Displaying items by tag: skf

SKF and Amazon Web Services collaborate to reinvent machine reliability industrial solutions

As asset reliability collaborators within the industrial segment, SKF and AWS are taking scalability of condition monitoring and data analysis to a new level as well as collaborating on the next generation of SKF’s condition monitoring technologies.

Gothenburg, 26 April 2022: SKF and Amazon Web Services, Inc. (AWS), an Amazon.com, Inc. company have announced a collaboration to reinvent the field of industrial machine reliability and predictive maintenance with a joint solution. The engagement will deliver an easy-to-use and easy-to-scale condition monitoring and analysis solution that makes the ability to collect and analyze data using machine learning technologies available to a wider range of applications and customers.

As a first step, SKF will combine its knowledge of rotating machinery and predictive maintenance with AWS’s Industrial AI servicesthat bring industrial expertise, AI and machine learning technologies together. The solution is comprised of sensors, gateways and a machine learning service that is easy to install, commission, and scale. SKF and AWS will also collaborate on the next generation of SKF’s data analysis platform.

By adding this solution to its current portfolio of condition monitoring products, SKF can help large manufacturing sites increase the number of rotating assets in the end user’s predictive maintenance programs by several thousands. SKF’s solution will provide these sites with machine alerts and alarms, enabling smarter, better decision making, and more efficient maintenance planning and scheduling. The same solution can also be utilized by entry-level users and small to mid-sized manufacturers, making the ability to use AI-driven analysis available to a larger portion of the industrial market segment.

John Schmidt, President Industrial Region Americas of SKF, says: “The key to maximizing the business value of machine data lies in scale. With more condition monitoring tools available for a wider variety of their assets, end users will gain more insights leading them to improved machine performance.”

Vasi Philomin, Vice President of AI Services at AWS says: “AWS's engagement with SKF spotlights how machine learning technologies, combined with scalability of the AWS cloud and condition monitoring expertise, can come together to improve operational efficiencies for industrial customers. Together with SKF, we are excited to deliver scalable, easy-to-use industrial solutions that will accelerate the pace of operational innovation for industrial customers of all sizes.”

SKF’s mission is to be the undisputed leader in the bearing business. We do this by offering solutions that reduce friction and CO2 emissions, whilst at the same time increasing machine uptime and performance. Our products and services around the rotating shaft include bearings, seals, lubrication management, artificial intelligence and wireless condition monitoring. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2021 were SEK 81,732 million and the number of employees was 42,602. www.skf.com

® SKF is a registered trademark of the SKF Group.

Latest SKF online catalogue makes bearings selection easier

SKF's latest Rolling Bearings Catalogue is packed with new features to help customers choose the optimum bearing arrangement for their project

The latest edition of SKF's popular Rolling Bearings Catalogue is now available online. The authors have aimed to make this new publication an essential engineering reference for users of rolling bearings, covering their appropriate selection, configurations and applications, and providing detailed guidance on correct installation procedures to ensure long and trouble-free service life.

The Engineering Section has been completely rewritten and now includes a step-by-step bearing selection guide - the 'Bearings Selection Process' - which makes it much easier for customers to select the right bearing arrangement for their particular machine or project. This innovative new tool, which benefits from SKF's extensive experience of rolling bearing design, installation and in-service care, is also available as an online engineering resource for OEMs, SKF approved distributors and other end-users.

The Engineering Section has been completely rewritten and now includes a step-by-step bearing selection guide - the 'Bearings Selection Process' - which makes it much easier for customers to select the right bearing arrangement for their particular machine or project. This innovative new tool, which benefits from SKF's extensive experience of rolling bearing design, installation and in-service care, is also available as an online engineering resource for OEMs, SKF approved distributors and other end-users.

The Engineering Section also includes a thermal analysis feature that can be used to highlight the influence of friction losses on clearance. A new 'Popular Items' feature has also been introduced; designed to speed and simplify the process of ordering bearings from SKF's commonly used product lines, this feature uses a special icon placed against products that are always available directly from stock due to their popularity.

The catalogue's online content is regularly updated to ensure that the very latest products are included along with the current SKF assortment, and that all obsolete items are removed from the Product Tables as soon as they are withdrawn from the catalogue.

As a global publication the new Rolling Bearings Catalogue is available in a number of languages, including German, Spanish, French, Italian, Polish, Portugese, Russian, Czech and Simplified Chinese. To Access the online copy in any of these languages, please visit www.skf.com

The new catalogue will be available in print in English during spring 2018.

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2016 were SEK 72 787 million and the number of employees was 44 868. www.skf.com

® SKF is a registered trademark of the SKF Group.

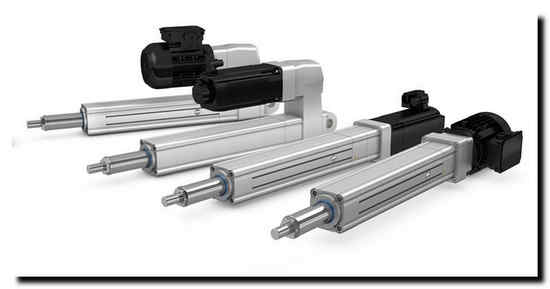

SKF launches unique modular electromechanical actuator

New CASM 100 electromechnical actuator offers exceptional flexibility for a broad range of applications

SKF has launched the versatile CASM 100 electromechanical actuator with a variety of different modules, making it exceptionally adaptable to satisfy a range of applications in a variety of sectors.

This problem-solving technology can, for example, be used in the automation sector on applications including servo presses, test benches, plastic injection moulding, dosing machinery and conveyors. In the metals sector, it can be used for continuous casting, steel bar handling, the regulation of foundry processes. It also has sawing and other applications in the woodworking sector, and roll adjustment in pulp and paper mills.

The product’s modular design offers a base platform with new modules planned for release over time to cater for future needs. The standardised interface between modules – similar to the concept of LEGO bricks – increases the unit’s flexibility and makes it backward compatible. This modularity design also offers the benefit of easy integration and fast assembly.

The CASM 100 actuator has a range of applications including the control of robots, handling and packaging machines, sorting systems and cutting machines. The availability of different modules also allows customers to change the CASM 100 to suit their own specific application needs, selecting the optimum combination of performance and cost.

The actuator consumes up to 80% less energy than pneumatic alternatives and 50% compared to hydraulic solutions. It also uses fewer consumables because, in many applications, is virtually maintenance-free, only requiring re-lubrication using standard grease. There is also no need to change hydraulic fluids and seals so it is remarkably clean, leak-free, cost-effective and environmentally-friendly.

Featuring a linear design that will withstand the harshest conditions, the CASM 100 is manufactured from high-grade materials, boasts a long service life and offers an outstanding level of precision and repeatability. The actuator has a force range up to 82kN and linear speed up to 890 mm/s, and will support OEMs and machine builders migrating to the latest Industry 4.0 technology.

The CASM 100 also benefits from a wide assortment of accessories, outstandingly long stroke lengths (up to 2m) to fit an array of applications, and an inline and parallel gearbox, the latter with spur gear technology and manual override available as standard for an extra safety in operations in case of power losses.

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2016 were SEK 72 787 million and the number of employees was 44 868. www.skf.com

® SKF is a registered trademark of the SKF Group.

SKF technology keeps Metsä Group’s pioneering bioproduct mill moving forward

With SKF providing cutting edge lubrication technology, the world's first next generation bioproduct mill from Metsä Group will operate reliably and efficiently, as well as sustainably.

SKF’s industry leading lubrication technology and system engineering support is being used to help ensure optimal operational performance on the world's first next generation bioproduct mill. The groundbreaking mill, which is being built by Metsä Fibre, part of Metsä Group, in the Finnish town of Äänekoski, will use 100 per cent of the raw materials and run solely on renewable energy.

The new mill is the largest ever single investment in the nation’s forest industry at approximately €1.2 billion and it is a major step forward in the development of sustainable production processes as it will produce significantly more electricity than it will need. It is expected to process 6.5 million cubic metres of wood into 1.3 million tonnes of pulp, with the remaining biomass and side streams being used to make high value bioproducts, including tall oil, turpentine, bioelectricity, process steam, district heat and wood fuel.

SKF was selected to supply lubrication systems – mainly dual-line grease lubrication devices – for about 3,000 lubrication points on the bioproduct mill. It is also providing specially developed, new generation lubrication control centres with mobile access to ensure maximum efficiency and reliability when the mill goes into operation in the third quarter of 2017.

Ossi Puromäki, Project Services Director at Metsä Fibre, said: “The new bioproduct mill is a step towards a world that is no longer dependent on fossil resources. Thanks to innovative technologies and support from trusted partners like SKF, we have been able to realise that ambition and satisfy the growing global demand for softwood pulp through sustainable means.”

Erkki Kemppainen, OEM Sales Manager at SKF’s Lubrication Business Unit, said: “Building on a relationship that already spans decades, we are proud to see our proven lubrication technologies in this state-of-the-art bioproduct mill that is transforming the face of the pulp, paper and wood production industry. Getting involved early in the process has allowed us to deliver a high performance, user friendly system that will support the mill as it manufactures products and produces energy.”

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2015 were SEK 75 997 million and the number of employees was 46 635. www.skf.com

® SKF is a registered trademark of the SKF Group.

SKF Extends Global Agreement with Valmet

SKF’s long-term collaboration with Valmet continues, through the supply of bearings and lubrication system solutions

SKF (STO:SKFB) (STO:SKFA) (Pink Sheets:SKFRY) (LSE:SKFB) has signed an agreement that extends its long-term collaboration with Valmet. SKF will supply bearings, units and lubrication systems to Valmet, the global supplier of technologies, automation and services for the pulp, paper and energy industries.

![]() Erik Nelander, President, Industrial Sales, Europe and MEA, says: “We have been working with Valmet for over 60 years. Our commitment to adopting a design-to-cost approach in our product development also supports Valmet in maximising the efficiency of their own investments in technology development. Our manufacturing and R&D presence across Finland, Sweden and China provides the local knowledge and short lead-times that Valmet requires. By combining our expertise around the rotating shaft, end-users are able to maximise usage of their machinery.”

Erik Nelander, President, Industrial Sales, Europe and MEA, says: “We have been working with Valmet for over 60 years. Our commitment to adopting a design-to-cost approach in our product development also supports Valmet in maximising the efficiency of their own investments in technology development. Our manufacturing and R&D presence across Finland, Sweden and China provides the local knowledge and short lead-times that Valmet requires. By combining our expertise around the rotating shaft, end-users are able to maximise usage of their machinery.”

SKF’s tailored bearing and units solutions have been developed with a focus on reducing design and manufacturing costs for Valmet and decreasing operating costs for machine owners and operators.

SKF’s patented Flowline circulating oil systems provide accurate lubrication, whilst at the same time reducing the amount of circulating oil needed, reducing costs and environmental impact.

Aktiebolaget SKF (publ)

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2015 were SEK 75 997 million and the number of employees was 46 635. www.skf.com

® SKF is a registered trademark of the SKF Group.

SKF First-quarter report 2010

Tom Johnstone, President and CEO:

"SKF delivered a very strong result in the quarter with better volume and higher manufacturing levels resulting in an operating margin of 11.8%. Demand developed positively during the quarter particularly within the automotive business which adversely affected our price/mix. We saw a very positive development of our business in Asia and Latin America and some improvement in North America. However, Europe still remains weak if we exclude our automotive business.

Going forward into the second quarter we expect demand to be significantly higher than the same quarter last year and slightly higher sequentially. As a result of this demand picture we increased our manufacturing as the first quarter progressed which gave a good effect on our cost absorption, particularly in March. We will keep this manufacturing level during the second quarter.”