Displaying items by tag: Andritz

ANDRITZ and Mondi discuss major technology trends for the pulp and paper industries

At the beginning of this week, international technology Group ANDRITZ welcomed a delegation of more than 25 experts from different mills and locations of the Mondi Group at its headquarters in Graz to discuss major technology trends and the latest innovations in the pulp and paper industries.

The various presentations given by representatives of ANDRITZ focused on mechanical pulping, stock preparation and recycled fiber systems, paper and board machines, rejects and recycling technologies, fabrics and rolls, and power boilers. ANDRITZ Automation experts demonstrated the capabilities of the Metris UX Digital Solutions by remotely monitoring the ANDRITZ Metris X control system installed at the Mondi paper production mill in Štětí, Czech Republic.

Site visit of Mondi representatives at the stock preparation pilot plant at the ANDRITZ headquarters. © ANDRITZ

Site visit of Mondi representatives at the stock preparation pilot plant at the ANDRITZ headquarters. © ANDRITZ

“It was a very interesting conference with a good mix of well-known proven technologies and latest innovations like the Vertical Screw Thickener, large steel cylinders, smart rolls, and solutions for digitalization. We collected some food for thought, and our teams are looking forward to more detailed technical discussions with ANDRITZ”, commented Lars Mallasch, Mondi Director Technology & Capex Corrugated Packaging.

The two-day event also included a guided workshop tour and a visit to the stock preparation pilot plant to get an impression of ANDRITZ’s manufacturing capabilities and R&D activities. “It was a great honor for ANDRITZ to welcome so many representatives of the Mondi Group here in Graz. This is a further proof of the excellent long-term partnership between the two companies”, said Wolfgang Lashofer, Manager of the Paper, Fiber and Recycling division. “

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ and Mondi discuss major technology trends for the pulp and paper industries

At the beginning of this week, international technology Group ANDRITZ welcomed a delegation of more than 25 experts from different mills and locations of the Mondi Group at its headquarters in Graz to discuss major technology trends and the latest innovations in the pulp and paper industries.

The various presentations given by representatives of ANDRITZ focused on mechanical pulping, stock preparation and recycled fiber systems, paper and board machines, rejects and recycling technologies, fabrics and rolls, and power boilers. ANDRITZ Automation experts demonstrated the capabilities of the Metris UX Digital Solutions by remotely monitoring the ANDRITZ Metris X control system installed at the Mondi paper production mill in Štětí, Czech Republic.

“It was a very interesting conference with a good mix of well-known proven technologies and latest innovations like the Vertical Screw Thickener, large steel cylinders, smart fabrics, and solutions for digitalization. We collected some food for thought, and our teams are looking forward to more detailed technical discussions with ANDRITZ”, commented Lars Mallasch, Mondi Director Technology & Capex Corrugated Packaging.

Site visit of Mondi representatives at the stock preparation pilot plant at the ANDRITZ headquarters. Photo "ANDRITZ"

Site visit of Mondi representatives at the stock preparation pilot plant at the ANDRITZ headquarters. Photo "ANDRITZ"

The two-day event also included a guided workshop tour and a visit to the stock preparation pilot plant to get an impression of ANDRITZ’s manufacturing capabilities and R&D activities. “It was a great honor for ANDRITZ to welcome so many representatives of the Mondi Group here in Graz. This is a further proof of the excellent long-term partnership between the two companies”, said Wolfgang Lashofer, Manager of the Paper, Fiber and Recycling division. “

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,700 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ successfully starts up Europe’s largest MG paper machine at Zellstoff Pöls, Austria

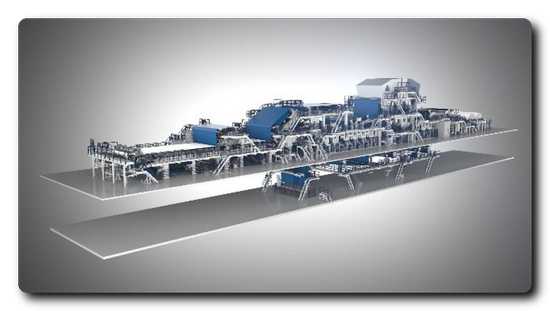

At the end of May 2019, international technology Group ANDRITZ started up the PM3 paper machine for speciality papers supplied to Zellstoff Pöls AG (part of the Heinzel Group), Austria, for the production of bleached kraft paper grades. This start-up took place two weeks before the date scheduled.

The ANDRITZ PrimeLine MG plant produces environmentally friendly MG paper for flexible packaging and release applications at the Pöls location.

With an annual capacity of 100,000 t, a design speed of 1,400 m/min. and a working width of 5.4 m, PM3 is setting a new benchmark in the production of these paper grades. The unique machine design enables the production of grades with low basis weight and highest strength with good printability and smoothness levels.

The PM3 delivered by ANDRITZ produces high-grade paper for flexible packaging and release applications at the Pöls location. © ANDRITZ

The PM3 delivered by ANDRITZ produces high-grade paper for flexible packaging and release applications at the Pöls location. © ANDRITZ

In terms of production and final product quality, PM3 exceeded all expectations right away in the first four weeks after start-up. The design capacity was achieved in stable operation within three months, and the majority of paper grades with basis weights between 22 and 52 g/m² were produced successfully.

The heart of the PrimeLine MG paper machine is the PrimeDry MG Steel Yankee, which is the largest of its kind worldwide with a diameter of 24 feet (7.315 m). ANDRITZ is thus breaking its own world record for size, established in 2013 when PM2 was started up successfully in Pöls with a 22-foot Yankee.

ANDRITZ supplied all process technologies, including the stock preparation line and approach flow system. One of the key components is the new ANDRITZ Vertical Screw Thickener (VST), which dewaters the pulp efficiently from a consistency at inlet of 3% to between 25 and 30% at the outlet.

Jürgen Rieger, Production Manager at Zellstoff Pöls AG, confirms, “We were very impressed with start-up and the first few months in operation that followed, just as we were with start-up of PM2 by ANDRITZ in 2013. Commencing operations ahead of schedule with a plant of this complexity is really exceptional.” Siegfried Gruber, overall Project Manager for PM3 adds: “Collaboration with the team from ANDRITZ was excellent, and this was also reflected in the outstanding PM3 start-up curve.”

Besides full responsibility for the technology, the ANDRITZ scope of supply also included the automation equipment, all process pumps, an extensive range of services, and the entire basic and detail engineering.

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, approximately 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

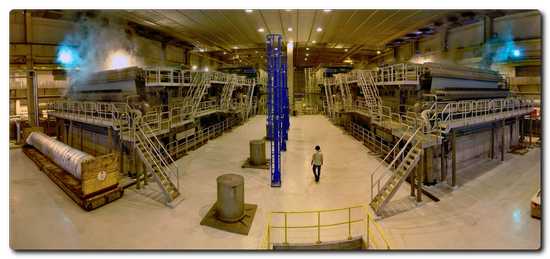

ANDRITZ technologies achieve production record at Eldorado Brasil

The Eldorado Brasil pulp mill in Três Lagoas, Brazil, set an outstanding production record of 5,576 ADmt/d on September 21, 2019, with ANDRITZ technologies. In addition, production has been running for the past 200 consecutive days without a sheet break on the MS2 line.

ANDRITZ pulp drying line © ANDRITZ

ANDRITZ pulp drying line © ANDRITZ

The mill was started up successfully at the end of 2012 and has achieved several production records since then. Metris OPP, which is part of ANDRITZ’s digital solutions, has been supporting Eldorado Brasil to reach these excellent results. ANDRITZ delivered the woodyard, complete fiberline, white liquor plant, and the new generation of pulp drying plants to Eldorado, including two parallel Twin Wire Former pulp machines, two airborne dryers, two cutter-layboys with 6,670 m working width, and four bale finishing lines.

These outstanding results are based on the combination of strong customer and supplier partnership, technology, and excellent planning and implementation.

Eldorado Brasil’s greenfield pulp mill achieves annual production of around 1.8 million mt of dried, bleached eucalyptus market pulp.

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, approximately 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

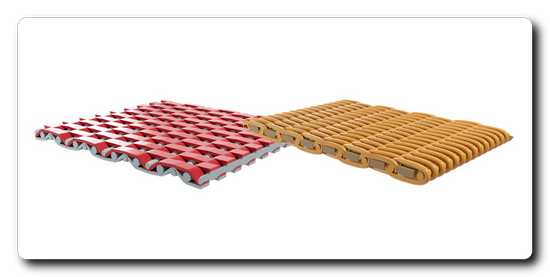

ANDRITZ launches MasterDry dryer fabric portfolio

International technology Group ANDRITZ presents its new “MasterDry™” dryer fabric portfolio based on premium-performance dryer fabric technology.

- World-class performance woven and spiral fabric technology

- For all applications including high-temperature and contamination-prone positions with improved sheet quality and long life

- Best-in-class seam technology for fast installation

- Modernized and expanded global manufacturing capabilities

MasterDry includes best-in-class woven and spiral fabrics specifically designed for the broadest range of applications, from the fastest low-caliper, single-tier positions, for high-temperature positions, and for those positions requiring extreme contamination resistance. It includes specially engineered woven or spiral dryer fabrics to cover an entire paper machine producing paperboard/packaging and graphical papers or also pulp machines, thus providing customers with a very comprehensive suite of high-performance dryer fabric options.

MasterDry offers a complete portfolio of high-quality woven and spiral dryer fabric technology for every application in paperboard/packaging, graphical, and pulp machines. © ANDRITZ

MasterDry offers a complete portfolio of high-quality woven and spiral dryer fabric technology for every application in paperboard/packaging, graphical, and pulp machines. © ANDRITZ

“We will continue to focus on R&D to launch new innovative products and to invest in our plants to become the premier global supplier of the highest quality dryer fabric technology with shortest delivery times,“ says Bill Butterfield, Executive Vice President and Chief Technology Officer at ANDRITZ Fabrics and Rolls.

With the new MasterDry portfolio of dryer fabrics, ANDRITZ once again confirms its position as one of the global market leaders for the supply of innovative fabrics, press felts, and roll technology solutions.

For more information, please visit andritz.com/fabrics-and-rolls.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

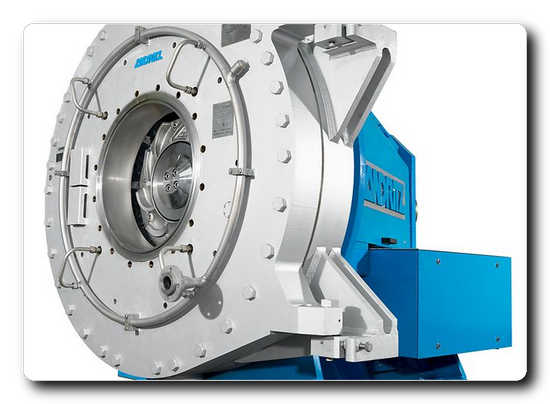

ANDRITZ to supply P-RC APMP fiberline to Dezhou Taiding, China

International technology Group ANDRITZ has received an order from Dezhou Taiding New Material Science and Technology Co., Ltd. (Dezhou Taiding) to supply a P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) fiberline with a capacity of 400 t/d to the mill in Dezhou, Shandong, China.

The new system will process poplar as raw material, and the fiber produced will be used on the company’s own paper machines for P&W (printing and writing paper) and board grades. Start-up is scheduled for the third quarter of 2020.

ANDRITZ’s scope of supply includes the key components for the entire mechanical fiberline, ranging from chip washing to the reject treatment system. Engineering, training, supervision of the mechanical installation, commissioning and start-up are also part of ANDRITZ’s scope.

ANDRITZ single-disc refiner S2070 © ANDRITZ

ANDRITZ single-disc refiner S2070 © ANDRITZ

The ANDRITZ MSD 400 Impressafiner ensures a high degree of chip delamination and thus contributes to uniform bulk density and optimal removal of moisture and extractives. The excellent material maceration and partial fiber delamination results in superior preconditions for chip impregnation, enabling maximum uptake of chemicals.

Pre-bleaching of chips as well as high-consistency refining by the ANDRITZ single-disc refiner S2070 will significantly improve pulp quality and keep the amount of shives as low as possible. The S2070 operates with a narrow and stable refining gap, which is especially important when producing P&W and board grades because enhanced fiber surface and efficient fibrillation have a considerable impact on fiber bonding. The swing-door refiner design ensures fast and easy change of refiner plates to save maintenance costs.

Numerous successful references for the ANDRITZ P-RC APMP systems worldwide were decisive in Dezhou Taiding placing the order with ANDRITZ.

Dezhou Taiding New Material Science and Technology Co., Ltd. was founded in 1998 and today is a joint-stock company serving the pulp production, papermaking and thermo-electricity business. It is one of the important players in the paper industry in the Shandong region, China.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ Brasil wins ABTCP 2019 awards

ANDRITZ Brasil Ltda., part of international technology Group ANDRITZ, has received the best manufacturer award in two categories of this year’s ABTCP “Best of of the Pulp & Paper Industry Award”:

- Machines and equipment for pulp production (for the fifth consecutive year)

- Equipment and systems for liquor recovery and energy generation (for the second consecutive year)

These awards, which are considered as the most important in the South American pulp and paper sector, are based on expert assessments as well as on votes by customers, suppliers and other stakeholders in the Brazilian pulp and paper industry.

Every year, ABTCP (Associação Brasileira Técnica de Celulose e Papel – the Brazilian Pulp and Paper Technical Association) honors companies that have contributed substantially to technological developments in the pulp and paper industry and thus to increasing productivity and competitiveness in this sector.

ANDRITZ Brasil has 400 employees located in Curitiba, Araucária, Belo Horizonte and Serra and is the ANDRITZ GROUP’s “South American hub”, with focus on pulp and paper technologies and services. Over the past ten years, ANDRITZ has obtained a leading position in the Brazilian pulp market due the continuous technological developments, improved workflows and a dedicated local organization that has enabled on-time deliveries and shown extraordinary performance in project execution. The ANDRITZ GROUP has around 2,850 employees in Brazil.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, approximately 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply three paper machine approach flow systems to Hamburger Rieger in Germany

International technology Group ANDRITZ has received an order from Hamburger Rieger GmbH, Papierfabrik Spremberg, to supply three paper machine approach flow systems as well as broke screening for the new greenfield production line PM2 in Spremberg, Germany. Start-up is scheduled for mid-2020.

The paper machine, with a total capacity of 500,000 tons per year, will produce both brown and white top test liner. The PMA systems for the top and back layers will be equipped with ANDRITZ ShortFlow Deaeration systems, comprising deaerators, the corresponding vacuum pumps, as well as the proven ModuScreen HBE screens for stock and dilution water screening. The patented ShortFlow Deaeration system enables effective air removal with partial deaeration. In comparison with conventional deaeration concepts on the market, ShortFlow Deaeration has an extremely small footprint.

ANDRITZ ModuScreen HBE screen © ANDRITZ

ANDRITZ ModuScreen HBE screen © ANDRITZ

The third PMA system will supply the back layer headbox with white water for cross-profile control. A two-stage broke screening system completes the scope of supply.

Hamburger Rieger is part of the Hamburger Containerboard Division of the Austrian Prinzhorn Group. The RiegerLiner, RiegerTop and SpreeWhite product lines have made the company the market leader in the white-covered corrugated board sector. Producing two million tons in seven plants, Hamburger Containerboard is one of the leading producers of high-quality corrugated board in Europe.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

ANDRITZ stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,600 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ successfully starts up rebuilt paper machine at PJSC Kyiv Cardboard and Paper Mill, Ukraine

International technology Group ANDRITZ has successfully started up the rebuilt BM1 for PJSC Kyiv Cardboard and Paper Mill at their site in Obukhiv, Ukraine.

The rebuild of the packaging paper machine covered the upgrade of the press and calender sections, including extensions to the existing automation system. To improve the machine’s capacity and the surface quality of the paper, ANDRITZ relocated the existing press from the second to the third press position and installed a new PrimePress X shoe press in the second position. Due to its special shoe design, the PrimePress X enables gentle dewatering and reduced energy consumption. In the calender section, a new PrimeCal Hard hard-nip calender was installed to provide a consistent CD caliper profile, bulk control, and excellent surface finish.

ANDRITZ PrimePress X shoe press for gentle dewatering and bulk savings. © ANDRITZ

ANDRITZ PrimePress X shoe press for gentle dewatering and bulk savings. © ANDRITZ

The BM1 has a design speed of 800 m/min and a working width of 4.2 m. It produces White Top Liner, White Lined Chipboard, and Testliner in a range of 125–420 gsm. Start-up of the rebuilt BM1 ran smoothly according to schedule and achieved the promised guarantee values for dryness, bulk and smoothness right away.

PJSC Kyiv Cardboard and Paper Mill, part of the Austrian Pulp Mill Holding, is one of the largest European cardboard and paper producers. The main raw material used for production at Obukhiv is recycled paper.

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue.

The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge.

The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ launches new StrataPress SX single-seam press felt technology

International technology Group ANDRITZ has launched its new-generation “StrataPress™ SX” felt with integrated single-seam technology.

- Integrated seam for faster and safer installation

- Most efficient water removal for reduced energy consumption

- Available with exclusive “QS” technology for superior sheet smoothness

- Enhanced seam flap integrity for longer lifetime

StrataPress SX is specifically engineered for the most demanding positions in paperboard/packaging, graphical, and pulp machines. Its integrated seam ensures strength and durability while delivering rapid and safe installation.

It is specially designed with a game-changing combination of materials, base fabric structures and unique batt concepts that deliver the highest sheet quality, faster machine speeds, reduced energy consumption, and extended life potential.

StrataPress SX is specifically engineered for the most demanding positions in paperboard/packaging, graphical, and pulp machines © ANDRITZ

StrataPress SX is specifically engineered for the most demanding positions in paperboard/packaging, graphical, and pulp machines © ANDRITZ

“With StrataPress SX, for the first time in our industry, customers can now enjoy the convenience and safety of seam felts along with the superior machine performance previously only available from premium-class endless press felts. And with its unique compressibility and nip dampening characteristics, StrataPress SX provides that superior dewatering performance even in the hardest press nip applications, and with reduced operating costs,” says Bill Butterfield, Executive Vice President and Chief Technology Officer at ANDRITZ Fabrics and Rolls.

STRATAPRESS SX – THREE PRODUCT CLASSES

As StrataPress SX technology is built utilizing three distinct warp systems, there is an exact product specification specially engineered to maximize machine performance for graphical, board and packaging, and pulp grades.

StrataPress SX is also available with ANDRITZ’s exclusive “QS” Quick Saturation technology. Hydrophilic components embedded in the base fabric structure ensure optimized water management to provide improved start-up behavior, enhanced profiles and better NIP dewatering over the entire service lifetime.

With the new StrataPress SX technology, ANDRITZ once again confirms its position as one of the global market leaders for the supply of innovative fabrics, press felts, and roll technology solutions.

For more information, please visit andritz.com/fabrics-and-rolls.