Displaying items by tag: Andritz

ANDRITZ successfully starts up steel Yankee and air and energy systems at Kartogroup in Spain

International technology group ANDRITZ has successfully started up the new steel Yankee and air and energy systems at Kartogroup España S.L., Burriana mill, Spain.

The turnkey order included a steel Yankee with steam and condensate system for the PM2 tissue machine as well as two dust removal systems for PM2 and PM4. ANDRITZ Novimpianti provided the complete project management, commissioning, and start-up for all these key components.

“The whole project ran smoothly and on schedule”, says Pascual Gómez, COO of Kartogroup. “The new ANDRITZ technology contributes to a substantial reduction in energy consumption compared to traditional concepts. We are especially impressed by the new steel Yankee. Only a few days after the successful start-up it is already operating at full performance.”

Arrival of the 14 ft. PrimeDry Steel Yankee at Kartogroup España, Burriana mill, Spain. “Photo: ANDRITZ”.

Arrival of the 14 ft. PrimeDry Steel Yankee at Kartogroup España, Burriana mill, Spain. “Photo: ANDRITZ”.

Kartogroup España S.L., a member of the COMINTER GROUP, has more than 40 years’ experience in the tissue business. At its mills in Burriana and Hernani (both Spain), the company produces high-quality tissue grades for household and industrial applications.

ANDRITZ Novimpianti, located in Lucca, Italy, has been part of the ANDRITZ GROUP since 2018 and is one of the leading suppliers of drying and ventilation equipment for all kinds of paper machines. Over the past 35 years, Novimpianti has installed around 700 air and energy systems in more than 50 countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ receives order for a major disc filter rebuild from SCA Pulp, Sweden

International technology group ANDRITZ has received an order from SCA (Svenska Cellulosa Aktiebolaget) to rebuild a disc filter at their pulp mill in Ortviken, Sundsvall, Sweden.

After the rebuild, the production capacity of the disc filter (originally supplied by ANDRITZ) will be tripled to 900 bdmt/d, and the filtrate flow will be increased to a maximum of 130,000 l/min. The refurbished disc filter will ensure the requested throughput at different beating degree levels, ranging from 300 to 700 CSF, for the production of various high-quality pulp grades. Start-up is scheduled for the fourth quarter 2022.

The ANDRITZ scope of supply comprises the main disc filter components, such as:

- New hollow shaft with high-volume filtrate channels – the largest-volume filtrate channels ever designed for an ANDRITZ disc filter

- 396 ANDRITZ SuperFlow sectors for 22 filter discs with customized filter bags

- State-of-the art disc guiding system

- New filtrate valve with automated adjustment to the different beating degrees

- New knock-off and cleaning shower systems

- New repulper screw

- On-site services for installation and start-up as well as supervision of start-up

SCA Ortviken mill in Sundsvall, Sweden “Photo: SCA”.

SCA Ortviken mill in Sundsvall, Sweden “Photo: SCA”.

ANDRITZ has developed a new filter bag solution able to handle beating degrees above 600 CSF. The new development was tested on a full-size disc filter during a 3-day trial at the ANDRITZ pilot plant in Graz, Austria. This was the first time that a single disc filter could be operated at such a wide CSF range.

The disc filter rebuild order is part of SCA's ongoing project to transform the existing TMP (thermo-mechanical pulp) line at the Ortviken site into a CTMP (chemo-thermo-mechanical pulp) plant with an annual capacity of 300,000 tons per year.

SCA Pulp is part of the SCA Group, Europe’s largest private forest owner, which offers packaging material, pulp, wood products, and renewable energy. The SCA Pulp facility at Ortviken, Sundsvall is expected to be operational by the beginning of 2023. This strategic investment is SCA's answer to the constantly rising market demands in the field of packaging and hygiene products.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to present innovative technologies for sustainable paper production at MIAC

International technology group ANDRITZ will be presenting its innovative technologies for sustainable paper production at MIAC 2021, booth #71, in Lucca, Italy, from October 12 to 15, 2021.

The ANDRITZ experts are looking forward to presenting the latest innovations and developments in the following areas:

- In fiber preparation, ANDRITZ will present its latest Prime technologies for enhanced fiber quality with economical use of resources, for example the PrimeFilter D, the cutting-edge technology in thickening and fiber recovery.

- For the tissue, paper and board industry, ANDRITZ will show its capabilities in the area of rebuilds, complete lines, and services with focus on sustainability and cost-efficiency, for example steel Yankees – giants up to 26 ft. in diameter – that enable energy-efficient drying at 8-10% better machine performance compared to cast-iron Yankees.

- The experts at ANDRITZ Fabrics and Rolls provide tailor-made roll covers, spreader rolls, shoe press belts and paper machine clothing solutions like the new StrataPress felt technology – a game-changing combination of materials, to deliver high sheet quality and reduced energy consumption at given machine speeds – or ANDRITZ’s durable, high temperature and contamination resistant MasterDry dryer fabrics that are specifically designed for extended fabric running times.

- The ANDRITZ service team will show ways of increasing the reliability, efficiency, and availability of process equipment regardless of the OEM, including service highlights like Yankee coating and on-site assembly.

- In the pumps business, ANDRITZ will show its broad pumps portfolio for all industrial applications and processes in the pulp and paper industry, including topics like model tests and after-sales service.

ANDRITZ will present its latest innovations for state-of-the-art paper production and value-added services at MIAC 2021 (booth no. 71). “Photo: ANDRITZ”.

ANDRITZ will present its latest innovations for state-of-the-art paper production and value-added services at MIAC 2021 (booth no. 71). “Photo: ANDRITZ”.

In conference speeches, ANDRITZ experts will also be presenting the latest solutions for efficient, sustainable paper production:

- Guido Lenzi, Sales Manager ANDRITZ Novimpianti, will be speaking about ANDRITZ’s solutions for upgrade of combustion systems to save resources and costs.

- Vincenzo Melilli, Senior Manager Technology and R&D Paper and Board ANDRITZ, and Mario Bernasconi, Senior Sales Manager Paper and Board ANDRITZ, will be introducing ANDRITZ’s cost-efficient technologies for sustainable paper and board production, including the world’s fastest kraftliner shoe-blade Gapformer and a 2,000 kN/m shoe press.

ANDRITZ is looking forward to meeting you in Lucca! Visit https://www.miac.info/en/preregister/ to register free of charge for the event or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up stock preparation system at Vinda Personal Care, China

International technology group ANDRITZ has successfully started up a stock preparation system supplied to Vinda Personal Care (Guangdong) Co., Ltd., as part of its tissue production at the mill in Yangjiang, Guangdong, China. With this new line, there are now more than 20 stock preparation systems from ANDRITZ operating in different mills belonging to the Vinda Group.

The new system comprises specific lines for NBKP (Needle Bleached Kraft Pulp), LBKP (Leaf Bleached Kraft Pulp) and bagasse as raw material. ANDRITZ installed the complete stock preparation system, with equipment for low-consistency (LC) pulping, low-consistency (LC) refining, high-consistency (HC) refining, the approach flow system, and broke handling. Two innovative 120 bdmt/d HC refining systems, each consisting of an ANDRITZ Pulp Screw Press and an HC refiner, enable excellent processing of the special raw material mix and ensure superior tissue properties at a minimized NBKP content.

ANDRITZ HC refiner at Vinda Personal Care’s Yangjiang mill “Photo: ANDRITZ”.

ANDRITZ HC refiner at Vinda Personal Care’s Yangjiang mill “Photo: ANDRITZ”.

Mr. Dong Yiping, Executive Director of Vinda International Holdings Limited, says: “With the new ANDRITZ HC refining systems, we achieve better fiber quality in terms of strength, softness and absorbency compared to a conventional LC system in a similar tissue application. Our customers gave very positive feedback as to handfeel and softness of the final product – further proof that our decision to trust in ANDRITZ again was absolutely right.”

Vinda Personal Care (Guangdong) Co., Ltd., part of the Vinda Group, is one of the top four tissue producers in China. The Vinda Group provides high-quality hygiene products and services and operates four core business segments with the key brands Vinda, Tempo, Tork, TENA, Dr. P, Libresse, VIA, Libero, and Drypers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to convert paper machine from newsprint to packaging paper production for Volga Pulp and Paper Mill, Russia

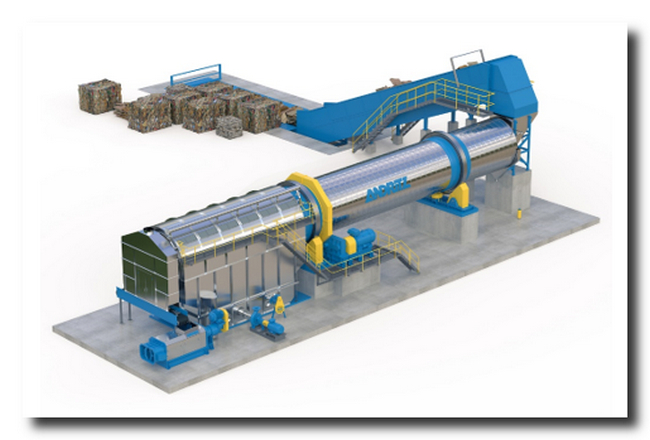

International technology Group ANDRITZ has received an order from Volga Pulp and Paper Mill in Balakhna, Nizhnij Novgorod Region, Russia, to supply a new OCC line as well as to convert its PM 6, a newsprint paper machine, to a packaging paper machine. Start-up is scheduled for the spring of 2023.

After the conversion, PM 6 will produce packaging paper from a unique mix of OCC and TMP fibers – a groundbreaking raw material composition for the production of packaging paper. Volga Pulp and Paper Mill is currently producing packaging paper from 100% TMP fibers and has now opted for this innovative solution to save resources. The rebuilt PM 6 will have an annual production capacity of 140,000 tons and a design speed of up to 720 m/min, producing lightweight fluting and testliner in the range of 65–120 gsm. The rebuild includes the paper machine approach flow system, the forming, press and dryer sections, including the steam and condensate system, a new PrimeFilm film press, some of the paper machine drives, as well as the complete tail threading system and the slitter rewinder.

The new OCC line will process local OCC (Old Corrugated Containers) and feature a capacity of 400 bdmt/d. ANDRITZ will supply all of the main equipment, from bale receiving to the dump chest, including a FibreFlow Drum pulper (type FFD350EE), which is a complete pulping system in one unit. The new drum pulper will ensure superior accept quality thanks to the gentle pulping concept and efficient removal of coarse contaminants with minimum fiber loss. Furthermore, the drum pulping technology is a perfect match for the upcoming changes in raw material and for furnish with increasing reject content. The OCC line will be delivered with an extended scope, including fractionation, screening, cleaning, and pumps as well as automation and electrification equipment with a DCS from ANDRITZ.

The ANDRITZ scope includes supervision of the mechanical installation work, commissioning, and start-up assistance.

ANDRITZ FibreFlow Drum pulper “Photo: ANDRITZ”.

ANDRITZ FibreFlow Drum pulper “Photo: ANDRITZ”.

In 2020, Volga Pulp and Paper Mill successfully started up a new TMP line supplied by ANDRITZ. This repeat order further strengthens the fruitful long-term relationship between the two companies.

CEO of Volga Pulp and Paper Mill Sergey Pondar says: ”The smooth start-up of our TMP line one year ago convinced us that ANDRITZ would once again be the right partner for us. The conversion of PM 6 will be an even more ambitious project, especially in view of the tight time frame.”

JSC Volga is one of the largest Russian newsprint producers and mainly uses 100% TMP as furnish. The company is also one of the top 200 exporting companies in Russia, ranking among the top 50 companies in the Russian forestry industry and the top 100 companies in the Nizhnij Novgorod region.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up major pulp production equipment for Bracell’s “STAR” project, Brazil

International technology group ANDRITZ has successfully started up key production equipment for the first of two environmentally friendly hardwood pulp production lines supplied for Bracell’s “STAR” project in Lençóis Paulista, São Paulo. The second line is expected to be started up by the end of September.

Project STAR is one of the largest and most sustainable pulp mills in the world, operating with the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

The ANDRITZ A-ConFlexTM continuous kraft and dissolving pulping technology enables flexibility in production of high-quality dissolving pulp and kraft pulp. With this delivery, ANDRITZ once again confirms its position as the only technology supplier with solid references and experience in continuous cooking of dissolving pulp. With a capacity of 13,000 tons per day, the ANDRITZ HERBTM recovery boiler is the largest in the world. It will make the mill self-sufficient in energy supply and additionally produce around 180 megawatts of green energy for the Brazilian grid. This covers the energy consumption of about three million people in the region.

ANDRITZ supplied major pulp production equipment for Project STAR, Brazil “Photo: ANDRITZ”

ANDRITZ supplied major pulp production equipment for Project STAR, Brazil “Photo: ANDRITZ”

The ANDRITZ scope of supply includes:

- a complete, high-capacity wood processing plant, enhanced with state-of-the-art ANDRITZ IIoT Smart Woodyard solutions to ensure optimum chip quality,

- two flexible fiberlines with DD-Washer technology,

- the largest EvoDryTM Pulp Drying System in the world, with two energy-efficient pulp drying lines and equipped with the Metris DryQ smart pulp drying solution and Metris remote connection to ensure a fast start-up,

- an ANDRITZ HERB recovery boiler,

- a non-condensable gas (NCG) treatment system.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,000 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply tissue plant to Astrabel, Croatia

International technology Group ANDRITZ has received an order from Astrabel d.o.o. to supply a tissue plant for cost-efficient production of high-quality grades to its mill in Belišće, Croatia. Start-up is planned for 2023.

The turn-key project includes stock preparation, tissue machine with air systems and rewinder, complete electrification and automation, and pumps.

The stock preparation plant will be equipped with a FibreSolve FSV pulper for energy-efficient bale pulping as well as HD cleaning, deflaking, TwinFlo disc refining and headbox screening machinery in the approach flow system.

PrimeLineCOMPACT tissue machine “Photo: ANDRITZ”.

PrimeLineCOMPACT tissue machine “Photo: ANDRITZ”.

The tissue machine is a PrimeLineCOMPACT S 1300 with a design speed of 1,300 m/min and will produce a paper web that is 2.85 m wide. It is equipped with a 15 ft. PrimeDry Steel Yankee and a PrimeDry Hood COMBO (combined efficiency hood with wet blowing and dry suction) to enable energy-efficient production.

Metris UX – the ANDRITZ digitalization platform with fully embedded ANDRITZ Distributed Control System Metris X – and numerous applications for remote assistance as well as process and production optimization will enable maximum mill performance.

Dinko Burić, M.D., Mayor of the city of Belišće, explains: “This investment is not only a major step for Astrabel but also for our city. ANDRITZ offers a perfect solution with local proximity as well as the opportunity to conduct trials and train the staff at their tissue pilot plant in Austria.” Prof. Milorad Krgović, PhD, Chairman of the Board of Astrabel, adds: “We are looking forward to receiving our state-of-the-art tissue production line that aims at sustainable, high-quality tissue production.”

Astrabel d.o.o. is a newly formed company for tissue production located in Belišće, Croatia. The tissue produced will be sold primarily on the domestic market to meet the growing demand for toilet paper, napkins and kitchen roll.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

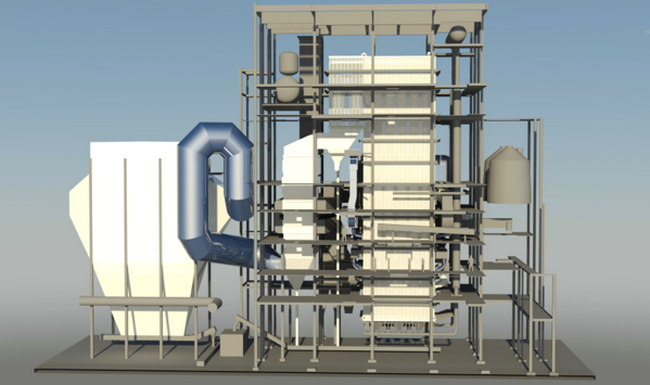

ANDRITZ to supply equipment for power and recovery boiler conversions to Domtar

ANDRITZ Inc., a member of international technology Group ANDRITZ, has been selected by Domtar Corporation to provide equipment and technical services for conversion of a power boiler and a recovery boiler at their Kingsport paper mill, in Kingsport, TN, USA. This mill will be converted into Domtar’s first packaging facility.

As part of this state-of-the-art conversion, the Kingsport Mill needed to repurpose their steam generation equipment. ANDRITZ will convert an existing recovery boiler into a natural gas-fired power boiler with back-up fuel oil capability by supplying the main equipment, including low NOx burners and associated fuel and air systems. ANDRITZ will also provide equipment for the mill to modify an existing bubbling fluidized bed (BFB) power boiler so that it can accommodate a change in fuels from wood and sludge firing to corrugated cardboard (OCC) rejects, natural gas, and fuel oil firing.

The scope of supply also includes boiler cleaning devices, pressure part upgrades, material handling equipment, air/flue gas system upgrades, and environmental equipment to enable the mill to meet the highest environmental standards.

BFB boiler model showing planned modifications “Photo: ANDRITZ”.

BFB boiler model showing planned modifications “Photo: ANDRITZ”.

ANDRITZ’s extensive experience with multi-fuel boilers and air pollution control were decisive reasons for Domtar to award the order to ANDRITZ.

Once completed, Domtar’s Kingsport Mill will become North America’s premier lightweight containerboard facility – able to produce over 600,000 tons of high-quality recycled linerboard and corrugated medium annually. This level of capacity will make the Kingsport machine the second largest in North America for recycled containerboard.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

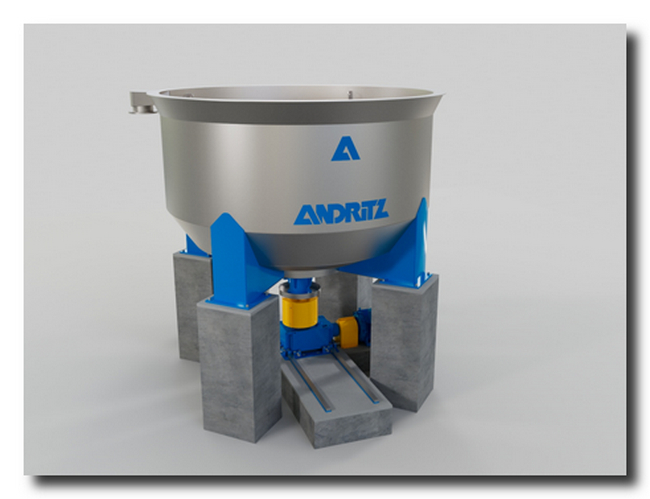

ANDRITZ to supply complete OCC line to United Paper, Thailand

International technology Group ANDRITZ has received an order from United Paper Public Company Limited (“United Paper”) to supply a complete OCC line for its mill in Prachinburi, Thailand. Start-up is scheduled for the second quarter of 2022.

ANDRITZ will supply the main equipment – from pulping to the storage tower – featuring the following technological highlights:

- LC pulping system comprising a FibreSolve FSR pulper with newly designed rotor and TrashWell standpipe for efficient reject removal as well as state-of-the-art detrashing machinery. The new pulping system not only enables excellent slushing of the raw material at minimum fiber loss, but also focuses on efficient separation and removal of rejects with highest availability.

- Innovative PrimeScreens X for screening and fractionation with new PrimeRotors for superior screening performance, savings in energy consumption by up to 25% as well as fast and easy maintenance.

ANDRITZ FibreSolve FSR pulper with new rotor design “Photo: ANDRITZ”.

ANDRITZ FibreSolve FSR pulper with new rotor design “Photo: ANDRITZ”.

The new OCC line will have a design capacity of 550 bdmt/d and process a mixture of AOCC and LOCC to produce linerboard. The scope of supply also includes the detailed engineering and supervision of installation, commissioning and start-up.

Wachara Chinsettawong, Deputy Managing Director, United Paper, says: “The benefits related to energy savings and maintenance as well as the excellent performance we are having from the first line that ANDRITZ delivered to us were the main reasons for our decision to trust in ANDRITZ once more.”

This order once again strengthens ANDRITZ’s leading position as a supplier of OCC lines in Thailand.

United Paper Public Company Limited was founded in 2004 and is an important producer of various kraft paper grades for linerboard and corrugated medium.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

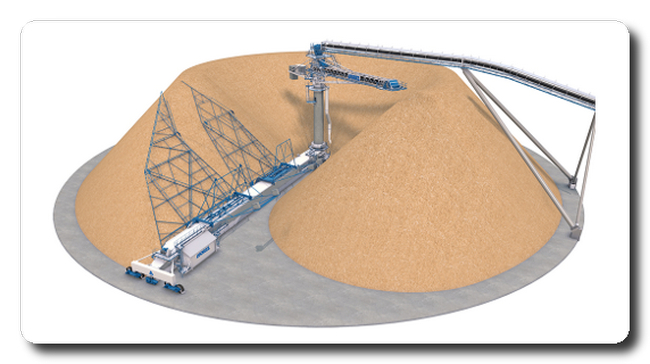

ANDRITZ to supply chip storage system to Visy Pulp & Paper, Tumut mill, Australia

International technology Group ANDRITZ has received an order from Visy Pulp & Paper for a 243,000 m3 chip handling and storage system, including a Stacker Reclaimer RST360, for its Tumut mill in New South Wales, Australia.

The ANDRITZ 360° Stacker Reclaimer is a complete system that stores and reclaims wood chips in a continuous 360° radial configuration. It operates on a true first-in, first-out (FIFO) chip management basis, ensuring homogeneous chip supply to the digester while at the same time offering a large storage capacity. ANDRITZ has several references for RST360 Stacker Reclaimers worldwide.

3D model of the ANDRITZ 360° Stacker Reclaimer. “Photo: ANDRITZ”.

3D model of the ANDRITZ 360° Stacker Reclaimer. “Photo: ANDRITZ”.

The discharge rate from the RST360 is automatically controlled, with the speed of the two metering screws in the hopper being adjusted to meet the capacity requirements of the pulping process. The equalizing hopper discharge is continuously monitored with a belt scale. Added to these features, the RST360 is delivered with a dedicated bypass to feed chips directly to the discharge hopper from the infeed conveyor.

Visy Pulp & Paper is a leading, privately owned packaging and resource recovery company, with more than 120 sites across Australia, New Zealand and Thailand and trading offices across Asia, Europe and the USA.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.