Displaying items by tag: lucart group

Intesa Sanpaolo and SACE support sustainable development of Lucart

Lucart, one of the most important European paper groups, known for, among other things, the brands Tenderly, Grazie Natural and Tutto Pannocarta, and Intesa Sanpaolo have signed a financing agreement for an amount of 10 million euros backed by a SACE Green Guarantee.

The financing is aimed at supporting Lucart Group's growth and development plan from an ESG (Environmental, Social and Governance) and circular economy perspective. The credit facility has a pricing mechanism linked to the achievement of specific sustainability targets. These objectives include, on the one hand, completion of the Castelnuovo di Garfagnana (LU) production line, which will enable the company to increase its use of alternative packaging, and, on the other, greater recovery of Tetra Pak® type poly-coupled food cartons at the Diecimo (LU) plant.

The transaction was concluded by Intesa Sanpaolo's IMI Corporate & Investment Banking Division, led by Mauro Micillo with the support of the Circular Economy Desk of Intesa Sanpaolo Innovation Centre, a company dedicated to innovation and to the spread of circular economy.

The transaction was concluded by Intesa Sanpaolo's IMI Corporate & Investment Banking Division, led by Mauro Micillo with the support of the Circular Economy Desk of Intesa Sanpaolo Innovation Centre, a company dedicated to innovation and to the spread of circular economy.

The financing is part of Lucart Group's strategy, which for years has adopted a sustainable development model aimed at optimising the use of raw materials and reducing waste by transforming it into new resources, in line with the principles of circular economy. Lucart is in fact the only tissue mill capable of recovering all the components of beverage cartons: both the fibrous part, which is converted into paper products of the Natural lines, and the aluminium and polyethylene part, converted into other objects such as pallets for transporting goods.

Thanks to their positive impact in terms of mitigating climate change, the financed projects meet the objectives of the Green New Deal, the plan for a modern, circular, sustainable and resilient Europe. In this context, SACE plays a central role in the implementation of the Green New Deal in Italian territory, as envisaged by the "Simplification" Decree Law of July 2020 (76/2020). The company led by Pierfrancesco Latini, can now issue “green guarantees” for domestic projects that encourage the transition to an economy with a lower environmental impact, integrate production cycles with low-emission technologies for the production of sustainable goods and services and promote initiatives aimed at developing new and greener modes of transport. Since the entry into force of the Decree, a team of specialists has been set up across the various corporate functions, encompassing different and complementary professional skills, capable of responding comprehensively to the needs of these new SACE operations. The deal in support of Lucart was concluded thanks to the commitment of the Florence office, one of SACE's 14 local offices in Italy, and the Green Task Force, set up to respond to the needs of the new operations linked to the Green New Deal.

"Lucart Group is a top Italian and international player that has embraced environmental sustainability issues for a some time," commented Richard Zatta, Head of Global Corporate at Intesa Sanpaolo's IMI Corporate & Investment Banking Division. "This transaction confirms Intesa Sanpaolo's commitment to boosting and concretely supporting the Green and Circular Economy by sustaining the development plans of companies in this area".

"We are proud," stressed Mario Bruni, Head of Mid Corporate at SACE, "to continue to support the growth of a key player like Lucart and to work alongside it in its sustainable development plans. With our involvement, the company will be able to pursue important objectives of environmental protection and circular economy in line with the objectives of the NRRP. SACE thus continues to play a leading role in Italy's ecological transition".

"We are very pleased with the support that Sace and Intesa Sanpaolo will be giving our projects. Their commitment to the sustainable economy dovetails perfectly with our dedication to applying circular business models through a strategic plan to increase the recovery of raw materials to 60%," commented Andrea Fano, Chief Financial Officer of Lucart Group. "Another important goal is to get to 100% recycled and/or compostable packaging by 2030, on all our production lines".

Lucart has chosen Enel X to proceed on the path to decarbonisation

Enel's innovative business line will support Lucart on the path to increasing energy efficiency by installing a photovoltaic system that will produce over 3 GWh of renewable energy a year

A new synergy for creating an industrial development model that is sustainable in economic and environmental terms. This is the partnership between Enel X, the innovative global business line of Enel Group, and Lucart, one of Europe's leading paper manufacturers, known for its Tenderly, Grazie Natural and Tutto Pannocarta brands, among others, which has chosen to embark on an ambitious project to reduce the climate-changing emissions of its production plants. The first step will be the installation of a 3 MWp photovoltaic plant in the Diecimo factory, in the province of Lucca, which will generate over 3 GWh of green energy a year achieving a reduction of CO2 emissions into the atmosphere equal to 1,160 tonnes per year.

“The agreement with Lucart demonstrates once again how important it is for Enel X to provide cutting-edge technologies to the country's most important companies to make their production sites more cost-effective and sustainable", said Augusto Raggi, Head of Enel X Italy. "This partnership is only the first step of a long-term project that we are sure will become the benchmark for the entire paper industry, which is a pride for our country and a strategic sector for our business”.

“The agreement with Lucart demonstrates once again how important it is for Enel X to provide cutting-edge technologies to the country's most important companies to make their production sites more cost-effective and sustainable", said Augusto Raggi, Head of Enel X Italy. "This partnership is only the first step of a long-term project that we are sure will become the benchmark for the entire paper industry, which is a pride for our country and a strategic sector for our business”.

“We have always been very mindful of how we produce the electricity and heat we need to manufacture and convert paper into the hygiene products that we use every day at home and at work. This is why we sought out a top-level partner such as Enel X to work alongside us in all our plants to find the best technological solutions and successfully proceed on our path to decarbonisation," said Massimo Pasquini, CEO of the Lucart Group. "The photovoltaic plant we are going to build in Diecimo will be one of the largest private-owned ones ever installed in Tuscany and will be a further reason of pride for our company”.

Enel X will operate at the Lucart plants on several aspects of the company's production chain, which in the future will include the installation of additional renewable energy plants. Integrated solutions dedicated to the paper industry and its supply chain are also being studied, covering distributed generation, flexibility, energy efficiency, decarbonisation and sustainable mobility.

Lucart consolidates in France with an €80 million plan to grow in Europe

Lucart, Europe's leading manufacturer of tissue, airlaid and MG paper hygiene solutions and famous for the Tenderly, Lucart Professional, Tutto Pannocarta and Grazie Natural brands, is announcing an €80 million three-year investment plan for 2022-2024 for the plant in Laval sur Vologne, France.

- The Group is focusing on a key strategic area to serve European markets in synergy with the other plants of the Group

- The operation pivots on a new paper making machine to enter into operation at the Laval sur Vologne plant by 2024 and the construction of a new 25,000 m2 logistics hub

- The plan is to reduce CO2 emissions by more than 12,000 tonnes/year by installing a biomass power plant at the French plant

The operation aims at consolidating the international presence of the Group that is Europe's second-largest player in the Away from Home sector (hygiene paper products for professional use) by focusing on an area of strategic importance to reach the markets of Central and Northern Europe. At the same time, the company will contribute to the decarbonisation of the sector by setting ambitious environmental goals.

“We are delighted to announce an investment plan of this magnitude, which for us is a major strategic step towards consolidating and bolstering our business growth outside Italy”, commented Massimo Pasquini, CEO of Lucart S.p.A. “With these new investments, the Laval sur Vologne plant will play an even more central role in driving our expansion into the European markets. We are also very proud to be able to export a responsible and sustainable growth model that values environmental achievements as much as economic performance”.

Increased recycled paper production capacity

The operation pivots on the opening of a new paper machine by 2024 and the installation of three new converting lines at the plant in Laval sur Vologne, France, to increase the recycled tissue paper production capacity and differentiate the finished product lines. The new paper machine will be called PM15 and will be able to produce up to 40,000 tonnes of high-quality tissue paper per year. It will be served by a state-of-the-art stock preparation plant, capable of processing pre- and post-consumer recycled paper. The Laval site will reach a production potential of about 100,000 tons of tissue paper per year and it will be able to serve other plants of the Group in addition to its own converting line.

Reduction of CO2 emissions

In line with the environmental principles that guide Lucart's strategic plans and growth, the plan also considers the energy needs associated with the construction of the manufacturing hub. Lucart is planning to install a biomass power plant capable of producing heat using wood chips from forestry in the areas surrounding the Laval plant that will achieve an estimated reduction in CO2 emissions of more than 12,000 tonnes per year.

Efficient distribution logistics

The plan also includes the construction of a new logistics hub in the Vosges department in north-eastern France. It will be highly automated and served by low-environmental-impact shuttles, based on the successful model already in place in Italy between the Diecimo and Altopascio plants in the province of Lucca. The plant will raise the standards of customer service even further in the spirit of continual improvement that characterises the Group. It will cover an area of approximately 100,000 square metres, of which 25,000 square metres will be indoors, and may be expanded to 45,000 square metres as storage requirements grow.

The Laval sur Vologne plant

The Laval site is strategically positioned for logistics occupying a central location for the European continent. The plant was acquired by Lucart in 2008 and has doubled its revenue in ten years, becoming the benchmark for the production and conversion of recycled tissue paper and Fiberpack® paper derived from recycled Tetra Pak® beverage cartons.

About Lucart:

Lucart, a leading company in Europe in the production of tissue paper products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.), airlaid products and MG paper, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area).

Lucart's production capacity exceeds 395,000 tonnes/year of paper on 12 paper machines.

Its consolidated turnover amounts to more than €500 million, with more than 1,600 employees in 10 production plants (five in Italy, one in France, one in Hungary, two in Spain and one in UK) and one Logistics Center in Italy.

Lucart is part of the United Nations Global Compact Network Italy and since 2018 has been a member of the Ellen MacArhur Foundation, the international organization leading the transition to the circular economy.

Lucart chooses Kӧrber integrated solutions to guarantee quality and performance even in packaging

Efficiency and performance also in the creation of packaging: this is what Lucart is looking for. Lucart is one of the leading companies in the tissue products sector and has been pursuing sustainability objectives for many years, starting from recycled paper made with beverage cartons to biodegradable packaging.

Gabriele Coli, Lucart’s Engineering Manager, comments: "Primary and secondary packaging are of fundamental importance in our company, so we were looking for a solution that would guarantee quality, efficiency, and performance and that would allow us to respond to the growing demand for eco-sustainable packaging. The analyses of our technicians have shown that, to achieve our objectives, Kӧrber Casmatic was the best technology, so we decided to invest in 8 machines to make primary and secondary packaging”.

Designed to reach production speeds of up to 27 bags per minute, Casmatic CMB270 is able to pack in a high range of formats. Synonymous with quality and reliability, these machines are extremely flexible and versatile, allow energy savings of 60% thanks to the new TOSS longitudinal sealing system, and have been designed to wrap small packaging even at high production speeds. This model is also equipped with a new patented Revolver system that significantly improves the production speed for bundles with single rolls and packages.

CMB270 responds perfectly to Industry 4.0 demands because it is equipped with ALL-IN-ONE technology, an intelligent application that helps to integrate and harmonize the converting and packaging processes, maximizing the result, without the need for human intervention.

In addition to the packaging machines, Lucart has also equipped itself with a Perini MyLine converting line. This line is designed for the production of toilet and kitchen paper rolls with diameters up to 200 mm at a maximum speed of 600m / min and a production of 40log / min. Based on the consolidated Sincro exchange phase system, the Perini MyLine line is equipped with a laminator-embosser with 409mm diameter steel rollers, with DESL or Catalyst technology for the automatic change of steel rollers, in the Pro and Flexy versions.

Giuseppe Alberti Sales Manager Kӧrber comments Kӧrber comments: "Our relationship with Lucart is a long one - 80% of their lines are Kӧrber - this has also allowed for an important customization of the line. With this investment Lucart was able to access the best technology to optimize its production efficiency. A strong competitive advantage for a company that has always focused on high quality and product differentiation to be competitive ".

Lucart

Lucart, a leading company in Europe in the production of tissue paper products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.), airlaid products and MG paper, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area). Lucart's production capacity exceeds 395,000 tonnes/year of paper on 12 paper machines.Its consolidated turnover amounts to more than €500 million, with more than 1,600 employees in 10 production plants (five in Italy, one in France, one in Hungary, two in Spain and one in UK) and one Logistics Center in Italy.Lucart is part of the United Nations Global Compact Network Italy and since 2018 has been a member of the Ellen MacArhur Foundation, the international organization leading the transition to the circular economy.

Körber Business Area Tissue

At Körber, our ultimate goal is to empower our customers’ ongoing success. We are the only truly integrated and global provider of advanced solutions for the tissue business. We offer the industry’s most comprehensive portfolio of tissue technology to support customers across the entire value chain — from roll to fold, from converting to packaging. Our advanced, automated, and easy-to-use integrated solutions are a fundamental asset to shape the success in tissue, take our customers operations to the next level, and strengthen their overall financial performance while optimizing their total cost of ownership.

About Körber

We are Körber – an international technology group with about 10,000 employees, more than 100 locations worldwide and a common goal: We turn entrepreneurial thinking into customer success and shape the technological change. In the Business Areas Digital, Pharma, Supply Chain, Tissue and Tobacco, we offer products, solutions and services that inspire. We act fast to customer needs, we execute ideas seamlessly, and with our innovations we create added value for our customers. In doing so, we are increasingly building on ecosystems that solve the challenges of today and tomorrow. Körber AG is the holding company of the Körber Group.

Lucart continues to focus on sustainability with the new recycled and recyclable packaging of the Natural lines developed at its research centre

Lucart, Europe’s leading manufacturer of tissue, airlaid and MG paper for flexible packaging, continues to focus on sustainability and on researching environmentally-friendly and innovative solutions with a view to reducing the environmental impact of its products.

In fact, the products in the Grazie Natural line for domestic use and those in the EcoNatural lines for professional markets are now even more eco-friendly thanks to the use of new recycled and recyclable paper packaging, which is designed for a more sustainable, natural choice.

With this new paper packaging, the company aims to contribute to the general policy of reducing the use of virgin plastics, replacing them with eco-friendly recycled packaging. This is an extremely important goal, especially considering the fact that as many as 570,000 tonnes of plastic end up in the Mediterranean Sea every year, which is equivalent to throwing 33,800 plastic bottles into the sea every minute.[1]

Guido Pasquini, Lucart’s Sales and Marketing Director, explains: “Consumers are becoming increasingly aware of the importance of making sustainable choices when it comes to buying products and are always looking for practical ways to help save the planet on a daily basis, but we must play a part in this too. This is why we aim to gradually replace the plastic packaging we use for our products with flexible recycled and recyclable paper packaging produced by us. We are particularly proud of this project, which was also made possible through excellent teamwork. By applying the principles of cooperation on which the circular economy is based, our R&D department has brought the Porcari plant (in the province of Lucca) – our historical headquarters where we produce paper for flexible packaging – into line with the requirements of the group’s other plants – where hygiene paper products are produced – by sharing the same goals and overcoming the technical problems associated with paper development and the use of printing inks. In fact, even the latter are compostable and biodegradable.

The products in the Natural lines, which are the only ones on the market made from recycled Tetra Pak® type beverage cartons and “wrapped with love” in recycled and recyclable paper packaging, are a practical way for our customers to make an active contribution to protecting the environment”.

The growing interest of consumers in sustainability issues and in making more responsible environmental choices is also reflected in recent data: in fact, according to the European Consumer Packaging Perceptions study by Pro Carton, 75% of Italian consumers claim that the environmental impact of a product’s packaging influences their purchasing decisions.

[1] Source: WWF

Lucart wins the European Cleaning and Hygiene Awards 2019

During the 2019 European Cleaning and Hygiene Awards, event held in London by the European Cleaning Journal on October 17th, Municipal-Material-Cycle® has been awarded as Best European Initiative Raising the Profile of the Professional Cleaning Sector.

The project, born with the aim of developing a system of circular economy, durable and replicable, able to actively involve local communities, consists in recycling and converting beverage cartons into new paper products for hygienic and sanitary use.

Thanks to the cooperation of the local waste management company and the consortium that manage, separate and sort the materials on their platforms, Lucart has collected and collects the used beverage cartons and recycles them through an exclusive production process. The company is in fact able to separate the technical component (polyethylene and aluminium) from the biological component (cellulose fibers) of beverage cartons: the first is used to produce dispensers and pallets made of recycled plastic, the second to produce the tissue products in the Grazie Natural and Lucart Professional EcoNatural range. These tissue products (towels, toilet paper, napkins, etc.) are sold, together with their dispensers, to a local distribution partner who delivers the products to the bathrooms of public offices, schools, public companies and sports and recreation centres in the area from which the recycled beverage cartons come. The whole cycle is carried out with the approval of the competent municipal administration.

"We are proud to have received this award, which is for us a tangible recognition of our commitment to the environment and to a concrete circular paper economy.” said Francesco Pasquini, Sales & Marketing Director AFH of Lucart "The MMC® project is not only a model of Circular Economy, but also a virtuous example of partnership between companies. Our local distribution partner Valtex, in fact, believed in the project's potential right from the start and played a fundamental role in involving local communities and administrations".

The MMC® project, which started in 2015 in Slovenia with a trial period in the city of Novo Mesto and seven neighbouring municipalities, initially involved the local community (about 65,000 inhabitants), leading in three years to the recycling of about 105 tons of beverage cartons. In 2019 the project was also activated in Ljubljana, with a potential for recycling and consumption almost five times higher than that of Novo Mesto.

Today MMC® is also being internationalized in other countries, thanks to a team of professionals who will offer advice and support to distributors interested in proposing the project to their local communities.

About Lucart

Lucart, a leading company in Europe in the production of tissue paper products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.), airlaid products and MG paper, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area).

Lucart's production capacity exceeds 395,000 tonnes/year of paper on 12 continuous machines.

Its consolidated turnover amounts to more than €480 million, with more than 1,500 employees in ten production plants (five in Italy, one in France, one in Hungary and three in Spain).

Since 2018, Lucart has been part of the CE100 network, the pre-competitive innovation program designed by the Ellen Macarthur Foundation to give organizations the opportunity to develop new opportunities and achieve their circular economy goals as quickly as possible.

Lucart continues to focus on sustainability with the new recycled and recyclable packaging of the Natural lines developed at its research centre

Lucart, Europe’s leading manufacturer of tissue, airlaid and MG paper for flexible packaging, continues to focus on sustainability and on researching environmentally-friendly and innovative solutions with a view to reducing the environmental impact of its products.

In fact, the products in the Grazie Natural line for domestic use and those in the EcoNatural lines for professional markets are now even more eco-friendly thanks to the use of new recycled and recyclable paper packaging, which is designed for a more sustainable, natural choice.

With this new paper packaging, the company aims to contribute to the general policy of reducing the use of virgin plastics, replacing them with eco-friendly recycled packaging. This is an extremely important goal, especially considering the fact that as many as 570,000 tonnes of plastic end up in the Mediterranean Sea every year, which is equivalent to throwing 33,800 plastic bottles into the sea every minute.[1]

Guido Pasquini, Lucart’s Sales and Marketing Director, explains: “Consumers are becoming increasingly aware of the importance of making sustainable choices when it comes to buying products and are always looking for practical ways to help save the planet on a daily basis, but we must play a part in this too. This is why we aim to gradually replace the plastic packaging we use for our products with flexible recycled and recyclable paper packaging produced by us. We are particularly proud of this project, which was also made possible through excellent teamwork. By applying the principles of cooperation on which the circular economy is based, our R&D department has brought the Porcari plant (in the province of Lucca) – our historical headquarters where we produce paper for flexible packaging – into line with the requirements of the group’s other plants – where hygiene paper products are produced – by sharing the same goals and overcoming the technical problems associated with paper development and the use of printing inks. In fact, even the latter are compostable and biodegradable.

The products in the Natural lines, which are the only ones on the market made from recycled Tetra Pak® type beverage cartons and “wrapped with love” in recycled and recyclable paper packaging, are a practical way for our customers to make an active contribution to protecting the environment”.

The growing interest of consumers in sustainability issues and in making more responsible environmental choices is also reflected in recent data: in fact, according to the European Consumer Packaging Perceptions study by Pro Carton, 75% of Italian consumers claim that the environmental impact of a product’s packaging influences their purchasing decisions.

[1] Source: WWF

Lucart presents its 2018 Sustainability Report with a focus on Circular Economy, new investments, dialogue with the stakeholders, and partnerships for sustainable development

Lucart’s 14th Sustainability Report, drawn up in accordance with the international guidelines of the Global Reporting Initiative (GRI Standard), highlights, among other things, an increase in turnover (+12%) and key investments such as the acquisition of three production plants in Spain, the construction of a new plant in Hungary, the start-up of a new Continuous Machine for the production of tissue paper (PM12) and the construction of a new, fully automated logistics centre to improve customer service.

- · In 2018, the company's turnover increased by 12% despite the rising price of cellulose

- · Major investments include the acquisition of three production plants in Spain and the construction of a new plant in Hungary

- · 53% of the materials used by Lucart for the production of paper originate from recycled paper

As always, the Report places considerable emphasis on the analysis of environmental data, which this year have been supplemented with more detailed information on recycled paper.

As always, the Report places considerable emphasis on the analysis of environmental data, which this year have been supplemented with more detailed information on recycled paper.

According to Lucart’s estimates, following an EPD[1] (Environmental Product Declaration) analysis carried out on two types of toilet paper produced by this Italian multinational company, different environmental benefits can be measured for each tonne of recycled toilet paper produced compared to paper made from “virgin” cellulose, including:

- · 80% reduction in the consumption of renewable resources, with savings of 4,060.90 kg of wood;

- · 38% reduction in the consumption of water resources, i.e. 50.63 m3 of water;

- · savings of 20% of the fossil CO2 emitted, one of the gases that are most to blame for climate change.

Clearly, therefore, it is important to manufacture products such as toilet paper from recycled materials, as they cannot be further recycled. However, this can only be achieved by implementing a regulatory framework that promotes the production and sale of recycled products, for example by approving End of Waste decrees and adopting tax incentives for recycled products.

According to data provided by Assocarta, approximately 1.5 million tonnes of tissue paper for hygiene and sanitary use are produced in Italy each year, of which only 7% is produced from recycled materials. Lucart goes completely against the trend in the industry as more than 53% of the paper it uses is recycled, and it also generates value locally since as much as 95% of the recycled paper it uses comes from Europe and, specifically, from Italy, France and Spain, the countries where Lucart has plants capable of producing recycled tissue paper.

In 2018, in order to speed up its transition to a circular economy, Lucart also joined the CE100 network of the Ellen MacArthur Foundation, the world’s largest network for companies seeking to develop new opportunities in circular economy.

The 2018 report also includes the Sustainable Development Goals (SDGs) of the United Nations’ General Assembly, which are valid for 2016 - 2030. These goals are the most concrete way to build a more inclusive world that respects the environment.

Lucart has acquired the Spanish Group CEL Technologies

The Lucca-based Group continues its development in the markets of paper for hygienic and sanitary use in Europe

Lucart welcomes 2018 with a major investment aimed at strengthening its market position in the Iberian peninsula, through the acquisition of the assets of the Spanish Group CEL Technologies & System.

In the summer of 2017, the CEL Group had to initiate an extraordinary administration process during which a tender procedure was launched for the sale of its production assets. The acquisition by Lucart was finalised on 31 January through a newly established company, Lucart Tissue & Soap S.L.U.

Lucart’s project for restarting the business includes an investment plan of more than €20 million over the next 5 years.

With this operation, Lucart has acquired three production facilities in Spain, in the Basque Country near the city of Bilbao, designated for the production and conversion of tissue paper and the production of personal care soaps and detergents in the Away from Home industry. The acquisition also includes a substantial de-inking plant, which will allow Lucart to exploit its know-how in the sector of high-quality recycled ecological tissue paper, further consolidating its position as a leader in this field.

In terms of logistics, the geographical location of the plants is ideal for Lucart for serving both the Iberian and French markets.

In order to gradually resume production, Lucart has confirmed 146 jobs in the three plants acquired, with a business plan that envisages the following:

- restarting two continuous machines at the Aranguren plant, for an overall capacity of 50,000 tonnes per year;

- gradually restarting and implementing the converting activity in the Gunes plant;

- the development and strengthening of soap and detergent production activities in the Artziniega plant, which has never been discontinued.

‘This acquisition will allow us to continue to strengthen our presence in the tissue paper market, in line with the company’s strategic growth plan in European markets, serving all of our Group’s Business Units,’ Massimo Pasquini, CEO of Lucart, explained.

Lucart

Lucart, a leading company in Europe in the production of MG paper, tissue products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.) and airlaid products, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area). With this new acquisition, Lucart’s production capacity exceeds 350,000 tonnes/year of paper on 12 continuous machines and 62 converting lines. Its consolidated turnover will amount to more than €450 million, with more than 1,500 employees in 10 production plants (five in Italy, one in France, one in Hungary and three in Spain).

Environment and innovation, a winning combination: at Ecomondo 2017

Lucart illustrates, in its Sustainability Report, the results achieved and prospects for development

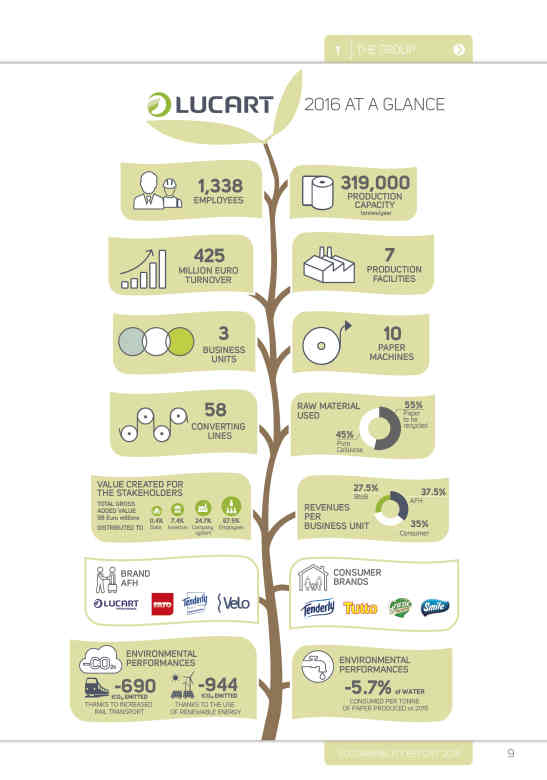

Reuse of raw materials, water conservation, energy efficiency and emission reduction: the Sustainability Report provides an overview of everything Lucart implemented in 2016

With seven production plants in Europe and more than 1,300 employees, Lucart's turnover exceeded €425 million in 2016.

Sustainability and innovation are the two mainstays of Lucart's activities, which have allowed it to achieve outstanding results, as illustrated by the 2016 Sustainability Report. Lucart is the first company in Italy to have launched a circular economy project in the tissue paper sector.

“I believe that we can be considered as a company that promotes a sustainable way of producing paper,” – Massimo Pasquini, Managing Director of Lucart, commented – “which is based on a systemic approach aimed at eliminating waste and reusing raw materials. To do this, we constantly strive to apply production and business models that are inspired by the circular economy and that are in line with EU environmental requirements. We are proud of the results we have achieved this year, since they are a successful example of our ongoing commitment to pursuing innovative and high-quality production” – Pasquini concluded – “We will continue to carry out all of our activities by placing people and the environment at the centre of our business strategy, leading the way towards a more sustainable future.”

Lucart has made positive progress towards the progressive elimination of waste and the reuse of raw materials, favouring the use of recovered materials (55% in 2016) over pure virgin cellulose (45%) for the production of its paper. The flagship of this sustainability strategy is the Natural project, a true example of the applicability of circular economy principles to the tissue sector.

The Natural project

This virtuous and award-winning project represents the evolution of paper, combining environmental sustainability and technological innovation. In partnership with Tetra Pak®, Lucart has developed an innovative technology that separates the cellulose fibres in beverage cartons from polyethylene and aluminium parts, without the use of substances that are harmful to humans or the environment. In this way, two new high-quality raw materials are produced. Fiberpack®, the paper used for the hygiene products in Lucart's Natural lines, is obtained from cellulose fibres. The company has also obtained a material called AL.PE.® from polyethylene and aluminium. This raw material is used to produce innovative systems for the dispensing of tissue products but also for pallets, mooring poles in Venice and floating platforms for wheelchair access and other commonly used items, which are all recycled and recyclable when they reach the end of their life cycle.

In just 4 years, from 2013 to 2016, the Natural project has produced great results:

- more than 2.8 billion 1-litre beverage cartons have been recycled, which, if lined up one after the other, would cover a distance equal to the circumvention of the Earth 16 times over

- more than 1.2 million trees have been saved thanks to this initiative, equal to a surface area of more than 4,200 football fields

- more than 73,000 tonnes of CO2 have been avoided, equal to the emissions produced by more than 578,000 Rome-Milan trips by car

The Natural project received an award on the occasion of the 14th edition of the “Sodalitas Social Award 2016”, namely, the “Best in Class” award, the most prestigious prize for corporate sustainability in Italy, and it also received the “Premio Non Sprecare” (Don’t Waste Award) in the “Companies” category in the same year thanks to its innovative and sustainable approach to circular economy and consumption. Lucart recently ranked second at the 6th edition of the European Paper Recycling Awards held in Brussels, for the Research & Development category, and received the EU Ecolabel Award 2017 for researching and developing new production and environmental solutions.

Water resources

Lucart has focused on using less raw materials and, in particular, on water resources by favouring water recycling, constantly monitoring the quality of wastewater as well as consumption in the various phases of the production process, and optimising consumption patterns. This resulted in a reduction in the specific water consumption for paper production with savings of -5.7% of water consumed per tonne of paper produced compared to 2015 and an overall reduction of 14% compared to 2014.

Logistics

With regard to logistics, Lucart has significantly reduced its impact on the environment in terms of emissions: 690 tonnes less CO2 thanks to increased rail transport, as part of the project “Sustainable Mobility: raw material transport with a shift from road to rail”, presented in 2015 and continued in 2016. The project, which mainly concerns the plant in Diecimo, in the province of Lucca, aims to use the existing railway network to significantly reduce the transport of raw materials and finished products by road.

Energy resources

In terms of energy resources, the company is constantly committed to making its production processes become increasingly efficient. Lucart was also one of the first paper manufacturing groups in Europe to focus on systems to self-generate electricity through cogeneration plants powered by methane gas.

Emissions into the atmosphere

As for its emissions into the atmosphere, Lucart has implemented a plan aimed at streamlining energy consumption by using energy from renewable sources, allowing for lower emissions per tonne of paper produced.

Lucart

Lucart, a leading company in Europe in the production of MG paper, tissue products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.) and airlaid products, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area). Lucart's production capacity exceeds 300,000 tonnes/year of paper on 10 continuous machines and 58 converting lines. Its consolidated turnover amounts to more than €400 million, with more than 1,300 employees in seven production plants (five in Italy, one in France and one in Hungary).