Ianadmin

Luvata solution wins Valmet business

Valmet Corporation has placed an order with Luvata for 900-industrial heat exchangers valued at EUR 5.7 million. The industrial coils will be used in paper pulp dryers at Valmet customer facilities in Brazil and Indonesia.

Valmet Corporation has placed an order with Luvata for 900-industrial heat exchangers valued at EUR 5.7 million. The industrial coils will be used in paper pulp dryers at Valmet customer facilities in Brazil and Indonesia.

With each heat exchanger weighing approximately 2-tons and measuring approximately 6 x 1,5 x 0,5 meters, the total project will involve over 217-tonnes of steel tube, 900-tonnes of steel bands and more than 143,800 tube plate drill holes, all delivered in two fixed delivery months.

"We have a very strong supplier network, and Luvata is one of them,” says Hannu T. Pietilä, Valmet Area President, Asia Pacific. “The evaporation system and pulp dryers delivering to Indonesia will be the largest in the world. This requires an unprecedented scale of pieces and parts that must all come together in a well-organized fashion.”

“We’ve designed and manufactured high-quality coils and coolers for industrial applications for over 70 years. Today that’s no longer enough,” indicates Mattias Lindhe, Commercial Director EMEA – Industrial with Luvata Söderköping. “We must also deliver complex, logistically challenging, turnkey supply solutions. And that’s when Luvata excels.”

Valmet signed a contract with OKI Pulp & Paper Mills to supply key technology for a pulp mill project in South Sumatra, Indonesia. The new mill is expected to produce approximately 2 million ADT (air dry tonne) of pulp annually. The commercial production is expected to begin in 2016.

Valmet will also supply two pulp drying lines to Klabin's new plant in Ortigueira in Parana, Brazil. The annual production capacity of Klabin's new plant will be 1.5 million tons, with start-up of the new plant scheduled for the first half of 2016..

BillerudKorsnäs packages Spotify

BillerudKorsnäs and Berghs School of Communication are giving Spotify a physical form. The collaboration is called SPICE:14 and is this year’s edition of a packaging design contest for students at Berghs. This is the first time an online brand will be physically packaged.

BillerudKorsnäs and Berghs School of Communication are giving Spotify a physical form. The collaboration is called SPICE:14 and is this year’s edition of a packaging design contest for students at Berghs. This is the first time an online brand will be physically packaged.

SPICE (Sustainable Packaging & Innovation Communication Event) is taking place for the fifth year in a row. In the first year, the event was merely a contest that Berghs students participated in, but now SPICE is part of the "Sustainable Packaging Design" course at Berghs.

This year, SPICE has been commissioned by the Swedish international music service Spotify. The company wants to try out a new way to reach consumers with its online music service.

"We’re delighted to have the opportunity to take part in SPICE. We get a lot of requests, and the reason we said ‘yes’ to this event was that it felt well organised and planned. There was also a clear schedule for us to consider," says Jonathan Forster, MD of Spotify Nordic.

Spotify is now putting the finishing touches to the brief that the students will receive when the course begins at the end of September.

"We want it to be fun for both Spotify and the students, but still be defined so narrowly so that they know what the scope is and what we want to achieve. It’ll be exciting to see what kinds of creative solutions the students come up with during the autumn," says Jonathan Forster.

Jimmy Nyström, Business Development Director at BillerudKorsnäs and Project Manager for SPICE:14 says that BillerudKorsnäs likes challenging the conventional and finding new packaging solutions.

"This is the first time we’ve been involved in packaging an internationally renowned digital brand, which shows that even digital brands need physical packaging to reach their target audience."

"The collaboration with BillerudKorsnäs is in line with the way Berghs structures its full-time courses – reality-based cases supported by specialists with excellent knowledge of the industry," says Pål Pettersson, Head of Graphic Design, Berghs School of Communication.

Voith opens its “one stop” Paper City in Kunshan.

It's the result of the largest investment of its kind in Asia and was designed with one purpose in mind, to make a one-stop destination for paper makers; from paper machines to rolls service, to fabrics.

The new facility has unprecedented capacity to support the industry in China and Asia with delivery times that will surprise…pleasantly. A large team of world class paper-making experts on the ground means Voith can advise Asian customers on optimal configurations to maximize quality, output and efficiency.

Voith Paper City has a staff of more than 1,200 people. It encompasses 111,049m(2), 66,139m(2) for Paper Fabric and Roll Systems and 44,910m(2) for Paper System.

The new fabrics plant at Voith Paper city alone is 55,000 m(2) and showcases unique weaving processes, the biggest press fabric carding & needling line in the world, and the most modern forming factory.

Voith team of international paper experts ensures your production runs smoothly, on time and with high quality.

The list of new technology break-throughs and Asian firsts for the new plant is impressive:

- The largest and most modern forming factory in the world

- The new I-Series™ products providing improved resilience, stability and longer life expectancy in harsh environments

- Velocity™, a new yarn technology

- Infinity™, a new and superior press technology

- Hyperpunch™ technology

- The largest and fastest needle loom in the world

- Smoothflex ™, our unique process belt system

- LEED Gold certified facilities

Voith I-Series forming fabrics utilize a completely unique SSB design concept to generate a fabric with a much wider range of operating features, offering today‘s papermaker an improved overall performance and optimal cost efficiencies.

Infinity™ is exclusive to Voith and eliminates many of the deficiencies associated with traditional manufacturing. Using Infinity inside your fabric allows improved dewatering which keeps the fabrics cleaner, reduces fibre loss and maintains fabric integrity.

Improving the dewatering performance means energy savings for the paper maker. In addition, less chemicals and less steam are required, which supports an environmentally friendly solution.

The needling department has impressive operating parameters of 1,200 punches per minute generated with a needling force of 120 tons per needle beam, resulting in a highly efficient needling process.

Voith employs Hyperpunch technology within the carding and needling process to ensure the highest quality of press fabrics in the market.

Voith’s process belts, with the trade name SmoothFlex™, are manufactured in the new plant. The process belts are used predominantly in tandem shoe press applications and help to facilitate the transfer of the paper web at high speeds.

Voith’s new fabric plant is one of very few buildings in China to be LEED Gold certified. With this standard the building gains international acknowledgement for environmental best practices.

The CHP plant makes a substantial contribution to Voith’s sustainability. CHP generates 600kw of electricity which is consumed directly and provides the base load for Voith’s constant operations. And at Voith nothing goes to waste, even the heat produced by the generators is used to warm both oil and water for the production processes.

Voith’s new fabric plant relies completely on low powered automated LED light systems, which are also produced by Voith. Voith has the biggest LED light installation in China. Further energy is saved by auto dimming the lights to exploit all available daylight.

The entire fabric plant is completely airtight. Combined with a state of the art AC system, this allows Voith to control the temperature and humidity inside the plant in a narrow band. This lab-like environment means Voith can produce an incredibly stable and uniform product, first time, every time.

Voith’s commitment in the Chinese market was further signaled by the opening of its China Training Centre, the largest training facility of Voith outside Germany. The centre will introduce the German model of dual vocational training to China, taking graduates from Chinese technical schools and giving these interns a further one year practical course at Voith. Graduates will emerge from the centre grounded in the art and science of paper making and the realities of industrial manufacturing.

So come and visit Voith’s Paper City.

Whether you make pulp, packaging paper, board, graphical or specialty papers or tissue, Voith has the right solution for you. Voith has the most innovative technologies from around the world to bring the future of paper making to Asia.

More than 20 successful rebuilds: BaglessPlus disc filter sectors from Voith

Paper manufacturers are convinced of BaglessPlus disc filter sectors made of corrugated stainless steel from Voith: Not only does a conversion to the most modern filter technology in the fiber recovery or dewatering process increase capacity and filtrate quality, but it also lowers maintenance costs.

Voith has already rebuilt more than 20 disc filters from various manufacturers in stock preparation and in the approach flow system with BaglessPlus disc filter sectors. Paper manufacturers all over the world are thus being assisted in managing sustainable processes.

The BaglessPlus disc filter sectors offer 15 - 20% higher capacity. In addition, the filtrate quality remains high during the entire service life. That is due above all to the stable design of the disc filter sectors. Since a consistent filtrate quality in the super-clear filtrate of up to 25 ppm can be achieved, it is possible to save large amounts of fresh water. BaglessPlus disc filters also impress with their excellent service life of 10 to 20 years. The first Bagless disc filter was put into operation in 1998 and is still in use. That not only saves time for maintenance work, but also reduces costs.

Voith uses products such as BaglessPlus disc filter sectors to rebuild existing machines from different manufacturers. Improved operation is thus achieved for a fraction of the costs involved in a new installation. The conversion to BaglessPlus is possible for most disc filter sizes.

Voith also offers filter bags made of polypropylene for various applications with a special protective fabric. Conventional filter discs with steel fabric are also in use. Sometimes achieving the optimum requires more than a conversion to the most modern disc filter sector technology. With a filtrate valve of the latest generation or a conversion to HiCon disc filter with a production increase of up to 80%, Voith has a large rebuild portfolio available for further optimizing a disc filter.

ANDRITZ successfully starts up PM7 at Mondi Štětí, Czech Republic

International technology Group ANDRITZ has successfully started up PM7 paper machine at Mondi Štětí, Czech Republic. The machine will mainly produce packaging paper grades.

In addition to supply of a new headbox (PrimeFlow SW) with PrimeProFiler dilution control, a new shoe press module was added in the press section to create a three-nip press with shoe press (PrimePress Trix) for efficient dewatering. A new micro-creping unit (PrimeUnit MC), a new PrimeCal X shoe calender for high smoothness, and a new rewinder were also installed. The dryer section was split into a pre- and an after-dryer section, including a new complete hood.

Mondi Štětí is a worldwide leading manufacturer of packaging paper.

ANDRITZ PULP & PAPER

The business area is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulps, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and board; the calendering and coating of paper; as well as treatment of reject materials and sludge.

The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, gasification plants for energy production, flue gas cleaning plants, production equipment for biofuel (second generation) and biomass pelleting, biomass torrefaction, plants for the production of nonwovens, dissolving pulp, plastic films, and panelboards (MDF), and recycling plants are also allocated to the business area.

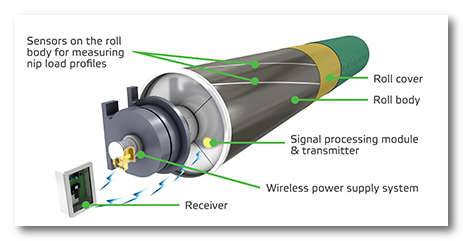

Valmet's iRoll technology improves paper quality and machine runnability

Valmet's iRoll product family is a complete set of tools for controlling paper tension and nip profiles. iRolls are now available for all main processes and positions in pulp, paper, board and tissue machines with the latest Valmet roll covers.

Thanks to good market feedback, Valmet is now expanding its iRoll manufacturing capability. By the end of June 2014, iRoll manufacturing will expand to cover Finland, France, the United States, Thailand and China. Valmet has also developed local field service competencies through an iRoll academy training program.

"After installing an iRoll, our customers have thanked us for 50% fewer wet end breaks per day, improved runnability, 100% longer grinding intervals and a 40% improvement in the coat weight 2-sigma value, just to name a few of the results iRoll has achieved," says Samppa Ahmaniemi, director of Roll Covers at Valmet.

Accurate online measurements

The main benefit of the iRoll technology is its accurate online profile measurement and process control opportunity in press, sizer, coater, reel and winder applications. Valmet's iRoll is the fastest and most sensitive online profile measurement tool in the industry.

In addition to nip load profile, iRoll also measures applicator rod load profile (sizer) and parent roll hardness profile (reel), as well as paper, board or tissue tension profiles in selected positions. iRoll can even be connected to the machine automation system for closed loop process control.

iRoll Portable is a quick, cost-effective process analysis and tuning tool that is based on dynamic nip profile or paper/fabric tension profile measurements. iRoll Portable provides rapid results as Valmet's experts can carry out an iRoll Portable analysis during shutdowns.

Pöyry awarded engineering and site services assignment for Stora Enso Varkaus pulp mill

Stora Enso has awarded Pöyry with the assignment for the engineering and site services for the pulp mill rebuild and paper machine conversion project at its Varkaus Mill in Finland. The assignment relates to the pulp mill rebuild, paper machine conversion, upgrading of existing utilities, and includes detail and civil engineering as well as site services as an option. The assignment is a continuation of the pre-feasibility and the feasibility studies performed by Pöyry during 2013.

Stora Enso has awarded Pöyry with the assignment for the engineering and site services for the pulp mill rebuild and paper machine conversion project at its Varkaus Mill in Finland. The assignment relates to the pulp mill rebuild, paper machine conversion, upgrading of existing utilities, and includes detail and civil engineering as well as site services as an option. The assignment is a continuation of the pre-feasibility and the feasibility studies performed by Pöyry during 2013.

The conversion work is expected to be undertaken mainly during autumn 2015 and the board machine is scheduled to start up during the fourth quarter of 2015. The current 280 000 tonnes per year uncoated fine paper machine is planned to cease production by the end of August 2015. Following the conversion into a board machine, Varkaus Mill's capacity will be about 390 000 tonnes per year of kraftliner and white top liner and 310 000 tonnes of unbleached kraft pulp.

"This project is a continuation of the long co-operation between Stora Enso and Pöyry, and strengthens Pöyry's position as the world's leading pulp and paper engineering consultancy, having delivered projects for 80% of the world's major pulp and paper companies", says Nicholas Oksanen, President of Pöyry's Pulp and Paper Global Competence Line.

The value of the order is not disclosed. The order will be recognised within the Industry Business Group order stock in Q2.

Kemira Oyj: Restated segment information for the first quarter of 2014 and the full year 2013

On March 6, 2014, Kemira closed the divestment of formic acid business, including the feed and the airport runway de-icing product lines, which had formed the major part of ChemSolutions segment.

On March 6, 2014, Kemira closed the divestment of formic acid business, including the feed and the airport runway de-icing product lines, which had formed the major part of ChemSolutions segment.

After the closure, the remaining sodium percarbonate business in ChemSolutions segment was transferred to Paper segment and ChemSolutions segment was discontinued as of the beginning of Q2 2014.

The figures for Q1 2013-Q1 2014 have been restated according to the new structure and are attached to this release.

Main change:

Kemira's sodium percarbonate business, previously a part of ChemSolutions segment, has been transferred to Paper segment.

Figures for Q1 2013 - Q1 2014 on Kemira Group level, Oil & Mining and Municipal & Industrial segments have not been changed.

The January-June 2014 Interim report will be published on July 22, 2014

Cyclus rebrand supports education in Africa

Cyclus rebrand supports education in Africa

- Arjowiggins Graphic campaign partners with charity to help support education in Africa through a rebrand of its Cyclus paper range -

Arjowiggins Graphic, a leading manufacturer of environmental paper solutions, today reveals a new look and feel for its leading-edge Cyclus paper range via a campaign that will support access to education for children in Vontovorona, Madagascar.

Partnering with SOS Children’s Villages France the company is launching a new innovative nine-week campaign that showcases the brand new Cyclus logo and identity across the various communication tools.

One of Cyclus’s biggest campaigns to date and the first new logo since the products launch in the 1990’s, the communication tools consist of 56,950 mailers, a notepad, a new swatch brochure, web banners, adverts and a dedicated website. Investing in its leading recycled paper brand, the campaign is targeting designers, printers and corporates in 36 countries across the world.

Childhood, but specifically a child’s education, is the other focus of this latest Arjowiggins Graphic campaign. For each customer that orders a free Cyclus notepad, Arjowiggins Graphic will gift one child from Vontovorana SOS Children’s Villages Madagascar their fees for one complete school year*.

Included in the mailer is an origami fortune teller that invites customers to step back into their childhood and have some fun by personalising it with their own text.

Angela De Vorchik, Operational Marketing Manager at Arjowiggins Graphic comments: "Taking inspiration from a declaration made by Nelson Mandela who once said, “Education is the most powerful weapon which you can use to change the world,” we wanted to create a mailer campaign that could support a child’s education in a really simple way. Each time our customers request a notepad they will be supporting access to education in a less-privileged part of the world and making a positive contribution to a child’s future. We’re delighted to be able to continue our long-standing partnership with SOS Children’s Villages for this campaign and raise awareness of the great work the charity is doing.”

Using CyclusOffset 140gsm for the fortune teller, 90 gsm for the envelope, Cyclus Print 250gsm for the mailer, and for the notepad a combination of Cyclus Print 350gsm and CyclusOffset 90gsm, all of the communication tools have been manufactured from 100% de-inked pulp and showcases the unique natural shade and finish that can be achieved from recycled waste paper. Both papers are 100% recycled, FSC®, Recycled Certified. Cyclus Offset is an uncoated, natural white paper, whilst Cyclus Print is a matt-coated printing paper for use in both full colour and black and white printing. With Cyclus Print the non-reflective matt surface is especially suitable for publications with a combination of large text areas and high quality pictures.

The campaign is being rolled out in the UK by Antalis a distributor of Cyclus.

Natalie Thomas Marketing Manager Antalis UK, comments: "The Cyclus paper range enable us to deliver the shade and finish businesses need for their printed communications, such as high-end marketing brochures and mailers, whilst also conveying their green credentials. When compared to the manufacture of non-recycled papers the manufacturing process reduces energy consumption, uses less water, diverts waste from landfill and CO2 emissions are substantially lower. It is a paper with an environmental story that contributes to a business’s message – superb quality, a beautiful texture and a unique subtle shade. The Ultimate Recycled!”

Customers are able to use Arjowiggins Graphic’s Eco Calculator to produce their own Environmental Benefit Statement (EBS), which is a great way to bring the decision to use Cyclus recycled paper to life and engages people with the benefits of printing on recycled paper. The EBS reveals the savings on landfill, greenhouse gases, litres of water, energy and wood and are tailored to specific print runs.

*Arjowiggins Graphic commits to provide education for one year to the 500 children of the Vontovorona SOS Children’s Village School

Mika Joukio appointed Metsä Board’s CEO

Metsä Board Corporation’s Board of Directors has appointed M.Sc. (Tech.), MBA Mika Joukio (49) as the company’s new CEO. Joukio will start in the position on 1 December 2014 at the latest.

Metsä Board Corporation’s Board of Directors has appointed M.Sc. (Tech.), MBA Mika Joukio (49) as the company’s new CEO. Joukio will start in the position on 1 December 2014 at the latest.

Joukio joins Metsä Board from Metsä Tissue Corporation, part of Metsä Group, where he has been the CEO since 2012. Prior to Metsä Tissue, Joukio worked as the head of Metsä Board’s paperboard business during 2006–2011. He has held various management positions in the company and its predecessors Metsä-Serla Corporation and M-real Corporation since 1990.

“Mika Joukio has strong earlier experience in Metsä Board and in paperboard as well as consumer product industries. He has a good track record of successful business management in Metsä Tissue. He has an excellent starting point to continuing profitable growth of Metsä Board”, says Kari Jordan, Chairman of the Board of Directors.

Metsä Board’s current CEO Mikko Helander will move to another company on 1 December 2014 at the latest.