Displaying items by tag: Andritz

ANDRITZ improves pulp mill performance at Mondi Frantschach, Austria

International technology group ANDRITZ has successfully improved performance of the pulp mill at Mondi Frantschach by implementing new advanced process controls.

The target was to reduce the variability of Kappa, an indication of the lignin content in the pulp, in order to run the process a step closer to its maximum specification limits. This measure leads to higher production efficiency in the mill because less wood is needed to produce the same amount of pulp.

As part of the optimization project, ANDRITZ Automation commissioned and fine-tuned three advanced process controls (APCs) in Mondi´s continuous cooking process. The controls implemented, including the chip level control for digester and impregnation vessel, the digester H-factor control (kinetic model for the rate of delignification in kraft pulping) and the blow-flow consistency control, were fully developed with Metris X – the distributed control system (DCS) developed by ANDRITZ Automation to simplify operational complexity, lower project risk, and improve plant performance. Metris X is a key application of the Metris UX Platform, a state-of-the-art digitalization platform that enables full functionality and support for industrial plants throughout their entire life cycle.

View of Mondi Frantschach’s continuous digester, where the optimization was performed © ANDRITZ

View of Mondi Frantschach’s continuous digester, where the optimization was performed © ANDRITZ

ANDRITZ’s scope of supply included the analysis of data correlated to Kappa, return of investment (ROI) calculations, an evaluation of the cooking process, instrumentation, and former Kappa control, performing of trials on the actual process, and the commissioning, start-up and fine-tuning of an advanced process control solution for Kappa stabilization.

The solution delivered proved better than the former system in all instances, showing that ANDRITZ Automation is capable of delivering the results promised.

Mondi Frantschach would like to point out that the fruitful working cooperation between the Mondi Frantschach team and ANDRITZ Automation was a key factor in this great achievement of further improving the complex kraft pulping process.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ AUTOMATION

ANDRITZ Automation covers the entire project life cycle of the plant. Starting with project management, hardware and software development, through installation works, commissioning, and operator training, to maintenance and design work for extensions and improvements. With the Metris technology brand, ANDRITZ Automation offers a wide range of digitization products that customers can use individually and in combinations for their own essential and sustainable benefit. The proprietary Metris UX platform adds significant value to the planning, operation, asset management, maintenance, and optimization of production plants and the associated supply chains. The division has around 2,000 employees and is active in over 100 locations.

ANDRITZ pulp drying lines at Bracell’s “STAR” project, Brazil, achieve new production world records

The pulp drying plant at Bracell’s “STAR” project in Lençóis Paulista, São Paulo, consisting of two identical pulp drying lines (L2A and L2B) supplied by ANDRITZ, has achieved new production world records.

On December 18, 2021, the L2A pulp drying line reached a total output of 4,672.5 air dry tons per day, which is a production world record on a single line. In terms of specific drying capacity, this corresponds to 456 tons per day and meter of working width produced on an ANDRITZ drying line for a sheet width of 10.24 meters.

Moreover, on December 18, 2021, the L2A and L2B pulp drying lines achieved a total of 8,897.4 air dry tons per day on both lines together, which is a new mill-wide capacity world record.

ANDRITZ pulp drying plant at Bracell’s “STAR” project, Brazil, achieves new production world record © ANDRITZ

ANDRITZ pulp drying plant at Bracell’s “STAR” project, Brazil, achieves new production world record © ANDRITZ

Both records were set during the first four months after start-up. This impressive performance was made possible by ANDRITZ’s leading and proven EvoDry pulp drying system, whose energy-efficient pulp drying is based on the high-capacity Twin Wire Former technology, includes airborne dryers, cutter-layboy and baling lines, and is equipped with the Metris DryQ smart pulp drying solution.

Bracell’s “STAR” project at the mill in Lençóis Paulista is one of the largest and most sustainable pulp mills in the world, meeting the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

These outstanding results are based on the combination of customer and supplier partnership, good plant management and technology as well as excellent planning and implementation.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient, and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

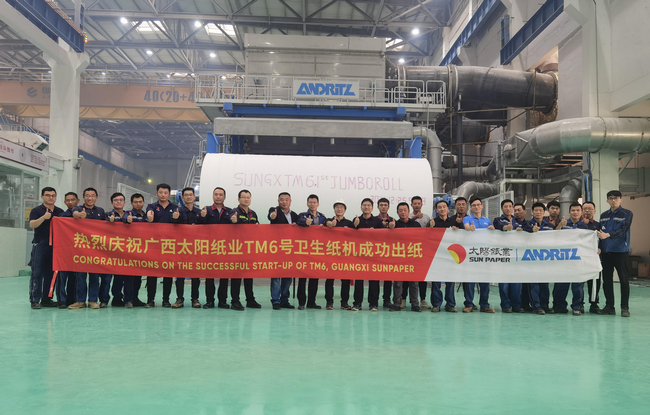

ANDRITZ successfully starts up the second of two tissue machines delivered to Guangxi Sun Paper, China

On December 25, 2021, international technology group ANDRITZ successfully started up the second of two PrimeLineTM W 2000 tissue machines delivered to Guangxi Sun Paper, China, for its mill in Beihai City, Guangxi Province.

The tissue machine (TM6) has a design speed of 2,000 m/min, a working width of 5.65 m and a capacity of 60,000 t/a, and it is equipped with energy-saving components (steel Yankee with head insulation, heat recovery system, Yankee Ecosteam system for re-evaporation). Forming fabrics and press felts by ANDRITZ Fabrics and Rolls were installed for optimum end-product quality.

Like the TM5 order, the scope of supply also included FibreSolve FSV pulpers, the paper machine approach flow systems, broke handling and fiber recovery, and automation systems.

Successful start-up of the PrimeLineTM tissue machine TM6 at Guangxi Sun Paper, China © ANDRITZ

Successful start-up of the PrimeLineTM tissue machine TM6 at Guangxi Sun Paper, China © ANDRITZ

Guangxi Sun Paper is part of the Sun Paper Group. It was founded in 2019 with the aim of establishing an integrated pulp and paper mill in Beihai City. The new greenfield mill will presumably have a total pulp and paper capacity of 3.5 million t/year and will be built in two phases over approximately four years. With this start-up, Sun Paper now has four ANDRITZ PrimeLine tissue machines successfully in operation.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up leading technologies for Klabin’s EukalinerTM brown pulp mill in Brazil

International technology group ANDRITZ has successfully started up state-of-the-art and environmentally leading pulp production and chemical recovery technologies for Klabin’s Puma II line in Ortigueira, Paraná, Brazil.

Pablo Cadaval, General Mill Manager of Klabin’s Puma Unit, says: “We are very satisfied with the way we were able to manage and finish the project and start our key equipment for the Puma II line together with ANDRITZ, despite the hardships of the COVID-19 pandemic.”

The ANDRITZ scope of supply included:

- A wood processing plant with debarking and chipping line, which can process both eucalyptus (350 m3 sob/h) and pine (400 m3 sob/h), meaning that a log truckload of wood is emptied onto the line every ten minutes.

- The HERBTM recovery boiler from ANDRITZ, which has a capacity of 3,300 tds/d with high steam parameters of 103 bar(a) and 502°C to maximize power generation. It is equipped with the autonomous Smart sootblowing control solution that combines Smart sensors (HEWI) and controls to ensure the cleanability period, a higher availability of the boiler, as well as greater operating safety.

- A power boiler based on ANDRITZ EcoFluid bubbling fluidized bed (BFB) technology with a steam production capacity of 220 t/h. It is combined with the recovery boiler to form a “boiler island”, and some of the auxiliary equipment is shared between the two boilers. This provides savings in investment and operating costs.

- A complete white liquor plant consisting of a recausticizing plant (5,000 m3/d) and an ANDRITZ LimeKiln (450 t/d) with a multi-fuel burner.

The new power boiler combined with the recovery boiler form a “boiler island”, providing savings in investment and operating costs. © ANDRITZ

The new power boiler combined with the recovery boiler form a “boiler island”, providing savings in investment and operating costs. © ANDRITZ

The excellent business relationship between ANDRITZ and Klabin was once again confirmed when the Puma II EukalinerTM production line started up successfully during the fourth quarter of 2021, almost on schedule regardless of the worldwide pandemic.

Francisco Razzolini, Klabin's Director of Industrial Technology, Innovation and Sustainability, says: "Klabin, along with its partners, has extensive expertise in creating solutions that contribute to the processes of pulp and packaging paper production. ANDRITZ is one of the great examples, which – besides being fundamental to the entire production area – also proves to be a reference in optimizing processes, with cutting-edge technology."

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

About KLABIN

Klabin is Brazil’s largest producer and exporter of packaging paper, the only company in the country to offer one-stop shop solutions in hardwood, softwood and fluff pulp, as well as the leader in the corrugated board packaging and industrial bags markets. Founded in 1899, it has 24 industrial units in Brazil and one in Argentina.

Its entire management is guided by sustainable development, pursuing integrated and responsible growth that combines profitability, social development and environmental commitment. Since 2014, Klabin has been a part of the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (B3), and in 2020, it was included in two portfolios of the Down Jones Sustainability Index: the World Index and the Emerging Markets Index. As a signatory to the United Nations Global Compact and the Brazilian Pact to Eradicate Slave Labor, Klabin seeks suppliers and business partners who share its values of ethics, transparency and respect for the principles of sustainability.

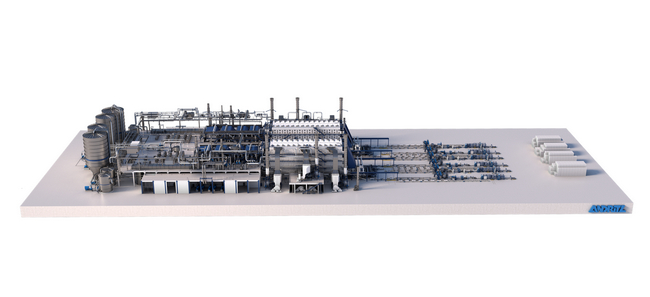

ANDRITZ to supply third OCC line to Nine Dragons, China

International technology group ANDRITZ has received a repeat order – now the third order within the past 12 months – from Nine Dragons Paper Industries to supply a complete OCC line to China. Start-up is scheduled for the third quarter of 2023.

The highly energy-saving stock preparation system will have a design capacity of 2,000 bdmt/d and will process 100% LOCC (Local Old Corrugated Container) for the production of high-quality packaging paper.

The ANDRITZ equipment will enable highest production performance and conservation of resources. These ambitious goals will be achieved with a well-developed line setup, a highly efficient drum pulping system and a range of Prime stock preparation products.

An ANDRITZ FibreFlow drum pulping system will ensure premium accept quality, gentle slushing, and efficient removal of contaminants at minimum fiber loss. Energy-saving and maintenance friendly PrimeScreen F screens and PrimeFilter D disc filters, as well as an ultra-high dispersing system that enables at a consistency of up to 40%, will achieve substantial savings in steam consumption and superior fiber strength development.

FibreFlow drum pulping system as part of the third OCC line ordered by Nine Dragons © ANDRITZ

FibreFlow drum pulping system as part of the third OCC line ordered by Nine Dragons © ANDRITZ

With the delivery of this FibreFlow drum pulper, ANDRITZ will have supplied more than 30 drum pulpers to Nine Dragons.

Nine Dragons Paper is part of the Nine Dragons Paper Group, an important global player in the pulp and paper industry with mills in China, Vietnam, Malaysia, and the United States. The group primarily produces linerboard, high-performance corrugating medium, coated duplex board, and printing and writing paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply Ash ReCrystallization plant to Suzano, Brazil

International technology group ANDRITZ has received an order from the Brazilian pulp and paper company Suzano to deliver an energy-efficient Ash ReCrystallization (ARC) plant for the recovery boilers at its eucalyptus kraft pulp mill in Barra do Riacho, Brazil. The estimated start-up date for the ARC plant is the first half of 2022.

3D rendering of the Ash ReCrystallization (ARC) plantThe ANDRITZ ARC plant removes the harmful chloride and potassium from the ElectroStatic Precipitator (ESP) ash and returns valuable chemicals to the chemical recovery cycle. The plant to be supplied is designed to handle 550 tons of ESP ash daily.

3D rendering of the Ash ReCrystallization (ARC) plantThe ANDRITZ ARC plant removes the harmful chloride and potassium from the ElectroStatic Precipitator (ESP) ash and returns valuable chemicals to the chemical recovery cycle. The plant to be supplied is designed to handle 550 tons of ESP ash daily.

Featuring the new energy recovery technology, the ARC plant will optimize energy efficiency significantly. This technology is also based on an enhanced evaporative crystallization concept that will improve the recovery process. With this order, ANDRITZ is demonstrating its strong global position in the supply of state-of-the-art and environmentally friendly ARC plants.

Suzano is the largest pulp and paper company in Latin America and a leader in the paperboard market. The company is also the largest producer of eucalyptus pulp in the world. This proven process technology from ANDRITZ will help Suzano achieve their financial and sustainability goals.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up a new HERB recovery boiler at JK Paper Limited, India

International technology group ANDRITZ has successfully started up a new 950 t/d HERB chemical recovery boiler at JK Paper Limited, Unit: CPM at Fort Songadh, in the Tapi District of Gujarat state, India.

The boiler is designed to process hardwood black liquor and enables environmentally friendly and more energy-efficient operation compared to the direct-contact evaporator boiler currently used at the mill. This will significantly increase the mill’s pulp production and power-to-heat-ratio. The boiler also features a unique air system to minimize air emissions.

The scope of supply also included:

- Engineering for the entire system except for the civil works and the electrical and automation equipment

- Complete pressure parts

- Auxiliaries such as start-up oil burners, black liquor burners, smelt spouts and high-pressure steam valves and piping

- Safety-related system (SRS)

New HERB recovery boiler from ANDRITZ at JK Paper Limited, Unit: CPM © ANDRITZ

New HERB recovery boiler from ANDRITZ at JK Paper Limited, Unit: CPM © ANDRITZ

AS Mehta, President & Director of JK Paper Ltd, says: “The entire ANDRITZ team has worked tirelessly and zealously to see that the commissioning was trouble-free and fast. This has been achieved despite many constraints during the COVID-19 pandemic. Team JK Paper conveys its warmest gratitude to the ANDRITZ team for this wonderful support.”

This is the fourth HERB recovery boiler ANDRITZ is currently installing in India, demonstrating ANDRITZ’s strong presence in the Indian pulp and paper market.

JK Paper Ltd. is one of the leading integrated pulp, paper, and packaging board manufacturers in India, offering quality paper and packaging board products through innovative and state-of-the-art technology from mixed hardwood raw material.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also forma part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply OCC line to HKB-Hoa Lu Paper, Vietnam

International technology group ANDRITZ has received a repeat order from HKB-Hoa Lu Paper Joint Stock Company to supply a complete OCC line including reject treatment system for its mill in Nho Quan District, Ninh Binh Province, Vietnam.

Start-up is scheduled for the third quarter of 2022.

The OCC line will have a design capacity of 500 t/d and process mixed OCC (Old Corrugated Containers) as raw material to produce high-quality testliner and corrugated medium for the Vietnamese and Chinese markets.

PrimeScreen X with highly efficient PrimeFoil rotor foils © ANDRITZ

PrimeScreen X with highly efficient PrimeFoil rotor foils © ANDRITZ

ANDRITZ’s scope of supply comprises the complete stock preparation equipment including the approach flow, fiber recovery, and reject treatment systems, featuring the following technological highlights:

- PrimePulping LC system with innovative design for lowest fiber loss in slushing and reject removal

- PrimeScreen X equipped with patented PrimeFoil rotor foils for optimum efficiency and lower power consumption

- Dispersing system with CompaDis disperser allowing superior fiber strength development and excellent final paper properties

- ModuScreen HBE for efficient and low-pulsation screening in the approach flow

- DiscFilter Saveall for high fiber recovery rate and superior filtrate quality at high availability

- Reject treatment line with ReSed separator for efficient removal of heavy solids from the liquid streams and ReCo Reject Compactor ensuring highest possible reject dryness.

ANDRITZ will also provide the detail engineering and erection as well as operation and maintenance (EOM) support.

In 2008, Phuong Dong Packaging Paper Manufacturing Co., Ltd, the parent company of HKB-Hoa Lu Paper Join Stock, and ANDRITZ collaborated the first time to build an OCC line at Phuong Dong Packaging Paper mill. The excellent performance of this line, especially in terms of product quality and energy consumption, was the decisive criterion for the customer to award the contract for the second OCC line to ANDRITZ.

HKB-Hoa Lu Paper Joint Stock Company was established in 2020 as an affiliate of Phuong Dong Packaging Paper Manufacturing Co., Ltd. and focuses on the production of various board products.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

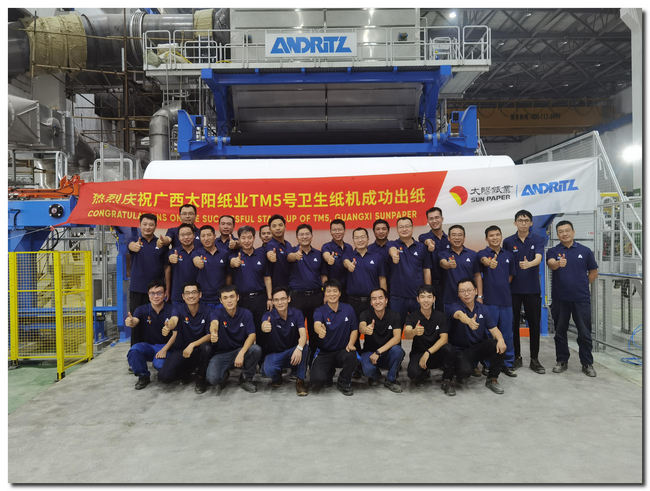

ANDRITZ successfully starts up the first of two tissue machines delivered to Guangxi Sun Paper, China

International technology group ANDRITZ has successfully started up one of the two PrimeLineTM W 2000 tissue machines delivered to Guangxi Sun Paper, China, for its mill in Beihai City, Guangxi Province.

The second tissue machine (TM6) is expected to be started up by the end of this year.

The tissue machine (TM5) has a design speed of 2,000 m/min, a working width of 5.65 m, and a capacity of 60,000 t/a. To enable energy-efficient production, it is equipped with a large suction press roll, an 18 ft. PrimeDry Steel Yankee with head insulation, and a re-evaporation system. For optimum end-product quality, forming fabrics and press felts by ANDRITZ Fabrics and Rolls were installed.

The scope of supply also included FibreSolve FSV pulpers, the paper machine approach flow systems as well as broke handling, fiber recovery, and automation systems.

Successful start-up of the PrimeLineTM tissue machine (TM5) at Guangxi Sun Paper, China © ANDRITZ

Successful start-up of the PrimeLineTM tissue machine (TM5) at Guangxi Sun Paper, China © ANDRITZ

Ying Guangdong, Vice General Manager and Chief Engineer of the Sun Paper Group, says: “With more than 20 years’ of successful cooperation with ANDRITZ, we know their capabilities very well and rely on their innovative solutions for sustainable, high-quality tissue production. This project went smoothly and very swiftly, which shortened our payback time remarkably.”

Gary Beckingham, Vice President and General Manager for Asia in the Paper, Fiber and Recycling Division at ANDRITZ, adds: ”Due to the excellent teamwork, we succeeded in setting a new benchmark. It took only 12 months from project kick-off to the first paper on reel and only 10 days for start-up and commissioning. We always try our best to improve our customers’ profitability and increase their return on investment.”

Guangxi Sun Paper is part of the Sun Paper Group. It was founded in 2019 with the aim of establishing an integrated pulp and paper mill in Beihai City. The new greenfield mill will presumably have a total pulp and paper capacity of 3.5 million t/a and will be built in two phases over approximately four years.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

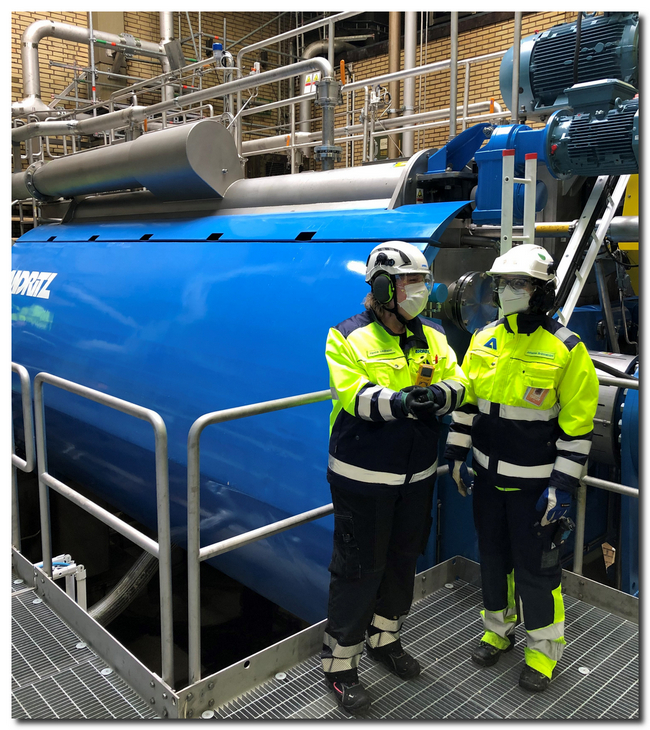

ANDRITZ successfully starts up new COMPACT PRESS at BillerudKorsnäs’ Gruvön mill in Sweden

International technology group ANDRITZ has successfully started up the first ANDRITZ COMPACT PRESS wash press at BillerudKorsnäs’ Gruvön mill located in Värmland, Sweden.

Final acceptance was received in September 2021.

With its small footprint, high availability and extremely effective washing efficiency, the COMPACT PRESS is well known in the pulp industry. Successful start-up and completion of the project was a result of the ongoing, close cooperation between ANDRITZ and BillerudKorsnäs. ANDRITZ also supplied a DD-Washer, MC pumps and a pulp Screw Press for a new brownstock washing sideline in 2019.

ANDRITZ’s start-up personnel next to the first ANDRITZ COMPACT PRESS wash press at BillerudKorsnäs’ Gruvön mill in Sweden © ANDRITZ

ANDRITZ’s start-up personnel next to the first ANDRITZ COMPACT PRESS wash press at BillerudKorsnäs’ Gruvön mill in Sweden © ANDRITZ

BillerudKorsnäs is a leading player for liquid packaging board and a global leader in the production of high-porosity sack paper manufactured from primary fibers. In Europe, the company holds a leading position for primary fiber-based kraft paper, fluting and pure white liner and is also one of the largest producers of cartonboard from primary fibers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.