Displaying items by tag: Andritz

ANDRITZ to supply upgrade to the world’s largest BCTMP system for P&W grades at Shandong Huatai Paper, China

International technology Group ANDRITZ has received an order from Shandong Huatai Paper Industry Shareholding to upgrade an existing BCTMP (bleached chemi-thermo-mechanical pulp) plant to become the world’s largest mechanical pulping line for P&W (Printing & Writing) paper production at the mill in Dongying, Shandong province, China. Start-up is scheduled for the fourth quarter of 2022.

The existing BCTMP line will be upgraded and rebuilt to become a state-of-the-art P-RC APMP- (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) system. The fiberline’s production capacity for mechanical pulp to make P&W paper grades will thus be increased from 100,000 to at least 300,000 admt/a, making it the largest in the world.

ANDRITZ will rebuild two existing high-consistency (HC) refiners as well as the existing screw presses, disc filters and screens, and supply new equipment for all other process steps. The upgrade project features the following technological highlights:

- New MSD Impressafiner with the latest IIoT features for optimum wood chip maceration and chemical impregnation

- New Side-Entry Plug Feeder (SEPF) feeding system for constant and efficient HC refiner feeding

- Rebuild of the existing HC refiners, including the Hydraulic Commander, to enable fully autonomous monitoring and control

- New DCS system as a future-oriented control system for the new fiberline

The upgraded mechanical pulping line will process a mixture of eucalyptus, poplar and acacia wood chips. The scope of supply also includes the basic engineering as well as the supervision of mechanical installation, commissioning and start-up.

ANDRITZ MSD Impressafiner for optimum chip pretreatment prior to HC refining “Photo: ANDRITZ”.

ANDRITZ MSD Impressafiner for optimum chip pretreatment prior to HC refining “Photo: ANDRITZ”.

Wang Hairong, Project Director of Shandong Huatai Paper Industry Shareholding says: “ANDRITZ offered a very convincing overall concept to boost our fiber quality and production capacity. With the new line we will also gain high flexibility in production – this exactly meets our needs.“

Shandong Huatai Paper Industry Shareholding is part of the Huatai Group, a company listed on the Shanghai Stock Exchange and an important global player in the paper and chemicals production sectors. The group is the world’s largest producer of newsprint and the largest producer in the chlorine-alkali industry in China. Besides this, the group makes all sorts of P&W paper, tissue and specialty paper grades. The Huatai Group produces three million tons of paper and board as well as two million tons of chemicals per year.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ introduces CircleToZero® – paving the way towards pulp production with zero emissions and zero waste

International technology Group ANDRITZ has launched CircleToZero®, a holistic program for the pulp-producing industry with the goal of providing strong support to customers in their efforts to achieve maximum, sustainable production, aiming at zero emissions and zero waste production. Pairing in-house innovations with ANDRITZ’s proven and state-of-the-art technologies, CircleToZero will enable the pulp-producing industry to either eliminate or make use of side streams in pulp production and convert by-products into new added-value products.

The ANDRITZ A-Recovery+ program already established is a major part of CircleToZero®. It unleashes the economic potential of the many traditionally unused side streams found in the recovery island of chemical pulp mills. These include purifying raw methanol into commercial quality bio-methanol for instance, on-site production of sulfuric acid, and recovery of kraft lignin. With this newly developed technology, ANDRITZ is helping Södra Cell Mönsterås pulp mill to become the first ever fossil-free biomethanol plant worldwide and also be climate-positive by the end of this decade.

CircleToZero® from ANDRITZ – paving the way towards pulp production with zero emissions and zero waste “Photo: ANDRITZ”.

CircleToZero® from ANDRITZ – paving the way towards pulp production with zero emissions and zero waste “Photo: ANDRITZ”.

CircleToZero enables customers to achieve immediate bottom-line savings, take up new business and investment opportunities and increase their ability to comply with ever tighter environmental regulations.

“We look forward to a shared roadmap towards a more sustainable society together with our business partners. Our CircleToZero team is happy to share the program and solutions in detail and define new ways to operate mills in more sustainable ways with enhanced bottom-line results.” Lauri Pehu-Lehtonen, Director A-Recovery+, ANDRITZ explains.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply high-speed tissue machine to ST Paper in Duluth, Minnesota, USA

International technology Group ANDRITZ has received an order from ST Paper to supply a new tissue machine for its recently acquired site in Duluth, Minnesota, USA.

Start-up is planned for the end of 2022.

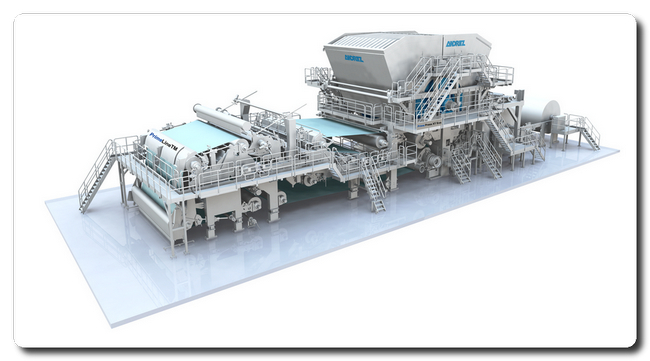

The ANDRITZ tissue machine of the type PrimeLineTM W 2000 has a design speed of 2,000 m/min and a working width of 5.65 m to produce a range of bath, napkin and towel grades. The order includes:

- the approach flow equipment with double dilution capability for excellent fiber preparation

- a fully cantilevered PrimePress XT Evo shoe press for gentle dewatering

- a 16 ft. PrimeDry Steel Yankee with head insulation, steam and condensate systems, and high-performance Yankee hood and process air systems for energy-efficient drying

- mist extraction and dust removal systems for safe operation and

- a PrimeReel standard reel with turn-up equipment for excellent end product quality

The entire production line will be equipped with an ANDRITZ PrimeControl MCS automation system which includes extended features for process automation throughout the tissue line and minimizes the number of subsystems and associated interfaces. Installation advisory services, start-up and commissioning services are also included in the scope of supply.

PrimeLineTM tissue machine with shoe press © ANDRITZ

PrimeLineTM tissue machine with shoe press © ANDRITZ

Sharad Tak, founder and principal partner of ST Paper: "We partnered with ANDRITZ because they offered state-of-the-art tissue machine technologies with a focus on optimized energy consumption and a commitment to achieve our project goals.”

Joseph Guadagno, ANDRITZ Vice President Tissue and Air Systems, North America, adds: “We are very pleased that ST Paper selected ANDRITZ as a trusted partner. The relationship developed with the ST Paper team on past projects contributed to this success”.

ST Paper acquired Verso Corporation’s idled Duluth mill in May, with the intention to convert the mill’s production from specialty paper grades to tissue. ST Paper has already successfully converted two fine paper machines into tissue machines at its Franklin, Virginia facility. ANDRITZ was a key supplier to ST Paper on both PM 5 & PM 6 rebuild projects at the Franklin mill, with the supply of the Yankee hoods and complete air systems for both rebuilds, including one of the widest Yankee hoods in the world at 8.43 m (332”) hood width installed on PM 6.

This order once again confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the North American tissue industry and ANDRITZ’s expertise specifically in wide tissue machines and energy-saving components.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ acquires parts of Air Quality Control System (AQCS) business from GE Steam Power

International technology group ANDRITZ has signed an agreement with GE Steam Power to acquire parts of their Air Quality Control System (AQCS) technology, including the technology center in Växjö, Sweden. Closing of the transaction was reached on 1st of July 2021.

ANDRITZ takes over the product portfolio for industrial dedusting (electrostatic precipitators - ESP, fabric filters (FF) and wet ESP), dry/semi-dry flue gas treatment, and industrial scrubbing, including condensation scrubbers and low-temperature heat recovery solutions. The acquisition also includes the AQCS main location in Växjö, Sweden, as well as employees involved in this business in Sweden and Finland. ANDRITZ acquires the respective intellectual property (IP), including patents, references, and trademarks, for global use with some exceptions. For parts, upgrade & service business in India, Bangladesh, Sri Lanka, the USA, and Canada as well as for FGD products in India, Bangladesh and Sri Lanka GE Steam Power will continue business as a licensee of ANDRITZ.

ANDRITZ Recovery Boiler and 5 chamber-ESP under construction Photo: ANDRITZ

ANDRITZ Recovery Boiler and 5 chamber-ESP under construction Photo: ANDRITZ

The dedusting portfolio acquired – especially the ESP and FF technologies – completes ANDRITZ’s air pollution control capabilities in the important pulp, metals, mining, and power markets.

ANDRITZ is now able to offer ESPs and Switch-Integrated Rectifier (SIR) technology from a single source, thus gaining access to service and maintenance business for an installed base of more than 2000 plants.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ is supplying major pulp production technologies and key process equipment for the world’s largest DP pulp mill

International technology group ANDRITZ is supplying major energy-efficient and environmentally friendly pulp production technologies and key process equipment for Bracell’s Project “STAR” in the city of Lençóis Paulista, São Paulo state, Brazil.

The mill features two flexible, environmentally friendly hardwood fiberlines for a capacity of 2.6 – 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp, which is used as raw material for the production of viscose. ANDRITZ was awarded this contract in July 2019, and start-up is scheduled for August 2021.

Bracell, one of the largest global producers of dissolving pulp and special pulp, is finalizing its Project Star work to expand the company's operations in Lençóis Paulista, in the interior of São Paulo state. The plant, which is one of the largest and most sustainable pulp mills in the world, will start operating in mid-August 2021, with a production capacity of up to three million tons per year. The project is outstanding due to its sustainable DNA, featuring advanced technology, operating entirely free of fossil fuel, and using renewable raw materials to create biodegradable products.

According to Pedro Stefanini, General Director of Bracell SP, the technologies applied in Project Star aim to make production in the mill even more sustainable. “The project is much more than a pulp mill. It is the future of the bioindustry. Here we will have the largest and cleanest recovery boiler in the world, equipped with state-of-the-art technologies that are not yet used on an industrial scale in the region,” says Pedro Stefanini.

Bracell’s Project “STAR” in Lençóis Paulista © ANDRITZ

Bracell’s Project “STAR” in Lençóis Paulista © ANDRITZ

ANDRITZ is providing – on EPCC (Engineering, Procurement, Construction and Civil Construction) basis – four of the six most important process islands in the pulp mill:

- A complete Wood Processing Plant using ANDRITZ’s proven technologies and including four chipping lines, two stacker-reclaimers, eight chip screening units, biomass handling with two ANDRITZ BioCrushers, and biomass storage. Each chipping line for eucalyptus processing includes ANDRITZ’s unique, horizontally fed HHQ-Chipper (EXL model), ensuring high capacity and optimum chip quality. Woodyard operation is enhanced with state-of-the-art Metris – ANDRITZ digital solutions, featuring artificial intelligence and digital sensors. The plant includes ChipperEKG, stone detection, the ScanChip chip analyzer, and a FlowScanner, which measures the density and moisture content of the chips to optimize the fiberline process and minimize wood consumption.

- An ANDRITZ HERB Recovery Boiler with high steam parameters of 101 bar(a) and 515°C to maximize power generation. This is the largest recovery boiler in the world, with the capacity to burn total solids of 13,000 tons per day, and it is being equipped with state-of-the-art technologies not yet used in the region so far on an industrial scale. The state-of-the-art boiler will not only make the mill self-sufficient in energy supply but will additionally produce around 180 megawatts of green energy that will be fed to the Brazilian grid to supply roughly three million people with clean energy. The HERB Recovery Boiler features energy-efficient flue gas cooling and feed water preheating technologies to maximize steam production for power generation. It is designed for extended operating periods without requiring wash water.

- Two environmentally friendly hardwood Fiberlines, for capacities of 2.6 to 2.8 million t/y of kraft pulp or 1.5 million t/y of dissolving pulp, that process certified eucalyptus trees ensure low effluent emissions and also include a chip feed system, LoSolids continuous cooking system with Pre-Hydrolysis Vessel (PHV), screen room and bleach plant as well as ANDRITZ’s DD-Washer technology, ensuring low operating costs, low emissions, extremely high washing efficiency, and excellent fiber quality. The cooking plant for the fiberline is state of the art in the continuous cooking process for production of dissolving pulp.

- Two innovative EvoDry Pulp Drying Systems for the most energy-efficient pulp drying based on the high-capacity Twin Wire Former technology, with airborne dryers, cutter-layboy and baling lines. The approach flow with cleaner systems ensures homogeneous pulp feed to the subsequent process stage for both types of pulps – dissolving and kraft. The pulp dewatering machine comprises a headbox with dilution control, a Twin Wire Former, and a press section with one combi-press and two shoe presses. The ANDRITZ technology for pulp drying is very well proven all over the world. The ANDRITZ cutter-layboy provides the pulp bales to be further processed in the high-capacity baling lines, where the final pulp bale units are produced.

- ANDRITZ is also supplying a Non-Condensable Gas (NCG) treatment system that enables safe and environmentally friendly treatment of all types of diluted or concentrated malodorous gases, thus meeting the strictest environmental and social requirements. The gases are collected and eliminated by waste gas incinerator with quenching as well as flue gas scrubbers. The NCG incineration system is based on the “A-Recovery+” concept developed by ANDRITZ, focusing on the use of side streams in the recovery cycle.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to rebuild board machine at Mayr-Melnhof Karton in Frohnleiten, Austria

International technology group ANDRITZ has received an order from Mayr-Melnhof Karton, Austria, to rebuild its KM3 at the mill in Frohnleiten.

The aim of the rebuild is to increase production as well as improve quality and the ecological footprint. Start-up is scheduled for 2023.

© ANDRITZ

© ANDRITZ

The scope of supply comprises:

- Rebuild of the wire section, including major modifications to the approach flow systems with new pumps, upgrade of three existing headboxes and the hybrid former, as well as a new 2-layer PrimeFlow AT headbox with the latest state-of-the art dilution water CD profiling for better high-end product quality

- New press section with two PrimePress X shoe presses for gentle, energy-efficient dewatering and bulk savings at higher dryness

- Rebuild of the pre-dryer section with PrimeRun web stabilizers for improved runability

- Upgrade of two under-machine pulpers in the area of the press and pre-dryer section

- Complete adaptation of the automation system to accommodate the scope of supply

- Machine clothings for the complete scope of supply

- Assembly, start-up and production assistance

The board machine KM3 has a design speed of 800 m/min and a wire width of 5 m. It produces folding boxboard (chromo duplex quality) with 230–450 gsm.

ANDRITZ will also adapt the automation system of the stock preparation lines for board machines KM2 and KM3 in Frohnleiten. The upgraded automation system will enable high equipment availability as well as fast and easy operation and maintenance. The modifications will be made in several stages, with final completion planned for 2022.

Mayr-Melnhof Karton is Europe's leading board producer. With a capacity of 540,000 t/y recycling board, the mill in Frohnleiten, Austria, has the highest production capacity in the European cartonboard industry.

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

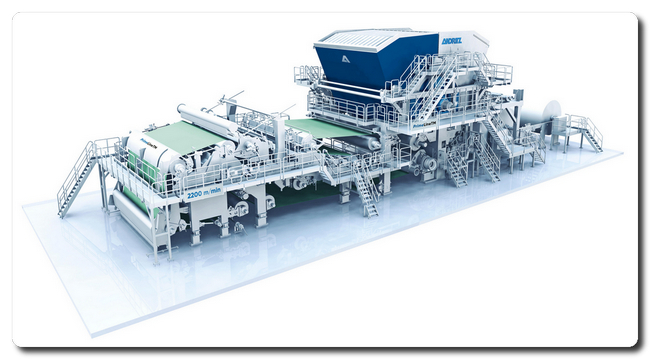

ANDRITZ presents high-speed tissue machines with 2,200 m/min design speed for maximum capacity

International technology Group ANDRITZ presents two new tissue machines with a design speed of 2,200 m/min for high production capacity:

- PrimeLineTM S 2200 with 2.6 to 2.85 m width at reel

- PrimeLineTM W 2200 with 5.4 to 5.6 m width at reel

All proven ANDRITZ key components can be installed, like

- the PrimePress XT shoe press for gentle dewatering and high nip-loads,

- the PrimeDry Steel Yankee for energy-efficient drying,

- the PrimeDry HeatRecovery re-evaporation system for returning energy to the production process or

- the PrimeDry Hood ST for steam-heated drying instead of using more expensive gas heating.

High-speed tissue production with ANDRITZ PrimeLine technology © ANDRITZ

High-speed tissue production with ANDRITZ PrimeLine technology © ANDRITZ

The new machines feature Metris – ANDRITZ digital solutions – which enable remote assistance during commissioning and start-up as well as improved operation. With the services offered by ANDRITZ at its Metris Performance Centers, tissue mills are able to benefit from individual and fast customer service by using the Metris UX Platform for optimization of production processes, troubleshooting by operators and decision-making support.

Günter Offenbacher, ANDRITZ Sales Director for Tissue and Drying, explains: “Based on our long-term experience and proven expertise in tissue machines, the design of the new machines has been updated with the latest technologies. With the new high-speed machines, we can offer an innovative concept for dry-crepe tissue machines with high production efficiency for every customer need. Our comprehensive product portfolio ranges from high-performance machines with speeds of up to 2,200 m/min down to efficient compact solutions for smaller production capacities.”

If you would like to receive more information, please visit andritz.com/tissue or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply two complete OCC lines to Nine Dragons, China

International technology Group ANDRITZ has received an order from Nine Dragons Paper Industries to supply two complete OCC lines with a capacity of 2,000 bdmt/d each to their mills in China.

Start-up is scheduled for the second and fourth quarter of 2022, respectively.

The lines feature the following technological highlights:

- FibreFlow Drum pulping systems, ensuring premium accept quality thanks to gentle slushing and efficient removal of coarse contaminants with minimum fiber loss

- PrimeScreen F fine screens and fractionators with newly developed PrimeFoils for increased efficiency and lower power consumption

- PrimeFilter D disc filters – the latest ANDRITZ innovation in thickening and fiber recovery – enabling the system to handle higher feed consistencies and higher-freeness pulp, even in the most demanding applications, and in parallel offering significant improvements in terms of energy consumption and maintenance

- Ultra-high dispersing, allowing dispersion at a consistency of up to 40% to achieve substantial savings in steam consumption and superior fiber strength development.

ANDRITZ FibreFlow Drum for OCC application © ANDRITZ

ANDRITZ FibreFlow Drum for OCC application © ANDRITZ

The stock preparation systems will use 100% LOCC (local old corrugated containers) as raw material to produce high-quality packaging paper.

Nine Dragons Paper is part of the Nine Dragons Paper Group, an important global player in the pulp and paper industry with mills in China, Vietnam, Malaysia, and the United States. The group primarily produces linerboard, high-performance corrugating medium and coated duplex board as well as printing and writing paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

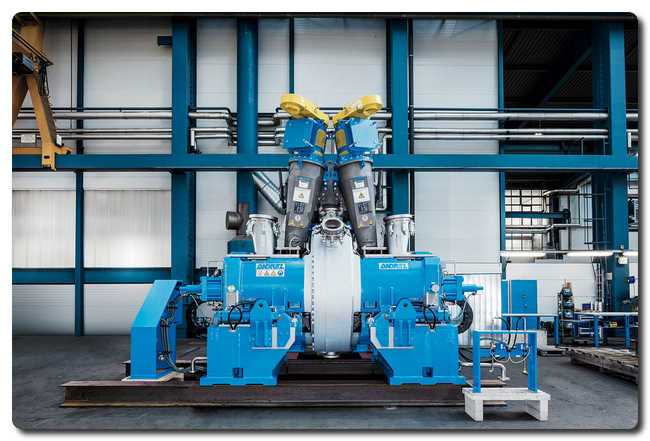

ANDRITZ to supply two P-RC APMP lines to Nine Dragons Paper Industries, China

International technology Group ANDRITZ has received an order from Nine Dragons Paper Industries to supply two chemi-thermomechanical pulping systems for their mills in China.

The start-ups are scheduled for spring and summer 2022.

ANDRITZ will install its well-proven P-RC APMP (pre-conditioning refiner chemical alkaline peroxide mechanical pulp) technology to ensure optimum pulp quality at lowest energy consumption and highest availability. The fiberlines will have a capacity of 1,000 admt/d and 670 admt/d, respectively, and will process a mixture of eucalyptus, acacia and poplar wood chips for the production of folding boxboard (FBB).

ANDRITZ will supply the main equipment – from chip washing to the storage tower – for both fiberlines, featuring the following highlights:

- MSD Impressafiner for wood chip maceration to enable optimum chemical impregnation

- High-consistency (HC) refining stage with TX68 refiner, including an advanced feeding system for optimum fiber development and lowest shive levels

- Low-consistency (LC) refining stages with TwinFlo refiners for low specific energy consumption and well-developed fibers

- Four newly developed PrimeFilter D disc filters for fiber recovery and thickening. The innovative disc filters feature the so-called HHw (high consistency, high freeness, wider space between discs) technology for advanced feeding and optimum flow conditions within the filter as well as CC bagless sectors for advanced operation and reduced maintenance.

The scope of supply also includes the basic engineering as well as supervision of mechanical installation, commissioning and start-up.

High-capacity and high-performance refining with the ANDRITZ TX68 refiner © Croce

High-capacity and high-performance refining with the ANDRITZ TX68 refiner © Croce

Nine Dragons Paper is part of the Nine Dragons Paper Group, an important global player in the pulp and paper industry with mills in China, Vietnam, Malaysia, and the United States. The group primarily produces linerboard, high-performance corrugating medium and coated duplex board as well as printing and writing paper.

ANDRITZ GROUP International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

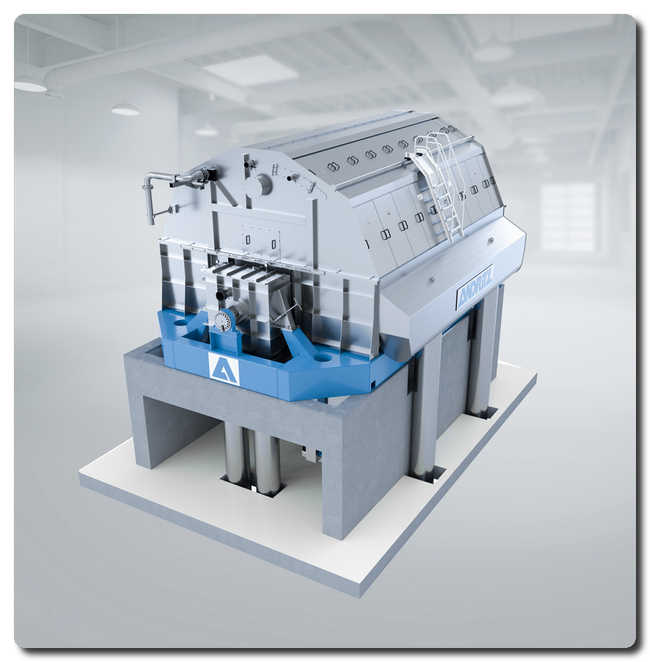

ANDRITZ to supply approach flow equipment for two board machines to Shanying Paper, China

International technology Group ANDRITZ has received an order from Shanying Paper (Guangdong) to supply the approach flow-, fiber recovery-, and broke handling systems for two board production lines to its mill in Zhaoqing, Guangdong Province, China.

Start-up is scheduled for the second quarter of 2022.

ANDRITZ’ scope of supply features the following technological highlights:

- ModuScreen HBE screens with proven inflow design for highly efficient and pulsation-free headbox screening at low energy consumption

- ModuScreen F screens with advanced rotor and screen basket design enabling high screening efficiency in the broke handling

- Newly developed PrimeFilter D saveall disc filters with Conical Cell bagless sectors providing excellent filtrate quality and minimum maintenance efforts in the fiber recovery

Newly developed PrimeFilter D saveall disc filter © ANDRITZ

Newly developed PrimeFilter D saveall disc filter © ANDRITZ

Zhaoqing mill’s production lines PM52 and PM53 feature a total capacity of 3,300 t/d and process OCC as raw material producing linerboard and testliner as final product.

Shanying Paper (Guangdong) Co., Ltd. is part of Shanying International Holdings Co., which is a leading enterprise producing various paper products like culture paper, kraft papers, various packaging paper boards, and corrugated cardboard boxes.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.