Displaying items by tag: Andritz

ANDRITZ completes the world’s largest P-RC APMP production system at Jiangsu Bohui Paper Industry, China

International technology Group ANDRITZ has received the Final Acceptance Certificate from Jiangsu Bohui Paper Industry Co., Ltd in Yancheng, Dafeng, China, for its chemi-thermo-mechanical pulping system. With a total capacity of 2,250 admt/d, this system is the largest worldwide.

ANDRITZ installed its well-proven P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) technology to ensure optimum pulp quality in terms of high bulk and low shive content at lowest energy consumption and highest availability. The system processes eucalyptus wood chips for the production of folding boxboard (specifically coated ivory board), and consists of the world’s largest single P-RC APMP fiberline with a capacity of 1,500 admt/d and a second fiberline with a capacity of 750 admt/d.

The ANDRITZ TX68 refiner with an advanced feeding system is the centerpiece of the process and the latest innovation in high-consistency (HC) refining. The new feeding system combines the proven concepts of ANDRITZ’s Side Entry Plug Feeder (SEPF) with a Constant Feeder (C-Feeder) on each side of the twin refiner. The “DoubleSEPF” feed system ensures constant chip feeding and excellent steam control thanks to the exact and adjustable split of incoming wood chips and thus by far exceeds the capacities so far achieved with a single HC refiner.

ANDRITZ TX68 refiner with newly developed feeding system. Photo: ANDRITZ

ANDRITZ TX68 refiner with newly developed feeding system. Photo: ANDRITZ

ANDRITZ also supplied basic engineering, supervision of mechanical installation, training, commissioning and start-up services. The latest ANDRITZ Metris IIoT technologies feature a connection to the ANDRITZ DCS system to collect and analyze statistical mill data for continuous optimization of both fiberlines.

Jin Xiaoshan, Production Manager at Jiangsu Bohui Paper Industry confirms: “The Final Acceptance Certificate was achieved in superior cooperation, even in the challenging situation of Covid-19. Our ANDRITZ key contacts in Europe provided professional and efficient remote support. At the same time, we were able to count on highly committed and experienced engineers from ANDRITZ China on site. We are very proud of our folding boxboard production line with its P-RC APMP fiberlines and the excellent performance already achieved.”

Jiangsu Bohui Paper Industry Co., Ltd. is a subsidiary of Shandong Bohui Paper Industrial Co., Ltd., a listed company established in 1994 that focuses on the production of ivory board, culture paper, linerboard, paper for gypsum plasterboard, and market pulp for the papermaking industry.

ANDRITZ to supply pulp production technologies and key process equipment for Sun Paper’s new mill in Beihai, China

International technology group ANDRITZ has received an order from Sun Paper to supply pulp dewatering and white liquor plant technologies and key process equipment for their new pulp mill in Beihai, China.

Start-up is scheduled for the fourth quarter of 2021.

ANDRITZ Twin Wire Press for pulp dewatering © ANDRITZ

ANDRITZ Twin Wire Press for pulp dewatering © ANDRITZ

The scope of supply on EPS basis includes the following equipment:

- Wet lap system with two production lines for a capacity of 1,120 admt/d bleached hardwood kraft pulp, each consisting of a Twin Wire Press for pulp dewatering, a cutter-layboy and a baling line.

The proven ANDRITZ wet lap technology ensures high operational availability and higher final dryness than other wet lap systems in the market. Wet lap is flexible with regard to the pulp type, with the option of producing also other pulp grades if needed. The wet lap system supplied by ANDRITZ will have the highest capacity ever installed in China.

ANDRITZ LimeKiln started up in 2015 at Shandong Sun Honghe mill in Zhoucheng, China. © ANDRITZ

ANDRITZ LimeKiln started up in 2015 at Shandong Sun Honghe mill in Zhoucheng, China. © ANDRITZ

- White liquor plant with a capacity of 10,500 m3/d and comprising major recausticizing equipment and an ANDRITZ LimeKiln. The recausticizing plant delivery includes a LimeSlake slaker-classifier, three causticizing tank agitators, white liquor filtration with a LimeWhite filter to maximize the white liquor quality, and efficient lime mud filtration with a LimeDry filter ensuring high lime mud dryness, which results in low heat consumption in the kiln. The new ANDRITZ LimeKiln, with a capacity of 950 t/d, has a multifuel burner and a high-efficiency LimeCool sector cooler.

This is the third ANDRITZ white liquor plant delivery to Sun Paper, China and underlines ANDRITZ’s strong competitive position for white liquor plants in China.

ANDRITZ has delivered several ARC systems for the removal of chlorides and potassium from the kraft chemical recovery cycle. © ANDRITZ Evaporation plant with a high-concentration section for a total evaporation capacity of 1,100 t/h and a final dry solids content of 85%. The evaporation plant delivery includes key equipment and technology with ANDRITZ multiple-effect lamella evaporators. The design of the evaporators and process reflects the latest and most modern ANDRITZ evaporator technology and delivers excellent environmental and economic performance.

ANDRITZ has delivered several ARC systems for the removal of chlorides and potassium from the kraft chemical recovery cycle. © ANDRITZ Evaporation plant with a high-concentration section for a total evaporation capacity of 1,100 t/h and a final dry solids content of 85%. The evaporation plant delivery includes key equipment and technology with ANDRITZ multiple-effect lamella evaporators. The design of the evaporators and process reflects the latest and most modern ANDRITZ evaporator technology and delivers excellent environmental and economic performance.

- Ash re-crystallization (ARC) system, with an ash handling capacity of 400 t/d, to treat the ash from the electrostatic precipitator by decreasing the chloride and potassium content while recovering sodium and sulfate. The ANDRITZ ARC process is based on evaporative crystallization by using economical mechanical vapor recompression (MVR) technology as the heat source.

This order once again confirms the excellent business relationship between ANDRITZ and Sun Paper.

In July 2019, Sun Paper established a wholly owned subsidiary – Guangxi Sun Paper – to build an integrated pulp and paper mill in Beihai. The new greenfield mill in Beihai will eventually have a total pulp and paper capacity of 3.5 million tons annually. The mill will be constructed in two phases over approximately five years.

ANDRITZ to supply a PrimeLineCOMPACT S 1300 tissue machine to Xuong Giang Paper Mill, Vietnam

International technology group ANDRITZ has received an order to supply a complete PrimeLineCOMPACT S 1300 tissue machine with stock preparation system to Xuong Giang Paper Mill, Vietnam, a subsidiary company of Bac Giang Import Export JSC.

The new line has a design capacity of 54 tons/d, a design speed of 1,300 m/min and a paper width of 2.85 meters. It will process virgin pulp as raw material to produce high-quality facial and toilet tissue as well as napkins. Start-up is scheduled for the fourth quarter of 2020.

The stock preparation plant is split into separate short fiber and long fiber systems and also includes the approach flow system, fiber recovery and broke handling equipment, and pumps.

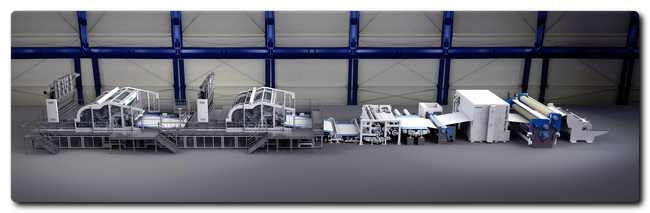

ANDRITZ PrimeLineCOMPACT S 1300 tissue machine © ANDRITZ

ANDRITZ PrimeLineCOMPACT S 1300 tissue machine © ANDRITZ

The tissue machine has a 12-ft. PrimeDry Steel Yankee, equipped with a steam-heated hood to ensure highly efficient drying and substantial energy cost savings compared to operations with a cast iron Yankee and gas-heated hood. The Yankee will be manufactured at the ANDRITZ Steel Yankee Business Center located in Foshan, China.

ANDRITZ will also supply a tailored automation system, including PrimeControl MCS (Machine Control System), DCS (Distributed Control System) and MMD (Multi-Motor Drive) as well as the complete LV MCC (Low-Voltage Motor Control Center). Detailed engineering, erection work supervision and commissioning services for the high-performance production process complete the scope of supply.

Excellent performance by ANDRITZ equipment already operating at the mill, successful cooperation during previous projects and responsive service capabilities were the decisive criteria for Xuong Giang Paper Mill to choose ANDRITZ as its partner once again. This ANDRITZ PrimeLineCOMPACT S 1300 is the third tissue machine to be supplied by ANDRITZ to the Vietnamese market in recent years.

ANDRITZ to supply complete stock preparation line to Kookil Paper, China

International technology Group ANDRITZ has received an order from Kookil Paper (Zhangjiagang) Limited Corporation to supply a complete 305 bdmt/d stock preparation line including approach flow system, broke handling and fiber recovery to the mill in Zhangjiagang, Jiangsu Province, China.

Start-up is scheduled for the first quarter of 2021.

The new line will process NBKP (Needle Bleached Kraft Pulp) and LBKP (Leaf Bleached Kraft Pulp) market pulp bales to produce specialty paper for food packaging as well as photo and special printing paper.

ANDRITZ ModuScreen HBE screen © ANDRITZ

ANDRITZ ModuScreen HBE screen © ANDRITZ

The market pulp bales are dissolved in ANDRITZ FibreSolve FSV pulpers, which enable highly efficient slushing at low specific energy consumption. The innovative rotor design ensures optimum impact effect of the rotor and intensive friction within the pulp itself, however without damaging the fibers. Four ANDRITZ TwinFlo double disc refiners achieve superior fiber properties with regard to fiber length and fibrillation.

The approach flow system allows fast grade changes and will be equipped with an ANDRITZ ShortFlow deaeration system, comprising four proven ModuScreen HBE headbox screens for stock and dilution water screening, a WW Deaerator for efficient air removal as well as a vacuum pump. The ShortFlow deaeration system has an extremely small footprint and makes a significant contribution towards lower energy and investment costs.

The broke handling and a DiscFilter Saveall fiber recovery system complete the scope of supply.

Established in 2003, Kookil Paper is an important South Korean paper manufacturer producing in China and specializing in the production of different types of specialty papers.

ANDRITZ to supply gasification plant and biomass handling line to Klabin’s Puma II project in Brazil

International technology group ANDRITZ has received an order from Klabin for a complete biomass gasification plant and a new biomass handling line for their Ortigueira mill in Brazil.

The scope of supply includes a 51 MW gasification plant, a belt dryer, a multi-fuel lime kiln burner and biomass handling equipment with auxiliaries. By replacing 100% of the heavy fuel oil currently burned in one of the mill’s lime kilns, the ANDRITZ gasification plant will significantly reduce the mill’s carbon footprint. The current lime kiln production will remain at 650 tons of reburnt lime per day.

Biomass gasification with product gas feeding a multi-fuel lime kiln burner (typical plant) © ANDRITZ

Biomass gasification with product gas feeding a multi-fuel lime kiln burner (typical plant) © ANDRITZ

ANDRITZ was one of the main suppliers of major process technologies and equipment areas to the Puma II project, and also supplied major technologies and equipment to Klabin’s Puma I project, which was started up successfully in 2016.

In the gasification sector, ANDRITZ offers advanced and state-of-the-art technologies, combining high efficiency with quality gas output for the replacement of fossil fuels.

ANDRITZ to supply new dewatering technology for RMP process to Mayr-Melnhof Karton, Austria

International technology Group ANDRITZ has received an order from Mayr-Melnhof Karton to supply a Vertical Screw Thickener (VST) dewatering system for the RMP (Refiner Mechanical Pulp) process at the mill in Frohnleiten, Austria.

Start-up is scheduled for the fourth quarter of 2020.

ANDRITZ Vertical Screw Thickener © ANDRITZ ANDRITZ will install its latest dewatering technology – the Vertical Screw Thickener (VST), an innovative screw press with a vertical design. The pulp is fed in from the top and then compressed and dewatered as it moves downwards. The self-filling and gravity-assisted dewatering principle allows higher throughput and pulp dryness because the available screen area is fully used.

ANDRITZ Vertical Screw Thickener © ANDRITZ ANDRITZ will install its latest dewatering technology – the Vertical Screw Thickener (VST), an innovative screw press with a vertical design. The pulp is fed in from the top and then compressed and dewatered as it moves downwards. The self-filling and gravity-assisted dewatering principle allows higher throughput and pulp dryness because the available screen area is fully used.

The new ANDRITZ system also comprises a dilution conveyor, MC pump including standpipe and a TurboMix agitator. Automation, instrumentation, engineering, mechanical installation, commissioning and start-up supervision are also part of the scope of supply.

At the Frohnleiten Mill, the RMP with Freeness of 350 ml is dewatered from an inlet consistency of 3.5% to 25% consistency at the discharge in one innovative unit. The pulp is then stored at a consistency of 10% in a new pulp storage tower that feeds the existing board machines.

The existing RMP system was supplied by ANDRITZ in 1996 and processes a mixture of wood chips containing spruce, larch and fir as raw material for the mill’s own board machines producing CRB (Coated Recycled Board).

Mayr-Melnhof Karton is the world’s leading producer of coated recycled cartonboard.

ANDRITZ to supply high-speed spunlace line to Karweb Nonwovens, Turkey

International technology Group ANDRITZ has received an order from Karweb Nonwovens to supply a complete neXline spunlace line for its plant located in Gaziantep, Turkey.

The line is scheduled for installation and start-up at the beginning of 2021.

ANDRITZ neXline spunlace eXcelle line © ANDRITZ

ANDRITZ neXline spunlace eXcelle line © ANDRITZ

This new neXline spunlace eXcelle line is dedicated to the production of viscose and polyester wipes as well as biodegradable wipes. The production capacity can be up to 18,000 t/a.

ANDRITZ will provide a full line with state-of-the-art equipment – from web forming to drying. The scope of supply includes the complete opening and blending machinery, two inline high-speed TT cards, a proven JetlaceEssentiel unit (including a water filtration unit) for hydroentanglement, a neXdry through-air dryer, and a neXecodry S1 system for energy saving.

This order confirms the strong and successful relationship between ANDRITZ and Karweb Nonwovens. In 2017, ANDRITZ supplied a spunlace line to Karweb for production of roll-goods made from several types of fibers, such as polyester, viscose, Tencel, cotton and polyamide.

Karweb Nonwovens spunlace line © ANDRITZ

Karweb Nonwovens spunlace line © ANDRITZ

Karweb Nonwovens, founded in 2013, is a division of Kara Holding and the first and only Turkish manufacturer of airlaid products for health care, hygiene and special disposable materials. The company serves customers worldwide.

ANDRITZ GROUP International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 29,500 employees and more than 280 locations in over 40 countries.

ANDRITZ successfully starts up the world’s first fossil-free biomethanol plant at Södra, Sweden

International technology group ANDRITZ has recently started up the world’s first biomethanol plant using ANDRITZ’s self-developed A-Recovery+ concept at the Södra Cell Mönsterås pulp mill in southeastern Sweden.

The plant has an annual production capacity of 6.3 million liters of biomethanol from forest biomass. The fossil-free biomethanol can be used for applications in the pulp mill itself, or as a substitute for fossil-based methanol in the transport sector (biodiesel) and as a chemical base substance. The ANDRITZ delivery to Södra included proprietary process design and full EPC delivery, excluding automation, instrumentation, electrification and civil works.

Biomethanol plant (3D image) © ANDRITZ

Biomethanol plant (3D image) © ANDRITZ

The A-Recovery+ concept from ANDRITZ delivers commercial grade biomethanol by using a patented extraction process. It offers next-generation solutions for the chemical recovery cycle of pulp mills, with the target of utilizing the pulp mill side streams to the maximum extent possible. In addition to biomethanol production, A-Recovery+ also produces sulfuric acid from odorous gases and recovers lignin for the production of high-quality lignin to be used in advanced bioproducts.

With this first ever fossil-free biomethanol plant worldwide, ANDRITZ is strongly supporting Södra’s ambitions to make its operations entirely fossil-free and be climate-positive by the end of this decade. To achieve this aim, Södra is aiming at eliminating fossil fuel use throughout its operations and producing innovative products that replace fossil-based raw materials.

Important information for the 113th Annual General Meeting of ANDRITZ AG - Precautions due to coronavirus

The Austrian government has adopted further measures to stop the coronavirus from spreading. These measures also affect the Annual General Meeting of ANDRITZ AG on March 25, 2020.

From today’s perspective, it will not be possible, according to the new regulations, to hold an Annual General Meeting if more than 100 people attend.

The Executive Board will make every effort to hold the Annual General Meeting on March 25, 2020, subject to any further measures and restrictions imposed by the authorities, also because a dividend can only be paid to the shareholders if the Annual General Meeting adopts a resolution to this effect.

However, the shareholders’ health must be our highest priority. That is why we recommend the shareholders of ANDRITZ AG to designate Dr. Michael Knap as voting proxy, bound by instructions, instead of personally attending the Annual General Meeting. A special proxy form can be downloaded below.

In addition, shareholders can contact Dr. Michael Knap directly c/o IVA – Interessensverband der Anleger, Feldmühlgasse 22, 1130 Wien, or by e-mail to: This email address is being protected from spambots. You need JavaScript enabled to view it..

Unfortunately, we cannot allow any guests to attend either. The traditional buffet after the Annual General Meeting has been canceled. If necessary, we will also make arrangements to keep the number of persons in any one room to the limit permitted.

We kindly ask for your understanding concerning these precautions in the interests of our shareholders’ safety and of holding the Annual General Meeting on March 25, 2020 in accordance with the restrictions applied by the Austrian government.

Depending on how the situation develops, ANDRITZ AG also reserves the right to implement further security measures in coordination with the authorities and to cancel the Annual General Meeting at short notice.

The ANDRITZ AG Executive Board kindly asks for your understanding concerning these measures and repeats its request not to attend the Annual General Meeting personally and to make use of a voting proxy instead.

Below you can download important information:

- ENCLOSURES OF ITEM 1 OF THE AGENDA:

- Annual financial report 2019

- Financial statement of ANDRITZ AG 2019 (German only)

- Corporate Governance report 2019

- Proposal for the use of the net earnings

- Report of the Supervisory Board - ENCLOSURES OF ITEM 7 OF THE AGENDA:

- Wolfgang BERNHARD: Declaration pursuant to § 87 (2) AktG & Curriculum vitae

- Overview Supervisory Board meetings and Committee meetings 2019

- ENCLOSURE OF ITEM 8 OF THE AGENDA:

- Remuneration policy of ANDRITZ AG

- Supplement to the ANDRITZ remuneration policy

- ENCLOSURES OF ITEM 9 OF THE AGENDA:

- ANDRITZ Stock Option Program 2020

- Explanations and comments on the ANDRITZ 2020 Stock Option Program

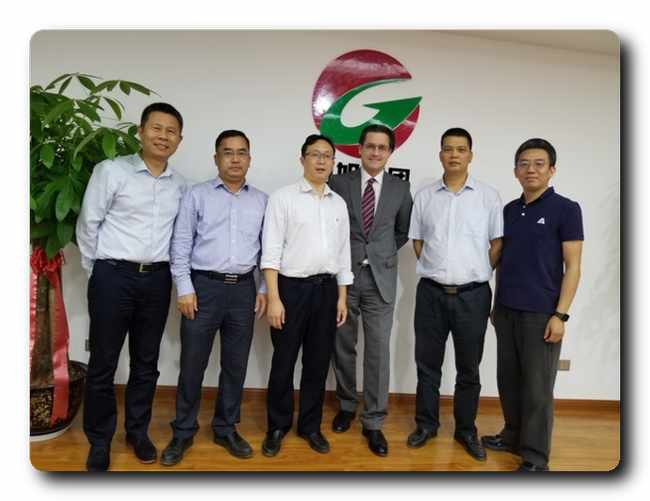

ANDRITZ to supply largest pressurized refining system to China

International technology Group ANDRITZ has received an order from Guangxi Guoxu Group Co., Ltd. to supply a pressurized refining system for their MDF production line in Wuzhou City, Guangxi Province. This will be the largest system ever installed in China, with a capacity of 45 bdmt/h and including an S2064M refiner. Start-up of the equipment is scheduled for the end of 2020.

The proven ANDRITZ equipment will process 60% eucalyptus and 40% pine and hardwood as raw materials. Its state-of-the-art design ensures best fiber quality at very low energy demand. The ANDRITZ refiner supplied is characterized by its long-lasting and proven bearing design, with many successful references around the globe.

Group photo (from left to right): Hao Zhifeng, Senior Sales Manager, ANDRITZ; Li Yongqiang, Vice General Manager, Guoxu Group; Li Xiaobo, General Manager, Guoxu Group; Michael Rupp, Vice President Panelboard, ANDRITZ; Liang Jiepei, Vice General Manager, Guoxu Group; Chen Zhuo, Sales Manager, ANDRITZ Photo: ANDRITZ

Group photo (from left to right): Hao Zhifeng, Senior Sales Manager, ANDRITZ; Li Yongqiang, Vice General Manager, Guoxu Group; Li Xiaobo, General Manager, Guoxu Group; Michael Rupp, Vice President Panelboard, ANDRITZ; Liang Jiepei, Vice General Manager, Guoxu Group; Chen Zhuo, Sales Manager, ANDRITZ Photo: ANDRITZ

The exceptional technological solutions proposed by ANDRITZ as well as the well-established service availability of ANDRITZ in China, with a service and spare part hub located in Foshan, were key in awarding the order to ANDRITZ.

“This project aims at the high-end fiberboard market, which requires excellent fiber quality. ANDRITZ has a globally leading position in fiber preparation and a strong market share. In this project, ANDRITZ introduced the advanced concept of pulping and papermaking into fiber preparation, and we believe that it will take the industry to a higher level in fiber quality and energy savings. We hope to work closely with ANDRITZ to become the benchmark in the industry and provide society with high-end fiberboard products,” says Li Xiaobo, General Manager of the Gouxu Group. “ANDRITZ refiners have a high market share in the world’s wood-based panel industry. We trust in their technology, products and services,” adds Vice General Manager Li Yongqiang.

This order once more demonstrates ANDRITZ’s strong position in the Chinese panelboard industry, with more than 170 references.

The Guoxu Group, headquartered in Nanning, is one of the largest wood-based panel industry groups in China, integrating R&D, production and sales of wood-based panels, and operates seven production sites in China.