Displaying items by tag: valmet

Valmet to deliver a new white liquor filter to Rottneros Vallvik pulp mill in Sweden

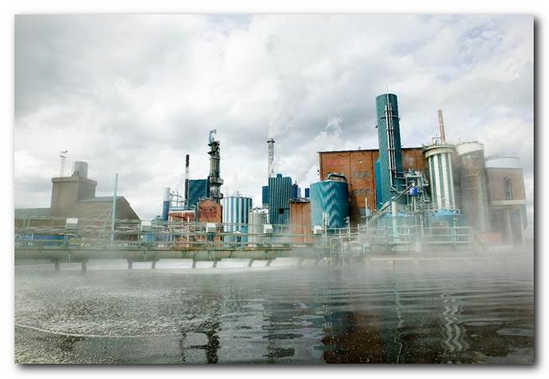

Valmet will deliver a white liquor filter to Rottneros Vallvik pulp mill located on the east coast of Sweden. White liquor filter is part of the pulp mill's chemical recovery process.

This investment is part of Rottneros AB's larger rebuild project called Agenda 500, which aims to increase availability and the total production volume at both of Rottneros AB's pulp mills, Rottneros Mill and Vallvik Mill, and with a target to reach a capacity of 500,000 tons per year.

Rottneros' Vallvik pulp mill. Photo: Rottneros image bank

The new white liquor filter will replace an existing filter delivered by Valmet in 1990. A larger filter is needed to handle the capacity increase at the mill. Start-up of the new filter is scheduled for autumn 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A white liquor filter is usually valued below EUR 5 million.

"Vallvik has great confidence in Valmet as a supplier and despite a very tough schedule, we have a good reason to assume that Valmet will deliver on time. In addition, I personally look forward to working with Valmet again because this is my third project with Valmet regarding installation of pressurized disc filter," says Per-Arne Nilsson, Project Manager at Vallvik mill.

"Despite being a trusted partner with Vallvik for more than 40 years in the white liquor area, the tight schedule of this project was a challenge when pursuing this project. All people involved in the sales phase participated in the strategic and proactive work to compress the delivery time, and they deserve big thanks for their efforts. We are very pleased and look forward to a good and safe project implementation phase," says Thomas Malmqvist, Sales Manager at Valmet.

Valmet will also deliver a new bleach plant to Rottneros pulp mill, which was published earlier this year.

Technical details about the delivery

Valmet's delivery includes a new PDW-type white liquor filter, erection, start-up services, basic engineering for piping, for instrument and for electrical and process control. The PDW pressure disc filter produces completely clear white liquor and washes the lime mud. The very high white liquor yield increases upstream capacity and eliminates the potential process disturbances that increased amount of dregs and other non-process elements (NPE's) in the white liquor can cause.

About the customer Rottneros and the Vallvik mill

The Rottneros Group produces paper pulp at two pulp mills. Chemical pulp is produced at the Vallvik Mill, while mechanical pulp is produced at the Rottneros Mill. Vallvik mill produces two grades of long-fiber sulphate pulp: fully bleached sulphate pulp - ECF (Elemental Chlorine Free) and unbleached sulphate pulp - UKP (Unbleached Kraft Pulp). The mill has recently received a permission to produce 255 000 tons per year.

For further information, please contact:

Thomas Malmqvist, Sales Manager, Pulp & Energy Business Line, Valmet tel. +46 54 14 23 87

Valmet to supply board machine key technology for two container board machines in China

Valmet will supply board machine key technology and machine control systems in two new containerboard machines in China. The customer remains confidential. Valmet's delivery includes headbox and press section technology and a machine control system.

Valmet will supply board machine key technology and machine control systems in two new containerboard machines in China. The customer remains confidential. Valmet's delivery includes headbox and press section technology and a machine control system.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. Typically, an upgrade of two lines of this scope is valued at EUR 20-30 million.

"In containerboard manufacturing, headbox and press section are one of the most important key technologies in order to secure high production quality. Our expertise and references convinced the customer to choose Valmet," comments Kari Räisänen, Area Sales Director from Valmet.

Technical information about the delivery

Valmet's delivery for the new containerboard machines will include all together five new OptiFlo Fourdrinier headboxes for improved product quality and increased productivity, two OptiPress Linear double-nip press sections with linear web run for excellent end product properties, high dewatering capacity and good runnability. All the delivered machinery will be equipped with machine control systems.

For further information, please contact:

- Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

- Fan Ze, Area Vice President, Sales, Valmet tel. +86 139 0133 6277

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

SKF Extends Global Agreement with Valmet

SKF’s long-term collaboration with Valmet continues, through the supply of bearings and lubrication system solutions

SKF (STO:SKFB) (STO:SKFA) (Pink Sheets:SKFRY) (LSE:SKFB) has signed an agreement that extends its long-term collaboration with Valmet. SKF will supply bearings, units and lubrication systems to Valmet, the global supplier of technologies, automation and services for the pulp, paper and energy industries.

![]() Erik Nelander, President, Industrial Sales, Europe and MEA, says: “We have been working with Valmet for over 60 years. Our commitment to adopting a design-to-cost approach in our product development also supports Valmet in maximising the efficiency of their own investments in technology development. Our manufacturing and R&D presence across Finland, Sweden and China provides the local knowledge and short lead-times that Valmet requires. By combining our expertise around the rotating shaft, end-users are able to maximise usage of their machinery.”

Erik Nelander, President, Industrial Sales, Europe and MEA, says: “We have been working with Valmet for over 60 years. Our commitment to adopting a design-to-cost approach in our product development also supports Valmet in maximising the efficiency of their own investments in technology development. Our manufacturing and R&D presence across Finland, Sweden and China provides the local knowledge and short lead-times that Valmet requires. By combining our expertise around the rotating shaft, end-users are able to maximise usage of their machinery.”

SKF’s tailored bearing and units solutions have been developed with a focus on reducing design and manufacturing costs for Valmet and decreasing operating costs for machine owners and operators.

SKF’s patented Flowline circulating oil systems provide accurate lubrication, whilst at the same time reducing the amount of circulating oil needed, reducing costs and environmental impact.

Aktiebolaget SKF (publ)

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2015 were SEK 75 997 million and the number of employees was 46 635. www.skf.com

® SKF is a registered trademark of the SKF Group.

Valmet's new Service Center inaugurated in Brazil

Valmet has inaugurated its fourth Service Center in Brazil. The center is located in Imperatriz, in Maranhão state to serve customers in the northern and northeastern parts of Brazil. The opening ceremony of the center was held on March 16, 2016.

"This service center supports Valmet's strategy of being close to customers and growth markets. We can provide significant customer benefits by utilizing our full offering of process technology, automation and services, and by continuously developing our local and remote services," says Jukka Tiitinen, Business Line President, Services at Valmet.

The new service center focuses on serving the pulp, paper, tissue and panelboard industry. The offering includes advanced machinery maintenance, welding, component and equipment reconditioning and manufacturing, as well as on-site maintenance at customer mills. The center also incorporates a consignment stock for selected spare parts and consumables.

"This new service center is one proof of our commitment to move our customers' performance forward. We are now able to serve our customers in Maranhão and also in the other states in the region better than ever before. This strengthens our cooperation especially with Suzano Papel e Celulose mill located in Imperatriz," states Celso Tacla, Area President, South America, Valmet.

Valmet currently has a network of 100 service locations serving the pulp, paper and energy industries around the world. In addition, Valmet's experts are close to customers also with the help of Industrial Internet and remote connections.

For further information, please contact:

- Celso Tacla, Area President, South America, Valmet, tel. +55 41 3341 4581

- Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

- Elio Krummenauer, Services Director, South America, Valmet, tel. +554199748123

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Picture captions.

-

pic 1 - The inauguration ceremonies were held on March 16, 2016. From left Elio Krummenauer, Sebastião Madeira, mayor of Imperatriz, Celso Tacla, Jukka Tiitinen -

pic 2 - Valmet's Imperatriz Service Center in Maranhão state in Brazil

Valmet Advantage NTT tissue line is producing 100% textured tissue at Forestal y Papelera Concepcion mill in Chile

A Valmet-delivered Advantage NTT tissue line has started up at the Forestal y Papelera Concepcion (FPC) mill in Chile. The new line fulfills FPC's target of producing 100% textured tissue, differentiating the company's product offering, and to produce high-quality tissue with low energy consumption. This is so far the widest installed Advantage NTT machine with a width of 5.5 meters. The delivery also included an automation package.

"Our strategy is to provide something different to the market. To succeed, we had to look for a new and innovative technology, so the choice fell on the Valmet Advantage NTT concept. We are also using 100% virgin pulp, and all in all, it has paid off. Today, we are producing great tissue products with very high bulk and softness," saysMarco Monsalve, Operations Manager of FPC.

"Our Advantage NTT tissue line is specially designed to produce textured tissue with high quality and low energy consumption. This has been an exciting and interesting project. Valmet's scope of supply was large and the mill had to be designed to resist earthquakes, which are a risk in the area. The cooperation between Valmet and the mill team has been great, and we enjoyed working with the people in FPC," says Gunnar Söderqvist, Project Manager, Tissue Mills business unit, Valmet.

Information about Valmet's delivery

Valmet's scope of delivery comprised a complete tissue production line, including a complete stock preparation system and an Advantage NTT 200 tissue machine with the latest technology for high-quality consumer tissue. The 5.5-meter-wide machine is equipped with an OptiFlo II TIS headbox and a cast iron Yankee cylinder. It is also features the well-proven Advantage tissue technology, including the AirCap Yankee hood, a SoftReel reel and the WetDust dust management system. The delivery also features a Valmet Focus Rewinder and an extensive automation package including Valmet DNA, dilution control, and quality control systems.

The production line is optimized for the highest flexibility, with the capability to swing between production of plain and textured tissue with low energy and fiber consumption. The design speed is 2,000 m/min in plain mode and 1,800 m/min in textured mode. The line has a capacity of 70,000 tonnes per year of bath, towel and napkin tissue grades.

Information about the customer Forestal y Papelera Concepcion

Forestal y Papelera Concepción S.A. (FPC) is paper manufacturer founded in 1995. Since 2009, the company has been mainly producing recycled fiber-based packaging paper. Its new tissue production line and converting facilities will deliver jumbo rolls and converted tissue products for the Latin and North American markets.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue Mills BU, Valmet, Tel. +46 70 517 14 90

Johan Björn, Sales Director, Tissue Mills BU, Valmet, Tel. +46 703 17 12 16

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

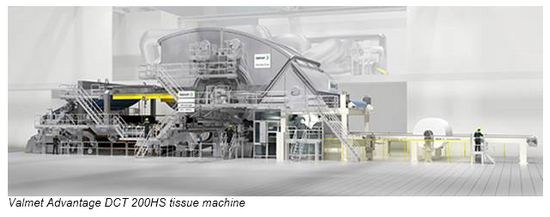

Valmet receives repeat order for two new tissue production lines from Lee & Man Paper Manufacturing in China

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The new lines will be installed at Lee & Man's mill in Chongqing and start-up is planned to take place in late 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order is not disclosed.

Continuation of good cooperation

The Valmet's Advantage DCT 200HS tissue lines to be delivered are designed for production of high quality tissue products. The new tissue lines will fulfill the high requirements for effective technology and sustainability set by Lee & Man. Previously the company has ordered three Advantage DCT 200HS tissue lines of which one started up at the Chongqing mill 2015 and two will start up this year.

"Our first installation in Chongqing is running very well and we are convinced that the Advantage DCT technology and the partnership with Valmet will support our market expansion in China," says Raymond Lee, Chairman of the Board, Lee & Man.

"It's an honor that Lee & Man have again decided to extend the cooperation which already includes three tissue machine deliveries to the Chongqing mill. As seen from the earlier installations, it is possible to reach significant drying energy savings and highest paper quality by our innovative combination of flexible pressing, casted Yankee and steam heated hood. With this combination we are able to bring concrete benefits to our customers and to take their performance forward,"says Svenerik Olsson, Director, Tissue Mills Business Unit, Valmet China.

Valmet's Advantage DCT concept is well established on the market and has proven to enable cost- and energy-efficient production of high quality tissue products.

Technical information about the delivery

The new tissue machines will have a width of 5.6 m and a design speed of 2,000 m/min. Each machine will produce 60.000 tons of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

Valmet's scope of delivery will comprise complete tissue production lines featuring stock preparation systems and Advantage DCT 200HS tissue machines. The machines will be equipped with OptiFlo headbox and cast alloy Yankee cylinders. The machines will also be featured with the well proven Advantage tissue technology including ViscoNip press, steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning are also included

The delivery will also include Valmet's proven automation package including Valmet DNA machine and process control system (DCS) as well as Valmet IQ quality control system (QCS) and Valmet IQ Dilution Profiler. The automation package provides a single source solution, utilizing only one system to perform all the essential measurements and controls for tissue production.

About the customer Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. The company's 6,500 employees are located at the company's five production sites in China. The company had a capacity of 7 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2014.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

For further information, please contact:

Svenerik Olsson, Director, Tissue mills, China area, Valmet, Tel. +86 139 10171872

Krister Harnesk, Sales Manager, Tissue mills, Valmet, Tel. + 46 766 397543

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply new white liquor plant to CMPC Celulosa S.A., Laja pulp mill in Chile

Valmet will deliver a new white liquor plant to CMPC Celulosa S.A.'s Laja pulp mill in Chile. The new white liquor plant will replace the existing one and will comply with new environmental permits coming into force in 2018. Furthermore it will give higher white liquor plant production rate and increase flexibility of the lime cycle management within CMPC Corporation. Start-up of the new plant is scheduled to be in February 2018.

Valmet will deliver a new white liquor plant to CMPC Celulosa S.A.'s Laja pulp mill in Chile. The new white liquor plant will replace the existing one and will comply with new environmental permits coming into force in 2018. Furthermore it will give higher white liquor plant production rate and increase flexibility of the lime cycle management within CMPC Corporation. Start-up of the new plant is scheduled to be in February 2018.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A new white liquor plant with this scope is usually valued between EUR 70-80 million.

"We have selected Valmet to supply this project due to the company's solid performance in carrying out different projects for us, while maintaining excellent environmental and safety standards during the construction phase. We trust that the new white liquor plant will not only improve Laja's environmental performance, but will also help to reduce our operational costs", says Neil Chablani, Director of Projects & Technology at CMPC Celulosa S.A.

"We have shown that our white liquor plant technology is competitive both from a capital as well as an operational point of view, and confirms our position as a leading technology supplier in South America region," says Carl Mikael Stål, Technical and Operational Manager at Valmet in Andes Region.

Technical information of the delivery

Valmet's delivery includes a white liquor plant with causticizing and lime kiln for efficient chemical recovery. The new white liquor plant will have a capacity of 5,500 m3 of white liquor per day and a lime kiln capacity of 450 tons per day. Valmet's reliable Recovery Analyzer is a key element for the process control of the white liquor plant. This implementation will be the first Recovery Analyzer reference for Valmet in the Andes region.

About the customer CMPC Celulosa S.A.

CMPC is a pulp and paper company, established in 1920, which produces solid wood products, pulp, paper, packaging products and tissue in Latin America, operating in 8 countries, selling to over 30 thousand clients in more than 45 countries. CMPC has around 16,800 employees around the world.

For further information, please contact:

Carl Mikael Stål, Technical and Operational Manager, Andes Region, Valmet tel. +56 9982 66 255.

Paulo Aguiar, Sales Manager, SA Fiber Process & WPH & Biotech BR, Valmet +55 41 3341 4663.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet receives two new orders for automation technology from Kotkamills in Finland

Valmet has received two orders for automation technology from Kotkamills Oy in Finland to complement the paper machine technology and automation system orders received in April and July 2015 for a paper machine conversion project. Kotkamills is currently rebuilding its magazine paper production line PM 2 and converting it to produce high-quality barrier board and folding boxboard grades. The rebuilt machine will start up during the second quarter of 2016. Valmet's automation system deliveries will take place in April 2016.

Valmet has received two orders for automation technology from Kotkamills Oy in Finland to complement the paper machine technology and automation system orders received in April and July 2015 for a paper machine conversion project. Kotkamills is currently rebuilding its magazine paper production line PM 2 and converting it to produce high-quality barrier board and folding boxboard grades. The rebuilt machine will start up during the second quarter of 2016. Valmet's automation system deliveries will take place in April 2016.

The new orders are included in Valmet's first quarter 2016 orders received and the fourth quarter 2015 orders received. The value of the orders is not disclosed.

"Valmet has long experience and a lot of know-how in automation solutions for the paper industry. We are confident that we will be able to increase efficiency and make the most of the process with Valmet's solutions. The products now ordered match well with and complement the automation concept that we have chosen. We have been using Valmet's automation earlier, so our operators and maintenance staff know it well," says Jari Mäkelä, Manager, Automation and Electrification, Kotkamills.

"Our solutions will enable Kotkamills to improve board quality management as well as the management of the whole production process. Using this technology, the mill will be able to produce high-quality board and improve machine runnability," points out Harri Kohonen, Sales Manager, Automation business line, Valmet.

Technical information about the delivery

The orders include two automation systems, analyzers, measurements, consistency transmitters and optimizing process controls for various process stages in board production.

Valmet will supply Valmet DNA automation systems for the thermomechanical pulp (TMP) plant and the coating kitchen to replace Valmet's earlier-generation systems. For the TMP plant, Valmet will also deliver an online Valmet Pulp Analyzer (Valmet MAP) and optimizing process controls with which the plant can control low-consistency grinding and reach its desired board properties.

Additionally, the delivery includes over 20 consistency transmitters for the TMP plant and the board machine. The latter will be equipped with a Valmet Retention Measurement (Valmet RM3) and a Valmet Wet End Analyzer (Valmet WEM) to control whitewater consistency and chemistry. In connection with the delivery, Valmet will upgrade the mill's existing automatic Valmet Pulp Expert analyzer.

All the solutions will be integrated with the Valmet DNA automation and Valmet IQ quality management systems that are included in the orders announced earlier. One seamless automation system for the process and machine controls from a single supplier ensures that the solutions are a seamless match.

Kotkamills already has an automation service agreement with Valmet, including remote service support. In case of disruptions, Valmet's experts have access to the mill's automation systems through a remote connection.

For further information, please contact:

Harri Kohonen, Sales Manager, Pulp and Paper Mills, Nordic Countries, Automation, Valmet Tel. +358 40 748 3845

Jari Ehrling, Sales Manager, Pulp and Paper Mills, Finland, Automation, Valmet, Tel. + 358 400 765 012

Product pages:

Valmet to supply an OptiConcept M boardmaking line and mill-wide automation system to Pro-Gest in Italy

Valmet will supply an OptiConcept M containerboard production line and a mill-wide Valmet DNA automation system for Pro-Gest S.p.a. for the company's new Mantova site in Italy. The new production line is planned to produce high-quality lightweight recycled case material.

The order is included in Valmet's first quarter 2016 orders received. The value of an order of this type is typically EUR 60-80 million.

"At Pro-Gest we are continuously investing to improve our products and exceed quality standards, applying the latest technologies in our mills. Mantova's new machine will be setting new levels in terms of performance and efficiency, with Valmet's highest range of solutions for papermaking. The whole team is very excited to work with the best paper machine manufacturer in the world for this high capacity and high quality paper mill," says Francesco Zago, General Manager and shareholder of Pro-Gest.

"This delivery combines Valmet's unique competence both in process technologies and automation. Our OptiConcept M modular paper and board making line demonstrates fresh design and engineering innovations which improve energy efficiency, safety and usability. It has proved to be a success since its launch in 2011 and the delivery to Pro-Gest is already the eleventh OptiConcept M machine that we have supplied to our customers," says Jari Vähäpesola, President of Paper Business Line, Valmet.

Details about the delivery

Valmet's OptiConcept M boardmaking line delivery will comprise a complete board making line from headbox to reel and a high-capacity two-drum winder. The mill-wide Valmet DNA automation package includes quality measurement system, process control system, machine controls, runnability and condition monitoring and quality controls. An extensive machine clothing package for start-up is also included of the delivery.

The line features number of latest technologies e.g. layering headbox and horizontal gap forming with shoe and blade technology. These technologies enable high end product quality with wide basis weight range and significant energy saving potential compared to conventional Multi-Fourdrinier technology. Also compact design with innovative fabric insertion unit technology are noteworthy. The unit makes cantilevering unnecessary and shortens installation time.

The width of the high speed machine is 7.6 m (reel) with installed capacity of 550,000 tons of recycled paper.

Information about the customer Pro-Gest

Owned by the Zago family, Pro-Gest is Italy's leading integrated producer of packaging and corrugated board, active in all fields, from the collection of raw materials to packaging production. The Group also includes an integrated tissue manufacturing division, featuring the full range of high quality products.

Pro-Gest is active in 8 Italian regions with 22 production sites, employing over 1,000 people, generating a consolidated annual turnover of EUR 450 million in 2015.

Change in Valmet's Nomination Board

Martin Oliw, nominated to Valmet's Nomination Board by Cevian Capital Partners Ltd., has resigned from the Nomination Board as Cevian Capital Partners Ltd. has sold down their shareholding in Valmet.

Martin Oliw, nominated to Valmet's Nomination Board by Cevian Capital Partners Ltd., has resigned from the Nomination Board as Cevian Capital Partners Ltd. has sold down their shareholding in Valmet.

In accordance with the Charter of the Nomination Board of Valmet, the representative nominated by a shareholder is obliged to resign from the Nomination Board if the shareholder concerned later transfers more than half of the shares it held on the September 1, 2015 which entitled it to nominate a representative and as result is no longer among Valmet's ten largest shareholders.

After the resignation of Martin Oliw, the members of the Nomination Board are Kari Järvinen, (Managing Director at Solidium Oy), Roger Hagborg (Investment Advisory Professional at Triton), Risto Murto (CEO at Varma Mutual Pension Insurance Company) and Bo Risberg, Chairman of Valmet's Board of Directors, as the Nomination Board's expert member.

The Nomination Board has prepared proposals on members of the Board of Directors and their remuneration for the Annual General Meeting, which will be held on March 22, 2016. The proposals are presented in the notice convening Valmet's Annual General Meeting, published on February 9, 2016, which is available at www.valmet.com/agm.

Further information, please contact:

Rasmus Oksala, General Counsel, Valmet, tel. +358 10 672 0026

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.