Super User

Dynamic testing and measuring solutions for pulp, paper, and board come to ExpoAcotepac 2023

The largest convention for the pulp and paper industry in Central and South America, the International Congress and ExpoAcotepac 2023, will take place in Cali, Colombia from February 8-10, 2023. IDM Test will be onsite to present innovative testing devices for quality control and product optimization at the event, including the emtec Electronic product line.

Accurate data regarding the cationic demand and zeta potential of fibers in the wet end of papermaking leads to a smoother running process and higher product quality. With this end in mind, emtec Electronic GmbH developed the partner instruments CAS touch! Charge Analyzing System and FPA touch! Fiber Potential Analyzer to specifically measure both parameters. Data from the dynamic duo allows technicians to easily determine the correct dosage of chemicals to add to achieve desired product properties and reduce resource waste. In addition, the devices’ small size and light weight make it easy to transport in a carry-on suitcase, which is especially beneficial for technicians providing on-the-go measurements and troubleshooting.

Instruments such as these from emtec Electronic will be among those presented by IDM Test at booth No. 20 in the Hotel Dann Carlton Cali, where the ExpoAcotepac is set to take place. In addition to the CAS and FPA, the emtec EST Surface and Sizing Tester and the TSA Tissue Softness Analyzer will be on display at the event. The EST was specifically designed to resolve issues with gluing, coating, and printing that can arise during conversion. The TSA provides objective and reliable data on the haptic parameters softness, smoothness, and stiffness.

Visitors to the ExpoAcotepac are encouraged to stop by the IDM Test Booth and chat with Sales Area Manager from IDM Test Patxi Arizmendi or emtec Sales Area Managers Daniel Ohndorf and Philipp Sievers for more information about the measuring principles and application examples of the devices.

More information about the ExpoAcotepac is available at the following link.

About emtec Electronic

emtec Electronic GmbH develops, produces and distributes worldwide testing and measuring devices for the detection of relevant processing properties of paper, board, nonwoven and textile materials. The portable measuring devices enable manufacturers and converters of paper, nonwoven and textile products for example, to control and optimize the manufacturing and converting processes during ongoing production. From the wet end to the final product, the application of the devices enables an efficient process to achieve and ensure the best possible quality with the least possible effort.

For 27 years, we have relied on innovative, highly specialized measuring instruments combined with a high degree of service orientation. Since the company was founded, we have been intensively involved in scientific cooperation with institutes and companies, further developing instruments for our customers and offering a broad network in over 80 countries from our Leipzig location.

For more information about emtec Electronic, please visit the website:

Resolute, Paper Excellence Merger Receives Canadian Competition Bureau Approval

The Paper Excellence Group (the "Group"), through its wholly-owned subsidiary Domtar Corporation ("Domtar"), a global diversified manufacturer of pulp and speciality, printing, writing, and packaging papers, and Resolute Forest Products Inc. ("Resolute") (NYSE: RFP) (TSX: RFP), a global forest products company, jointly announced that the Canadian Commissioner of Competition has entered into a consent agreement regarding the parties' business combination. Once the combination has been finalized, Domtar will acquire all of the outstanding common shares of Resolute stock for $20.50 per share and one contingent value right tied to potential duty deposit refunds of up to $500 million.

The consent agreement filed by the Canadian Commissioner of Competition with the Competition Tribunal today completes one of the remaining conditions for the closing of the transaction.

The consent agreement filed by the Canadian Commissioner of Competition with the Competition Tribunal today completes one of the remaining conditions for the closing of the transaction.

The transaction remains on course to close in the first half of 2023, subject to the satisfaction or waiver of the other conditions to the closing of the merger.

Resolute is a global leader in the forest products industry with a diverse range of products, including market pulp, tissue, wood products and papers, which are marketed in over 60 countries. The company owns or operates some 40 facilities, as well as power generation assets, in the United States and Canada. Resolute has third-party certified 100% of its managed woodlands to internationally recognized sustainable forest management standards. The shares of Resolute trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute has received regional, North American and global recognition for its leadership in corporate social responsibility and sustainable development, as well as for its business practices. Visit www.resolutefp.com for more information.

Domtar is a leading provider of a wide variety of fiber-based products including communication, specialty and packaging papers, market pulp and airlaid nonwovens. With approximately 6,400 employees serving more than 50 countries around the world, Domtar is driven by a commitment to turn sustainable wood fiber into useful products that people rely on every day. Domtar's principal executive office is in Fort Mill, South Carolina and Domtar is part of the Paper Excellence group of companies. To learn more, visit www.domtar.com.

The Paper Excellence Group is a privately-held holding company that oversees individual pulp and paper business units. Its operations include the manufacturing of pulp and specialty, printing and writing, and packaging papers, producing over 7 million tons annually with a workforce of over 10,000 in its nearly 40 locations across the Americas and Europe. For more information on Paper Excellence, please visit www.paperexcellence.com.

SOURCE Paper Excellence Group

Valmet to deliver a coating section upgrade with electric heated air dryers to Stora Enso in Finland

Valmet upgrades the coating section of the board machine 5 at Stora Enso Imatra Mills, Tainionkoski in Finland. In addition to electric heated OptiDry Coat air dryers, the upgrade includes a drying capacity increase in the coating section, a new wire loop to the existing dryer group and automation. The upgrade will bring energy savings and reduce emissions.

The order was included in Valmet’s orders received of the third quarter 2022. The value of the order will not be disclosed. The value of deliveries of this type is usually around EUR 5–8 million. The installations are planned to start in the fourth quarter 2023.

“The delivery helps the customer to take another step forward on their path to a CO2 free future. By replacing the old gas heated dryers by modern electric heated air dryers, the customer can reduce energy consumption for the existing board grades and ensure higher production capacity. The new wire loop will create an additional draw point for the web and allows controlled operating in the modified area. This will bring more safety in tail threading and minimize oil leakages,” says Kimmo Vehmas, Senior Mill Sales Manager, EMEA, Valmet.

“The delivery helps the customer to take another step forward on their path to a CO2 free future. By replacing the old gas heated dryers by modern electric heated air dryers, the customer can reduce energy consumption for the existing board grades and ensure higher production capacity. The new wire loop will create an additional draw point for the web and allows controlled operating in the modified area. This will bring more safety in tail threading and minimize oil leakages,” says Kimmo Vehmas, Senior Mill Sales Manager, EMEA, Valmet.

The increasing energy prices and the uncertainty of natural gas availability are driving mills to convert from gas to electricity operation.

About the customer

Stora Enso Imatra mills in southeastern Finland was founded in 1935. It consists of two production units – Kaukopää and Tainionkoski – that produce pulp and consumer packaging board. The annual capacity is 1 200 000 tonnes of consumer packaging board, 1 300 000 tonnes of pulp and 455 000 tonnes of polymer coating. Imatra Mills is one of the largest mills producing consumer packaging board in the world, with over 90% of its production exported to Europe, Southeast Asia and other continents.

As part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

ANDRITZ to supply energy-saving wastepaper processing systems to Lipy Paper Mills, Bangladesh

International technology group ANDRITZ has received an order from Lipy Paper Mills Ltd. to supply wastepaper processing systems to the mill in Changine, Modonpur, Kanchpur, Sonargaon. These are the first ANDRITZ RCF (Recycled Fiber) lines for Bangladesh. Start-up is scheduled for the third quarter in 2023.

ANDRITZ will supply key equipment for two RCF lines, featuring a total capacity of 150 t/d and processing LOCC (Local OCC) and MOW (Mixed Office Waste) as raw material for production of testliner, writing and printing paper.

Shahiar Hasan Khan, Deputy Managing Director, Lipy Paper Mills says: “ANDRITZ convinced us because of its energy-saving technology for screening and flotation and its focus on minimum fiber loss. In addition, with the Ultra High Dispersion we’ll be able to keep steam demand at a low level. All these topics are strategic development targets for an aspiring company like Lipy Paper Mills.”

Typical SelectaFlot flotation system by ANDRITZ © ANDRITZ

Typical SelectaFlot flotation system by ANDRITZ © ANDRITZ

Lipy Paper Mills Ltd. is an aspiring company, established in 2016 by Lipy Group, a family-owned Bangladeshi enterprise and successful player in the paper market.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Valmet introduces a new lime kiln flame profile application for pulp mills

Valmet introduces a new flame profiling application that enables real-time flame detection and monitoring in a pulp mill’s lime kiln environments. At the same time, the Valmet Furnace Imaging System, IR is updated with new optics and a port rodder, improving the overall Valmet Boiler Diagnostics Systems offering.

“We are constantly developing our camera-based diagnostics offering for both pulp and energy customers. The new flame profile application can be used to control the hot end temperatures of a lime kiln to optimize the residual carbonite in lime. In the end it helps to decrease the energy consumption of the kiln,” says Matti Selkälä, Business Manager, Pulp and Energy Analyzers, Automation Systems business line, Valmet.

Real-time information on lime kiln flame temperature and profile

Real-time information on lime kiln flame temperature and profile

The new flame profiling software is an add-on application for Valmet Visible Thermal Imaging System. The software detects the flame, measures its relative size and provides distance measurements from the end of the detected flame to user defined markers. These features help to optimize fuel combustion, increase availability and reduce emissions. At the same time, they improve safety by offering users a better understanding of the current conditions.

The software is used in conjunction with the Valmet Visible Thermal Imaging System, an advanced solution with high-definition imaging and temperature analysis, ideally suited for lime kiln applications. The system is engineered for durability and longevity and delivers visual and thermal analysis for optimizing fuel combustion and lime quality in lime kilns.

New mechanics improve availability and performance

Additionally, Valmet Furnace Imaging System, IR has been upgraded with new optics and port rodder technology for enhanced image quality and more accurate metrics. The infrared camera system provides online visual analysis to see through flue gas and fly ash. It enables a comprehensive observation and analysis at full load which reduces risks and improves productivity. The new port rodder makes cleaning of the camera more effective, improving availability and operational safety.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

ANDRITZ to supply key equipment and processes to Stora Enso in Oulu, Finland

ANDRITZ has received an order from Stora Enso to deliver a new debarking line, a new biomass boiler, and to upgrade the recausticizing plant for its Oulu mill in Finland.

- ANDRITZ sustainable technologies help Stora Enso achieve its sustainability goals

- ANDRITZ debarking line minimizes wood losses, biomass boiler ensures lowest emissions, and recausticizing plant minimizes effluent volume

ANDRITZ is suppling sustainable technologies, including a new debarking line, a new biomass boiler, and a recausticizing plant upgrade, to help Stora Enso achieve its sustainability commitments at its Oulu mill, Finland. © ANDRITZ

ANDRITZ is suppling sustainable technologies, including a new debarking line, a new biomass boiler, and a recausticizing plant upgrade, to help Stora Enso achieve its sustainability commitments at its Oulu mill, Finland. © ANDRITZ

The scope of supply, on EPC basis, includes:

- New debarking line, equipped with digital Smart Wood Processing products, with a capacity of about 270 m3 solid wood over-bark per hour, providing excellent debarking results with very low wood losses.

- New biomass power boiler with a steam production capacity of 216 t/h based on the high-efficiency ANDRITZ EcoFluid bubbling fluidized bed (BFB) technology, ensuring low NOx and other gaseous emissions.

- Recausticizing plant upgrade for 5,000 m3/d white liquor production. The delivery includes new generation LimeLine recausticizing equipment such as LimeWhite-H filter maximizing the white liquor quality and minimizing effluent amount, and StiroX white liquor oxidizer.

The order is part of Stora Ensoʼs project to convert a former paper machine at the Oulu mill into a high-volume consumer board production line.

This order demonstrates the ongoing solid business relationship between ANDRITZ and Stora Enso. ANDRITZ also supplied production technologies and key process equipment to the Oulu mill for the first machine conversion from paper to kraftliner in 2021, which included the rebuild of the fiberline and drying machine, as well as modernization of the stock preparation system.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Sustainable fabrics and roll covers from Voith ensure significant energy and cost savings

Various factors support more sustainable paper production. Fabrics and roll covers, for example, can contribute to improved resource efficiency by directly optimizing production efficiency and because they are themselves sustainably manufactured. Based on many years of experience, Voith offers specific solutions for sustainable paper production, the advantages of which are proven by many positive customer references. A German graphic papers manufacturer, for example, reported that Voith's SolarPress roll covers have enabled energy savings due to a 1.5 percentage point higher dry content after the press section. Efficiency add-ons for press fabrics are another example. In particular, +Peak technology, a specially developed elastomer material, optimizes nip dewatering and increases the service life of a press fabric. For one paper producer, +Peak resulted in higher dry content in the tandem press and reduced the average amount of steam by 11 percent, from 1.6 t/ton to 1.43 t/ton. In addition to energy savings, significant water savings are also enabled. For example, customers worldwide benefit from HydroSeal, the modern version of sealing strips for suction rolls. At a board mill in the USA, HydroSeal reduced water usage by 80 percent and saved the papermaker more than $30,000 per year in sealing strip lubrication.

- Positive feedback from many customers confirms more sustainable production thanks to wear parts from Voith

- Research and development team is working on bio-based materials for the production of wear parts

- Voith focuses on the entire life cycle of wear parts, from production and use in operation to material recycling

"In addition to production that conserves resources as much as possible, it is important that the products themselves are also manufactured sustainably," emphasizes Lidia Loskan, R&D Project Manager Sustainability at Voith Paper. Here, it is important to be able to offer the same product properties as with petroleum-based roll covers and fabrics.

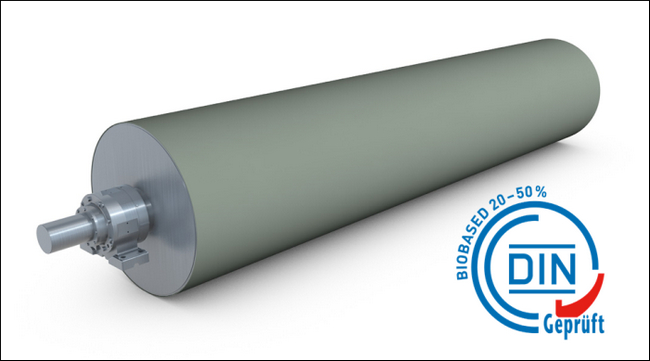

To further optimize the product portfolio in terms of sustainability, Voith's R&D team is working on new possibilities with the help of life cycle analyses (LCAs). As an example, Dr. Robert Hilbing, Senior Vice President R&D FRS at Voith Paper, mentions the newly launched roll cover AiroGuide Tune Green. The innovative roll cover is certified according to the international DIN CERTCO standard for bio-based products. The fiber composite roll cover is manufactured with bio-based raw materials and was specially developed for the wet-end section. It also has improved corrosion properties and a long service life. This makes AiroGuide Tune Green the first DIN CERTCO-certified sustainable roll cover on the market with the same performance data as the petroleum-based alternatives.

Furthermore, Voith is increasingly focused on the entire manufacturing process of wear parts. The company has already been systematically measuring its own energy, water and waste volumes since 2012 and reducing them in a targeted manner. Measures include the use of renewable energies and the establishment of material recycling processes at Voith locations. For example, the unavoidable waste produced during the surface treatment of QualiFlex press sleeves is recycled. For this purpose, the Voith team, together with partners, implements a special thermal treatment process for polyurethanes. Subsequently, the production waste is used again in the manufacture of other products and reduces the company’s carbon footprint.

"As part of Voith Paper's sustainability program Papermaking for Life, Voith is working intensively on sustainable solutions to strengthen the circular economy and reduce its carbon footprint," summarizes Dr. Hilbing. "Our goal is to offer our customers an optimal portfolio of fabrics and roll covers that increases performance and sustainability while reducing operating costs."

Sustainability program Papermaking for Life

As part of the innovation and development offensive "Papermaking for Life," Voith Paper presents versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The emphasis is on the topics of water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: voith.com/papermaking-for-life.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Essel Kâğıt achieves maximum production efficiency with Toscotec’s tissue line

Turkish tissue producer Essel Kâğıt’s new AHEAD 2.2L machine has exceeded its guaranteed production by a large margin and surpassed bulk and softness parameters. Supplied by Toscotec on a turnkey basis, PM3 had come online at Essel’s Osmaniye mill in Turkey in October 2021. After start-up, Toscotec has been providing continuous support to fine-tune the whole plant and achieve top performance.

Ahmet Temuroglu, Production Coordinator and Burak Ipek, Maintenance Manager at Essel Kâğit, say, “The target of our performance test was successfully accomplished with a production of 290.5 tpd on a 23 gsm towel grade at the speed of 1,810 m/min. We are now fully reaping the benefits of Toscotec’s first-in-class technology across our entire product range both for tissue quality and consumptions.”

Nicola Fontana, Senior Papermaker at Toscotec, says, “This double-width AHEAD line is delivering a high and stable performance. TT NextPress is offering good results of bulk and hand-feel even at maximum load on low basis weights, exceeding Essel Kâğıt’s strict quality standards.”

Andrea Rossi, Toscotec’s Commissioning Manager, says, “The performance test confirmed the machine’s low energy usage we had been monitoring including at the speed of 2,000 m/min. The total energy consumption is well below the guaranteed figure. The cooperation with Essel’s team was extraordinary and they did a fantastic job in getting the machine ready to achieve its top efficiency.”

For more information, please contact:

Valter Di Nardo, Toscotec Chief Customer Service Officer, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet and Opal Botany Mill extend the Mill Maintenance Operations Agreement in Australia

Valmet and Opal have agreed to extend the Mill Maintenance Operations Agreement and thus continue the long-term cooperation for mill maintenance services at Opal’s B9 board-making line in Sydney, New South Wales, Australia. The Valmet-supplied B9 started up in 2012. After the start-up, Valmet took responsibility of the establishment of maintenance operations, site maintenance services and specific performance optimization projects. The value of the agreement will not be disclosed.

“We have been collaborating with Valmet for over 10 years. Tangible results have been seen during this time with progressive and continuous improvements, such as production efficiency and cost reduction. We are delighted to continue the collaboration with Valmet to ensure the B9 facility becomes an industry benchmark in all areas,” says Robert Carry, General Manager Operations, Botany Mill.

"Valmet maintenance and Opal production teams at B9 have been able to capture the true meaning of production assets’ lifecycle management. Successful collaboration on site supported by global Valmet experts creates a strong foundation for reliable operations. The new recently launched digital tool, Valmet Mobile Maintenance application, and maintenance assessments support the further development of the mill maintenance,” says Timo Harjunpää, Director, Maintenance Outsourcing, Services, Valmet.

"Valmet maintenance and Opal production teams at B9 have been able to capture the true meaning of production assets’ lifecycle management. Successful collaboration on site supported by global Valmet experts creates a strong foundation for reliable operations. The new recently launched digital tool, Valmet Mobile Maintenance application, and maintenance assessments support the further development of the mill maintenance,” says Timo Harjunpää, Director, Maintenance Outsourcing, Services, Valmet.

Technical information about the delivery

Valmet provides mill maintenance services for the Opal Botany mill. Valmet is responsible for securing the reliability at the site through planning, leadership, management, development, and execution of maintenance. Additionally, Valmet will bring new solutions to improve efficiency and accuracy of the daily maintenance.

About Opal Botany Mill

Opal operates the Botany Mill, Australia’s most advanced brown packaging recycling facility where they produce 100% recycled liners and corrugating mediums.

Opal is an innovative renewable packaging company which is part of the Nippon Paper Group.

Maintenance development and outsourcing services for board and paper | Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Voith increases winder performance with integrated technology service and automatic format change

Voith introduces an integrated service offering to increase winder performance in all applications, along with FastFormat, a new solution for automatic format changes.

- Voith increases winder performance for paper, board and packaging machines

- Integrated service offering results in higher machine availability

- Automatic format change with FastFormat provides greater safety

The performance of the winder is crucial for the efficiency of the paper machine, because winder operation that is not optimal can lead to capacity bottlenecks across the entire paper production process. To avoid this, Voith now offers an integrated technology service for higher winder availability. FastFormat, a new product for automatic format changes, also increases winder performance and ensures greater safety for operators.

Service offering with outstanding know-how

Voith's extensive winder service enables quick identification of bottlenecks and increases capacity, paper quality and safety. Customers benefit from comprehensive technology service to improve winder availability, increase productivity and cut costs.

The scope and content of the service offering are individually adapted to the respective requirements of each customer. As a result, key production figures, such as set change time and acceleration, can be demonstrably improved. An important part of the service offering is a 24/7 hotline support that provides customers with rapid assistance and solutions to problems.

At its PM 1 in Munksund, Sweden, forest industry company SCA already relies on Voith's winder technology service. “The biggest benefit of our winder service partnership with Voith is the fact that it can’t be simply narrowed down to a single advantage,” says Urban Marklund, Production Technician at SCA Munksund AB in Sweden. “It’s the complete package that makes it so valuable to us. It’s everything from Voith’s unrivaled expertise in the areas of automation and technology to the annual on-site visits and 24/7 hotline support. All this adds up to a deal that is very useful and important to us.”

“With our comprehensive service offering, we support our customers even better in continuously improving the performance of their winder,” adds Sven Franke, Senior Automation Engineer at Voith Paper. “Through regular service visits to our customers’ sites, the winders are continuously optimized and adapted to changing influences and needs. Another important aspect is our availability as a reliable partner in case of malfunctions. This is exactly what we have implemented with our 24/7 hotline support.”

FastFormat for quick and safe format changes

With FastFormat, Voith is presenting its first product for fast and safe format changes. FastFormat has a return on investment of only a few months and particularly helps paper manufacturers avoid capacity losses due to frequent format changes.

FastFormat allows the winder’s engaging edge slitters to be moved at crawl speed and the web width to be changed, enabling automated format changes without operator intervention. This not only increases safety for the operator but also boosts winder production.

“Approximately one minute can be saved per format change, which really makes a difference, especially for customers with frequent format changes,” says Fabian Köberle, Global Product Manager at Voith Paper. “In addition, FastFormat eliminates the need for operator intervention previously required on a regular basis.”

The solution is already being used successfully at DS Smith Paper in the German town of Witzenhausen. “FastFormat offers us enormous productivity and safety benefits and is an important step towards a fully automated process,” confirms Ulf Heiligtag, Head of Technology at DS Smith Paper.

“The installation process went smoothly, and the solution runs as expected – we are extremely satisfied,” adds Stephan Siebold, Project Director at DS Smith Paper.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.