Super User

A.Celli successfully starts up key parts for the Anhui Linping’s PM7

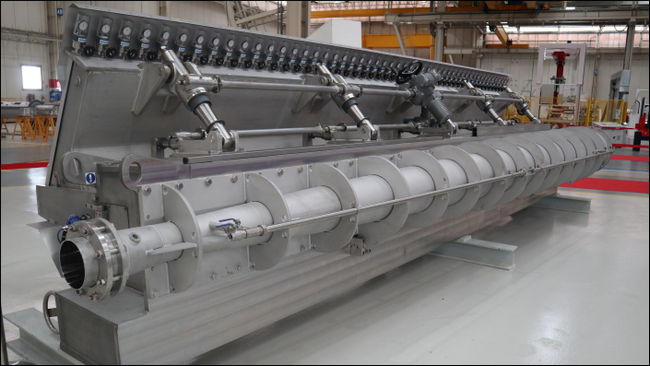

The joint efforts of A.Celli and Anhui Linping’s teams resulted in a smooth start up of the headbox, suction rolls and rewinder delivered to the production plant in Xiao County, Anhui province.

In December 2022, A.Celli Paper and Anhui Linping Recycling Development Co., Ltd. have successfully started up the components supplied for the PM7 destined to the production of testliner and corrugated paper, recording performance perfectly in line with those agreed.

The PM7 in object, characterized by a wire width of 7300 mm and a design speed of 1000 mpm, included key components supplied by A.Celli/PMT, such as the ÆGO™STREAM S headbox with SMARPRO dilution water control system, two ÆGO™ suction press rolls and a E-WIND® P100 paper rewinder.

Mr. Yao, Chief Engineer of Anhui Linping Paper, said: “We are very pleased to see that the key parts provided by A.Celli are running smoothly. Thanks to the hydraulic headbox with dilution control, the formation and 2-Sigma values meet our requirements, while the suction press rolls and rewinder remain stable even at high speed".

ANHUI LINPING RECYCLING DEVELOPMENT CO., LTD. – COMPANY PROFILE

Anhui Linping Recycling Development Co., Ltd., founded in 2002, is a Chinese packaging paper producer. With seven production lines and a production capacity of 1,200,000 tons, Anhui Linping Paper is one of the leading companies in the industry in the entire Anhui Province.

Source: https://www.acelli.it/en/news-events/a.celli-paper-start-up-anhui-linping

Valmet to supply another paper machine rebuild to Sappi North America’s Somerset facility

Valmet will supply an extensive rebuild for Sappi’s Somerset paper manufacturing facility in Skowhegan, Maine, USA. Previously, Valmet rebuilt the paper machine 1 (PM1) and with its success, Sappi has chosen Valmet again to rebuild the paper machine 2 (PM2).

The order is included in Valmet's orders received of the fourth quarter 2022. Its value will not be disclosed, but such an order is typically worth between EUR 90 and 120 million.

As a result of the PM2 conversion from coated woodfree graphic paper to solid bleached sulphate board, the machine capacity will be increased from 240,000 tons to 470,000 tons per annum. The start-up of the rebuilt machine is scheduled for the mid-year of 2025.

“Valmet has proven to be a trusted supplier to Sappi over the years and we’re pleased to work with them again on our PM2 project. This investment is fully aligned with our Thrive25 strategic focus to reduce our exposure to graphic paper and transition our portfolio to packaging and specialty papers, pulp and biomaterials,” says Michael Haws, President and CEO, Sappi North America.

“We look forward to continued collaboration with Sappi North America, and we thank them for their partnership on another conversion project. We know the demand for packaging and specialty papers in North America is high and we’re confident that through our combined efforts, we’ll meet future market needs,” says Jukka Tiitinen, Area President, North America, Valmet.

Technical information about the delivery

PM2 will be rebuilt using some of the most advanced packaging manufacturing technology to produce a variety of both packaging and coated paper products.

Valmet's delivery will include a number of modifications and new machine parts in the existing machine to meet the requirements of the new packaging grades. In addition, the mill will benefit from Valmet Industrial Internet and Automation Solutions including a new Quality Measurement System, a Process Control System (DCS and Valmet DNA), web monitoring and web inspection systems.

About Sappi North America, Inc.

Sappi North America, Inc., headquartered in Boston, is a market leader in converting wood fiber into superior products that customers demand worldwide. Their four diversified businesses – high-quality Graphic Papers, Dissolving Pulp, Packaging and Specialty Papers deliver premium products and services with consistent quality and reliability. Sappi North America is a subsidiary of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with more than 12,000 employees and manufacturing operations on three continents in seven countries and customers in over 150 countries. www.sappi.com

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Reliable, flexible and efficient quality measurement and control OnQuality successfully commissioned at customers Smurfit Kappa, WEPA and Johns Manville

Quality control systems are an important factor in paper production to continuously optimize production and quality processes. Thanks to their compact design, flexible use and high reliability, Voith's OnQuality quality control systems (QCS) have already been used in over 750 installations worldwide on existing and new lines. The system can be used for all paper grades as well as for nonwovens.

- Successful commissioning of quality control systems (QCS) OnQuality at various customers including the nonwovens sector

- Fast rebuild achieved within only 12 hours

- OnQuality.Scanners can be used flexibly, also rotated by 90°

Positive customer feedback – from Smurfit Kappa, WEPA and Johns Manville among others – confirms Voith's leading position. The advantages are obvious, as Mahmut Altunkaya, Lead Engineer QCS at Voith Paper, explains: "The smart solution OnQuality from our Papermaking 4.0 automation and digitalization portfolio stabilizes and optimizes the production process, increases productivity and at the same time reduces operating and maintenance costs."

Positive customer feedback – from Smurfit Kappa, WEPA and Johns Manville among others – confirms Voith's leading position. The advantages are obvious, as Mahmut Altunkaya, Lead Engineer QCS at Voith Paper, explains: "The smart solution OnQuality from our Papermaking 4.0 automation and digitalization portfolio stabilizes and optimizes the production process, increases productivity and at the same time reduces operating and maintenance costs."

The high flexibility of the system is particularly evident in the project with customer WEPA. Here, the solution was installed at TM 1 in Mainz, Germany. "We decided to replace our existing QCS with Voith OnQuality because of the short rebuild and commissioning time of only 12 hours, as well as the seamless and individual integration into our existing process control system," reports Jürgen Birk, Mill Manager Mainz at WEPA.

Especially for tissue paper manufacturers, Voith offers scanner models that are equipped with covers and additional cleaning nozzles for the measuring carriage. They facilitate cleaning and maintenance work and improve the accuracy of the measurements.

Due to the high level of satisfaction with the new quality control system, the tissue paper manufacturer decided to take another step on the road to digitalization with Voith. As part of OnQuality 4.0, the Voith Cloud platform will in the future collect and store all relevant production and quality data from the TM 1, enabling WEPA to perform in-depth analyses via personalized dashboards. With just a few clicks, profile charts, color maps, maintenance cockpits, trends and reports can be intuitively created and viewed on mobile devices. In addition, the use of a virtual sensor will complement the physical measurements and thus quickly and directly reveal deviations in the critical target quality in a profitable manner, which can otherwise only be measured in the laboratory on a sample basis.

Individual solutions for optimum quality measurement and control

Smurfit Kappa Herzberg mill also commissioned Voith to install an OnQuality quality control system at KM 1 at the Herzberg am Harz site, Germany. "Due to the very compact and flexible design, only Voith was able to fulfill a challenging installation position with a necessary 90° pivoting of the scanner. Now we can determine exact measured values even in this difficult location," reports Danny Polske, Maintenance Manager at Smurfit Kappa Herzberg mill. The OnQuality quality control system is used here as a stand-alone system with a direct connection to the existing process control system.

Another order from Johns Manville shows that the quality control system is also suitable for use in the nonwovens sector. At VLM 15 in Steinach, Germany, the OnQuality Nonwoven Caliper Sensor is now used in addition to a special filter for measuring binder content. The Voith caliper sensor for nonwovens is specially designed for nonwoven applications. This effectively prevents marking or damage to the web. Thilo Behringer-Stephan, Electrical Engineering at Johns Manville, sums up: "Thanks to the Voith QCS system, we can better monitor our manufacturing process and intervene in time if necessary. This allows us to optimize our product quality and increase efficiency."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Kemira strengthens services offering by acquiring advanced process optimization start-up SimAnalytics

Kemira strengthens services offering by acquiring advanced process optimization start-up SimAnalytics

Kemira announced in August 2021 its investment in SimAnalytics and has now acquired the rest of the business. With the acquisition, Kemira strengthens its capability to support its customers’ business with data-driven predictive services and machine learning solutions.

“Services are an integral part of our growth strategy, and this acquisition is a logical step forward in the strategy execution. We are dedicated to serving our customers with future-proof solutions and services that enable profitable, efficient, and sustainable business. SimAnalytics has for years been one of our key partners for developing digital services for paper and board production. Now we can continue, accelerate, and expand the collaboration, also to benefit the other industries Kemira serves,” states Antti Pirneskoski, Director of Services Business Line, Pulp & Paper, at Kemira.

“Services are an integral part of our growth strategy, and this acquisition is a logical step forward in the strategy execution. We are dedicated to serving our customers with future-proof solutions and services that enable profitable, efficient, and sustainable business. SimAnalytics has for years been one of our key partners for developing digital services for paper and board production. Now we can continue, accelerate, and expand the collaboration, also to benefit the other industries Kemira serves,” states Antti Pirneskoski, Director of Services Business Line, Pulp & Paper, at Kemira.

The two companies have collaborated since 2019 and, as a result, today offer a commercialized digital service, Kemira KemConnect Harmonizer, that helps paper and board mills run production more efficiently, with less disruptions and saving raw materials, energy and water. The unique combination of Kemira’s chemistry and application expertise and SimAnalytics’ capabilities creates transparency and predictability in complex production processes, where chemistry plays a key role. Kemira is currently broadening this service offering also for its water treatment customers.

“This is a natural step for SimAnalytics after many years of collaboration with Kemira. As a part of the Kemira family, we can implement our vision of sustainable, safe, and cost-efficient future of industrial production faster,” states Mikko Jääskeläinen, Managing Director of SimAnalytics.

SimAnalytics employes 12 people in Finland and had a turnover of less than million euros in 2022. There will be no changes to SimAnalytics’ operational business, and the founders/employees will continue with the business.

Kemira is a global leader in sustainable chemical solutions for water intensive industries. We provide best suited products and expertise to improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, water treatment and energy industry. In 2021, Kemira had annual revenue of around EUR 2.7 billion and around 5,000 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Stora Enso signs an agreement to divest its Hylte paper site and will discontinue the Anjala site divestment process

Stora Enso has signed an agreement to divest its paper production site in Hylte, Sweden and all its related assets to Sweden Timber, a Sweden-based sawmill and planing mill company. The enterprise value is approximately EUR 18 million. The completion of the transaction is expected in the first half of 2023. Concerning the Anjala paper site in Finland, Stora Enso has decided to discontinue the divestment process.

The Hylte site transaction, along with the discontinuation of the Anjala divestment, concludes Stora Enso’s plan announced in March 2022 to divest four of Stora Enso’s five paper production sites. In line with its strategy, Stora Enso’s focus is on long-term growth for its renewable products in packaging, building solutions and biomaterials innovations.

“I am pleased that Sweden Timber will continue to serve Hylte’s paper customers with the intent to further develop the operations. For the Anjala site, we have concluded that the benefits from retaining the site within the Group exceed the value of explored divestment opportunities,” says Seppo Parvi, CFO at Stora Enso.

“I am pleased that Sweden Timber will continue to serve Hylte’s paper customers with the intent to further develop the operations. For the Anjala site, we have concluded that the benefits from retaining the site within the Group exceed the value of explored divestment opportunities,” says Seppo Parvi, CFO at Stora Enso.

The Hylte site’s annual capacity is 245,000 tonnes of newsprint paper. Based on the 2021 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 90 million. Subject to closing date adjustments, Stora Enso will book a disposal loss of approximately EUR 35 million, in addition to the impairment loss of EUR 19 million recorded in Q4/2022, in its IFRS operating profit in Q1/2023, as an item affecting comparability. The transaction does not affect the Packaging Solutions division’s formed fiber and biocomposite operations located at the Hylte site.

The Anjala paper site, together with the retained Langerbrugge paper site in Belgium, were integrated into the Packaging Materials division on 1 January 2023. The Anjala site already today leverages integrated operations with Stora Enso’s neighbouring Ingerois packaging materials site, utilising synergies in raw material and energy supply. For the Langerbrugge site, the ongoing feasibility study for a potential conversion of one of the site’s two paper lines into a packaging materials line is expected to be finalised in the first half of 2023.

The retained Anjala and Langerbrugge sites will continue paper production and serving their respective customers. The agreement to divest the Hylte paper site to Sweden Timber has no immediate impact on production nor customer deliveries. The previously disclosed agreement to divest the Maxau paper site in Germany to Schwartz Produktion is expected to conclude at the beginning of this year. Divestment of the Nymölla paper site in Sweden was concluded on 2 January with ownership transferred to Sylvamo.

BofA Securities acted as Stora Enso’s financial advisor on this transaction.

About Sweden Timber

Sweden Timber is a Swedish-owned and growing wood industry company. The company produces and sells high-quality wood products to the construction industry and wood retailers, with customers in several export markets. The business today consists of sawmills and planing production sites in four Swedish locations, Malmbäck, Hjortkvarn, Skillingaryd and Mora. www.swedentimber.se/.

Recent releases on Stora Enso’s paper assets:

29 March 2022: Stora Enso plans to divest four paper sites to focus on strategic growth areas

7 June 2022: Stora Enso assesses growth opportunities in recycled packaging materials with a conversion in Langerbrugge

13 September 2022: Stora Enso has signed an agreement to divest its Maxau paper site to Schwarz Produktion

2 January 2023: Stora Enso completes the divestment of its Nymölla paper site to Sylvamo

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Michigan State legislatures have approved legislation to grant Billerud investment support

Billerud is evaluating significant investments to transform its Escanaba mill into a world-class paperboard production facility and has applied for investment support from the State of Michigan.

The Michigan House of Representatives and Senate has passed legislation approving an appropriation of up to USD 200 million in funding to support Billerud’s plans. The legislation must be approved by Michigan’s Governor, which is expected to occur within two weeks.

The Michigan House of Representatives and Senate has passed legislation approving an appropriation of up to USD 200 million in funding to support Billerud’s plans. The legislation must be approved by Michigan’s Governor, which is expected to occur within two weeks.

A pre-feasibility study about Billerud’s planned conversion of the Escanaba mill to paperboard production is ongoing and planned to be completed during the first half of 2023, after which the company’s Board of Directors can make an investment decision.

For further information, please contact:

Ivar Vatne, CFO, +46 8 553 335 07, This email address is being protected from spambots. You need JavaScript enabled to view it.

Lena Schattauer, Director Investor Relations, +46 8 553 335 10, This email address is being protected from spambots. You need JavaScript enabled to view it.

This information constituted inside information prior to publication. This is information that BillerudKorsnäs AB (publ) is obliged to make public pursuant to the EU Market Abuse Regulation. The information was submitted for publication, through the agency of the contact person set out above, at 8:50 CET on 27 January 2022.

Colourform and maison perrier-jouët box up the perfect blend of beauty and sustainability

Maison Perrier-Jouët, one of France’s most historic and distinctive champagne houses, has partnered with sustainable packaging brand, COLOURFORM by James Cropper, to challenge the norms of luxury. Together they have created an eco-designed gift box that marries beauty with environmental commitment seamlessly in the luxury market.

Crafted from paper pulp and vine shoots, the Belle Epoque Cocoon has been designed for the champagne house’s vintage cuvees Perrier-Jouët Belle Epoque and Perrier-Jouët Belle Epoque Rosé.

The vine shoots are recovered after pruning at the end of winter, ensuring that this naturally derived agrifibre is given a second life and that the packaging is both recyclable with other paper products and circular in design. The upcycled vine shoots also provide a beautiful coloured speckled aesthetic to the finished gift box.

The box perfectly envelops the Perrier-Jouët Belle Epoque bottle, enhancing its shape. Offering a unique design profile with a pleasing sweep producing an organic and natural feel, only the golden cap crowning the champagne is revealed which is showcased by a small petal-like collar. With an enchanting minimalist elegance, the emblematic Art Nouveau inspired anemone of the Perrier-Jouët house is subtly conveyed through the intricately sculpted floral decoration which beautifully fades out at the packaging edge with a double-deboss.

In addition to its featherweight of 49 grams, which is 93% lighter than the previous gift box, the Belle Epoque Cocoon wrap doesn’t include any varnish or glue. It is designed with only two natural materials, paper pulp prepared from FSC® approved sustainably managed forests and vine shoots from France. The vine shoots evoke the Champagne region and nod to the house’s passion for nature and art which has been passed down through the generations since the house formed in 1811. James Cropper’s Colourform production uses 100% renewable energy, with the majority of power being generated on site by their own solar and hydro plants.

Richard Dancy, COLOURFORM brand manager, comments: “A beautiful and sustainable solution that delivers the essence of the Belle Epoque brand through this luxury packaging. The high attention to detail behind this unique box design has been born from Maison Perrier-Jouët’s close relationship with nature and love of art and natural materials. The wash cut crafted finish is both simple and elegant, and offers up a fine example of circularity and recyclability, adding to the other initiatives that the house of Perrier-Jouët has pioneered.

“By reducing the impact on the environment as much as possible with Belle Epoque Cocoon, Maison Perrier-Jouët is giving meaning to all moments of celebration and has reinvented the codes of luxury.”

The box is varnish free, with a long sleek hinge and fastened with a double locking clasp mechanism it does not require any glue. The clasp closes with a crisp audible click, lies flat and also features a debossed logo. The presentation is finished with a paper label.

With its rich botanical heritage, Maison Perrier-Jouët has evolved in symbiosis with nature since 1811. In 2020, it began a new model of viticulture, inspired by the cycle of nature, which is in line with the evolution of the brand’s practices over the last decade. Regenerative viticulture allows Maison Perrier-Jouët to act on the life of the soil, local species and people at the pace dictated by nature. The aim is to pass on to future generations a terroir, capable of adapting to climate change by limiting the influence of human activities on the ecosystem to which we all belong.

Audrey Guerin, Packaging Development Manager at Perrier-Jouët, says: “This work represents a fantastic collaboration between the James Cropper and Maison Perrier-Jouët development teams.

“Maison Perrier-Jouët has always been guided by a love of nature. The new sustainable wrap reflects the evolution of this passion, with the house taking sincere, ethical and lasting action to reduce its impact on nature and sustain the environment.

“The ultra-light creation represents a huge moment for the brand since it marks the goal we set out to achieve of having our entire gift offer eco-designed by 2023. We’re delighted to mark the achievement with such a beautiful design that seamlessly showcases how beauty and sustainability can work together, in the luxury market.”

The house’s vintage cuvees Perrier-Jouët Belle Epoque and Perrier-Jouët Belle Epoque Rosé will initially launch in the US, France and Italy in the Belle Epoque Cocoon wrap. More than ever, Maison Perrier-Jouët re-enchants the world we share.

About James Cropper

James Cropper is a world-class advanced materials and paper products group, with an operational reach in over 50 countries. Using materials from cotton and wood to carbon fibre the business supports industries from packaging to digital imaging and aerospace with products that are at the cutting edge of performance.

James Cropper is a specialist; providing niche solutions such as materials essential for a hydrogen fuel cell, a bespoke colour and texture for a luxury brand’s packaging or moulded fibre alternatives to single use plastics.

James Cropper has a rich heritage at the Burneside mill, the company was established in 1845, and respectfully manufactures on this site, in the foothills of the English Lake District. The business is renowned globally for its dedicated responses to custom projects and its award-winning commitment to the highest standards of sustainability.

The Burneside mill location is the official Head Quarters for James Cropper PLC and all associated businesses.

ANDRITZ to supply SulfoLoop plant for commercial grade, concentrated sulfuric acid to the new Suzano mill in Ribas do Rio Pardo, Brazil

ANDRITZ has received an order from Brazilian pulp producer Suzano to deliver a SulfoLoop concentrated sulfuric acid plant for its new pulp mill that Suzano is building in the municipality of Ribas do Rio Pardo, state of Mato Grosso do Sul. The pulp mill, delivered by ANDRITZ, is in the construction phase with start-up scheduled for the second half of 2024.

- ANDRITZ sustainable technologies enable production of commercial grade sulfuric acid from the mill’s odorous gases, making the mill self-sufficient in sulfuric acid

- The plant is part of ANDRITZ’s CircleToZero product portfolio that focuses on eliminating unused side streams, create new added value products and lay a foundation for zero emissions and zero waste production.

The sulfuric acid plant will have the capacity to produce 153 tons of commercial grade (>97%) sulfuric acid per day from the pulp mill’s concentrated odorous gases and elemental sulfur - thus making the mill completely self-sufficient in sulfuric acid and recycling sulfur from the waste streams. The ANDRITZ SulfoLoop solution is based on the Wet-gas Sulfuric Acid (WSA) technology for converting wet, sulfur-rich gases and elemental sulfur into sulfuric acid.

The ANDRITZ SulfoLoop sulfuric acid plant produces commercial grade, concentrated sulfuric acid © ANDRITZ

The ANDRITZ SulfoLoop sulfuric acid plant produces commercial grade, concentrated sulfuric acid © ANDRITZ

The sulfuric acid mill will help the new Suzano mill in Ribas do Rio Pardo to control the sodium and sulfur (Na/S) balance and the sulfidity of the pulp mill. Also, the resource-efficiency of the mill will be improved because less sulfate needs to be discharged due to the optimized Na/S balance. An added advantage is that there is no need for hazardous sulfuric acid transport to the mill, which results in a major reduction in the truck transportation volume. The sulfuric acid plant also meets very strict air emission limits and therefore brings a significant improvement to the overall footprint of the new Suzano plant in Ribas do Rio Pardo.

This order once again confirms the excellent business relationship between ANDRITZ and Suzano. Currently ANDRITZ is in the process of supplying all pulp mill technology and process equipment for the new Suzano plant in Ribas do Rio Pardo. Once completed, the pulp mill will be the world’s largest plant with a single eucalyptus pulp production line.

SulfoLoop sulfuric acid plants are part of the company’s CircleToZero initiative, which includes new technologies aimed at optimizing pulp mill side streams. This global initiative for pulp and paper customers brings together the continuous development and improvement of existing ANDRITZ technology solutions with an ambitious innovation goal for the future: To eliminate unused side streams, create new added-value products, and lay the foundation for zero emissions and zero waste production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Kelheim Fibres welcomes EU agreement on deforestation-free supply chains

The renowned viscose fibre manufacturer Kelheim Fibres welcomes the preliminary political agreement reached between the European Parliament and the Council on an EU regulation on deforestation-free supply chains, which was adopted at the end of 2022. The new rules are intended to prevent goods that cause forest degradation or deforestation from being placed on the EU market.

As one of the largest economies worldwide, the EU is a major consumer of wood-based raw materials. Therefore, the new law can significantly contribute to reducing global deforestation and forest degradation as well as protecting threatened forest areas.

As one of the largest economies worldwide, the EU is a major consumer of wood-based raw materials. Therefore, the new law can significantly contribute to reducing global deforestation and forest degradation as well as protecting threatened forest areas.

“Wood is an incredibly versatile and valuable renewable resource and the basis for countless products. Our viscose fibres are just one example – they offer an environmentally friendly alternative to synthetic materials in various applications and are thus a promising material for the future. Of course, this only applies if the production of our raw materials does not take place at the expense of our earth's natural forest resources. These forests are a bastion of biodiversity and climate protection for our entire planet and must be protected at all costs. No one can escape this responsibility," says Craig Barker, CEO at Kelheim Fibres.

Therefore, Kelheim Fibres has been exclusively using FSC® or PEFCTM certified pulps exclusively from sustainably managed sources for many years and has received a top spot in the HotButton ranking three times in a row. This ranking is compiled annually by the Canadian NGO Canopy that campaigns for the preservation of ancient and endangered forests.

About Kelheim Fibres Kelheim Fibres GmbH is the world’s leading manufacturer of viscose speciality fibres.

Innovative products, flexible technologies and an exceptional focus on sustainability form the foundation of the company’s success.

Our speciality fibres are used in most diverse applications from fashion, hygiene and medical products to nonwovens and speciality papers.

All our fibres are made from 100% wood pulp from PEFCTM or FSC© certified sources. They are fully biodegradable and offer an environmentally sound alternative to petroleum-based materials in a broad range of different end products – while maintaining or even enhancing the functional performance of the product.

The production takes place exclusively in Germany and complies with the strict German environmental legislation. Our closed-loop philosophy and an energy-efficient way to operate our plants help to save valuable resources. Kelheim Fibres is the first viscose manufacturer worldwide with an EMAS-validated environmental management system.

www.kelheim-fibres.com

Voith expands service activities of OnPerformance.Lab (OPL) with new location in Kunshan, China

Voith has opened another OnPerformance.Lab (OPL) location in Kunshan, China, to offer the comprehensive know-how and competencies of its experts worldwide as close to the customer as possible. With this step, Voith is strengthening the global network of the remote service center, which offers data-based services such as data analysis, condition monitoring, smart monitoring and expert advice. From the OPL, the Voith team is available quickly and easily via remote support, regardless of whether short-term problems or long-term optimization projects are involved. OPL locations can already be found in Heidenheim, Germany, and Tokyo, Japan. The opening of additional regional offices is planned.

- New OnPerformance.Lab site in Kunshan, China, strengthens regional footprint for service, optimization and consulting activities

- OPL experts partner with customers to implement innovative Papermaking 4.0 solutions for sustainable cost and efficiency improvements

- New location helps meet increasing customer demand for digitalization solutions and process optimization for higher resource efficiency

"Our new location in Kunshan is specifically geared toward our customers in the Chinese market who want to use automation and digitalization even more profitably in their plants," says Dr. Dieter Wenninger, Regional President Products & Services Asia at Voith Paper. "We also ensure more resource-efficient production so that customers can reliably achieve their sustainability goals. Voith supports both the installation and commissioning of the digital applications as well as the subsequent monitoring and further process optimization. As part of the global OPL network, the new site will also drive innovative projects and technologies for the Chinese market."

All OPL services can be configured individually for each customer as a modular system. Together with OPL, paper producers define their targets and specific key performance indicators (KPIs), such as fiber consumption, basis weight and moisture stability as well as grade change times. Building on continuous data analysis linked to data mining methods and artificial intelligence, targeted optimization measures are then implemented.

"Voith customers have always and increasingly relied on our support and know-how when it comes to elevating their efficiency, production volume and availability,” says Ulrike Welp-Wallenmaier, Senior Manager Business Development at Voith Paper. “OPL's data-based remote services are an innovative way to profitably apply our knowledge for our customers and their individual challenges."

The solution is an ideal addition to the on-site service portfolio and, in combination with the digitalization solutions of the Papermaking 4.0 portfolio, ensures continuous and sustainable improvements in many areas. For more information on the Voith OnPerformance.Lab, please visit https://voith.com/corp-en/onperformancelab/paper.html.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.