Displaying items by tag: valmet

Valmet celebrates the 50th Kappa Analyzer start up in South America

The 50th Valmet Kappa Analyzer in South America was successfully started up in May 2015 at the CMPC Guaíba pulp mill in Rio Grande do Sul state, south of Brazil. Installed in the mill's second fiber line, a greenfield project supplied by Valmet, the Kappa Q analyzer measures Kappa and brightness from 6 points starting at the blow line through to bleaching.

The 50th Valmet Kappa Analyzer in South America was successfully started up in May 2015 at the CMPC Guaíba pulp mill in Rio Grande do Sul state, south of Brazil. Installed in the mill's second fiber line, a greenfield project supplied by Valmet, the Kappa Q analyzer measures Kappa and brightness from 6 points starting at the blow line through to bleaching.

According to Andrea R. S. Busnello, Fiber Line Process engineer, "The Kappa Q analyzer provides us with fast and reliable information. Based on the analyzer measurements it is possible to get a better process understanding, calculate the right amount of chemical, reduce the raw material variation impact and it also helps to achieve the final pulp quality".

The Valmet Kappa Q utilizes patented sweep technology to measure kappa and brightness with a unique two-point calibration method. Capable of measuring critical properties - lignin content, brightness, pulp fiber and shives, the analyzer is easily expanded according to measurement needs and the number of sampling points.

The Valmet Kappa Q utilizes patented sweep technology to measure kappa and brightness with a unique two-point calibration method. Capable of measuring critical properties - lignin content, brightness, pulp fiber and shives, the analyzer is easily expanded according to measurement needs and the number of sampling points.

CMPC Celulose Riograndense Ltda is part of the Chilean group, CMPC, one of the largest forestry-based companies in Latin America. Its mills in Chile and Brazil produces around 4.3 million tonnes of pulp per year (Hardwood and Softwood).

For further information, please contact:

Andre Luiz Kakehasi, Product Manager, Automation South America Area, Brazil, Valmet

+55 15 21029747

Risto Ikäheimo, Product Manager, Automation CMS AMP Pulp Analyzers, Finland, Valmet

+354 00 406 094

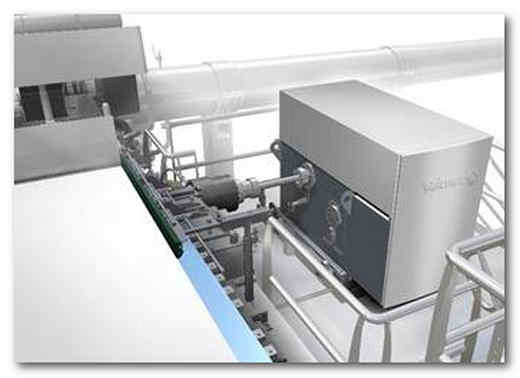

Valmet-supplied LignoBoost plant now handed over to Stora Enso's Sunila mill in Finland

Stora Enso's Sunila mill is now running the Valmet-supplied LignoBoost lignin separation plant. As the last part of the handover process, the lignin dryer, was taken over by the Stora Enso team on September 15, 2015. The LignoBoost plant is integrated with the pulp mill to separate and collect lignin from the black liquor. This is a significant step in transforming the Sunila mill towards an innovative and customer focused biorefinery. The plant has been running since January 2015 and production has been ramped up during the year.

Stora Enso's Sunila mill is now running the Valmet-supplied LignoBoost lignin separation plant. As the last part of the handover process, the lignin dryer, was taken over by the Stora Enso team on September 15, 2015. The LignoBoost plant is integrated with the pulp mill to separate and collect lignin from the black liquor. This is a significant step in transforming the Sunila mill towards an innovative and customer focused biorefinery. The plant has been running since January 2015 and production has been ramped up during the year.

"Through the lignin extraction process we have replaced a great amount of natural gas with the dried lignin produced in the new LignoBoost plant, and by doing that reduced our carbon dioxide emissions. We are developing this new product and working together with our customers to start external sales," says Sakari Eloranta, Senior Vice President, Operations and Investment Projects, Stora Enso Biomaterials.

"This is the second commercial scale LignoBoost plant in the world. We continue to develop this technology, as we see a great potential in utilizing lignin in various uses. Lignin powder can be used as raw material at the mill for firing or it can be converted into other materials and products. Lignin separation will at the same time improve the environmental performance of the mill," says Anders Larsson, Director, Bio materials, Pulp and Energy business line, Valmet

LignoBoost lignin separation technology

LignoBoost is one of Valmet's biotechnology solutions that responds to the growing interest for utilizing bio-based raw materials. LignoBoost is Valmet's patented method of extracting lignin from Kraft Pulp process' spent cocking chemicals, the black liquor. By treating the black liquor with carbon-dioxide and a strong acid the lignin is precipitated, which is then washed and dried. Lignin is an organic polymer and has a heating value similar to carbon. Lignin is besides cellulose and hemi cellulose the most common material in wood.

In addition to LignoBoost, Valmet has several bio initiatives including products such as bio coal, solutions for second generation ethanol, pyrolysis oil as well as direct and indirect gasification of biomaterials.

About the customer Stora Enso Biomaterials

Stora Enso Biomaterials offers a variety of pulp grades to meet the demands of paper, board and tissue producers. The mission is to develop higher value added bio-based products that contribute positively to our customers by helping them reduce their environmental footprint. The Sunila mill has an annual capacity of 370,000 ton of softwood pulp. The mill employs approximately 160 people.

For further information, please contact:

Anders Larsson, Director, Bio Materials, Pulp and Energy business line, Valmet, tel. +46 70 588 5477

Marita Niemelä, Vice President, Strategy, Pulp and Energy business line, Valmet, tel. +358 50 4120 802

Valmet to deliver new pulp cooking system to Clearwater Paper's Lewiston Mill in the USA

Valmet will deliver key technology to Clearwater Paper's Lewiston, Idaho, Mill upgrade project. Valmet's delivery includes a Compact Cooking G2 pulp cooking system, a new plant for generating polysulfide and a minor upgrade of existing bleach plant.

Valmet will deliver key technology to Clearwater Paper's Lewiston, Idaho, Mill upgrade project. Valmet's delivery includes a Compact Cooking G2 pulp cooking system, a new plant for generating polysulfide and a minor upgrade of existing bleach plant.

Construction of the upgrade project is planned to begin in October 2015 and expected to be completed in September 2017. The order was included in Valmet's second quarter orders received 2015.The value of the order will not be disclosed.

This delivery is part of Clearwater Paper's USD 160 million project to install a continuous pulp digester that will replace 12 batch digesters. Benefits from the project include significant reduction in air emissions, improved pulp quality, increased production and a more efficient utilization of wood chips.

"The efficient utilization of raw material is a vital part from a sustainability perspective. We decided to base our new cooking process on polysulfide to optimize yield. The concept and process included in the CompactCooking system from Valmet was a perfect match to our targets," says John Deuser, Project Manager in Lewiston.

"This is our second new cooking system project in North America in recent times, and confirms the capabilities of our CompactCooking G2 process. We are proud to be given the trust and opportunity to be the main process supplier for both the cooking plant as well as polysulfide generation plant in this important project. We are prepared and confident that the systems will meet all the expectations of this project," says Mona Henderson, Business Manager at Valmet.

Technical details about CompactCooking G2

The cooking plant is the first stage in a chemical pulping line where lignin is chemically separated from the fiber. CompactCooking G2 is Valmet's 2-vessel continuous cooking system mainly consisting of an impregnation system and a digester for cooking of chips. It is characterized by its simple, yet sophisticated design, a flexible system that is easy to operate. Valmet's ImpBin impregnation technology with its unique features enables higher kappa level operation with low reject content. Using a 2-vessel design ensures well defined impregnation as well as cooking zones. Effective impregnation in combination with the benefits of the CompactCooking process produce pulps with high yield and excellent pulp quality.

About Clearwater Paper Corporation

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, parent roll tissue, bleached paperboard and pulp at manufacturing facilities across the nation. The company is a premier supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters.

For further information, please contact:

Mona Henderson, Business Manager, Chemical Pulping, North America, Valmet, tel. +1 770-368-7376

Bill Bohn, Area President, North America, Valmet, tel. +1 404 394 5924

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet launches Valmet IQ product family for pulp and paper quality control and monitoring

Valmet launches renewed Valmet IQ product family to the pulp and paper industry customers. Valmet IQ is a scalable, on-line quality management solution to optimize the production processes and the end product quality.

Valmet IQ is designed with the experience of thousands of system deliveries by Valmet over longer than half a century. The renewed solution consists of a quality control system (QCS), profilers, web monitoring (WMS) and web inspection systems (WIS).

Valmet IQ is designed with the experience of thousands of system deliveries by Valmet over longer than half a century. The renewed solution consists of a quality control system (QCS), profilers, web monitoring (WMS) and web inspection systems (WIS).

"The launch of Valmet IQ Quality Management Solution marks a new milestone in pulp and paper quality management featuring a number of innovations like on-line softness measurement for tissue. The new Valmet IQ is a beneficial solution whether our customer is looking to replace aging or obsolete quality control systems or to build up an entirely new quality management solution," says Jari Almi, Director, Quality Management Solutions at Valmet.

Valmet IQ provides innovative solutions in paper quality management

Valmet IQ product family features a number of innovations as well as evolutionary product improvements. New first-in-the-market measurements include: an on-line softness measurement for tissue; a non-nuclear basis weight measurement for pulp drying; camera-based measurements and control for fiber orientation, and a topography-based surface properties and printability prediction.

The profilers, WIS and WMS are renewed in many areas as well: innovations in air-water spray nozzles for re-moisturizing, fully removable diffuser plate with advanced steam injection technology, new advanced solutions for improved image quality, detection and classification.

New Valmet IQ user interface with integrated performance reporting takes the user experience to a new level revealing a clear view of the past, present and the future of the process and product quality through intuitive navigation. It also allows for easy grade management.

The Valmet IQ MD Optimizer brings all process and quality measurements into a single controller for maximizing production efficiency and achieving optimum product quality. Advanced tools for process analysis and adaptive scanning make the life of the operators easier.

Valmet IQ helps to move business performance forward

All Valmet IQ products are based on vast process knowledge and long experience in the pulp and paper industry supported by local expert services to assure lifelong performance at the lowest total cost of ownership. Valmet expertise is also available remotely for all customer mills through remote connections.

All components of Valmet IQ solution are designed to work together. The forward and backward compatibility helps to future-proof the investment and maximize the effectiveness of existing equipment. The products are designed to work seamlessly also with other automation systems and all paper machines regardless of manufacturer. The easy connectivity with any system allows replacements even piece by piece.

For further information, please contact:

Jari Almi, Director, Quality Management Solutions, Automation business line, Valmet, Tel: +358 40 764 7512

Helena Lamberg, Director, Marketing & Planning, Automation business line, Valmet, Tel. +358 40 568 1055

Valmet's breast roll shaker improves board and paper quality

Valmet has introduced its new FormMaster 120 for board and paper machine forming sections. It has proven to offer better board and paper quality with a smoother surface and better printability with reduced raw material costs and lower power consumption.

Improved formation and strength properties

Valmet's new FormMaster 120 improves paper and board formation through even longer strokes and higher shaking force than its predecessor. This self-balancing breast roll shaker can achieve the same strength properties with a lower basis weight, improving the visual appearance of the final product.

With an axial shaking force of 120 kN - double that of the original FormMaster - the new FormMaster 120 improves strength properties and formation by optimizing fiber web structure on the wire. FormMaster 120 makes it possible to use less refining energy, minimize starch usage and reduce calendering, while still achieving the same final quality of board and paper.

FormMaster 120 provides the best stroke length on the market for a large range of breast roll weights.

Best stroke length on the market

"FormMaster 120 is an excellent tool for paper machine operators to optimize the properties of their board and paper. The extended stroke length, achieved with this new breast roll shaker, is key to improved formation and available with a wide range of shaking frequencies," says Pekka Hirsilä, Product Sales Manager at Valmet.

Maintenance issues were also addressed in the design of FormMaster 120 by improving access to the main maintenance points. Customers all over the world have found FormMaster 120 safe, easy and reliable to use and maintain.

Further information, please contact:

Pekka Hirsilä, Product Sales Manager, Paper Technology Sales, Valmet, tel. +358 10 672 6626,

Markku Pohjola, Senior Chief Engineer, Paper Mills, Valmet, tel. +358 10 672 6354,

Valmet receives repeat order for two new tissue production lines from Lee & Man Paper Manufacturing in China

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The start-up of the two new lines is planned to take place in late 2016.

Valmet will supply two Advantage DCT tissue production lines and related automation systems to one of China's leading paper and pulp producers, Lee & Man Manufacturing Ltd. The start-up of the two new lines is planned to take place in late 2016.

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

The Valmet's Advantage DCT 200HS tissue lines to be delivered are designed for production of high quality tissue products. The new tissue lines will fulfill the high requirements for effective technology and sustainability set by Lee & Man. In 2014, the company ordered an Advantage DCT 200HS tissue line which is planned to start up at the Chongqing mill later this year.

"We see Valmet as strategic partner in the development of our tissue business. Their position as market leader in tissue machinery made us confident to repeat our previous order with Valmet", says Raymond Lee, Chairman of the Board, Lee & Man.

"We are very pleased that Lee & Man have decided to extend the cooperation we started with the delivery of the first tissue machine to Chongqing mill. As seen from earlier installations, it is possible to reach significant drying energy savings and highest paper quality by combining the Advantage ViscoNip press with a cast alloy Yankee cylinder and steam heated Advantage AirCap hood. We also see this order as confirmation of the winning concept," says Svenerik Olsson, Director, Tissue Mills Business Unit, Valmet China.

Valmet's Advantage DCT concept is well established on the market and has proven to enable cost- and energy-efficient production of high quality tissue products.

Technical information about the delivery

The new tissue machines will have a width of 5.6 m and a design speed of 2,000 m/min. Each machine will produce 60.000 tons of toilet and facial tissue per year, using virgin wood pulp and bleached bamboo fiber as raw material.

Valmet's scope of delivery will comprise complete tissue production lines featuring stock preparation systems and Advantage DCT 200HS tissue machines. The machines will be equipped with OptiFlo headbox and cast alloy Yankee cylinders. The machines will also be featured with the well proven Advantage tissue technology including ViscoNip press, steam heated AirCap hood, WetDust dust system and a SoftReel P reel. Basic engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

The delivery will also include an automation package from Valmet with Valmet DCS and QCS process control system.

About the customer Lee & Man Paper Manufacturing

Established in 1994, Lee & Man Paper Manufacturing Ltd has grown from a small company into a leading paper and pulp manufacturer. The company's 6,500 employees are located at the company's five production sites in China. The company had a capacity of 7 million tons of container board, duplex board and tissue paper as well as 180,000 tons of pulp in 2014.

For further information, please contact:

Svenerik Olsson, Director, Tissue mills, China area, Valmet, Tel. +86 139 10171872

Krister Harnesk, Sales Manager, Tissue mills, Valmet, Tel. + 46 766 397543

Valmet to supply a tissue production line to Renova in Portugal

Valmet will supply an Advantage NTT tissue production line and an automation system to the European tissue brand Renova. Renova is the first tissue producer in Europe to invest in Valmet's Advantage NTT tissue technology for the production of textured and plain tissue products.

Image: Valmet Advantage NTT tissue machine

The new line, to be installed at the Torres Novas mill in Zibreira, Portugal, will allow Renova to increase its paper production capacity with 50%. The start-up is scheduled for the end of 2016.

The order was included in Valmet's second Quarter 2015 orders received. The value of the order is not disclosed.

"We are eager to see the result from the combination of Renova's proactive innovativeness and Valmet's sustainable Advantage NTT technology. Its flexibility provides endless possibilities to produce special designed textured tissue products," says Mr. Pereira da Silva, CEO of Renova

"Our Advantage NTT technology has established a strong market position in high efficiency innovative and flexible tissue production. We are excited to support Renova to bring their tissue products to the next level. We are looking forward to working with Renova and making this project a benchmark on the European tissue market," says Jan Erikson, VP Tissue Sales, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1 800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with a WetDust system. Basic and detailed mill engineering, complete stock preparation and process ventilation are also included in the scope. Furthermore, the delivery will include a Valmet DNA Automation system.

About the customer Renova

Renova is a European brand of high quality and innovative products. Available in more than 60 countries it offers colorful designs and new functional solutions through stylish and environmental friendly tissue consumer products.

For further information, please contact:

Jan Eriksson, Vice President Sales Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90

Bernhard Glifberg, Sales Manager, Valmet Tissue Mills Business Unit, tel. +46 705 17 14 27

Valmet maintains its position among the world's sustainability leaders

Valmet has been included in the Dow Jones Sustainability Index (DJSI) for the second consecutive year. The DJSI is a sustainability index family which includes the global sustainability leaders across industries. Valmet was listed both in the Dow Jones Sustainability World and Europe indices.

Valmet has been included in the Dow Jones Sustainability Index (DJSI) for the second consecutive year. The DJSI is a sustainability index family which includes the global sustainability leaders across industries. Valmet was listed both in the Dow Jones Sustainability World and Europe indices.

"Being included in the Dow Jones Sustainability Index for the second year in a row is an excellent achievement for Valmet. It shows that we have been able to constantly improve our sustainability performance. We have systematically proceeded with our sustainability agenda and continued to nurture our shared values and global operating principles which serve as a strong foundation for all of us at Valmet," says Pasi Laine, President and CEO of Valmet Corporation.

The annual evaluation conducted by a Swiss investment specialist RobecoSAM comprehensively reviews the company's performance with regard to social, environmental and financial factors. In total 317 companies were included in the DJSI World for 2015-2016. In addition to Valmet, three other companies from Finland are included in the World index this year.

About the Dow Jones Sustainability Indices

The DJSI is the world's leading sustainability index family. It serves as a benchmark for investors who are committed to ethical investing and review companies' sustainability performance as part of their analyses. The company inclusion is based on a best-in-class approach, which means that the indices only include the top ranked companies within each industry.

For further information, please contact:

Anu Salonsaari-Posti, SVP, Marketing, Communications and Sustainability, Valmet, tel. +358 50 453 4262

Laura Puustjärvi, Head of Sustainability, Valmet, tel. +358 50 337 4473

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet and Stora Enso Kvarnsveden sign multi-year consumables and roll service agreement

Valmet and Stora Enso Kvarnsveden have signed a five-year (three plus two) agreement on the supply of paper machine and fiber line consumables including clothing, doctor blades, refiner segments, winder consumables and selected roll covers. The agreement also includes local roll maintenance operations next to Kvarnsveden's site at Borlänge. The agreement is valid as of July 1, 2015.

Valmet and Stora Enso Kvarnsveden have signed a five-year (three plus two) agreement on the supply of paper machine and fiber line consumables including clothing, doctor blades, refiner segments, winder consumables and selected roll covers. The agreement also includes local roll maintenance operations next to Kvarnsveden's site at Borlänge. The agreement is valid as of July 1, 2015.

Technical support for maintenance and production is part of the agreement. The performance of consumables is optimized by taking advantage of remote analytics and the skills of Valmet's technology experts. In addition, Valmet will keep a ready stock of consumables for Kvarnsveden. This total cost of ownership agreement (TCO) is an exclusive agreement with a fixed monthly fee. The value of the agreement has not been disclosed.

Optimizing consumable performance and simplifying daily operations

The agreement provides a framework for long-term collaboration between Kvarnsveden and Valmet. The aim is to improve the efficiency of daily operations and decrease costs for both partners. Fixed monthly invoicing increases cost predictability.

"With our advanced services offering Valmet's goal is to continuously simplify our customers' daily operations, reduce the consumption of consumables and find cost efficient solutions. I am convinced that we will exceed Kvarnsveden's expectations of us," says Per Holm, Vice President, Sales, Scandinavia at Valmet.

Information about the customer Stora Enso and the Kvarnsveden Mill

Stora Enso is the global rethinker of the paper, biomaterials, wood products and packaging industry. The company produces chemical pulp, paper and board, corrugated packaging and sawn wood products. The Kvarnsveden Mill produces improved newsprint and magazine paper on three paper machines. The production capacity is approximately 720,000 tons per year.

Further information, please contact:

Per Holm, Vice President, Sales, Scandinavia, Valmet, tel. +46 705 17 13 88,

Peter Lindgren, Sales Manager, Consumable Solutions, Scandinavia, Valmet, tel. +46 54 17 11 38

Juha Ojala, Senior Manager, Concept Development, Services, Valmet, tel. +358 40 702 9117

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet to supply a tissue production line to Resolute Forest Products in the United States

Resolute Forest Products Inc. has selected Valmet's Advantage NTT tissue production technology and Valmet's automation solution for the new facility it is building in the United States to manufacture at-home, premium private label tissue paper, including bath and towel. The new machine will be installed at the company's mill in Calhoun (Tennessee), and start-up of the tissue production line is planned for early 2017.

Valmet Advantage NTT tissue machine

The order is included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

"We are very proud to work with Resolute on this important project, and we will deliver first-class tissue technology to their state-of-the-art facility," says Soren Eriksson, Director of Sales, Tissue Mills Business Unit, Valmet.

Valmet's Advantage NTT tissue production technology is designed for maximum flexibility as well as enhanced product quality and can easily change between production of conventional tissue and textured tissue in just a few hours. It has been well received by the market, and this will be the fifth NTT machine to be delivered. The first Advantage NTT line was started up in Mexico in 2013, the second line started up in the second quarter of 2015 in Chile, a third NTT line will be started up in Abu Dhabi in 2015, followed by a fourth NTT line in the U.S. in early 2016.

Technical information

The new tissue machine will have a width of 5.2 m and a design speed of 2,000 m/min. The raw material for the new line will be virgin fiber, and the production line is optimized to save energy and fiber as well as provide flexibility and product differentiation for premium quality products.

Valmet's scope of delivery will comprise a complete tissue production line, including an Advantage NTT 200HS tissue machine. The tissue machine will be equipped with a layered OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology, including an AirCap hood and a SoftReel -B. Basic mill engineering, process equipment and process ventilation are also included in the scope.

Furthermore, the delivery includes an integrated automation solution with Valmet DNA process control system, Valmet IQ scanner with IQFibre & Moisture sensor, as well as IQProfilers and a state-of-the-art web camera system for quality and reliability control. Installation supervision, training and commissioning as well as product development support are part of the delivery.

For further information, please contact:

Soren Eriksson, Director of Sales, Valmet Tissue Mills Business Unit, North America, +1 404 242 8845

Jan Erikson, Vice President, Sales, Valmet Tissue Mills Business Unit, tel. +46 705 17 14 90