Displaying items by tag: valmet

Valmet to supply analyzers and quality control system for Stora Enso's Varkaus Mill in Finland

Valmet will supply pulp mill and board machine quality management solutions for Stora Enso's Varkaus Mill in Finland. The orders are an addition to the extensive rebuild of the Varkaus mill's PM 3 fine paper machine supplied by Valmet to produce lightweight containerboard grades announced on May 13, 2014.

Valmet IQ Quality Control System

The order was included in Valmet's second quarter 2015 orders received. The value of the order is not disclosed. Typically, the order value of automation system deliveries ranges from below EUR 1 million to EUR 3 million.

"After the upgrades of both pulp mill and board machine quality management systems, the Varkaus mill will be able to fully exploit the rebuilt machine's performance potential," says Aki Korhonen, Director of Analyzers, Measurements and Performance Solutions from Valmet.

The Valmet delivery includes a Valmet Kappa Analyzer for the pulp mill and Valmet IQ quality control system (QCS) for the rebuilt board machine.

Technical details of the automation delivery

The Valmet delivery includes a Valmet Kappa Analyzer for the pulp mill. The analyzer will provide all the necessary measurements of fibers, shives and kappa number, for brown unbleached kraft production. Sampling capacity of the mill's Valmet Pulp Expert automatic pulp laboratory will also be expanded with 5 new samplers to accurately follow pulp property development in stock preparation.

The delivery also includes a new Valmet IQ quality control system (QCS) for the rebuilt board machine. With sensors for basis weight, moisture, caliper ash content and color; the IQ system features state-of-the-art machine and cross direction controls. Additionally four Valmet RM3 sensors will be supplied to measure wet end consistencies with the exclusive ability to monitor both total and true ash consistency from the process for active fines retention management. New modules will also be installed to the mill's existing Valmet Paper Lab and provide automated laboratory testing for key board quality parameters.

Information about the customer Stora Enso

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wood and paper on global markets. Customers include packaging, joinery and construction industries as well as publishers, printing houses and paper merchants. The Group has some 27 000 employees in more than 35 countries with sales in 2014 of EUR 10.2 billion.

VALMET

Corporate Communications

For further information, please contact:

Janne Tolonen, Sales Manager, Pulp & Paper, Nordics, Automation, Valmet, tel. +358 40 566 9374

Harri Kohonen, Sales Manager, Pulp & Paper, Nordics, Automation, Valmet, tel. +358 40 748 3845

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply tenth OptiConcept M paper making line for Lee & Man in China

Valmet will supply a complete OptiConcept M containerboard production line for Lee & Man in Jiang Xi in China. The new production line is planned to produce high-quality containerboard grades out of 100 percent recycled raw materials. The start-up of the machine is scheduled for the fourth quarter of 2016.

The order is included in Valmet's third quarter 2015 orders received. The value of the order will not be disclosed. An order of this scope is typically valued around EUR 40-50 million.

"OptiConcept M has really made its breakthrough as an industry standard for paper and board manufacturing, which is proven by this repeat order from Lee & Man", says Juha Kivimaa, Director, Sales Technology in Valmet's Paper business.

"This repeat order to Valmet strengthens our long partnership in this business area. With good combination of local and imported know how Valmet has shown its capability in earlier projects. Lightweighting is a trend in containerboard business and Valmet's technology is very suitable for these grades", says Edmond Lee, CEO of Lee & Man.

The line ordered by Lee & Man will be the tenth OptiConcept M production line to be supplied by Valmet since the first delivery in 2012. In addition to Asia, Valmet has delivered OptiConcpet M lines also in North America and Europe. The compact and efficient OptiConcept M production line concept covers grades from recycled containerboards to cartonboards and fine paper.

Valmet's delivery will comprise a complete board machine with related process automation solutions, air systems and winder. The annual production capacity of the new machine will be approximately 300,000 tonnes and the design speed 1,200 m/min.

Information about the customer Lee & Man

Lee & Man Paper Manufacturing Ltd manufactures linerboard and corrugating medium grades for industrial packaging purposes. Lee & Man Paper Manufacturing Ltd has been established in 1994 and it is listed on the Hong Kong Stock Exchange. At present the company has about 7 million tons board production capacity in China.

For further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Fan Ze, Vice President, Capital Sales in China, Valmet, tel. +86 10 6566 6600 3108

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com, www.twitter.com/valmetglobal

Valmet to rebuild Metsä Tissue's tissue machine in Raubach in Germany

Metsä Tissue has chosen Valmet's Advantage DCT concept including the Advantage ViscoNip pressing technology for the upgrade of their tissue machine TM 1 in Raubach, Germany. The start-up of the rebuilt machine is scheduled for the first half of 2016.

Metsä Tissue has chosen Valmet's Advantage DCT concept including the Advantage ViscoNip pressing technology for the upgrade of their tissue machine TM 1 in Raubach, Germany. The start-up of the rebuilt machine is scheduled for the first half of 2016.

The order was included in Valmet's second quarter, 2015 orders received. The value of the order will not be disclosed.

"Metsä Tissue is one of the leading suppliers of tissue paper products to households and professional users in Europe. We continuously develop our products, operations and production units to be able to supply high-quality tissue products and to ensure reliable deliveries to our customers. Through this tissue machine renewal in Raubach mill, we aim to enhance the product qualities as well as energy efficiency and process performance in a sustainable way. We have chosen Valmet as our partner because of Valmet's excellent reputation and strong technology know-how in tissue manufacturing," says Christoph Zeiler, Senior Vice President Tissue West Europe, Metsä Tissue.

"The most important benefits of using Valmet's Advantage ViscoNip technology are both the considerable savings in drying energy consumed and improved tissue paper quality. We are proud that Metsä Tissue has selected our well proven Advantage technology for the upgrade of TM1 in Raubach and look forward to working in close partnership to make this a successful project," says Björn Magnus, Sales Director, Tissue Mills Business Unit, EMEA, Valmet.

Technical information

The machine rebuild to be delivered by Valmet includes a new Advantage DCT wet end section with an OptiFlo Tis II headbox and an Advantage ViscoNip press for improved product quality and decreased energy consumption. A new tail threading system and sheet transfer will further advance runnability and performance. The delivery also includes key stock preparation equipment such as an Optislush Pulper and a OptiScreen machine screen.

An extensive package of services including engineering, installation of the tissue machine, supervision, training, commissioning and start-up is also included in the delivery.

Information about the customer Metsä Tissue

Metsä Tissue is one of the leading tissue paper products suppliers to households and professionals in Europe and the world's leading supplier of baking and cooking papers. Metsä Tissue is part of Metsä Group, which is a forest industry group focusing on tissue and cooking papers, fresh forest fibre paperboards, pulp, wood products, and wood supply and forest services. Its high-quality products combine renewable raw materials, customer-orientation, sustainable development and innovation. Metsä Group's sales totalled EUR 5 billion in 2014, and it employs approximately 10,500 people. The Group operates in some 30 countries.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue Mills business unit, Valmet, tel. +46 70 517 14 90

Björn Magnus, Sales Director, EMEA, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet supplies main equipment to the pulp mill project of Huanggang Chenming Pulp & Paper Co., Ltd. in China

Valmet will supply main equipment to Huanggang Chenming Pulp & Paper's new pulp mill located in the city of Huanggang in Hubei province, China. The pulp mill is designed for flexible production to respond to market developments. The pulp line can be run to produce softwood kraft pulp and dissolving pulp depending on the market needs. The new mill is expected to start up in 2017. Valmet's delivery includes the main equipment excluding only some specific process parts.

Valmet will supply main equipment to Huanggang Chenming Pulp & Paper's new pulp mill located in the city of Huanggang in Hubei province, China. The pulp mill is designed for flexible production to respond to market developments. The pulp line can be run to produce softwood kraft pulp and dissolving pulp depending on the market needs. The new mill is expected to start up in 2017. Valmet's delivery includes the main equipment excluding only some specific process parts.

The value of the order is about EUR 110 million. The order is included in Valmet's third quarter orders received.

"Huanggang will be our new business location, where we plan to have a three-phase investment. This pulp mill investment is the first phase. We have been cooperating with Valmet close to 20 years. Our people trust Valmet's know-how and its service spirit. We are happy to select Valmet as the main equipment supplier to this project," says Mr. Chen Hongguo, Chairman of Chenming Group.

"Huanggang pulp mill project offers both our engineering and production personnel work in the Nordics, Asia Pacific and China. This pulp mill will be the world's largest dissolving pulp producer, and the order shows the customer's trust on Valmet's know-how in pulp and dissolving pulp technology," says Bertel Karlstedt, President of Valmet's Pulp and Energy Business Line.

Details of Valmet's delivery

Valmet's delivery presents state-of-the art technology in optimizing mill production, tailor making of dissolving grades, maximizing energy efficiency and minimizing environmental impact. The delivery includes specific equipment and services for wood handling and pulp drying areas, hardwood and softwood multi-grade fiber line (excluding cooking), high dry solids evaporation plant, high power recovery boiler with integrated crystallization system, biomass gasification, lime kiln and recausticizing.

In addition to the delivered equipment, the delivery includes process and basic engineering, detail engineering services and virtual site training simulator for selected areas as well as installation and start-up advisory services.

In parallel with the Huanggang supply contract, Chenming and Valmet agreed on the delivery of a separate non-condensable gas incinerator for the Chenming Group's Zhanjiang mill.

Information about the customer Huanggang Chenming

Huanggang Chenming Pulp and Paper is part of Shandong Chenming Paper Group Co., Ltd, which is one of the leading paper manufacturers in China. The group's activities include afforestation, pulp making, and paper manufacturing. Chenming Group is listed on both the China and Hong Kong stock exchanges. The company has more than 10 production sites around China. The group's annual paper production capacity is 6 million tons and it has about 13,000 employees.

For further information, please contact:

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 676 3026

Yutong Feng, Vice President, Pulp and Energy, China, Valmet, tel. +86 1360 108 9397

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet and Australian Paper sign a multi-year maintenance technical support agreement for Maryvale Mill

Valmet and Australian Paper have signed a multi-year agreement for Valmet to provide maintenance technical support at the Maryvale Mill in Victoria, Australia. The new technical support agreement (TSA) which will focus on providing onsite maintenance technical advice and expertise to the mill's maintenance organization, replaces the old maintenance agreements between Valmet and Australian Paper. The agreement came into effect on August 1, 2015.

Peter Williams, COO of Australian Paper, and Pierre de Villiers, Vice President Sales, Australia and New Zealand from Valmet.

The Maryvale Mill has three pulp lines, five papermaking machines, an elemental chlorine free bleach plant, pulp lapping machine, deinked pulp line, finishing facility and a waste paper processing plant. Valmet's TSA resources will be located within the mills power and recovery, fibre lines, paper mill and central maintenance areas.

"The new agreement builds on the partnership between Australian Paper and Valmet, providing long term technical input into Australian Paper's maintenance operation allowing for continuous improvement and development programs to be identified and implemented along with specific Pulp & Paper knowledge and knowhow," says Peter Williams, COO of Australian Paper.

"Australian Paper has developed continue to develop the Maryvale Mill to ensure its long term sustainability and profitability as a domestic producer of fine paper and packaging grades. The Technical Service Agreement provides the needed alignment to meet these objectives, reinforces the high level cooperation and commitment between our organizations and provides the platform to move our customer's performance forward," says Pierre de Villiers, Vice President Sales, Australia and New Zealand, Valmet.

Information about the customer Australian Paper

Australian Paper is Australia's largest manufacturer of fine papers for print and office applications and produces high-quality packaging papers. Australian Paper employs over 1,400 Australians and supplies more than 600,000 tonnes of product within Australia and around the world. Australian Paper is part of Nippon Paper Group that consists of approximately 180 affiliates and related companies. The Maryvale Mill is Australia's largest integrated fine paper-making and packaging papers complex, producing more than 500,000 tonnes of paper every year.

For further information, please contact:

Pierre de Villiers, Vice President, Sales, Australia and New Zealand, Valmet, tel. +61 417 055 564

Miikka Kettunen, Senior Manager, Maintenance Agreements, Asia Pacific, Services business line, Valmet, tel. +62 811 871 1571

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to acquire tissue rewinder business from Massimiliano Corsini srl. Italy to strengthen its product portfolio

Valmet and Massimiliano Corsini srl. have signed a Sale and Purchase Agreement of MC Paper Machinery and Focus Rewinding business to Valmet on July 31, 2015. The acquisition is estimated to be completed by August 6, 2015.

Valmet and Massimiliano Corsini srl. have signed a Sale and Purchase Agreement of MC Paper Machinery and Focus Rewinding business to Valmet on July 31, 2015. The acquisition is estimated to be completed by August 6, 2015.

The acquired operations mainly supply rewinders for tissue and non-woven machines. In the past years the net sales of the acquired business has been around EUR 10 million. The operations employ 33 people and are located in Pescia, close to Lucca, Italy.

Combination of Valmet and MC Paper Machinery creates complete customer offering

As a result of the acquisition, Valmet will have a more extensive product portfolio and becomes a stronger technology and services company in its field. The acquisition strengthens Valmet's competitiveness by combining tissue making equipment from stock preparation to rewinding, process know-how, automation and services into one customer value-adding entity.

Valmet and MC Paper Machinery have had a long-term partnership and a large amount of MC Paper rewinders have been installed in connection to Valmet tissue machines.

The company being acquired is a strong business, with established customer relations and a high level of technology and know-how, including the successful Focus technology. During the last 20 years MC Paper Machinery has become world leading in designing and manufacturing rewinding plants specifically devoted to the field of non-woven and tissue paper.

Through the acquisition, Valmet strengthens its offering and continues to develop its business.

Strengthened tissue market position

"Valmet and MC Paper Machinery share the same determination to offer leading technologies, with highest customer satisfaction. Through the acquisition, Valmet will become a technology and service company with a wider offering of high technology equipment for tissue production. By combining tissue paper and re-winding machinery with process know-how, automation and services and global presence from both companies, we can serve the tissue producers even better than before and move our customers' performance forward," says Anders Björn, Vice President of Valmet's Tissue Mills Business Unit.

Valmet's Interim Review January 1 - June 30, 2015: Strong start for Automation as part of Valmet - profitability reached the targeted range in Q2/2015

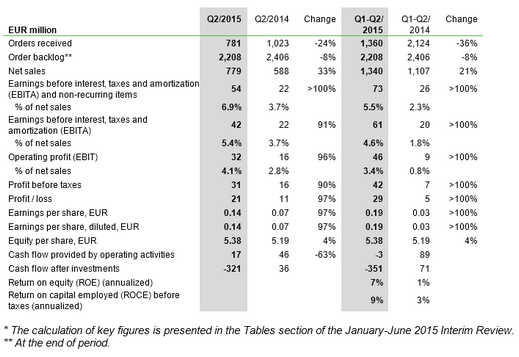

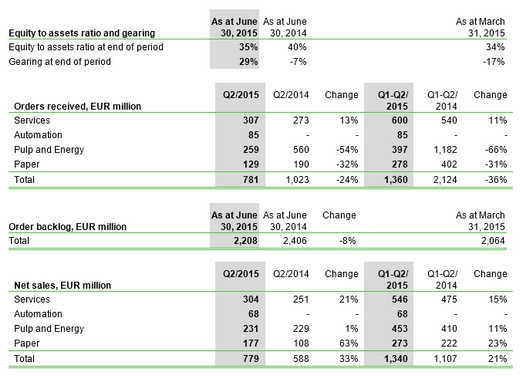

Figures in brackets, unless otherwise stated, refer to the comparison period, i.e. the same period of the previous year. Automation has been consolidated into Valmet's financials since April 1, 2015, when the acquisition of Automation was completed.

April-June 2015: Strong start for Automation - Valmet's EBITA more than doubled

- Orders received decreased to EUR 781 million (EUR 1,023 million).

- Orders received increased in the Services business line and decreased in the Pulp and Energy, and Paper business lines.

- Net sales increased to EUR 779 million (EUR 588 million).

- Net sales increased in the Paper, and Services business lines and remained at the previous year's level in the Pulp and Energy business line.

- Automation contributed to net sales by EUR 68 million.

- Earnings before interest, taxes and amortization (EBITA) and non-recurring items were EUR 54 million (EUR 22 million), and the corresponding EBITA margin was 6.9 percent (3.7%).

- Profitability improved due to the higher level of net sales, improved gross profit, and the acquisition of Automation.

- Earnings per share were EUR 0.14 (EUR 0.07).

- Non-recurring items amounted to EUR -12 million (EUR 0 million), of which costs related to acquisition of Automation amounted to approximately EUR 10 million.

- Cash flow provided by operating activities was EUR 17 million (EUR 46 million).

January-June 2015: EBITA more than doubled - continued good development in Services

- Orders received decreased to EUR 1,360 million (EUR 2,124 million).

- Orders received increased in the Services business line and declined from the high levels in H1/2014 in the Pulp and Energy, and Paper business lines.

- Net sales increased to EUR 1,340 million (EUR 1,107 million).

- Net sales increased in Services, Pulp and Energy, and Paper business lines.

- Automation contributed to net sales by EUR 68 million.

- Earnings before interest, taxes and amortization (EBITA) and non-recurring items were EUR 73 million (EUR 26 million), and the corresponding EBITA margin was 5.5 percent (2.3%).

- Profitability improved due to the higher level of net sales, improved gross profit, and the acquisition of Automation.

- Earnings per share were EUR 0.19 (EUR 0.03).

- Non-recurring items amounted to EUR -12 million (EUR -6 million), of which costs related to acquisition of Automation amounted to approximately EUR 10 million.

- Cash flow provided by operating activities was EUR -3 million (EUR 89 million).

Valmet reiterates its guidance for 2015

Valmet is reiterating its guidance presented on February 6, 2015 in which Valmet estimates that, including the acquisition of Process Automation Systems, net sales in 2015 will increase in comparison with 2014 (EUR 2,473 million) and EBITA before non-recurring items in 2015 will increase in comparison with 2014 (EUR 106 million).

Short-term outlook

General economic outlook

Global growth is projected at 3.3 percent in 2015, marginally lower than in 2014, with a gradual pickup in advanced economies and a slowdown in emerging market and developing economies. In 2016, growth is expected to strengthen to 3.8 percent. The distribution of risks to global economic activity is still tilted to the downside. Near-term risks include increased financial market volatility and disruptive asset price shifts, while lower potential output. (International Monetary Fund, July 9, 2015)

Short-term market outlook

Valmet is reiterating its short-term market outlook presented on April 29, 2015. Valmet estimates that activity in pulp, and board and paper markets will remain on a good level. The activity in the services, tissue, and automation markets is estimated to remain satisfactory. The activity in the energy markets is expected to remain weak.

President and CEO Pasi Laine: Together with Automation, Valmet becomes a stronger company

When the acquisition of Process Automation Systems was completed on April 1, 2015, Valmet got its fourth business line, called Automation. Our customers appreciate that we have reunited the automation expertise with paper, pulp, and power plant technology and process know-how, within the same company. This change has energized and motivated our employees too.

Automation had a strong start as a part of Valmet, and over time I believe that we can achieve even greater benefits through good internal cooperation. With an integrated sales process, harmonized project execution, wider offering and enhanced product development, we will be able to serve our customers even better than before. All in all, Valmet will become a stronger company.

Valmet's performance in the second quarter of 2015 was solid: net sales increased, profitability improved and the EBITA margin reached our targeted range. Good development continued in the Services business line. Additionally we are continuing our focus on cost control and successful project execution.

In addition to expanding Valmet's offering, the automation business somewhat decreases cyclicality of Valmet's businesses. On annual level the automation business is typically fairly stable, thus increasing the stability and visibility of Valmet's business.

Key figures*

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet's Interim Review January 1 - June 30, 2015

Publishing of Valmet Corporation's Interim Review for January-June 2015 on July 30, 2015

Valmet Corporation's Interim Review for January 1 - June 30, 2015 will be published on Thursday, July 30, 2015 at approximately 3:00 p.m. Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

Valmet Corporation's Interim Review for January 1 - June 30, 2015 will be published on Thursday, July 30, 2015 at approximately 3:00 p.m. Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

Invitation to conference call and audiocast

Valmet will arrange a conference call and an audiocast in English for analysts, investors, and media on Thursday, July 30, 2015 at 4:00 p.m. Finnish time (EET). President and CEO Pasi Laine and CFO Markku Honkasalo will be presenting Valmet's Interim Review.

Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 3:55 p.m. (EET), at +44 1452 553430. The participants will be asked to provide the following event passcode: 1719244

The audiocast can be followed live at www.valmet.com/webcasts. The live audiocast starts at 4:00 p.m. (EET) and a recording of the audiocast will be available shortly after the event at the same address.

It is possible to ask questions at the conference call after the presentations by the President and CEO, and the CFO. At the audiocast, written questions can also be sent via a chat function.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, VP, Investor Relations, Valmet, tel. +358 10 672 0007

For media: Anu Salonsaari-Posti, SVP, Marketing & Communications, Valmet, tel. +358 10 672 0033

VALMET CORPORATION

Markku Honkasalo

CFO

Hanna-Maria Heikkinen

VP, Investor Relations

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet delivers white liquor handling system to BillerudKorsnäs's pulp mill in Skärblacka, Sweden

Valmet will deliver a white liquor handling system to BillerudKorsnäs's pulp mill in Skärblacka, Sweden. The start-up of the rebuilt plant is planned in June 2016.

The order is included in Valmet's second quarter 2015 orders received and the value of the order will not be disclosed.

"Previously Valmet has delivered a recovery boiler rebuild and a new evaporation plant to the Skärblacka mill. This upgrade will enable a production capacity increase, as existing equipment has become too small and is in a need of extensive maintenance," says Thomas Malmqvist, Sales Manager Pulp and Energy, from Valmet.

Details about the delivery

The new equipment that Valmet will install are a white liquor filter of type PDW and a causticizer tank. The white liquor filter produces a clear white liquor which increases the efficiency and availability in the pulping process. The separation of white liquor from lime mud is done by pressure filtration. After the rebuild the white liquor plant will have a capacity of 5 200 m3 per day.

About the customer BillerudKorsnäs and Skärblacka mill

BillerudKorsnäs is a leading company within renewable packaging materials. Together with their partners, they create smart packaging solutions. The company has about 4 300 employees and eight production units, one of which is the Skärblacka mill.

Skärblacka mill develops and produces everything from highly porous sack paper to fluting and white machine glazed kraft paper. Production capacity of the mill is 430 000 tonnes/year.

For further information, please contact:

Thomas Malmqvist, Sales Manager, Pulp and Energy Business Line, Valmet, Tel. +46 70 310 53 22

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply winding technology for Parenco's paper machine grade conversion rebuild

Valmet will supply Parenco B. V. with high capacity winder for company's containerboard making line PM2 in Renkum, Netherlands. The PM2 was shut down in 2009 by mill's earlier owner due to declining demand of newsprint paper. Now, the machine will be converted to produce testliner and fluting grades, which are used in containerboards. The converted PM2 is scheduled to start-up during the third quarter of 2016.

The order is included in Valmet's second quarter 2015 orders received. The value of the order will not be disclosed.

Valmet OptiWin Drum high capacity winder

"Valmet's winding technology enables high capacity and reliable production of lightweight packaging board. The proof of this is our strong reference base in Europe. Our OptiWin two drum winders are well suited for multiple grades and models are available for all machine widths", says Kenneth Åkerlund, Product Manager, Winders and Reels, from Valmet.

Technical information about the delivery

Parenco's PM2 has a trim width of 8.5 m. After the conversion it will produce testliner and fluting grades at a capacity of around 385,000 tonnes/yr.

Valmet's delivery includes a fully automated OptiWin two-drum winder comprisingcore feeding, automatic set change and an end gluing device. Valmet's delivery also includes parent roll handling system, fully automatic roll marking and roll conveyor system, automatic core cutting and core handling system as well as related pulper and air systems and machine control system.

About the customer Parenco

Parenco B. V., located in the Netherlands, has a yearly turnover of approximately EUR 140 million and the company operates two paper machines PM1 and PM2 in their Renkum mill. Parenco has over 200 employees. Since October 2012 the company has been owned by H2 Equity Partners.

Further information, please contact:

Kenneth Åkerlund, Product Manager, Winders and Reels, tel. + 358 40 865 6287

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills Business Unit, tel. +358 40 744 8182

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.