Ianadmin

MoveRoll supports ReBuild Mexico 2015

During PulPaper in Helsinki, Vince Maynard of Pulp Paper & Logistics told us about Joshua, his son. In April 2015 Joshua wishes to set off to Mexico together with a small group of other teenagers and help a poverty stricken family build their first basic secure home. The new home will be built from the foundation upwards only with basic hand tools. Design and structure of the new home will be simple to ensure that a group of unskilled people can complete the project in as little as five days.

During PulPaper in Helsinki, Vince Maynard of Pulp Paper & Logistics told us about Joshua, his son. In April 2015 Joshua wishes to set off to Mexico together with a small group of other teenagers and help a poverty stricken family build their first basic secure home. The new home will be built from the foundation upwards only with basic hand tools. Design and structure of the new home will be simple to ensure that a group of unskilled people can complete the project in as little as five days.

To cover the cost of the trip and building work each member of Joshua's group needs to raise over £1,300. Once the group's financial target of over £11,700 is met, the trip in April 2015 can happen.

To cover the cost of the trip and building work each member of Joshua's group needs to raise over £1,300. Once the group's financial target of over £11,700 is met, the trip in April 2015 can happen.

The envisioned trip is part of the ReBuild Mexico 2015 project which is designed to provide practical help needy Mexican families while creating cross-cultural understanding for the participants. ReBuild is organized by Urban Saints UK and Amor Ministries in San Diego, California.

“MoveRoll operates in a global environment, and we are aware of our social responsibility, both domestically and internationally. As a sponsor of PS Kemi Kings, we are giving something back to the local community of Kemi, which has been a big part of MoveRoll's development and success story. By supporting Joshua,we help him and his group improve the life of a family in Mexico, just across the border of the USA, which is currently one of our biggest markets”, says Mikko Rantanen.

If you would like to find out how you can help the group to help a Mexican family build their first basic secure home, contact Vince Maynard via This email address is being protected from spambots. You need JavaScript enabled to view it. for more information.

Valmet enhances roll cover manufacturing capacity in Thailand

Valmet is investing in roll cover manufacturing capacity at its service center in Laem Chabang, Thailand. The investment will double Valmet's composite roll cover production capacity in the Asia-Pacific region. Production of Valmet's newest polyurethane products will begin by the end of June 2014.

The Laem Chabang service center is to begin manufacturing PressPolar press roll covers for board making, PressHusky press roll covers for tissue making, and CoteFalcon and CoteCondor covers for sizing and blade coating. These covers have a proven track record of providing energy savings, extending running times and lowering maintenance costs.

Calender composite cover capacity is also being expanded to meet growing demand from customers. This will improve delivery times and permit more flexible deliveries to meet varied customer needs with proven cover solutions - like the nanomaterial-based CalLeopard cover - throughout the Asia-Pacific area.

Manufacturing iRolls, Valmet's intelligent roll solution, has also been made possible with new roll cover products at Laem Chabang. iRolls are available for all main processes and positions in pulp, paper, board and tissue machines with the latest Valmet roll covers. The main benefit of iRoll technology is its accurate online profile measurement and process control in press, sizer, coater, reel and winder applications. Valmet's iRoll is the fastest, most sensitive online profile measurement tool in the industry.

Information about Valmet's service center in Thailand

Valmet's Laem Chabang service center is a one-stop service center for the pulp and paper industry in Asia-Pacific. The center features a fully equipped roll service workshop which can serve and cover even the most demanding process rolls of up to 12 m, as well as manufacturing suction roll seals and wear plates. It was inaugurated in January 1998.

Read more:

Laem Chabang service center

Mercer International Inc. Announces Joint Venture With Resolute Forest Products Inc.

Mercer International Inc. ("Mercer" or "the Company") has announced the launch of a new joint venture company called Performance BioFilaments Inc. ("Performance BioFilaments") established to commercialize an innovative biomaterial derived from wood fiber called cellulose filaments. The joint venture will be equally owned with Resolute Forest Products Inc. ("Resolute"), a leader in the forest products business.

Mercer International Inc. ("Mercer" or "the Company") has announced the launch of a new joint venture company called Performance BioFilaments Inc. ("Performance BioFilaments") established to commercialize an innovative biomaterial derived from wood fiber called cellulose filaments. The joint venture will be equally owned with Resolute Forest Products Inc. ("Resolute"), a leader in the forest products business.

Cellulose filaments are derived from wood pulp which has been processed using innovative technology licensed from FPInnovations Inc. ("FPInnovations"), one of the world's leading forest products research organizations. The cellulose filaments' exceptional strength and high aspect ratio make it a unique cellulose-based biomaterial. We believe it has the potential to make a wide array of consumer and industrial products stronger, lighter, more flexible and more durable, while leveraging a sustainable and renewable resource with a low carbon footprint.

"Commercializing cellulose filaments represents a compelling business opportunity developed through our focus on collaborative innovation and takes one of our initiatives to the next level," says Jimmy S.H. Lee, President and Chairman of Mercer. "We are excited to be working jointly with Resolute, which allows us to leverage our respective global research knowledge and resources to implement the commercialization process for this high potential material."

Performance BioFilaments will seek joint development partners from a range of industries – from automotive and manufacturing, to construction and high-end consumer products – to develop new commercial product applications for cellulose filaments. While we are optimistic about the potential for commercialization of this product, we recognize that, as with the development of all novel product applications, the process can be lengthy and without assurances.

Performance BioFilaments will build upon the significant investment made by FPInnovations in technology development and production through its current C$43.1 million cellulose filaments project. All of the know-how gained from their project, as well as commercial development quantities of cellulose filaments, will be available to Performance BioFilaments for its commercialization efforts.

About Performance BioFilaments Inc.

Performance BioFilaments Inc., a joint venture between Mercer International Inc. and Resolute Forest Products Inc., is focused on the development of commercial applications for cellulose filaments, one of the world's most exciting new biomaterials. Cellulose filaments can be used to enhance the performance characteristics of a wide variety of products. Derived from wood fiber – a renewable and natural resource – cellulose filaments optimize the strength, stability, flexibility and longevity of a variety of materials including composites, coatings and consumer products. For more information, please visit www.performancebiofilaments.com.

About Mercer International Inc.

Mercer International Inc. is the world's largest producer of Northern Bleached Softwood Kraft ("NBSK") market pulp and has become a leader among forest products companies in embracing the bio-economy and maximizing value derived from residual forest resources. Mercer has three modern, large-scale pulp mills located in Germany (Rosenthal and Stendal), as well as BC, Canada (Celgar). The Company's total NBSK pulp production capacity is 1.54 million tonnes per year.

The mills utilize all parts of the wood they process to create not only pulp, but also valuable by-products. These by-products often provide renewable alternatives to traditionally petrochemical-based materials. For example, Mercer's mills have a combined green energy generation capacity of 305 MW. All of the mills are net exporters of energy, meaning they produce more energy than they consume. Biochemicals have become an increasingly important by-product of Mercer's pulping process, as well.

The Company's shares are listed on the NASDAQ Global Market (MERC) and on the Toronto Stock Exchange (MRI.U). For more information, please visit www.mercerint.com.

About Resolute Forest Products Inc.

Resolute Forest Products Inc. is a global leader in the forest products industry with a diverse range of products, including newsprint, specialty papers, market pulp and wood products. Resolute owns or operates nearly 40 pulp and paper mills and wood products facilities in the United States, Canada and South Korea, and power generation assets in Canada. The shares of Resolute trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange. For more information, please visit www.resolutefp.com.

International Paper Named Among 100 Best Places to Work in IT by IDG's Computerworld for 2014

![]() International Paper (NYSE: IP) has announced that Computerworld, the leading source of technology news and information for IT influencers worldwide, ranked International Paper No. 34 on its 2014 Top 100 Best Places to Work in IT. International Paper was recognized as one of the Top 100 organizations that challenge its IT staff while providing great benefits and compensation. "This is terrific recognition for a first class IT team," said Bob Wenker, vice president and chief information officer. "To be recognized as one of the Best Places to Work in IT is a reflection of all-in commitment, and stellar day-in and day-out execution by talented, aligned and engaged teammates around the globe."

International Paper (NYSE: IP) has announced that Computerworld, the leading source of technology news and information for IT influencers worldwide, ranked International Paper No. 34 on its 2014 Top 100 Best Places to Work in IT. International Paper was recognized as one of the Top 100 organizations that challenge its IT staff while providing great benefits and compensation. "This is terrific recognition for a first class IT team," said Bob Wenker, vice president and chief information officer. "To be recognized as one of the Best Places to Work in IT is a reflection of all-in commitment, and stellar day-in and day-out execution by talented, aligned and engaged teammates around the globe."

International Paper's IT organization employs more than 1,600 IT professionals delivering solutions for business advantage and support services to International Paper's 70,000 employees in 24 countries.

"Hiring the best and the brightest IT pros, offering them competitive pay and providing top-notch benefits is just the beginning for the outstanding employers on this year's Best Places to Work in IT list," said Scot Finnie, editor in chief of Computerworld. "Both newcomers to the list and rock-steady stalwarts nurture their talent with challenging business-critical projects, extensive training opportunities and ongoing career development programs. They invest in their own futures by investing in their employees."

Organizations will be included in coverage in Computerworld along with results from the 21st annual Best Places to Work in IT survey.

About the Best Places to Work in IT

The Best Places to Work in Information Technology (IT) list is an annual ranking of the top 100 work environments for technology professionals by IDG's Computerworld. The list is compiled based on a comprehensive questionnaire regarding company offerings in categories such as benefits, career development, training and retention. In addition, Computerworld conducts extensive surveys of IT workers, and their responses factor heavily in determining the rankings.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging and uncoated papers, complemented by xpedx, the company's North American distribution company. Headquartered in Memphis, Tenn., the company employs approximately 70,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2013 were $29 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

About Computerworld

Computerworld is the leading IT media brand helping Sr. IT, business decision-makers and key influencers navigate change with effective business strategy. Computerworld enables the IT value chain with unique editorial coverage from setting strategies to deriving value from core to edge technologies. Computerworld's award-winning website (www.computerworld.com), publication, focused conference series, custom solutions and research forms the hub of the world's largest (40+ edition) global IT media network and provides opportunities for IT vendors to engage this audience. Computerworld leads the industry with an online audience of over 7.1 million monthly page views (Omniture, February 2013) and was recognized in BtoB's 2013 Media Power 50 list; recognition Computerworld has received for more than 5 consecutive years. Computerworld is published by IDG Enterprise, a subsidiary of International Data Group (IDG), the world's leading media, events and research company. Company information is available at www.idgenterprise.com.

New BillerudKorsnäs products meet growing demand for paper bags and carriers

With the European Parliament voting to significantly cut plastic bag use by 2019, BillerudKorsnäs has launched two new families of paper for use in carriers for the food and retail sectors. The products offer outstanding value, quality, and flexibility and are produced from renewable raw materials. The fact that they are biodegradable means they pose far less of a threat to waterways than plastics

BillerudKorsnäs has launched two new paper product families, aimed at meeting growing demand for paper bags and carriers within the retail and food sectors. The Xpression and Basix product lines both offer outstanding strength, printability and environmental credentials, but are carefully designed for use in distinct applications.

The Xpression range of high-quality kraft paper products is suitable for use in paper carriers produced for use in retail and in other sectors. Papers in the range offer benefits across the value chain. They allow for outstanding colour and text reproduction during printing and enable brand owners to produce strong, durable and appealing carrier bags that reflect on their brands in the best possible way.

The Basix range of kraft paper, meanwhile, is intended for use in consumer bags that provide protection for food, or that are used in other daily applications. The range consists of stiff papers with an even quality that allows for effective and functional conversion as well as easy-to-use end products. The papers boast good printability, and grease-resistant variants are available for paper bags that come into close contact with greasy food, such as Danish pastries and French fries.

Marcus Lager, Business Segment Director at BillerudKorsnäs, says there has been an increase in demand for quality paper products, particularly in Europe where tough measures have been introduced to reduce the use of plastic bags and plastic carrier bags.

In April, the European Parliament voted in favour of new targets that will force nations within the EU to reduce plastic bag use by 80 per cent before 2019," Lager says. "Many consumers have also expressed a strong preference for sustainable, non-plastic alternatives, both in retail and food retail situations."

Luigi Fiorini, President of global packaging manufacturer Fiorini International, says a major advantage of the Xpression and Basix ranges is their strong environmental credentials. BillerudKorsnäs is recognised as an industry leader in terms of sustainability and environmental focus.

Patrik Bosander, Business Development Director at BillerudKorsnäs, says, "The independent research body IVL Svenska Miljöinstitutet (IVL Swedish Environmental Institute) conducted climate change impact studies on all the products manufactured in three of our Swedish paper mills. The results showed that our products had a very small carbon footprint. This is due to the paper being made from renewable raw material from sustainable forestry, as well to our investments in environmentally effective technology."

About Fiorini International

Fiorini International is a market-leading company that produces packaging for the industrial, retail and fashion sectors. The company has modern plants in Italy and the Czech Republic, employs some 420 people and has an annual turnover of about 100 million euros. Fiorini International has customers all over the world and recently won the "Best Converter" prize at the prestigious La Vedovella awards in Italy.

A large package of Metso's process automation technologies and valve solutions for Belarus's first bleached kraft pulp mill

Metso will supply a comprehensive package of process automation technologies and valve solutions for JSC Svetlogorsk Pulp & Board Plant's new bleached kraft pulp mill in Svetlogorsk, the Republic of Belarus. The new 400,000 ton-per-year mill under construction will be the first bleached kraft pulp mill in the country. Metso's technology will enable the mill to reach high efficiency, product quality and process stability, as well as gain savings in chemicals, steam and water consumption. In addition, it will result in better sustainability.

Metso will supply a comprehensive package of process automation technologies and valve solutions for JSC Svetlogorsk Pulp & Board Plant's new bleached kraft pulp mill in Svetlogorsk, the Republic of Belarus. The new 400,000 ton-per-year mill under construction will be the first bleached kraft pulp mill in the country. Metso's technology will enable the mill to reach high efficiency, product quality and process stability, as well as gain savings in chemicals, steam and water consumption. In addition, it will result in better sustainability.

The order was placed by China CAMC Engineering Co., Ltd. (CAMCE), a major EPC contractor responsible for the turnkey delivery of the plant. The company chose Metso as a supplier based on earlier good experiences with its leading technologies, proven performance in demanding environments and critical applications, good results, along with value-adding services.

Metso received these orders in the second quarter of 2014. Deliveries will take place during the autumn of 2014, and the equipment is estimated to start up during the third quarter of 2015. The value of the order is not disclosed.

The world's most profitable pulp and paper operations run with Metso's solutions

Metso has the world's widest scope of process automation and valve solutions and related services for the pulp and paper industry - from single measurements to mill-wide turnkey automation projects with roots deep in the pulp and paper industry and a history of more than 50 years.

For example, Metso's analyzer offering is the global leader and industry benchmark in measurement-based and first-ever process control solutions. The consistency transmitter portfolio has been built on a half-century-long path of innovative development, migration of unique technologies and close cooperation with customers. Today, Metso is the leading pulp consistency transmitter supplier globally.

In addition to analyzers, the company is the market leader in quality control systems, as well as in control and on-off valves for this industry sector. Metso also holds a leading position in pulp performance optimization with its advanced controls. Metso's system-independent solutions help customers lower their operating and maintenance costs.

Technical information

Metso's delivery scope includes Kappa Q analyzers, Metso Polarox5 residual sensors, several Metso Piston filtrate samplers for pH measurement, Metso SP and Metso Rotary consistency transmitters, as well as Metso NOVE samplers. Valve solutions include over 900 Neles® automated valves of various types and sizes for both control and on-off applications. All the control valves will be equipped with ND 9000 series intelligent valve controllers, which ensure long-term reliability, reduce process variability and improve process efficiency.

China CAMC Engineering Co., Ltd. (CAMCE) is an incorporated company affiliated to China National Machinery Industry Corporation (SINOMACH). Its business mainly consists of engineering procurement construction (EPC) projects, domestic and overseas investment as well as trade. www.camce.com.cn/en/

Valmet to supply new sizing technology for Papierfabrik Niederauer Mühle GmbH in Germany

Valmet will supply Papierfabrik Niederauer Mühle GmbH with a sizer and auxiliaries for its PM3 containerboard machine located in the company's Kreuzau mill in Germany. The target of the project is to improve the strength properties of the white top liner grades. This high quality paper is used for instance as printed cover layer for cardboards and as headliner. The sizer is scheduled to start up during the first quarter of 2015.

The order is included in Valmet's second quarter 2014 orders received. The value of the order will not be disclosed.

Valmet's innovative sizing technology will boost the quality of white top linerboard

In addition to the new sizer, Valmet's delivery will include a calender rebuild, an air dryer, starch preparation and starch supply systems as well as ropeless tail threading equipment.

"The new sizer will combine the best features of both spray application and film application, and improve the strength properties of the white top liner grades. The main advantages of the back side spray application technology compared to conventional starch application method are drying energy reduction, fast and accurate starch amount control as well as elimination of wearing parts. The top side film application ensures excellent properties of the white top liner surface," says Ilkka Naatti, Product Manager of coaters and sizers in Valmet.

"Niederauer Mühle will also be the first paper mill in the Central Europe to benefit from the advantages of safe, reliable and fully ropeless tail threading technology in the size press area. After the rebuild the tail threading process of PM3 will be totally ropeless for all machine parts."

About Papierfabrik Niederauer Mühle GmbH

Niederauer Mühle specializes in white corrugated medium paper of which basis weight ranges from 120 - 200 g/m2. Its production volume is more than 300,000 tons of paper per year today. The company has currently 155 employees.

ANDRITZ successfully starts up tissue machine with steel Yankee for Hebei Yihoucheng, China

International technology Group ANDRITZ has successfully completed start-up of the PrimeLineCOMPACT tissue machine – the first of its kind in China – with steel Yankee supplied to Hebei Yihoucheng, China.

International technology Group ANDRITZ has successfully completed start-up of the PrimeLineCOMPACT tissue machine – the first of its kind in China – with steel Yankee supplied to Hebei Yihoucheng, China.

The machine has a design speed of 1,650 m/min and a width of 2.85 m. The Yankee, manufactured entirely of steel, has a diameter of 3.65 m.

According to Tian Yuwei, General Manager of Hebei Yihoucheng, ”The smooth start-up was further confirmation that we had chosen the right partner in ANDRITZ. The energy-efficient drying and excellent operating safety of the Yankee are particularly impressive.”

The tissue machine and components (the order also included supply of the complete stock preparation plant, automation, and drives) were manufactured at ANDRITZ production sites in Europe and China. With this turnkey supply, ANDRITZ PULP & PAPER is strengthening its position as one of the leading suppliers of tissue machines including local services in China.

Valmet's SealFlo cuts suction roll lubrication water use by up to 50%

There is a continuous need for paper manufacturers to reduce their environmental impact. Valmet is contributing to this need by introducing SealFlo, an easy upgrade for suction roll lubrication showers.

"Valmet's new SealFlo technology reduces water consumption by as much as 50%, while maintaining or improving lubrication results," says Pekka Kivioja, director of Roll Maintenance at Valmet.

Worn, aged and outdated showers and nozzles lead to substandard lubrication results and consume excessive amounts of water. The new SealFlo axial seal lubrication shower from Valmet features a design which improves the lubrication process, as well as reducing the roll's environmental impact through significantly reduced water consumption.

Significant savings

In addition to improved lubrication results, many applications show an improved moisture profile and reduced costs of shower water preparation. Kivioja gives an example: "On a paper or board machine, this could mean savings of as much as 2,500 to 5,000 euros per roll meter per year, resulting in average savings of 100,000 to 200,000 euros a year on a ten-meter wide machine that has four suction rolls." The improved shower functionality also has a positive effect on the lifespan of the axial seal and on the suction roll shell.

This modification is now available with suction roll maintenance through Valmet's extensive roll service network.

Further information, please contact:

Pekka Kivioja, Director, Roll Maintenance, tel. +358 400 546 779, This email address is being protected from spambots. You need JavaScript enabled to view it.

Read more: Improved suction roll operation with SealFlo

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

ANDRITZ to deliver wood processing line for Stora Enso mechanical pulp plant in China

International technology Group ANDRITZ received an order from Stora Enso Packaging, China, to supply a complete wood handling line for a greenfield mechanical pulp plant and board machine in Guangxi Province, China. Start-up of the wood processing line is scheduled for the beginning of 2016.

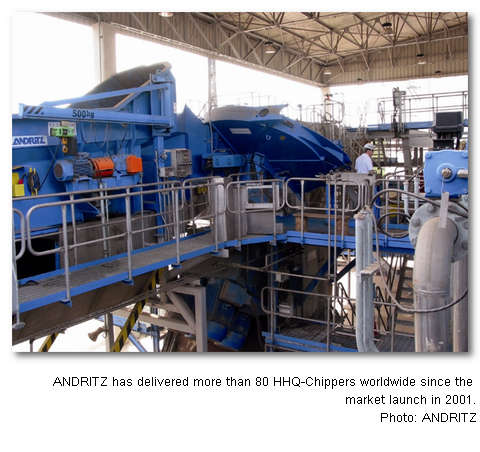

The raw material for the mill will be forest-debarked plantation wood. ANDRITZ’s scope of supply includes the main systems for wood intake and washing, chipping (with unique, horizontally fed HHQ-Chipper), chip storage and reclaiming, chip screening, chip conveying systems to the BCTMP mill,as well as bark and fines handling. The design flow of the chipping line is 120 m3 sub (solid under bark)/h to enable 725 adt/d of BCTMP pulp production. The covered silo will be able to house 16,000 m3 of chips. In addition to the equipment and machinery, ANDRITZ will provide erection supervision, training, and start-up services.

The design capacity of the board machine, which will produce several grades from eucalyptus mechanical pulp, is 450,000 adt/a. Initial design capacity of the BCTMP plant is 725 adt/d.