Displaying items by tag: DS Smith

DS Smith solves e-commerce supply chain challenges

DS Smith, Europe’s leading packaging strategist, has revealed details of two major technological developments at one of Europe’s largest e-commerce events, #Deliver2 in Berlin.

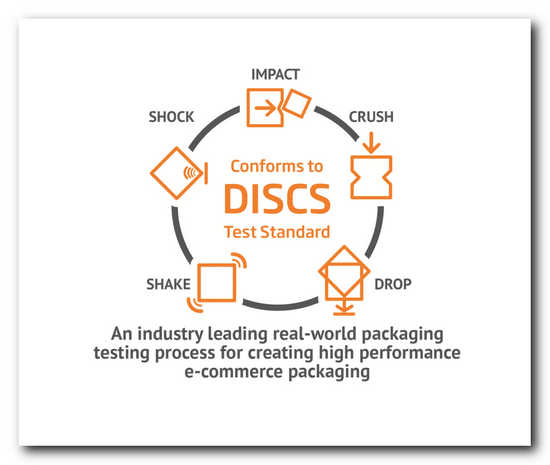

- DISCS™

An industry first, DISCS™ tests whether packages can survive the bumps and scrapes of the average e-commerce supply chain. Online orders sometimes need to survive up to 50 touch points, so packaging must be durable but also sustainable.

Named after the different types of testing (Drop Impact Shock Crush Shake), the system consists of five pieces of equipment, each replicating a part of the product journey and therefore providing real world testing.

Isabel Rocher, head of e-commerce solutions at DS Smith, commented: “Finding the balance between protecting packaging and limiting the amount of materials used is a constant source of concern for retailers. Likewise, shoppers do not want to receive broken goods or have to deal with excess packaging. Our new DISCS™ technology enables us to scientifically assess our customers’ requirements and get this balance right.”

DS Smith has been pioneering and refining DISCS™ confidentially over the last year in the UK. The engineers used insight from customers and the logistics industry to design tests which accurately replicate the stresses and strains of the ecommerce supply chain.

There are three test levels for customers to choose from, depending on whether a package is delivered straight to customer first time, delivered and returned or delivered with three failed attempts and then returned. This final option can include up to 50 touchpoints, and replicates the most severe damage a pack can receive.

An initial three testing suites are planned, based in the UK, France and Germany.

- Made2fit

DS Smith is also launching new technology called Made2fit, to enable the creation of right size packaging. This innovation has been developed to specifically tackle the e-commerce challenge of void space, as shipping air is a waste of resources. Creating a right size pack lowers costs for e-tailers by reducing both operational and shipping costs: saving storage space, cutting labour costs and order administration, and significantly cutting assembly and packing times. It also significantly reduces product movement, helping to reduce damage.

There is both a manual and an automated version. The manual Made2fit solution, is designed to work for lower volume orders, creating 39 possible box size combinations from just three blank sizes of cardboard.

The automated version of Made2fit is for larger volume orders, with the capability to manufacture more than 10 million box size combinations, in a process that is omnichannel ready.

Isabel comments: “Our two new offerings should revolutionize the industry, giving our customers access to state-of-the-art technology that will meet all their e-commerce packaging needs. The investment is great for our customers and great for us as a company as once again we are at the forefront, investing in world class technology and pushing the industry to embrace new standards. With e-commerce predicted to continue its dramatic growth over the coming years, this will be vital in helping retailers and manufacturers stay ahead and target growth.”

DS Smith launched both DISCS™ and the automated version of Made2fit at #Deliver2 in Berlin. Made2fit automated will then launch to the rest of Europe from October 2017 until early 2018. Made2fit manual is officially launching in September 2017 and will be rolled out across Europe in the months to follow.

About DS Smith:

DS Smith operates in over 36 countries and employs around 26,000 people. Using the combined expertise of our four divisions – Packaging, Recycling, Paper and Plastics – we work with customers to deliver solutions that reduce complexity and deliver results throughout the Supply Cycle. For more information, visit www.dssmith.com.

DS Smith is the leading supplier of recycled corrugated packaging. Our comprehensive product range includes retail ready packaging, transit cases, consumer units, packs printed for gift and POS applications, and heavy duty packaging for industry. DS Smith’s European network of manufacturing plants services thousands of customers, from multinationals to local businesses.

Using PackRight®, our unique way of working, our highly-skilled people work closely with customers to specify packaging that achieves real results. Typically, our customers achieve increased sales, reduced costs and managed risk at every stage of the Supply Cycle. For more information, visit www.dssmith.com/packaging.

DS Smith is the perfect fit for Aquascutum

DS Smith’s UK packaging division has helped produce a streamlined packaging design for the iconic British brand, Aquascutum.

Since 1851, the Aquascutum brand has been synonymous with fine British craftsmanship and technical innovation. The company invented the perennially popular trench coat and counts kings, prime ministers, celebrities and even a GB Olympic team among its customers.

When Aquascutum noticed that their packaging solutions were too bulky for internal operations, causing supply chain inefficiencies, they engaged DS Smith to work on a new design. The packaging and supply chain specialists recognised the improvement potential, and applied their PackRight process, collaborating with Aquascutum to gather insight and develop a solution that was right for them and their supply chain.

Serena Fortuna, E-commerce Manager at Aquascutum, said: “Both from a business and consumer perspective the new packaging is fantastic. It conveys the message that we’re a luxury brand, and reflects the value and quality of our products.

“Customers have actually requested extra boxes to use as gifts because they are so pleased with them! It’s been great working with DS Smith on this project, and we hope to further our package solution with them to continue to provide our customers with the best possible service.”

DS Smith worked closely with Aquascutum from the very early stages of development, to produce a new two-piece, high quality post print pack which is suitable for use in stores or for online ordering and delivery.

The new efficient pack is smaller, solving Aquascutum’s transport and supply chain issues. It uses fewer materials, resulting in reduced costs and environmental footprint. And additionally, it features a sleek, elegant design that is consistent with customers’ expectations of the Aquascutum brand.

Tony Foster, of DS Smith’s UK Packaging Division, said: “For our customers, packaging isn’t just a means to protect content, but central to how customers perceive their brand. We were proud to deliver a product that not only upholds Aquascutum’s long heritage of quality craftsmanship, but is also built to face the realities of contemporary supply chains. Innovation is at the heart of our business and we’re always striving to deliver packaging solutions that help our customers achieve more, this includes strengthening their brand awareness.”

About DS Smith

DS Smith operates in over 36 countries and employs around 26,000 people. Using the combined expertise of our four divisions – Packaging, Recycling, Paper and Plastics – we work with customers to deliver solutions that reduce complexity and deliver results throughout the Supply Cycle. For more information, visit www.dssmith.com.

DS Smith is the UK’s leading supplier of corrugated packaging. Our comprehensive product range includes retail ready packaging, transit cases, consumer units, packs printed for gift and POS applications, and heavy duty packaging for industry. DS Smith’s national network of manufacturing plants service thousands of customers, from multinationals to local businesses.

Using PackRight®, our unique way of working, our highly-skilled people work closely with customers to specify packaging that achieves real results. Typically our customers achieve sales growth, or reductions in cost, waste and carbon at every stage of the Supply Cycle. For more information, visit www.dssmithpackaging.co.uk.

DS Smith announces sponsorship of FAB FEST

DS Smith is providing enough cardboard and plastic sheets to cover three Olympic pools as part of its sponsorship of a new international fabrication festival.

A new international fabrication festival that celebrates design and making, launched by the Faculty of Architecture and the Built Environment and the Fabrication Laboratory at the University of Westminster, has received a boost thanks to support from leading packaging and plastics strategist, DS Smith.

FAB FEST will be held on 28th June – 2nd July 2016 and will see 60 teams of students from across the world design innovative cardboard pavilions, transforming the exhibition space into a mini ‘Glastonbury-in-the-City’.

DS Smith’s packaging and plastic divisions are providing the materials to make this happen, donating 2,400 sheets of corrugated board and 300 translucent sheets of plastic. Each team will be mentored by an academic or a practising professional from the field of architecture or the built environment. DS Smith’s recycling division will also ensure that the materials are collected for recycling after the event.

Gareth Jenkins, Managing Director at DS Smith’s UK packaging division, said: “We are extremely excited to be involved in the inaugural FAB FEST. At DS Smith, we innovate every day, in every way. This event is a brilliant way for industry and academia to come together to inspire the next generation of designers who will be driving innovation in the industry in years to come.”

The event will culminate on the Saturday with a day of live entertainment and family friendly activities hosted in the pavilions.

Dr David Scott, the Director of the Fabrication Laboratory at the University of Westminster, concludes: “We are delighted that DS Smith has partnered with us on this new venture and provided our teams with such high quality materials. We can’t wait to see what sorts of wonderful components and architectural installations our teams create through innovative fabrication processes and applying their ingenuity!”

About DS Smith

DS Smith operates in over 36 countries and employs around 26,000 people. Using the combined expertise of our four divisions – Packaging, Recycling, Paper and Plastics – we work with customers to deliver solutions that reduce complexity and deliver results throughout the Supply Cycle. For more information, visit www.dssmith.com.

DS Smith is the UK’s leading supplier of corrugated packaging. Our comprehensive product range includes retail ready packaging, transit cases, consumer units, packs printed for gift and POS applications, and heavy duty packaging for industry. DS Smith’s national network of manufacturing plants service thousands of customers, from multinationals to local businesses.

Using PackRight®, our unique way of working, our highly-skilled people work closely with customers to specify packaging that achieves real results. Typically our customers achieve sales growth, or reductions in cost, waste and carbon at every stage of the Supply Cycle. For more information, visit www.dssmithpackaging.co.uk.

About the University of Westminster’s Faculty of Architecture and the Built Environment

The University of Westminster is one of the UK's leading centres for the study of Architecture and the Built Environment, inspiring more than 2,000 students at its teaching base at Marylebone, in central London. The Faculty aims to explore the core subject areas that address the future shape of our cities and encourage the dynamic thinking that makes our courses the envy of others. The undergraduate programmes are based on strong links with industry professions, and our acclaimed postgraduate programmes offer a range of specialised courses underpinned by our strong research base. Learn more at www.westminster.ac.uk/abe

About Fabrication Laboratory Westminster

Located at the University of Westminster’s Marylebone Campus, the cutting-edge Fabrication Laboratory opened in April 2015 putting the University at the leading edge of digital fabrication. The Lab provides an innovative learning environment inspiring and preparing students for the challenges and versatility of digital fabrication in the 21st century. It offers specialist training short courses and support for research and PhD students. As well as traditional metal and wood workshops, the Fabrication Laboratory includes two new purpose-built spaces offering advanced digital making facilities. It is equipped with flexible computer controlled tools covering a wide range of scales, materials and processes. Its wide selection of digital equipment enables a range of design and fabrication processes including laser cutting, ABS and plaster 3D printing, CNC knife cutting, large scale CNC routing, CNC metal milling and robot fabrication. The collection of robots uniquely includes an industrial robot arm running on a five-metre rail across a window visible from Marylebone Road. Learn more at: http://www.westminster.ac.uk/about-us/faculties/architecture/fabrication-laboratory-westminster

DS Smith in Lucca reduces maintenance costs with Voith OnQ Profilmatic

DS Smith, an Italian market leader in containerboard production, has reduced maintenance costs and increased its paper quality and machine productivity thanks to the OnQ Profilmatic control system and OnQ ModuleJet headbox actuators from Voith.

The company's mill in Lucca, Italy, was experiencing inconsistent paper profiles and wrinkles due to the former actuator control of the existing control system of its PM 2. Voith recommended the OnQ Profilmatic cross profile control software, which is part of its modular and flexible Voith ComCore platform to optimize the shape of the profiles.

“Our existing system was obsolete. The actuator delivery time was a problem and we were spending too much on maintenance," said Stefano Andreotti, Technical and Technology Manager at DS Smith.

"Our production engineers are now very happy with Voith's OnQ Profilmatic. The system automates a process that before was entirely manual. Wrinkles have been reduced, and we are pleased with the deviation of the profiles,” said Andreotti.

The OnQ Profilmatic has the ability to determine the portion of random noise in the measurements. Continuous, dynamic profile mapping allows exact local mapping of the actuator control zones to the measurements and leads to better paper quality.

A major part of the Voith ComCore platform is the OnView information system, which makes all the details of the papermaking process available for analysis. This is the key to continued performance improvements for the machine. With this powerful toolset Voith accompanies DS Smith to achieve further efficiencies on the PM 2.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

RockTenn and DS Smith announce licensing agreement

SCA has accepted DS Smith´s formal offer

SCA has accepted DS Smith´s formal offer to acquire the packaging operations in France following consultations with appropriate works councils. As a result, a sale and purchase agreement has been signed by both parties.

On 17 January 2012, SCA announced that its packaging operations – excluding the two kraftliner mills in Sweden – will be sold to DS Smith. The agreed purchase price amounts to EUR 1.7bn on a debt free basis.

As for the French part of the packaging operations, the price for which is included in the announced purchase price, DS Smith had made a formal offer to acquire also those operations. This acquisition was subject to consultation with the French works councils and has been managed separately.

After the consultation with the French works councils has been completed, SCA has accepted DS Smith's formal offer, and as a result, a sale and purchase agreement for the French operations has now been signed.

Following the signing of the sale and purchase agreement, the process will continue towards completing the entire transaction, which includes review of relevant competition authorities. Closing of the transaction is expected to take place in the second quarter 2012.

DS Smith’s acquire SCA´s packaging operations

Today, Friday February 3, 2012, the shareholders of UK-based packaging group DS Smith Plc approved the company´s proposal to acquire SCA’s packaging operations, excluding the two kraftliner mills in Sweden.

The transaction remains subject, amongst other things, to antitrust clearance from the European Commission. Closing is expected during the second quarter of 2012.

Regarding the French part of the packaging operations, DS Smith has made a formal offer to acquire this business. This process is subject to an information and consultation procedure with the relevant works councils and will be treated separately.

The first press release on this deal was published on January 17, 2012. http://www.sca.com/en/Media/Press-releases/Press-releases/2012/2012-01-17-SCA-divests-its-packaging-operations/

ABB Wins Upgrade Order to Improve Paper Quality at U.K. Mill

New systems will help diversify products at DS Smith Paper’s Kemsley Mill

ABB, the leading power and automation technology group, recently won an extensive order to upgrade automation at DS Smith Paper Ltd’s Kemsley Mill in Sittingbourne, Kent, England. The new systems will help the mill produce a greater diversity of high quality paper products.

The order includes an upgrade of the mill’s PM3 automation and drives systems, including a new Quality Control System (QCS), upgraded and expanded Distributed Control System (DCS) and upgraded and expanded Drive System, as well as a new Web Imaging Solution (WIS). All of the systems will be integrated with the existing System 800xA.

The order includes an upgrade of the mill’s PM3 automation and drives systems, including a new Quality Control System (QCS), upgraded and expanded Distributed Control System (DCS) and upgraded and expanded Drive System, as well as a new Web Imaging Solution (WIS). All of the systems will be integrated with the existing System 800xA.

The mill’s Advant QCS will be upgraded to an 800xA with two new Network Platforms and an Air Water Spray. The drives upgrade includes new ACS800 drives and AC800M Controllers. One of the existing DCS Advant Controllers will be upgraded to an AC800M and integrated into the system.

The new QCS will help improve product quality on the PM3, while it increases production and reduces costs. ABB’s System 800xA DCS will provide a solid platform for the mill’s integrated process operation. The upgraded ABB drives will deliver fast start ups and benefits over the equipment lifecycle that include increased productivity, improved quality and energy savings, while the new WIS will give the mill a state-of-the-art tool for identifying web defects and managing visual uniformity.

The Kemsley Mill is rebuilding its PM3 so it can produce highest quality linerboard and white-top liner grades.

The new systems will be ready for start-up in June 2012.

Source: ABB

Disposal of Spicers completed

Further to our previous announcements in July and September 2011 regarding the disposal of Spicers to Unipapel SA, DS Smith Plc is pleased to confirm that this transaction has now completed. The enterprise value for Spicers is £200 million, and net proceeds, after tax and related costs, are c. £160 million. Following the disposal, the Group is focused on its recycled packaging businesses.

Enquiries

DS Smith Plc +44 (0) 1628 583 400

Miles Roberts Group Chief Executive

Steve Dryden Group Finance Director

Rachel Stevens Head of Investor Relations

Tulchan 020 7353 4200

John Sunnucks

David Allchurch

James Macey White

DS Smith PLC Pre-Close Statement

DS Smith Plc, the international supplier of recycled packaging for consumer goods, today issues its pre-close statement for the half-year to 31 October 2011.

DS Smith Group

The encouraging overall trading reported in our IMS of 6 September 2011 has continued. Like-for-like volumes in corrugated packaging are up 3% for the financial year to date and are set against strong comparatives in the corresponding period. This is in line with the previously announced Group targets, reflecting our resilient fast-moving consumer goods (FMCG) customer base. At the same time, we have continued to generate strong cashflow and to make progress on margins. As a consequence of this, and due to a strong contribution from Otor, we expect the half year to 31 October 2011 to show significant EPS growth compared to the comparable period last year.

We have recently completed a refinancing of our revolving credit facility with a new five year facility of £610 million.

Packaging

Our Corrugated Packaging businesses have continued to perform well. We are recovering our input cost increases progressively. Margins are improving due to our focus on offering customers a high standard of service and quality and innovative solutions that differentiate our packaging offering and add value to customers’ supply chains.

Our previously announced operating cost and capital savings programmes are making good progress. Specifically, we are well on track to reach the targeted £10 million run-rate savings from procurement by the end of this financial year, split between cost and capital savings. We now expect to see £9 million benefit from procurement savings in the current financial year (up from £6 million previously). The programme to save £10 million run-rate in operating expenditure in the UK by April 2014 is on course, as is the programme for €13 million of cost synergies from the Otor acquisition.

As part of the strategy to reduce non-integrated paper manufacturing, we have sold one paper mill in this period, Higher Kings Mill, which produced 34kt per annum of specialist paper. The previously announced process to close our paper mill at Hollins (95kt) is on track.

The performance of the Plastics business continues to develop, with strong volume growth, and good cost control.

Office Products Wholesaling

The trading performance at Spicers has been good. The process to dispose of the Spicers business is on track with a binding agreement in respect of the sale signed on 7 September 2011. Completion is expected before 31 December 2011. Accordingly, Spicers will be

treated as a discontinued item in the half year results, (to see appendix download link below)

Delivering against our strategic goals

Following the disposal of Spicers, DS Smith will be a focused, international supplier of recycled packaging for FMCG customers with improving operational performance, and the financial strength to invest in the organic growth of the business and to pursue acquisitions within a fragmented packaging sector. We shall maintain strict financial discipline, pursuing only acquisition opportunities that would result in returns to shareholders in line with our medium term financial targets, as we have done with Otor.

Outlook

We remain confident in our trading outlook for the year, despite the challenging macroeconomic environment and the recent turmoil in global markets. The Group expects to make further progress towards its previously announced medium term financial objectives in this financial year, in terms of margin improvement, return on capital and cash generation.

Forthcoming Dates

Results for the half-year to 31 October 2011 7 December 2011