Ian Melin-Jones

Valmet and Fabio Perini start Industrial Internet ecosystem partnership to provide digital solutions for tissue production and converting

Valmet and Fabio Perini have established an Industrial Internet ecosystem partnership to strengthen collaboration in the tissue industry. The target is to allow tissue producers and converters to work together more efficiently, and to exchange knowledge and resources for the benefit of their customers.

The partnership combines Valmet's comprehensive tissue making technology and process optimization know-how with Fabio Perini’s strong expertise in complete solutions for converting and packaging machines as well as in the converting process and technology. The two companies’ solid expertise combined with data from tissue mills and converting plants will provide a new dimension to tissue mill optimization.

The collaboration aims at providing an unbroken chain of production data from the tissue machine to the converting line and utilizing artificial intelligence-driven applications in the tissue production process to make the converting operations downstream more efficient. This will bring significant mill-level quality and efficiency improvements for tissue producers and converters.

The collaboration aims at providing an unbroken chain of production data from the tissue machine to the converting line and utilizing artificial intelligence-driven applications in the tissue production process to make the converting operations downstream more efficient. This will bring significant mill-level quality and efficiency improvements for tissue producers and converters.

“Starting from customer needs, Valmet and Fabio Perini are now taking the first steps to develop solutions where innovation goes beyond company borders, covering both tissue production and converting processes. Through collaboration with our common customers we can provide new digital solutions and services to help move tissue mills’ performance forward,” says Jari Almi, Vice President, Industrial Internet, Valmet.

“We believe an open innovation model is a key concept through which companies within tissue business can create different partnerships to make their innovation process more efficient, as well as exchange knowledge and resources. By combining the strengths of our companies, we can facilitate broad innovation and fast adaptation, enable new business and service models and help improve the profitability of companies in the tissue business,” says Oswaldo Cruz Junior, CEO of Körber's Business Area Tissue.

Both Valmet and Fabio Perini have a long history in offering measurement and optimization applications for tissue production. These reliable measurements have provided proven results for their customers.

Information about Fabio Perini

Fabio Perini S.p.A. with the brands Fabio Perini, Casmatic and Concept X, is specialized in the production of machinery, lines and integrated systems, for the converting and packaging of tissue paper, for a wide range of products: toilet rolls, kitchen towels, industrial rolls. Founded in 1966 at Lucca, the Italian district of tissue production and converting technology, Fabio Perini is a point of reference for its high level of innovation and advanced technology. Fabio Perini S.p.A. is the leading company of the Körber Group’s Business Area Tissue. www.fabioperini.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Future Neles strengthens its valves service availability with new service centers in Portugal and France

Metso’s valve business, future Neles Corporation, will establish two new service centers in Lisbon, Portugal, and in the Mulhouse area, France, to increase its valves’ service availability and presence close to customers. Service centers offer valve repair services as well as predictive maintenance services, e.g. digitalized process diagnostic services and shutdown planning, to help customers to increase their plant reliability.

“We are constantly developing our operations to fulfill our customers’ needs. We have a comprehensive service portfolio, ranging from genuine quality parts to complex shutdown solutions. We want to be a reliability partner by helping our customers to reduce the risks of valve failure and expensive unplanned shutdowns,” says Timo Hänninen, Vice President of Valve Services at Metso.

The service center in Portugal was opened during the third quarter of 2019. The opening of the service center in France is planned for the second quarter of 2020.

Future Neles currently has 40 service sites in more than 20 countries. “Our valve services experts are involved in more than 150 large-size shutdowns globally every year, and today we have more than 100 valve service agreements with our customers,” Hänninen says.

About future Neles Corporation

The future Neles Corporation is a well-known flow control solutions and services provider to the oil and gas refining, the pulp, paper and bioproducts industry, the chemicals and other process industries. Neles employs 2,900 people and it has operations in more than 40 countries. Neles’ unaudited carve-out sales for full-year 2018 were EUR 593 million (January-September 2019: EUR 493 million) and carve-out operating profit was EUR 83 million (January-September 2019: EUR 75 million.)

Neles Corporation is planned to be created in a partial demerger of Metso, in which Metso’s Flow Control business would become the independent Neles Corporation and it would continue Metso’s listing on Nasdaq Helsinki. Simultaneously, Metso’s Minerals Business would combine with Outotec to create Metso Outotec.

The partial demerger is targeted to be completed in the second quarter of 2020, subject to the receipt of all required regulatory and other approvals. The Extraordinary General Meetings of both Metso and Outotec approved the transaction on October 29, 2019.

Metso is a world-leading industrial company offering equipment and services for the sustainable processing and flow of natural resources in the mining, aggregates, recycling and process industries. With our unique knowledge and innovative solutions, we help our customers improve their operational efficiency, reduce risks and increase profitability. Metso is listed on the Nasdaq Helsinki in Finland and had sales of about EUR 3.2 billion in 2018. Metso employs over 14,000 people in more than 50 countries.

4 Tools for Tissue and Nonwovens Machines to Reduce and Optimize Idle Times

In today’s world consumers want to know if the companies they do business with are acting in a sustainable manner. In addition, the environment is teetering dangerously close to the point of no return when it comes to carbon emissions, and manufacturers are increasingly expected to reduce waste and energy usage, while making the highest quality products possible.

This is a tall order, but it is one that every company within the manufacturing sector must meet, including the tissue and nonwovens ones.

One of the issues that has to be addressed to achieve our objective is the loss of productivity on a production line, and one of the top reasons for this is machine idle times.

What is Idle Time

Idle times occur when a machine is unproductive for reasons that are outside of the control of workers or management. During this idle time, workers are generally waiting while a machine is being serviced or it is offline, and the production can continue only if the idle machine can be bypassed.

Impact of machine Idle Times

When machinery on the production line is idle, the cost for a factory is between 5% and 20% of its productivity capacity. Not only that but an estimated 80% of industrial facilities are not able to accurately estimate the scope of their machine idle times.

It is common for facilities to underestimate the cost of these machine idle times by as much as 200% to 300%, and when it comes to meeting production targets and profit margins this is unacceptable. The starting point for a tissue and nonwovens plant is to gain an understanding of their machinery and what causes idle times to occur.

Causes of Idle Times

Idle times can be either planned or unplanned. The former are generally for regular machine maintenance, software and hardware upgrades, inspections, and anything else required for the upkeep of the machine, while the latter are are generally due to machine breakage or malfunction, software or hardware errors, or overall poor performance. It goes without saying that unplanned idle times are costly and obviously more disruptive because they can cause significant interruption to productivity.

According to the American Productivity and Quality Center (APQC) unplanned idle times are responsible for a loss of between $0.40 and $1.20 for every $20, and it is therefore vitally important for every manufacturing company to avoid these phenomena.

Reducing and Optimizing Machine Idle Times: 4 key tools

The Industry 4.0 technology is the answer to these problems.

Industry 4.0 has brought machine communication and automation to a point at which data can be collected from every machine of the production line in real-time and subsequently analyze these data in isolation or in relation to those coming from every other machine.

Read more: How to measure tissue and nonwovens mill machinery performance with real time analytics

To accomplish this, there are a number of tools that tissue and nonwovens companies need to have in place.

1. Machine Sensors

Each machine on the production line will be equipped with numerous sensors in order to collect data in real-time during operation. These data will reveal, for example, the operating state of the machine, its speed, vibrations and other environmental factors, such as temperature and humidity, that the human senses cannot detect.

2. The Cloud

Thanks to Cloud computing, the various machines will be connected wirelessly to each other, as well as to computers and mobile devices used by workers on the production line and in head office. This will allow for the remote collection and analysis of data from any production line in any plant.

Read more: Cloud Computing and Integration with Machine and Corporate Applications

3. Software/Platform

The data that are sent across the cloud will need to be integrated into a single platform capable of analysing them and to allow both a bird’s eye view of the production line and a closeup view of the operation of any individual machine.

This data integration is incredibly important in light of the fact that the machines on production lines tend to have their own unique software, isolating their data from those of the other machines and from every other data related to business operations.

4. AI/Machine Learning

Finally, artificial intelligence and machine learning will be capable of analyzing the data coming in, recognize anomalous ones and act accordingly. Machine learning will use algorithms to understand anomalous readings and to schedule predictive maintenance. These tools are key in improving machine performance and reducing unplanned idle times or avoiding it altogether.

Reduce Idle Time and Boost Productivity with Industry 4.0

We have seen that, despite the pressures to which companies are subjected, there is nowadays a technology capable of minimizing or eliminating machine idle times.

Thanks to these tools you will be able to gather all the data sent by disparate machines in any production line, integrate them, analyze them, interpret those analyses, and implement automated measures to ensure machines are always running at peak efficiency.

For more information on how to keep your tissue and nonwovens production line operating at peak efficiency, download our free eBook “5 Industry 4.0 Tools that Boost Productivity in the Tissue Paper and Nonwovens Industry”!

ANDRITZ to supply major pulp production technologies and key process equipment for Bracell’s new pulp mill in Brazil

International technology group ANDRITZ has received an order from Bracell to supply energy-efficient and environmentally friendly pulp production technologies and key process equipment for Bracell’s Project “STAR” in Lençóis Paulista, in the state of São Paulo, Brazil.

Start-up is scheduled for the third quarter of 2021. Award of this contract to ANDRITZ was announced in July 2019, however the name of the customer remained confidential at that time.

Bracell’s Project “STAR” in Lençóis Paulista, in the state of São Paulo, Brazil. © ANDRITZ

Bracell’s Project “STAR” in Lençóis Paulista, in the state of São Paulo, Brazil. © ANDRITZ

ANDRITZ will provide four of the six most important process islands in the pulp mill, which are to be supplied on EPCC (Engineering, Procurement, Construction and Civil Construction) basis:

- A complete Wood Processing Plant using ANDRITZ’s proven technologies and including chipping lines, stacker-reclaimer, chip screening, biomass handling with ANDRITZ BioCrushers, and biomass storage. Each chipping line for eucalyptus processing consists of ANDRITZ’s unique horizontally fed HHQ-Chipper (EXL model), ensuring high capacity without compromising on chip quality. Woodyard operation is enhanced with state-of-the-art ANDRITZ IIoT products, including ChipperEKG, stone detection, the ScanChip chip analyzer and a FlowScanner, which measures the density and moisture content of the chips to optimize the fiberline process.

- An ANDRITZ HERB Recovery Boiler with high steam parameters of 101 bar(a) and 515°C to maximize power generation. The HERB Recovery Boiler features energy-efficient flue gas cooling and feed water preheating technologies to maximize steam production for power generation. It is designed for extended operating periods without requiring wash water. At the beginning of December 2019, ANDRITZ successfully completed assembly of the first Recovery Boiler column.

- Environmentally friendly hardwood Fiber Lines that ensure low-effluent emissions, can produce both kraft and dissolving pulp, and which also include a chip feed system, LoSolids continuous cooking system with Pre-Hydrolysis Vessel (PHV), screen room and bleach plant, as well as ANDRITZ’s DD-Washer technology, ensuring low operating costs, low emissions, extremely high washing efficiency, and excellent fiber quality. The cooking plant for the fiberline is state of the art in the continuous cooking process for production of dissolving pulp.

- A new innovative EvoDry Pulp Drying System with energy-efficient pulp drying based on the high-capacity Twin Wire Former technology, with airborne dryers, cutter-layboy and baling lines. The approach flow with cleaner systems ensures homogeneous pulp feed to the subsequent process stage for both types of pulps – dissolving and kraft. The pulp dewatering machine comprises a headbox with dilution control, a Twin Wire Former, and a press section with one combi-press and two shoe presses. The ANDRITZ technology for pulp drying is very well proven all over the world. In addition, the ANDRITZ EvoDry sheet dryer is the most energy-efficient of its kind. Finally, the reliable ANDRITZ cutter-layboy provides the pulp bales to be further processed in the high-capacity baling lines, where the final pulp bale units are produced.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

BRACELL

Bracell is one of the largest specialty cellulose producers in the world and has operated in Brazil for 15 years. The company has its main operations in Bahia Specialty Cellulose in Camaçari, Bahia and in Lençóis Paulista, São Paulo. By the time the expansion project is completed in 2021, Bracell will have an annual production capacity of two million tons of dissolving pulp and 7,300 direct and indirect employees.

Decision taken: Lenzing joint venture to build dissolving wood pulp plant in Brazil

The Lenzing Group, world market leader for wood-based cellulosic fibers, and Duratex, the largest producer of industrialized wood panels in the southern hemisphere, announce that they will build a 500,000 t dissolving wood pulp plant in the State of Minas Gerais, near Sao Paulo (Brazil). The start-up is planned for the first half of 2022. In the joint venture, Lenzing holds a 51 percent, Duratex a 49 percent stake. The expected industrial CAPEX will be approx. USD 1.3 bn (based on current exchange rates and customary tax refunds). The project is financed through long-term debt. The corresponding financing contracts are expected to be concluded at the end of the first quarter of 2020.

- Investment of approx. USD 1.3 bn in 500,000 t dissolving wood pulp plant

- Key milestone to structurally strengthen cost leadership position

- Significant step towards carbon neutrality

Key milestone to structurally strengthen cost leadership position

The new dissolving wood pulp plant strengthens the Lenzing Group’s backward integration and cost position as well as its specialty fiber growth in line with its sCore TEN corporate strategy. The single-line dissolving wood pulp plant with an annual nameplate capacity of 500,000 tons will be the largest and most competitive production facility of its kind. Dissolving wood pulp is a key raw material required for manufacturing Lenzing’s biobased fibers. The joint venture will supply the entire volume of dissolving wood pulp to the Lenzing Group.

“Wood-based cellulosic fibers offer an important contribution to enhance sustainability in the textile industry. In line with its corporate strategy sCore TEN, Lenzing is committed to drive organic growth in this market. With this investment, we will become more competitive, act more independently and subsequently strengthen our market position. The trust and support of the main shareholders of Lenzing and Duratex were of great importance for this key project”, states Stefan Doboczky, CEO of the Lenzing Group.

Strong focus on sustainability

In planning the new production facility, particular importance was given to sustainability aspects. The joint venture secured FSC®-certified plantations1 covering an area of over 44,000 hectares to provide the necessary biomass. These plantations operate completely in accordance with the guidelines and high standards of the Lenzing Group for sourcing wood and pulp. The plant will operate among the highest productive and energy-efficient in the world and will feed the 40 percent of excess bioelectricity generated on site as “green energy” into the public grid. With this project, Lenzing sets a milestone in its strategy to carbon neutrality.

About the Lenzing Group

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed-loop economy.

Metsä Board to modernise finishing area at Kyro mill

Metsä Board will modernise its board machine finishing area at Kyro mill in Kyroskoski. The rebuild includes a new reeler, winder and renewal of the reel broke handling system. Metsä Board’s Kyro mill produces high quality coated folding boxboard and the new eco-barrier paperboard.

The investment value is EUR 20 million and the new machinery is scheduled to start up during autumn 2021. The annual production capacity of Metsä Board Kyro mill is 190,000 tonnes.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2018, the company’s sales totalled EUR 1.9 billion, and it has approximately 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group is a forerunner in sustainable bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and greaseproof papers.

In 2018, Metsä Group’s sales totalled EUR 5.7 billion, and it employs approximately 9,300 people. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 103,000 Finnish forest owners.

Lenzing leads Canopy ranking for sustainable wood procurement

Sbt.: In its “Hot Button Report”, the Canadian non-profit organization Canopy particularly highlights the innovative strength of the Lenzing Group, its active contribution to forest conservation and high level of transparency.

Lenzing – In the “Hot Button Report” issued by the Canadian non-profit organization Canopy, the Lenzing Group was once again rated number one in the world, thus confirming its role as the sustainability trailblazer in the textile industry. In this widely recognized ranking, Canopy grades the world’s 32 largest producers of wood-based fibers with respect to their success in achieving sustainable wood and pulp sourcing. Wood and the pulp derived from it are the most important raw materials underlying Lenzing’s sustainable production of cellulosic fibers.

“We are extremely proud of this top ranking. It underlines our leading position as a sustainability trailblazer in the manufacturing sector and in the fiber industry in particular. It gives our customers the confidence that we have created the right structures to prevent the sourcing and use of wood from ancient and endangered forests”, says Stefan Doboczky, CEO of the Lenzing Group. “Environmental protection and the prudent use of resources are an integral part of our responsibility to nature and society”, he adds.

Lenzing primarily convinced the non-profit organization Canopy this year thanks to its innovative strength used to promote the circular economy in the textile industry, its active contribution towards protecting the forests and preserving biodiversity as well as its high level of transparency in pulp sourcing.

Lenzing received a total of 26.5 points (up 3.5 points from the previous year) and was thus given the “light to mid green shirt” rating. This means that in using the wood-based cellulosic fibers produced by the Lenzing Group, there is only a very minimal danger that wood is derived from primeval forests and endangered forest areas. In the Wood and Pulp Policy published by Lenzing, the company confirms that it only sources wood and pulp from non-controversial sources.

About the Lenzing Group

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed-loop economy.

Greycon have partnered with Allard Emballages

With their business expanding, Allard Emballages decided it was the opportune moment to implement a planning and MES software to replace their internal customised system. Their older system worked well for them for many years, however, as with many internal systems, they started to experience the downfalls lacking support while the business complexity is changing. With objectives to reduce the risk of technology obsolescence and increase efficiencies, Allard Emballages decided the best solution for their requirements was to implement the Greycon software into their Varennes site.

“I would like to thank the Greycon team for the implementation of our new MES in our Varennes site. During this project, I worked with different Greycon representatives, all of whom had very good sense of customer relationships, good general knowledge about the process, and good expertise of the information systems of a paper mill. I’d like to say a special thank you to Leví, Nicolas and Angelos for visiting our site, I appreciated your skills and kindness throughout the whole process.”

Frédéric Bourge

Project Manager at Allard Emballages

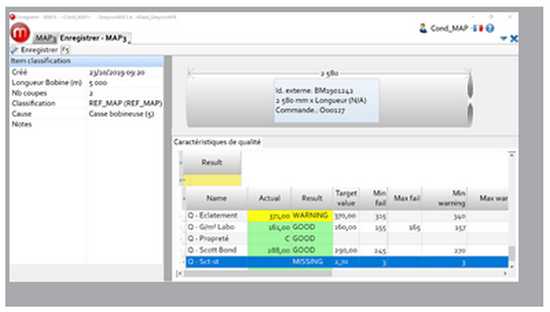

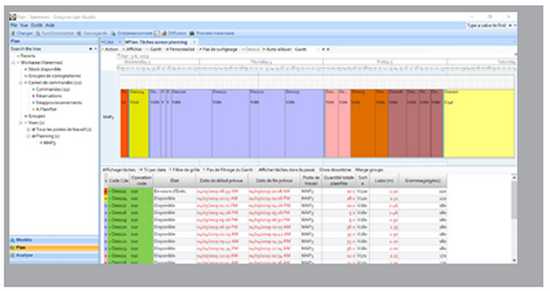

Working closely with Allard Emballages, considering their requirements and necessities, Greycon implemented opt-Studio for order entry, planning and scheduling, and GreyconMill for manufacturing execution. The software included production recording and tracking, quality management, transport planning and shipping, product labelling and reporting with GreyconMill capability to integrate with Microsoft Reporting Services.

GreyconMill Production Tracking and Quality Control

GreyconMill Production Tracking and Quality Control

The project was a great success with a smooth transition from the older in-house MES system to the new one, allowing the Varennes team to continue with their normal operations without issues.

BENEFITS

- Visibility of order flow and status

- Integrated system (covering planning, production, quality, logistics)

- Up-to-date technology & long-term support

opt-Studio Planning

opt-Studio Planning

Voith Group plans takeover of Toscotec S.p.A.

Technology Group Voith is planning on acquiring 90 percent of the shares in Toscotec S.p.A. A corresponding purchase contract was signed on Dec. 20, 2019. Both parties agreed not to disclose the purchase price.

Toscotec S.p.A. is a global supplier of systems, products and services for the paper industry with headquarters in Lucca, Italy. Its focus is on tissue machines for manufacturing sanitary products such as paper towels, paper napkins, or toilet paper. The closing of the transaction is anticipated to occur at the first half of 2020 and is subject to regulatory approvals and meeting of other usual closing conditions.

Toscotec S.p.A. is a global supplier of systems, products and services for the paper industry with headquarters in Lucca, Italy. Its focus is on tissue machines for manufacturing sanitary products such as paper towels, paper napkins, or toilet paper. The closing of the transaction is anticipated to occur at the first half of 2020 and is subject to regulatory approvals and meeting of other usual closing conditions.

“Especially in the tissue range, Toscotec is a highly regarded and established company that strengthens our offering in this important growth area. With this acquisition, Voith can expand its position as a full-line supplier in all areas of the paper industry and gains a tradition-rich, powerful and agile unit,” says Andreas Endters, President & CEO Group Division Voith Paper, explaining the significance of the takeover.

Toscotec S.p.A. has specialized in the manufacturing of machines for the tissue and paper industry since 1948. “The focus of our efforts is on maximum production efficiency, reduced consumption, and the highest quality. We are happy to have gained a renowned partner with Voith that pursues sustainable business activities and a likewise sustainable investment strategy,” emphasizes Alessandro Mennucci, CEO at Toscotec.

The Lucca-based company, with locations in China and the U.S., develops and produces paper machines, systems, and components for the manufacturing of sanitary papers, paper and board. Toscotec S.p.A. supplies its customers with state-of-the-art technologies and services, from the production line through conversions and rebuilds to individual components. Toscotec S.p.A. employs around 200 people and generates a turnover of approximately 100 million euros.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Verso Issues Statement in Response to Atlas and Blue Wolf

Verso Corporation (NYSE: VRS) ("Verso" or the "Company") has just issued the following statement in response to Lapetus Capital II LLC ("Lapetus", and together with its affiliates, "Atlas") and BW Coated LLC ("BW Coated" and together with its affiliates, "Blue Wolf" and, collectively with Atlas, "Atlas and Blue Wolf"):

As Verso has just announced the 2019 annual meeting of stockholders of the Company, previously scheduled for January 21, 2020, has been rescheduled to January 31, 2020 in order to combine the matters to be voted on at the annual meeting with proposals related to the previously announced sale of Verso's Androscoggin and Stevens Point mills to Pixelle Specialty Solutions LLC (the "Pixelle Transaction").

As Verso has just announced the 2019 annual meeting of stockholders of the Company, previously scheduled for January 21, 2020, has been rescheduled to January 31, 2020 in order to combine the matters to be voted on at the annual meeting with proposals related to the previously announced sale of Verso's Androscoggin and Stevens Point mills to Pixelle Specialty Solutions LLC (the "Pixelle Transaction").

Holding a single meeting will make it easier for stockholders to evaluate all proposals, streamline the proxy solicitation process, and if approved, expedite and facilitate the closing of the Pixelle Transaction and accelerate the return to stockholders of at least $225 million of the anticipated net cash proceeds of the Pixelle Transaction.

Earlier this month, Atlas and Blue Wolf communicated to Verso that it was pleased that the Company had put forth the Pixelle Transaction for consideration by stockholders and requested additional disclosure regarding the Pixelle Transaction. Disclosure regarding the Pixelle Transaction, including the anticipated net cash proceeds, has been publicly available in the Company's preliminary proxy statement filed with the Securities and Exchange Commission since December 11, 2019, and can be found on the "Investors" section of Verso's website, http://investor.versoco.com. The definitive proxy statement, when available, can be found online at http://www.proxyvoting.com/VRS.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. A leading North American producer of specialty and graphic papers, packaging and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.