Ianadmin

Clearwater Paper's North Las Vegas Tissue Facility Achieves OSHA VPP Star Status

At a ceremony today in North Las Vegas, Nev., Clearwater Paper Corporation (NYSE: CLW) received the Nevada Occupational Safety and Health Administration's (OSHA) highest level of recognition offered by the agency's Voluntary Protection Programs (VPP) as Star status. Clearwater Paper now becomes one of only nine such VPP sites in the state of Nevada.

At a ceremony today in North Las Vegas, Nev., Clearwater Paper Corporation (NYSE: CLW) received the Nevada Occupational Safety and Health Administration's (OSHA) highest level of recognition offered by the agency's Voluntary Protection Programs (VPP) as Star status. Clearwater Paper now becomes one of only nine such VPP sites in the state of Nevada.

"At Clearwater Paper, we believe that safety comes first in everything we do, and we put that concept into action by striving for continuous safety improvement," said Linda K. Massman, president and CEO. "Today's event is a time to reflect and celebrate a truly great safety achievement that required five years of hard work and collaboration with OSHA, but more importantly recognize that what our employees have put in place today will help protect each individual and fellow employees going forward."

In order to attain VPP Star status, Clearwater Paper's Las Vegas facility completed a multipoint safety and health analysis and an intensive on-site inspection by OSHA staff. Both include proactive measures to prevent fatalities, injuries and illnesses through a program of focused management commitment and employee involvement, hazard prevention and control, worksite analysis, and safety and health training.

"My fellow employees were determined to reach VPP Star status, and we did it by building a positive and productive partnership with OSHA—this is a big day for all of us," said Nick Marquart, Clearwater Paper's safety and VPP coordinator at the Las Vegas facility. "We were also very pleased to see so many of our elected representatives and agency officials come to help celebrate our success, including our Nevada Congressional delegation, Governor Sandoval's office, our state representatives, and many important agencies, including of course, OSHA."

VPP promotes effective worksite-based safety and health. In the VPP, management, employees, and OSHA establish cooperative relationships at workplaces that have implemented a comprehensive safety and health management system. Acceptance into VPP is OSHA's official recognition of the outstanding efforts of employers and employees who have achieved exemplary occupational safety and health.

Source: Clearwater Paper Corporation

Verso to Locate Ohio Operations Center in Miamisburg Following Completion of Pending Newpage Acquisition

Verso Paper Corp. (NYSE: VRS), a leading North American producer of coated papers, has announced plans to consolidate its existing West Chester office and the NewPage Miamisburg office into a single Ohio Operations Center. The Ohio Operations Center will be located in the existing Miamisburg facility shortly following the completion of Verso's pending acquisition of NewPage expected later this year. Verso's corporate headquarters will remain in Memphis, Tenn.

Verso Paper Corp. (NYSE: VRS), a leading North American producer of coated papers, has announced plans to consolidate its existing West Chester office and the NewPage Miamisburg office into a single Ohio Operations Center. The Ohio Operations Center will be located in the existing Miamisburg facility shortly following the completion of Verso's pending acquisition of NewPage expected later this year. Verso's corporate headquarters will remain in Memphis, Tenn.

Verso's West Chester office currently houses about 55 employees in customer-facing and Information Technology functions. "We're committed to presenting a single face to our customers on Day 1," said Mike Weinhold, Verso's senior vice president of Sales, Marketing and Product Development. "Quickly co-locating our teams will help ensure we deliver on our promise of a seamless transition for customers."

The NewPage Miamisburg office is located at 8540 Gander Creek Drive, about 20 miles north of West Chester. "While we understand this will be an adjustment for our West Chester employees, we plan to do our best to minimize the potential disruption that such a move entails," Verso's Vice President of Human Resources Kenny Sawyer said. "We conducted a thoughtful and rigorous analysis of our options for a single Ohio Operations Center. Ultimately, our decision was based on a combination of financial, logistical and employee considerations that led us to select Miamisburg as the best option."

Source: Verso Paper Corp.

Valmet selected as the main supplier for Södra Cell's major pulp mill rebuild in Sweden

Valmet has received a major rebuild and new equipment order from Södra Cell for the Värö pulp mill in Sweden. The order is part of Södra Cell's over 400 million euro investment to increase the Värö mill's pulp production capacity from 425,000 tons to 700,000 tons per year.

Valmet has received a major rebuild and new equipment order from Södra Cell for the Värö pulp mill in Sweden. The order is part of Södra Cell's over 400 million euro investment to increase the Värö mill's pulp production capacity from 425,000 tons to 700,000 tons per year.

The order is included in Valmet's second quarter 2014 orders received and is valued at around EUR 200 million.

Valmet's delivery will contribute to Södra's performance by significantly increasing the Värö mill's pulp production capacity and energy efficiency. The order consists of a new continuous cooking plant and upgrades of wood handling, fiber line, evaporation plant, recovery boiler, recausticizing, flash dryer, pulp dryer and baling. On completion of the project, Värö will be one of the world's largest softwood sulphate pulp mills. The start-up of the renewed pulp mill is scheduled in the third quarter of 2016.

"We have good experiences of Valmet and feel confident that this project will be a success. We have worked closely together with Valmet in planning the project and it gives us a good start. This investment increases our pulp production, makes the mill more energy efficient and increases its bioenergy supply potential", says Gunilla Saltin, CEO, Södra Cell.

"We are very pleased that Södra Cell trusted us with this significant order. It is a strong token of our technological leadership and competitiveness in the pulp technology market. Investments in pulp production are active at the moment and Valmet is strongly involved with many major on-going projects", says Jyrki Holmala, President, Pulp and Energy Business Line, Valmet.

Significant employment impact

The estimated employment impact of the order is about 650 man years mainly in Sweden. A large part of the order will be delivered from Valmet's operations in Sweden: the cooking plant and recausticizing from Karlstad, fiber line, flash dryer and baling from Sundsvall, and evaporation and recovery boiler from Gothenburg. The wood handling and pulp dryer delivery will come from Finland.

A prerequisite for construction start is the receipt of a permit from the Environmental Court of Appeal.

About Södra Cell

Södra is an economic association with a membership base of 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,800 people and has four business areas Södra Skog, Södra Cell, Södra Timber and Södra Interiör.

Södra Cell is one of the world's largest market pulp supplier, with a total annual production of 1.6 million tonnes.

With the tools provided by modern automation, pulp and paper makers can produce more with less

"In automation, new applications featuring the latest control technology enable papermakers to reach totally new levels with their processes when it comes to quality and productivity. Replacing outdated automation systems with modern cutting-edge solutions provides the means to stay in the race", points out Ilkka Saarinen, Director, Pulp & Paper Applications, EMEA, Automation, Metso

Pls feel free to ask for more information. We also appreciate your feedback in all automation related issues.

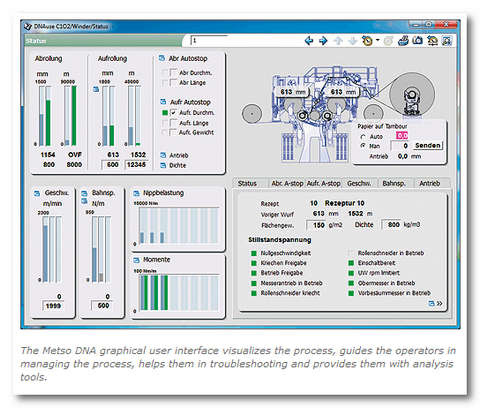

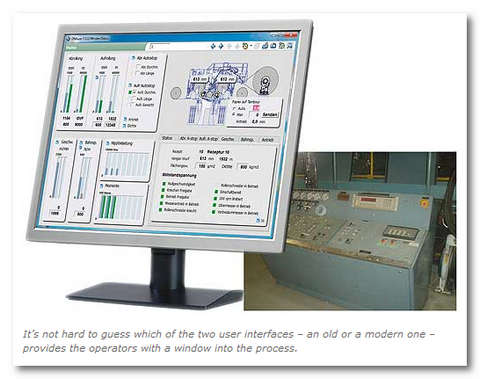

“There is a vast technology gap between the aging systems and modern solutions. For example, today’s graphical user interfaces visualize the process, guide operators in managing the process, help them troubleshoot, and provide them with analysis tools. Development steps in process controllers have been huge, too,” Saarinen adds.

“Automation not only is a tool to manage the process and production, it provides a window into the process and the end product,” points out Ilkka Saarinen, Director, Pulp & Paper Applications, EMEA, Automation, Metso. “Today, the automation structure in many paper mills is largely a ‘historical patchwork quilt’, consisting of many isolated system islands. This does not provide a competitive platform for the efficiency race.”

Mind the technology gap

Having separate outdated systems for various tasks within a process often creates major challenges. Typical examples include limited functionality in the operator interface, reliability problems due to aging hardware, and complicated data links between the various systems. With the many different types of engineering tools, maintenance is a headache. It is difficult to find faults and identify interlocks, as well as add new loops in the old system. Plus, the people who can program are retiring, and spare parts and system support are no longer available.

“There is a vast technology gap between the aging systems and modern solutions. For example, today’s graphical user interfaces visualize the process, guide operators in managing the process, help them troubleshoot, and provide them with analysis tools. Development steps in process controllers have been huge, too,” Saarinen adds. “In automation, new applications featuring the latest control technology enable papermakers to reach totally new levels with their processes when it comes to quality and productivity.”

The architecture of new-generation automation systems, such as Metso DNA, provides users with one single platform for all control functions in a paper mill, including process controls, machine controls, quality controls, drive controls, condition and runnability monitoring, as well as web break and web inspection analysis. As Saarinen puts it: “The system gives operators a feeling of control through high reliability, an effective user interface and advanced control algorithms.”

“There is a vast technology gap between the aging systems and modern solutions. For example, today’s graphical user interfaces visualize the process, guide operators in managing the process, help them troubleshoot, and provide them with analysis tools. Development steps in process controllers have been huge, too,” Saarinen adds. “In automation, new applications featuring the latest control technology enable papermakers to reach totally new levels with their processes when it comes to quality and productivity.”

The architecture of new-generation automation systems, such as Metso DNA, provides users with one single platform for all control functions in a paper mill, including process controls, machine controls, quality controls, drive controls, condition and runnability monitoring, as well as web break and web inspection analysis. As Saarinen puts it: “The system gives operators a feeling of control through high reliability, an effective user interface and advanced control algorithms.”

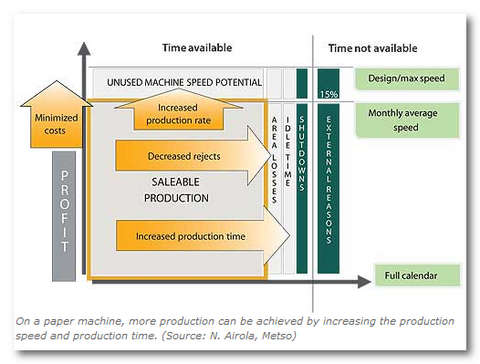

Minimizing area losses and idle time

Operational efficiency is about identifying wasteful processes and resources that drain the organization’s profits and designing new work processes that improve quality and productivity. Modern automation makes this possible, as it enables mills to minimize area losses and idle time, and utilize the speed potential hidden in the production line.

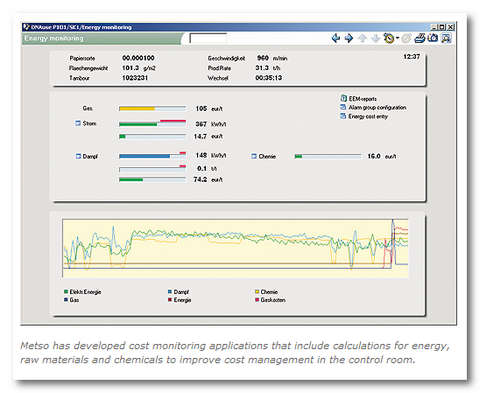

Carrying out automation migration also contributes to better efficiency by preventing unplanned shutdowns and allowing better cost management with new tools. Saarinen continues: “Traditionally, cost awareness in the production line control room has not been very evident when operators take care of process stability. This has led to a situation of having safety margins in several places, as stability can be easily improved by adding more chemicals, more raw materials, and more drying. Metso, for example, has developed cost monitoring applications that include calculations for energy, raw materials and chemicals.”

Operational efficiency is about identifying wasteful processes and resources that drain the organization’s profits and designing new work processes that improve quality and productivity. Modern automation makes this possible, as it enables mills to minimize area losses and idle time, and utilize the speed potential hidden in the production line.

Carrying out automation migration also contributes to better efficiency by preventing unplanned shutdowns and allowing better cost management with new tools. Saarinen continues: “Traditionally, cost awareness in the production line control room has not been very evident when operators take care of process stability. This has led to a situation of having safety margins in several places, as stability can be easily improved by adding more chemicals, more raw materials, and more drying. Metso, for example, has developed cost monitoring applications that include calculations for energy, raw materials and chemicals.”

Something old, something new

Saarinen names two main alternatives for automation migration. The first one is the so-called Bulldozer method, where only field equipment and parts of the field wiring remain. “This alternative is the most costly in terms of new equipment and shutdown time,” he says.

The second one preserves the mill’s existing I/O connections and field wiring, but the I/Os are replaced. Profibus I/O cards or some other I/O cards with Profibus converters can be reused. “Metso has successfully used this second alternative with numerous paper mills. This concept uses the old automation system as much as possible, and a new control strategy is built on top of it,” Saarinen points out. “In this way, there is no need to increase the amount of expensive field instrumentation.”

An automation migration project is usually scheduled to be carried out in small steps over 1 to 3 years. Only in the case of a complete paper grade changeover in a production line is a machine shutdown is long enough to carry out the replacement in one stage.

Fast payback to be expected

Replacing a control system (DCS, QCS) or machine controls (MCS) is major investment. However, it soon pays back with increased operational efficiency. The payback is visible through increased time efficiency, as there are fewer unplanned shutdowns thanks to better process reliability. The process recovers faster from shutdowns and breaks, and has less break time thanks to faster troubleshooting. Grade changes are faster, too, thanks to new control applications.

Cost savings are gained by using less raw material and energy per produced ton paper. With only one single integrated system, fewer spare parts are needed and less maintenance effort is required as the same people with the same tools can maintain all applications. According to Saarinen, the average target is to have a 16-month payback for an automation migration investment.

“When planning an automation replacement project, it is vital to understand that like-to-like replacement doesn’t generate payback,” he emphasizes. “The components generating the payback offer reliability through new technology, faster troubleshooting through increased information from the process, as well as overall visibility and increased information from the system components and field equipment. Included are also new control applications and cost savings through higher efficiency, fewer spare parts and less maintenance.”

Well planned and executed equals success

In migration projects, professional project flow and management are key to success. Each project should start with an audit that provides an overview of the mill’s installed base and expectations for the outcome. An audit is also necessary when a paper machine is moved to another location or a production shift occurs from one grade to another during a machine rebuild.

In the following pre-study phase, a detailed plan needs to be made about how the system will be replaced and defines which field devices (transmitters and valves) have to be replaced or repaired. This work produces a detailed replacement plan, which sets the framework for basic engineering. During the basic engineering, a new process and machine control strategy based on the existing field devices will be defined.

Pls feel free to ask for more information. We also appreciate your feedback in all automation related issues.

Södra chooses Valmet as main supplier for Värö

Södra has appointed Valmet of Finland as its main supplier for process equipment for the expansion of the pulp mill in Värö, near Varberg. This order is part of Södra's investment totalling more than SEK 4 billion.

The order placed with Valmet includes a new continuous digester and upgrades to wood handling, the fibre line, evaporation plant, soda recovery boiler, causticisation, flashdryer, drying machine and baling.

A large portion of the order will be supplied by Valmet in Sweden: The digester and causticisation will be supplied by Karlstad, the fibre line, flashdryer and baling by Sundsvall, and evaporation and the soda recovery boiler by Gothenburg. The wood handling and pulp dryer will be supplied by Finland. Valmet states that the order from Södra is worth around SEK 2 billion.

"We have good experiences of Valmet and feel confident that this project will be a success. We have worked closely together with Valmet in planning the project and it gives us a good start. This investment increases our pulp production, makes the mill more energy efficient and increases its bioenergy supply potential", says Gunilla Saltin, President, Södra Cell.

"We are very pleased that Södra Cell trusted us with this significant order. It is a strong token of our technological leadership and competitiveness in the pulp technology market. Investments in pulp production are active at the moment and Valmet is strongly involved with many major on-going projects", says Jyrki Holmala, President, Pulp and Energy Business Line, Valmet.

Södra has previously purchased groundwork, building work and construction work from NCC with regard to the expansion of Värö. Another major supplier is Raumaster, which will be supplying storage and transport equipment for chips and bark.

When the expansion work is complete, Värö will be one of the biggest pine sulphate pulp mills in the world, with a total production capacity of 700,000 tonnes of pulp per year. These investments will also considerably increase Värö's energy efficiency.

Valmet Corporation is a global developer and supplier of services and technology for the pulp, paper and energy industry. Valmet has revenues of around EUR 2.6 billion (2013) and employs 11,000 staff, and its head office is based in Espoo, Finland.

New Metso Kappa QC Analyzer enhances fiberline process performance with integrated measurements and controls

New control features maximize discrete to continuous pulp measurement benefits in total pulp quality management, enhance process stability and save on chemical costs.

New control features maximize discrete to continuous pulp measurement benefits in total pulp quality management, enhance process stability and save on chemical costs.

Metso has further developed its industry-standard online Metso Kappa Analyzer (Metso Kappa Q) by now introducing an enhanced Metso Kappa QC version. For the first time, a fiberline analyzer not only measures pulp lignin content and brightness, but also includes a new unique stabilizing control capability in all process stages, from the oxygen stage up to the finished pulp.

The new control capabilities incorporated enable pulp makers to improve total pulp quality management, boost process stability and gain major savings in chemical costs throughout the process stages.

Number one in analyzer technology

The enhanced version of the Metso Kappa Analyzer represents the fourth generation of Metso's pioneering pulp mill analyzer technology. For almost 40 years, Metso's products have played a key role in the evolution of chemical pulp mill delignification and bleaching controls. Today, Metso Kappa and brightness analyzers and the well-known inline sensors provide the standard platform for process optimization and quality control at most of the leading chemical pulp mills in the world.

Metso has the world's widest scope of automation solutions and services for the pulp and paper industry - from fiber to print and from single measurements to mill-wide turnkey automation projects. It is the market leader not only in analyzers, but also in quality control systems as well as in control and on-off valves for this industry sector. Metso's system-independent solutions help customers lower their operating and maintenance costs, and keep their assets' operating value as high as possible.

High flexibility and user friendliness

Thanks to a flexible structure, the measurement capacity of Metso Kappa QC can easily be expanded by adding measurement modules and sampling points. Measurement capacity alternatives include 10, 20, 30 or 40 measurements per hour. It is also possible to benefit from the analyzer's advanced continuous Kappa measurement and COD index in applications where fast changes in process conditions and washing efficiency exist by using inline sensor integration in the control structure.

To fully utilize the efficiency, safety and ease of use of the Kappa QC centralized user interface, Metso is introducing a new high-definition touch screen as part of the new analyzer unit.

Metso’s automation runs successfully in one of the world’s most modern pulp mills, Suzano Maranhão in Brazil

Controlling all key processes at the greenfield mill is a showcase of Metso’s global manufacturing and project management capabilities and marks the company as a leading automation partner for pulp and paper makers.

Suzano Maranhão in Brazil, one of the world’s most modern pulp mills owned by Suzano Papel e Celulose S.A., in Imperatriz, Maranhão, Brazil, has run its processes successfully with Metso’s process automation and valve technologies since its startup in late December 2013.

The greenfield pulp mill controls all its key processes with Metso’s integrated automation controls, including wood handling, cooking plant and fiber line, pulp drying and baling, evaporation, power boiler, recovery boiler, causticizing and lime kiln.

Metso’s technologies at Suzano include Metso DNA distributed control system, valves, a quality control system, analyzers, advanced process controls, an operator training simulator, profilers, a web runnability monitoring system, condition monitoring systems, and bale quality management.

“I had no previous experience with Metso’s distributed control system, but now can say that Metso is a great supplier for capital-intensive projects like Suzano Maranhão,’’ says Vitor Wuo, Suzano’s Project Coordinator.

“The system has met our expectations thanks to its user-friendly interface and easy operation. The advanced diagnostics and trend features allow faster decision-making for our operational team,” adds Volnei Hilbert, Industrial Manager at Suzano Maranhão.

Metso’s operator training simulator is used in the local school that Suzano is building in the area. The simulator will have important role in training the local work force for the new pulp mill.

The mill produces 1.5 million tons of bleached eucalyptus market pulp per year. Key technology was supplied by Valmet.

Professional project management in a key role

The project was a real showcase of Metso’s manufacturing and project management capabilities. For example, the distributed control system was engineered in India, Brazil and Finland and manufactured in Finland and in Brazil. Out of the over 1,300 automated valves, the main part was supplied from Metso’s valve factory in China, whereas large valves with special materials were manufactured in Finland.

DCS system hardware and software testing took place at Metso’s Sorocaba office. To meet the customer’s expectations, seamless and continuous communication for smooth cooperation was mandatory among all the supplier locations and continents.

The location of the pulp mill in northeastern Brazil set some extra challenges for the project.

“The arrival port in Brazil lacked modern container handling equipment, which required additional arrangements to get the containers to the quay and onto road trucks that transported them 700 kilometers to the construction site. Due to the rainy season, the roads were nearly in impassable condition in some places,” recalls Project Manager Tuomo Marjomaa, Automation, Metso. Despite the challenging circumstances, the construction phase proceeded as scheduled.

ABTCP names Metso repeatedly ‘Outstanding Company in Automation for Pulp & Paper’

To meet the increasing pulp and paper industry demands in Brazil, Metso has strongly invested in expanding its local operations. The company has invested in infrastructure and equipment, offering better service on a quick and competitive basis to its customers throughout South America.

Metso’s expertise, solutions and services for the pulp and paper market help meet customer needs, improve production process efficiency and reduce supplies, raw material and energy consumption where resources are getting limited.

“As an example of this, Metso has been recognized as an ‘Outstanding Company in Automation for the Pulp & Paper segment’ for seven consecutive years by Brazilian Pulp & Paper Technical Association ABTCP, showing its power as the best automation supplier for the sector,” points out Maximilian Furley, General Manager, South America, Automation, Metso. “We are very proud of the recognition from our customers. We will continue to invest in this industry through our efforts in new technological developments.”

According to Furley, the Suzano Maranhão project is of great importance in positioning Metso as a leading distributed control system supplier in South America. “The DCS market is extremely competitive in Brazil, and now we can say that Metso is even more prepared for future projects.”

In 2013, Metso’s other deliveries to South America included, among others, an integrated automation solution for CMPC Group’s new plant in Guaíba, in the state of Rio Grande do Sul, Brazil.

Suzano Papel e Celulose is a forestry-based company and one of the largest vertically integrated producers of pulp and paper in Latin America. The company’s main products, sold on the domestic and international markets, are eucalyptus pulp, printing and writing paper and paperboard. www.suzano.com.br

OnV FeltView for press felt measurements offers energy savings, maximum productivity and safety

The OnV FeltView system developed by Voith enables accurate, continuous and especially safe real-time measurement of press felt moisture and permeability. The OnV FeltView system supports paper manufacturers with both routine operation and troubleshooting, as it makes profile and trend information constantly available.

OnV FeltView consists of a cross-beam and a carriage fitted with sensors for measuring moisture and permeability. This means that sporadic manual measurements by operating personnel are no longer necessary. The system offers the paper manufacturer significant benefits in respect of cross-profile problems and daily operation of the plant: On the one hand, profile problems can now be identified in the measurement profile at an early stage, allowing appropriate remedial action to be taken. On the other hand, the manufacturer is now able to tailor the felt conditioning process to the actual measured condition of the felt. As a result, the felt can always be operated so as to optimize runability and dewatering, all without risking the health of operating personnel.

The innovative OnV FeltView technology is already being used successfully by nine tissue manufacturers. The condition of the press felt in tissue production is crucial to the runability of the entire plant as well as for gas and steam consumption. If the felt is in an optimum condition, massive energy savings and maximum productivity levels are possible. With OnV FeltView and a wide range of extra services Voith is helping paper manufacturers to achieve these goals. The OnView information system, which integrates the data from OnV FeltView, facilitates a highly efficient analysis of historical and current felt data.

ANDRITZ successfully starts up TM2 tissue machine for Ganzhou Hwagain Paper, China

Following start-up of the TM1 PrimeLine tissue machine, international technology Group ANDRITZ has also successfully completed start-up of the second tissue machine supplied to Ganzhou Hwagain Paper, China.

Following start-up of the TM1 PrimeLine tissue machine, international technology Group ANDRITZ has also successfully completed start-up of the second tissue machine supplied to Ganzhou Hwagain Paper, China.

The scope of supply for TM 2 comprised the stock preparation plant for softwood, hardwood, and bamboo pulp, the 2-layer headbox with dilution control system, a shoe press, the wet dust removal system, a reel system, and the machine automation control system.

The shoe presses supplied for both tissue machines provide a higher after-press dryness, which reduces thermal drying requirements and lowers energy costs for the customer or can increase production levels at the same thermal energy consumption. The raw fiber consumption is also reduced, thus enabling the customer to obtain the same quality level in the final product by at the same time using lower-cost fibers.

“Photo: ANDRITZ”

Iggesund’s fossil-free mill: The vision is within reach

“We’re getting close to the vision of a fossil-free mill that we’ve lived with and that has driven our investments for a long time,” says Mill Director Olov Winblad von Walter. “Our new recovery boiler, which came on line in spring 2012, is getting better and better as we fine tune it, and our increasing pulp production is also boosting our energy production.”

“We’re getting close to the vision of a fossil-free mill that we’ve lived with and that has driven our investments for a long time,” says Mill Director Olov Winblad von Walter. “Our new recovery boiler, which came on line in spring 2012, is getting better and better as we fine tune it, and our increasing pulp production is also boosting our energy production.”

For a while in mid-April Iggesund Paperboard’s Swedish paperboard mill, Iggesund Mill, was able to operate solely on bioenergy and also supply almost all its own electricity needs. Another important aspect in the vision for Iggesund Mill is that emissions to air and water should be so low that Iggesund is among the global leaders among comparable manufacturers. Yet another goal is that a minimum of by-products will go to landfill.

Iggesund Mill is one of the world’s integrated paperboard mills with the highest level of investment. When it started up the new recovery boiler was the mill’s biggest investment to date, at a cost of about EUR 250 million. The boiler enabled the mill to gradually increase its annual pulp production from what was then 350,000 tonnes to 420,000.

“Our sulphate process for pulp production means that we separate out the cellulose fibres that comprise half the mass of a log,” Winblad von Walter continues. “The other half consists of the wood’s binding agent, which is mostly an energy-rich substance called lignin. We burn this in the recovery boiler and it produces enough steam and electricity to cover more than 90 per cent of our energy needs.”

A fossil-free energy supply is not the only benefit from Iggesund’s new recovery boiler. After the boiler had been fine tuned, it turned out that particle emissions from the mill, which were already low, had been halved. Sulphur emissions, which contribute to the acidification of surrounding land, have also fallen by more than 80 per cent from what were already low levels.

Just over a year ago Iggesund’s board mill in Workington, England, radically changed its own energy source. From having run on fossil natural gas, the mill switched to using biomass. Achieving this required the investment of about EUR 122 million in a new biofuel boiler. Today the mill operates solely on biofuel and in addition to covering its own energy needs it also supplies fossil-free electricity to the UK electricity grid.

“One of the goals driving our investments is long-term sustainability, and the investments in both Iggesund and Workington are the result of that approach,” explains Staffan Jonsson, head of Group Technology at the Holmen Group, to which Iggesund belongs.

The Holmen Group is one of the world’s 100 most sustainable companies according to the UN sustainability index, the Global Compact Index.

Caption 1: Iggesund Mill’s new recovery boiler – which was completed in 2012 at a cost of about EUR 250 million – is one of the basic requirements for being able to operate the mill without using any fossil fuel.© Iggesund