of the large rolls. The other subcategory is a thinner-walled variety of tube used for the packaging and dispensing of retail products, such as the core of aluminum foil, plastic wrap, paper towel and toilet paper rolls, as well as adhesive tape and labels.

Protect Products and the Environment

Custom boxes and tubes are more effective at protecting products than stock boxes, and they have far less impact on the environment compared to plastic packaging. A custom packaging solution means a perfect fit for your product, with less waste and more efficient packing and transport, resulting in cost savings, as well as a distinctive image that enhances brand image and supports marketing campaigns.

AGE Industries Announces New Equipment to Increase Efficiency and Throughput

Upgrades will substantially reduce lead times and improve plant safety

AGE Industries, Ltd, a leading supplier of custom paper tubes, innovative packaging and shipping solutions, announces the addition of two flexo /folder/gluers, two unitizers, one automated stitcher, and one new scrap handling system to its Texas plants that will increase efficiency, improve throughput at each shift, and reduce forklift handling operations to create a safer work environment. Positioning itself for the future, AGE Industries is investing in equipment that will help manufacturers meet the challenges posed by increasing freight, raw material, and labor costs.

The addition of the 37” Flexo folder gluers will significantly increase open capacity, enable faster production, and reduce lead times. These two-color flexo’s features a full rotary die cut section and are rated to run 18,000 boxes an hour with a 3-person crew, reducing headcount while increasing efficiency by nine times compared to its old printer slotters. Each new Flexo can comfortably convert an additional two tractor trailer loads of product per shift. With its die cutting capability, the Flexo facilitates running specialty boxes in one pass, unlike competitors that must use two different machines.

Also added are 4-head Signode unitizers, which can compress and strap units at a rate of 40+ units per hour – more than a tractor trailer per hour – all while moving product safely through plants. What took the prior 2-person manual strapping process 10 to 15 minutes can now be done in under 30 seconds with one person. The new equipment also provides a more consistent and tightly strapped product with a better presentation, so customers can easily double stack them in warehouses. AGE has fully conveyorized two of its plants, so products can be taken from the end of the machines it is being manufactured on all the way to the unitizer, reducing the need for forklifts to handle material on the plant floor and creating a safer environment.

AGE has also added a new automated stitching machine that measures the spacing for each staple on a box, automatically adjusting staple length for the type of material being stitched. This machine can produce roughly double the number of boxes as other manual equipment. Finally, AGE has added a new scrap handling system for corrugated and paper scrap generated. All scrap is now moved by conveyor over to a horizontal baler, reducing the time needed to produce scrap bales and eliminating the need to shut down machines to remove scrap bales.

Next to be added will be an Eberle tube cutting machine, which can cut 88 cycles per minute. The new machine will allow the tube division to use a blade cut, which eliminates particulates while meeting tolerances of three-thousandths of an inch.

About AGE Industries, Ltd.

Founded by Arthur G. Eltzroth in 1974, AGE offers innovative custom packaging and shipping solutions for private industry and government agencies. AGE designs and manufactures corrugated boxes, fiber tubes, and wood crating for Texas, Arkansas, Oklahoma, Louisiana, and New Mexico in the United States. AGE Box de Mexico, based out of Reynosa, Tamps. Mexico, provides custom corrugated packaging and overall packaging solutions for Mexico. AGE meets WBENC, Tx HUB, and CMBL certifications.

For more information, contact AGE Industries at 817-641-8178 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

AGE Industries, Ltd Now Offers KN95 Masks

AGE Industries provides cost effective KN95 masks that are comfortable and protective

AGE Industries, Ltd, a leading supplier of innovative and custom packaging and shipping solutions for industry and government agencies, offers highly protective KN95 masks that are comfortable and cost effective.

KN95 masks feature 4-layer protection, a step above most masks on the market, which are 1 to 3 layers thick. Further, KN95 masks provide a striking 95% protection against all particles that are greater than 0.3 µm in diameter. This includes bacteria, viruses, pollution particles, fine particles, dust, smog, pollen, and more.

KN95s offer even more protection than cloth masks, confirms the CDC on their website. The CDC also provided an update on January 14th, 2022 removing concerns related to supply shortages for these masks, clarifying that people can in fact choose masks such as N95s and KN95s. Currently approved by the WHO as a safety measure from COVID-19, these masks’ superior protection is the reason why they are used by healthcare providers, patients, and citizens across the globe. KN95 respiratory masks are also regulated by the Chinese government under GB2626-2006, GB262-2019, and GB19083-2010.

KN95 masks offer considerable comfort. They are skin-friendly and do not cause rashes or irritation. KN95 masks also have a 3D foldable design, ear loops, and a nose bridge, allowing them to provide excellent fitting and sealing. The ability for these masks to fit the form of your face leads to better protection and also reduces fogging in glasses. Most other masks on the market do not fit well, leaving gaps near the side of the face and the nose uncovered.

Providing packages at 20 masks per box and 50 boxes per case, AGE Industries can ship anywhere in the US, Mexico, and Canada and can also deliver globally via AGE Industries or one of its partners. AGE Industries is committed to providing these protective and comfortable masks at affordable prices to people around the world who need them.

For more information about the AGE Industries, Ltd, visit www.ageindustries.com.

About AGE Industries, Ltd.

Founded by Arthur G. Eltzroth in 1974, AGE offers innovative custom packaging and shipping solutions for private industry and governmental agencies. AGE designs and manufactures corrugated boxes, fiber tubes, and wood crating for Texas, Arkansas, Oklahoma, Louisiana, and New Mexico in the United States. AGE Box de Mexico, based out of Reynosa, Tamps. Mexico, provides custom corrugated packaging and overall packaging solutions for Mexico. AGE meets WBENC, Tx HUB, and CMBL certifications.

AGE Industries, Ltd offers Just-in-Time Delivery of Custom Boxes and Packaging

Dynamic inventory management system ensures timely delivery of packaging materials to keep manufacturing and distribution flowing

AGE Industries, Ltd, a leading supplier of innovative and custom packaging and shipping solutions for industry and government agencies, offers Just-in-time (JIT) delivery of corrugated boxes, fiber tubes, and packaging materials. During the current supply chain challenges, customers rely on AGE Industries’ dynamic inventory management system and efficient operations for timely delivery of packaging materials to keep manufacturing and distribution flowing.

AGE Industries offers a comprehensive one-stop shop for corrugated boxes, fiber tubes, and ancillary shipping items including stretch wrap, bubble tape, and labels. An in-house design and engineering team works with customers to develop custom solutions and ensure that exact specifications are met.

Custom design solutions enhance the protection of products and reduce shipping costs, and custom printing increases brand awareness and supports point-of-purchase marketing campaigns. Options for custom boxes are limitless which allows you to tailor your packaging for its market.

With six manufacturing facilities in the U.S. and Mexico, AGE Industries ships to any location in the United States, Mexico, and Canada. Products can also be delivered to anywhere in the world by AGE Industries or one of its affiliated partners, providing customers with an integrated program for satisfying all their custom design and packaging needs.

For more information about the AGE Industries, Ltd, visit www.ageindustries.com.

About AGE Industries, Ltd.

Founded by Arthur G. Eltzroth in 1974, AGE offers innovative custom packaging and shipping solutions for private industry and governmental agencies. AGE designs and manufactures corrugated boxes, fiber tubes, and wood crating for Texas, Arkansas, Oklahoma, Louisiana, and New Mexico in the United States. AGE Box de Mexico, based out of Reynosa, Tamps. Mexico, provides custom corrugated packaging and overall packaging solutions for Mexico. AGE meets WBENC, Tx HUB, and CMBL certifications.