Displaying items by tag: valmet corporation

The rebuilt paper machine successfully started up at VPK Paper's Oudegem mill in Belgium

After a comprehensive rebuild supplied by Valmet the rebuilt paper machine PM6 at VPK Paper's Oudegem mill in Belgium has been successfully started. The rebuild in the forming, drying and reeling sections will lift up PM6's production capacity from approximately 185,000 t/a to some 200,000 t/a of high quality packaging grades.

The rebuild was executed in spring 2016 with 148 workers on site during 11 days. Safety is top priority in Valmet's projects, and the rebuild was carried out with no accidents.

Paper machine 6 (PM6) at VPK Paper's Oudegem mill in Belgium

"The rebuild project went very well. The whole PM6 crew and Valmet experts worked towards the same target: safe and on-time start-up," says Jaakko Kerttula, Project Manager at Valmet.

Technical details of the delivery

The target of this rebuild was to improve machine speed, safety and efficiency. Valmet delivery for the forming section included among others mist eliminators, vacuum foil boxes and top wire lengthening with additional drive. For the drying section, Valmet delivered UnoRun S runnability boxes, new lead rolls and mechanical drive modification and, additionally, FoilForce tail threading after the dryer section. Also, a complete oil lubrication center including piping, tail threading equipment for the reel area, three sets of forming fabrics and spare parts were part of the delivery.

In spring 2015, Valmet had successfully installed a new Quality Control System (QCS) which has proved excellent performance. "We have achieved high availability and remarkably increased production with automatic grade change, improved process monitoring, and faster paper specifications after web break. Working together with Valmet in these two projects has truly moved our performance forward," states Alexis Zenner, Business Unit Manager at the Oudegem Mill.

Information about the customer VPK Paper

Started in 1935, VPK Paper was built out over the years to one of the leading paper mills in her sector. Annually 500.000 T of waste paper and cardboard are converted to produce just as much new paper. The produced paper qualities are used as raw material to make corrugated and solid board and tubes and cores.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet-supplied key technology and automation for Kotkamills started up in Finland

The start-up of Kotkamills' rebuilt board machine 2 (BM2) in Finland took place on July 22, 2016. Valmet supplied key technology and automation package for the extensive paper machine grade conversion project. The printing paper (MFC) production line was converted to produce a range of folding boxboards and food service boards.

"Our BM2 is the first machine in the world to have the capability to produce dispersion barrier coatings directly on the machine, producing barrier boards that can be recycled with normal paper waste due to having zero plastic content. The interest in our new sustainable products has been massive. The new machine offers a wide range of interesting possibilities for converters, brand owners and designers alike," says Markku Hämäläinen, Chief Executive Officer of Kotkamills.

Kotkamills personnel at start-up on July 22, 2016. Kotkamill's CEO Markku Hämäläinen the third from left and Project Director Stefan Fors in the front row kneeling (the second from right). Photo by Johanna Mäkelä.

"The project schedule was really tight; from the change of the ownership of Kotkamills to start-up in less than sixteen months. That is extremely fast. I am very pleased with cooperation with Valmet and how well-prepared Valmet's project organization was for such an extensive project," says Stefan Fors, Project Director of Kotkamills.

About Valmet's delivery

Valmet's delivery included equipment for stock preparation, a new coating section with two layering curtain coating stations, a blade coating station with roll application, a sizing section with film application and all relatedcoating air dryers. A wide scope of equipment for coating color kitchen and machine circulation for sizing and coating was included. The delivery also included a center driven reel, a two-drum compact winder, modernization of dryer section and calender.

An extensive automation package for BM2 included Valmet DNA machine and drive controls with integrated condition monitoring, and Valmet IQquality management solution including QCS, several profilers and web runnability monitoring and inspection system. Automation deliveries for the pulp mill and the Chemithermomechanical pulp (CTMP) plant include a number of analyzers and measurements including optimizing process controlsfor various process stages. CTMP plant and the coating kitchen are also equipped with Valmet DNA automation system.

A performance agreement betweenKotkamills and Valmet was made to continuously develop BM2 coating process to qualify as high class coated board. The agreement involves both on-site support and troubleshooting support via remote connection to speed up problem solving.

"The Valmet-delivered equipment has worked well without any major setbacks. We have also made the first barrier coating run with success," says Petri Aspholm Senior Project Manager from Valmet.

Information about the customer Kotkamills Oy

Kotkamills Oy is a Finnish forest industry company with a long tradition of over 140 years in the business. Kotkamills is part of Kotkamills Group Oyj which was established in early 2015.

Kotkamills produces folding boxboard and food service board, saturating base kraft papers for laminate production, impregnated products and sawn timber. It has two production facilities in Finland and one in Malaysia. The company has approximately 500 employees, with a majority located in Finland. The turnover of Kotkamills Oy was 266 million euros in 2015.

Valmet to supply a moisturizer system to Zhejiang Dongda Paper in China

Valmet will supply a moisturizer system to Zhejiang Dongda Paper Co. Ltd. in Hangzhou, Zhejiang Province, China. The new solution, Valmet IQ Moisturizer, will enable the mill to improve board quality on its paper machine PM2.

The order is included in Valmet's second quarter 2016 orders received. The delivery will take place in September 2016.

"IQ Moisturizer is very important for our PM2. Before our decision, we visited another mill where it has been installed and were very impressed by its performance. We expect the solution to solve our current curl issue and help us to increase the machine speed to the targeted level," says Sun Guanfa, General Manager, Zhejiang Dongda Paper Co. Ltd.

"We have earlier supplied a Valmet DNA distributed control system, a Valmet IQ quality control system and a ValmetIQ Process and Quality Vision (PQV) system for Zhejiang Dongda Paper's PM2, and the mill has been very satisfied with their good performance and stable runnability. IQ Moisturizer will now provide the mill with easy and fast curl control without any other curl control measures," says Guo Zhutuan, Sales Director, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

Valmet IQ Moisturizer is a moisturizing system with applications for moisture cross-direction profiling, curl control and smooth moisture level increase. It features an air atomized spray nozzle, a linear water control valve and a mist removal system.

The solution is part of the Valmet IQ product family for monitoring and optimizing process performance and end product quality.

Information about the customer Zhejiang Dongda Paper Co. Ltd

Zhejiang Dongda Paper Co. Ltd is a major producer of coated white cartonboard and paper in Zhejiang Province. The company was founded in 1999, and its annual production capacity is 400,000 tons.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

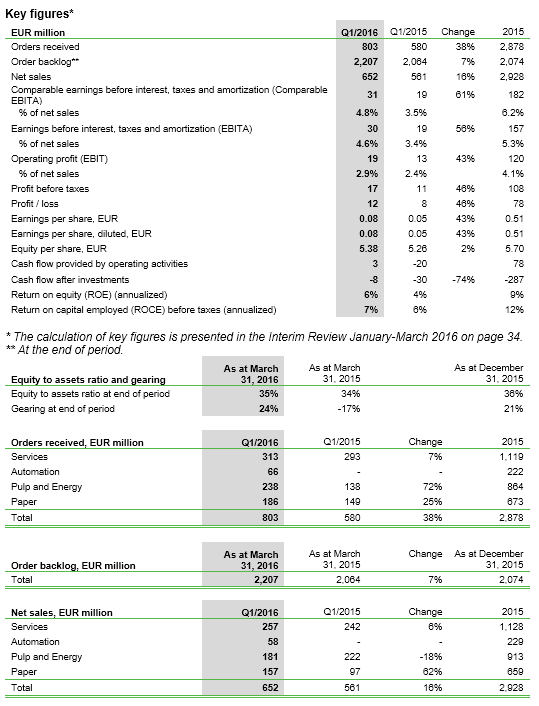

Valmet's Interim Review January 1 - March 31, 2016: Orders received, net sales and profitability increased

Figures in brackets, unless otherwise stated, refer to the comparison period, i.e. the same period of the previous year. Automation has been consolidated into Valmet's financials since April 1, 2015, when the acquisition of Automation was completed.

Due to new regulation by the European Securities and Market Authority concerning alternative performance measures, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items'. Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business. Valmet discloses alternative performance measures to describe the underlying business performance and to improve comparability between reporting periods.

Due to new regulation by the European Securities and Market Authority concerning alternative performance measures, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items'. Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business. Valmet discloses alternative performance measures to describe the underlying business performance and to improve comparability between reporting periods.

January-March 2016: Orders received, net sales and profitability increased

- Orders received increased to EUR 803 million (EUR 580 million).

- Orders received increased in the Pulp and Energy, Paper, and Services business lines.

- Automation contributed to orders received with EUR 66 million.

- Orders received more than doubled in EMEA (Europe, Middle East and Africa) and South America.

- Net sales increased to EUR 652 million (EUR 561 million).

- Net sales increased in the Paper and Services business lines and decreased in the Pulp and Energy business line.

- Automation contributed to net sales with EUR 58 million.

- Comparable earnings before interest, taxes and amortization (Comparable EBITA) were EUR 31 million (EUR 19 million), and the corresponding Comparable EBITA margin was 4.8 percent (3.5%). Earnings per share were EUR 0.08 (EUR 0.05).

- Profitability improved due to the higher level of net sales in Paper and Services business lines, improved gross profit, and the acquisition of Automation.

- Items affecting comparability amounted to EUR -2 million (EUR 0 million).

- Cash flow provided by operating activities was EUR 3 million (EUR -20 million).

Valmet reiterates its guidance for 2016

Valmet is reiterating its guidance presented on February 9, 2016 in which Valmet estimates that net sales in 2016 will remain at the same level with 2015 (EUR 2,928 million) and Comparable EBITA in 2016 will increase in comparison with 2015 (EUR 182 million).

Due to new regulation by the European Securities and Market Authority, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items' (EUR 182 million in 2015). Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business.

Short-term outlook

General economic outlook

The baseline projection for global growth in 2016 is a modest 3.2 percent, broadly in line with last year, and a 0.2 percentage point downward revision relative to the January 2016 World Economic Outlook Update. The recovery is projected to strengthen in 2017 and beyond, driven primarily by emerging market and developing economies, as conditions in stressed economies start gradually to normalize. But uncertainty has increased, and risks of weaker growth scenarios are becoming more tangible. The fragile conjuncture increases the urgency of a broad-based policy response to raise growth and manage vulnerabilities. (International Monetary Fund, April 12, 2016)

Short-term market outlook

Valmet reiterates the good short-term market outlook for board and paper, and the satisfactory short-term market outlook for services, automation, pulp, energy, and tissue.

President and CEO Pasi Laine: Solid start of the year with increase in orders received, net sales and profitability

Valmet had a solid start of the year 2016 with an increase in orders received, net sales and profitability. Orders received increased in Pulp and Energy, Paper, and Services business lines. As a result of both customer activity and good work in all parts of the organization, the orders received development has been trending upwards in all business lines. The orders received were at an all-time high level in the Services business line. Profitability improved in the first quarter of the year compared to the first quarter of 2015.

Automation has now been a part of Valmet for a full year, and I am very pleased with the development. Summing up the year from the Automation perspective, the integration was a success. Both customers and employees are pleased and energized, we launched new automation products during the year, strengthened Valmet's position in Industrial Internet and, in financial terms, we can be satisfied with the development of the Automation business line. Furthermore, our four business lines have found a good and continuously improving way to cooperate in the customer interface and to bring benefits of our unique and market's widest offering to our customers.

News conference and webcast for analysts, investors and media

Valmet will arrange a news conference in English for investment analysts, investors, and media on Wednesday, April 27, 2016 at 2:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. The news conference can also be followed through a live webcast at www.valmet.com/webcasts.

It is also possible to take part in the news conference through a conference call. Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 1:55 p.m. (EET), at +44 1452 560304. The participants will be asked to provide the following conference ID: 82571086.

During the webcast and the conference call, all questions should be presented in English. After the webcast and the conference call, media has a possibility to interview the management in Finnish.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Kari Saarinen, Chief Financial Officer, Valmet, tel. +358 10 672 0031

The Nomination Board of Valmet's proposal for the composition and remuneration of the Board of Directors

Proposal for the composition of the Board of Directors

The Nomination Board of Valmet proposes to the next Annual General Meeting, which is planned to be held on March 22, 2016, that the number of members of the Board of Directors until closing of the Annual General Meeting 2017 will be eight and that

The Nomination Board of Valmet proposes to the next Annual General Meeting, which is planned to be held on March 22, 2016, that the number of members of the Board of Directors until closing of the Annual General Meeting 2017 will be eight and that

- Bo Risberg, Mikael von Frenckell, Lone Fønss Schrøder, Friederike Helfer and Rogerio Ziviani are re-elected as Board members,

- Aaro Cantell, Jouko Karvinen and Tarja Tyni are elected as new Board members.

The Nomination Board proposes that Bo Risberg is re-elected as the Chairman of the Board and Mikael von Frenckell is re-elected as the Vice-Chairman of the Board.

Erkki Pehu-Lehtonen, Member of the Board of Directors of Valmet, has informed Valmet's Nomination Board that he will not be available in the election of the Board of Directors in the next Annual General Meeting. Erkki Pehu-Lehtonen (born 1950) has served as a member of Metso's Board of Directors 2010-2013, and he has served as a member of Valmet's Board of Directors since the demerger (December 31, 2013).

The Nomination Board notes, that a personnel representative will participate as an invited expert in Board meetings within the limitations imposed by the Finnish law. The new Board of Directors will invite the personnel representative as its external expert in its organizing meeting after the Annual General Meeting.

"I am very pleased with the diversity of the knowhow and experience that the nominees for the Board of Directors possess. These requirements, forming part of the principles on diversity agreed for Valmet, were high on the Nomination Board's agenda in the procedure preparing the proposal for the Board composition", says Kari Järvinen, the Chairman of the Nomination Board.

Proposed new Members of the Board of Directors

Aaro Cantell is an entrepreneur and Chairman of the Board in Normet Group Oy since 2005. He has previously worked at Fenno Management Oy and Finnish Innovation Fund Sitra, among others. Aaro Cantell is currently Chairman of the Board of Normet Group Oy, VTT Technical Research Centre of Finland Ltd and Affecto Oyj, and Member of the Board of Federation of Finnish Technology Industries.

Jouko Karvinen was the CEO of Stora Enso Oyj between 2007 and 2014. From 2002 to 2006 he was the CEO of the Medical Division of Royal Philips and before that held several executive positions within ABB Asea Brown Boveri Ltd. Jouko Karvinen is currently Member of the Board of Nokia Oyj and SKF AB, Member of Foundation and Supervisory Boards of IMD business school, Lausanne, Switzerland, and Member of International Advisory Board of Komatsu Corporation of Japan.

Tarja Tyni works as Senior Vice President, Corporate Clients and Business Development in Mandatum Life Insurance Company Limited since 2008. She has previously held several positions within Investment Banking of Nordea Group and its predecessors. Tarja Tyni is also Chairman of the Board of Innova Oy and Mandatum Life Investment Services, and Member of the Board of Euroben Life & Pension Limited.

Proposal for the remuneration of the Board of Directors

The Nomination Board proposes to the Annual General Meeting that the annual remuneration payable to the members of the Board of Directors to be elected at the Annual General Meeting for the term until the close of the Annual General Meeting in 2017 be as follows:

- EUR 100,000 for the Chairman of the Board,

- EUR 60,000 for the Vice Chairman of the Board and for the Chairman of the Audit Committee,

- EUR 48,000 for each Board member.

In addition, the Nomination Board proposes that a meeting fee in the amount of EUR 700 shall be paid for those members whose place of residence is in Nordic countries, EUR 1,400 for those members whose place of residence is elsewhere in Europe and EUR 2,800 for those members whose place of residence is outside of Europe for the Board meeting attended, including the meetings of the committees of the Board of Directors.

The Nomination Board proposes to the General Meeting that as a condition for the annual remuneration the members of the Board of Directors are obliged, directly based on the Annual General Meeting's decision, to use 40 percent of the fixed annual remuneration for purchasing Valmet shares from the market at a price formed in trading at Nasdaq Helsinki's stock exchange list and that the purchase will be carried out within two weeks from the publication of the Interim Review for the period January 1, 2016 to March 31, 2016.

The Nomination Board

Kari Järvinen (Managing Director, Solidium Oy)acted as the Chairman of the Nomination Board. The members the Nomination Board were Martin Oliw (Partner, Cevian Capital AB), Roger Hagborg (Investment Advisory Professional, Triton), Risto Murto (CEO, Varma Mutual Pension Insurance Company) and Bo Risberg as an expert member in his capacity as the Chairman of the Board of Directors of Valmet.

Valmet's Board of Directors will include these proposals into the notice of the Annual General Meeting of 2016, which is estimated to be published on February 9, 2016.

Further information, please contact:

Kari Järvinen, Chairman of Valmet's Nomination Board, tel. +358 40 548 3995

Rasmus Oksala, General Counsel, Valmet, tel. +358 10 672 0026

Publishing of Valmet's Financial Statements Review 2015 on February 9, 2016

Valmet's Financial Statements Review 2015 will be published on Tuesday, February 9, 2016 at approximately 12:00 noon Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

Valmet's Financial Statements Review 2015 will be published on Tuesday, February 9, 2016 at approximately 12:00 noon Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

News conference for analysts, investors and media

Valmet will arrange a news conference in English for investment analysts, investors, and media on Tuesday, February 9, 2016 at 2:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. President and CEO Pasi Laine and CFO Kari Saarinen will be presenting at the news conference.

Webcast

The news conference can also be followed through a live webcast at www.valmet.com/webcasts. The live webcast starts at 2:00 p.m. (EET) and a recording of the webcast will be available shortly after the event at the same address.

Conference call

It is also possible to take part in the news conference through a conference call. Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 1:55 p.m. (EET), at +44 1452 560304. The participants will be asked to provide the following conference ID: 25632403.

During the webcast and the conference call, all questions should be presented in English. After the webcast and the conference call, media has a possibility to interview the management in Finnish.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +359 10 672 0007

For media: Anu Salonsaari-Posti, Senior Vice President, Marketing & Communications, Valmet, tel. +358 10 672 0033

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet-supplied OptiConcept M board making line started up at Pratt Industries in the USA

Pratt Industries' Valmet-supplied containerboard production line, PM 16, successfully came on stream on October 04, 2015 at their greenfield paper mill in Valparaiso, Indiana, USA. This is Valmet's first OptiConcept M installation in North America.

"PM 16 is one of the industry's most efficient paper mill, employing 120 people to make 370,000 tons a year - twice the productivity of many competitor mills. It is the world's most environmentally-friendly paper mill and a showcase for the latest in 21st Century paper-making technology," says Anthony Pratt, Global Chairman of Pratt Industries.

Valmet OptiConcept M board making line is designed to use less water, electricity and raw materials. "That's important not only for our environment but also for our customers who realize the importance of sustainable packaging." says Pratt.

The Valmet OptiConcept M containerboard production line started up on October 4, 2015 for Pratt Industries at the Valparaiso mill in Indiana, USA.

About Pratt Industries

Pratt is America's 5th Largest corrugated packaging company and the world's largest, privately-held 100% recycled paper and packaging company, with more than 5200 highly-skilled employees dedicated to the environment and sustainability. Pratt was founded in the USA some 25 years ago and, since then, has shown dramatic growth with sophisticated manufacturing facilities in more than 20 states.

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Further information, please contact:

Tuomo Rämö, Senior Project Manager, Paper Mills, Valmet, tel. +358 40 748 8513

Mike Gray, Area Vice President, North America, Valmet, tel. +1 920 738 8542

Valmet's headbox technology awarded first prize at ATIP Innovation Contest

Valmet won this year's prestigious 'Palme d'Or' Innovation Award with its OptiFlo headbox with Aqua layering technology. The award was given by the French Paper Industry Technical Association (ATIP). The innovation contest was arranged in connection with the ATIP Conference and Exhibition in Grenoble, France on November 24-26, 2015.

The ATIP Innovation Award rewards innovative equipment and solutions for pulp and paper industry. The award is highly regarded among the European pulp and paper industry and it is divided into three categories: Gold - Palme d'Or, Silver - Palme d'Argent and Bronze - Palme de Bronze. The ATIP Innovation Award winners are selected by a committee consisting of Paper Mill Managers, R&D Directors, Technology Directors and Production Managers from the French paper industry. The ATIP Innovation Award was established already in 1995.

Award ceremony from left Rémi Poirson, Mill Manager of Smurfit Kappa Saillat-sur-Vienne, Jean-Nicolas Bailly, Mill Improvement Manager from Valmet, Marc Bortolotti, Senior Sales Manager from Valmet, Hugues Leydier, President of ATIP and Daniel Gomez, Director of ATIP

Raw material savings with Aqua layering technology

Valmet's OptiFlo headbox with new innovative Aqua layering technology makes it possible to produce a two-layer sheet with very good layer coverage using only one headbox and one forming unit. A thin layer of water is used as a headbox wedge to separate different stocks fed into the headbox. Previously this separation has been done with mechanical elements like vanes and solid wedges.

Valmet's OptiFlo headbox with new innovative Aqua layering technology makes it possible to produce a two-layer sheet with very good layer coverage using only one headbox and one forming unit. A thin layer of water is used as a headbox wedge to separate different stocks fed into the headbox. Previously this separation has been done with mechanical elements like vanes and solid wedges.

The layer separation with water delivers excellent layer coverage without mixing of the layers. It enables lower grammages on top ply of the paper and significant raw material savings. Besides delivering excellent layer purity, the separating water layer can also act as a carrier for different additives enabling a totally new dosage point for chemicals. This delivers the same end product strength with less raw materials or with raw materials of poorer quality. Cost efficiency of papermaking can be further improved by for example feeding reject stock through the water layer together with additives. This reject stock would normally be used as landfill.

Innovation is a result of seamless team work.

Valmet's technology development aims at ensuring advanced and competitive technologies and services, enhancing raw material and energy efficiency and promoting renewable materials.

"We would not have been able to present this innovation without the hard work and contribution of several teams in Valmet. We have a long history of bringing new innovations to the market and we focus on solutions that improve energy and raw material efficiency. The pilot facilities that Valmet has play a crucial role in both testing and demonstrating the value of new technology for our customers in realistic process conditions," says Sami Anttilainen, Vice President, Technology at Valmet.

For further information, please contact:

Sami Anttilainen, Vice President, Technology, Paper Mills Business Unit, Valmet, tel. +358 10 672 6501

Philippe Bentz, Vice President, Sales, SEMEA, Phone +33389753312

Information about Aqua layering at valmet.com:

http://www.valmet.com/aqua-layering

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

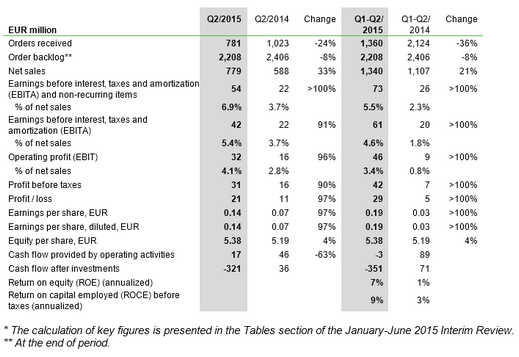

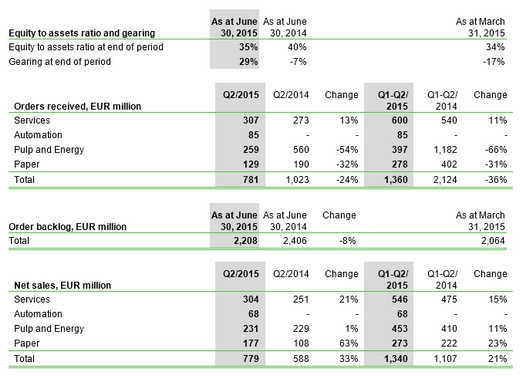

Valmet's Interim Review January 1 - June 30, 2015: Strong start for Automation as part of Valmet - profitability reached the targeted range in Q2/2015

Figures in brackets, unless otherwise stated, refer to the comparison period, i.e. the same period of the previous year. Automation has been consolidated into Valmet's financials since April 1, 2015, when the acquisition of Automation was completed.

April-June 2015: Strong start for Automation - Valmet's EBITA more than doubled

- Orders received decreased to EUR 781 million (EUR 1,023 million).

- Orders received increased in the Services business line and decreased in the Pulp and Energy, and Paper business lines.

- Net sales increased to EUR 779 million (EUR 588 million).

- Net sales increased in the Paper, and Services business lines and remained at the previous year's level in the Pulp and Energy business line.

- Automation contributed to net sales by EUR 68 million.

- Earnings before interest, taxes and amortization (EBITA) and non-recurring items were EUR 54 million (EUR 22 million), and the corresponding EBITA margin was 6.9 percent (3.7%).

- Profitability improved due to the higher level of net sales, improved gross profit, and the acquisition of Automation.

- Earnings per share were EUR 0.14 (EUR 0.07).

- Non-recurring items amounted to EUR -12 million (EUR 0 million), of which costs related to acquisition of Automation amounted to approximately EUR 10 million.

- Cash flow provided by operating activities was EUR 17 million (EUR 46 million).

January-June 2015: EBITA more than doubled - continued good development in Services

- Orders received decreased to EUR 1,360 million (EUR 2,124 million).

- Orders received increased in the Services business line and declined from the high levels in H1/2014 in the Pulp and Energy, and Paper business lines.

- Net sales increased to EUR 1,340 million (EUR 1,107 million).

- Net sales increased in Services, Pulp and Energy, and Paper business lines.

- Automation contributed to net sales by EUR 68 million.

- Earnings before interest, taxes and amortization (EBITA) and non-recurring items were EUR 73 million (EUR 26 million), and the corresponding EBITA margin was 5.5 percent (2.3%).

- Profitability improved due to the higher level of net sales, improved gross profit, and the acquisition of Automation.

- Earnings per share were EUR 0.19 (EUR 0.03).

- Non-recurring items amounted to EUR -12 million (EUR -6 million), of which costs related to acquisition of Automation amounted to approximately EUR 10 million.

- Cash flow provided by operating activities was EUR -3 million (EUR 89 million).

Valmet reiterates its guidance for 2015

Valmet is reiterating its guidance presented on February 6, 2015 in which Valmet estimates that, including the acquisition of Process Automation Systems, net sales in 2015 will increase in comparison with 2014 (EUR 2,473 million) and EBITA before non-recurring items in 2015 will increase in comparison with 2014 (EUR 106 million).

Short-term outlook

General economic outlook

Global growth is projected at 3.3 percent in 2015, marginally lower than in 2014, with a gradual pickup in advanced economies and a slowdown in emerging market and developing economies. In 2016, growth is expected to strengthen to 3.8 percent. The distribution of risks to global economic activity is still tilted to the downside. Near-term risks include increased financial market volatility and disruptive asset price shifts, while lower potential output. (International Monetary Fund, July 9, 2015)

Short-term market outlook

Valmet is reiterating its short-term market outlook presented on April 29, 2015. Valmet estimates that activity in pulp, and board and paper markets will remain on a good level. The activity in the services, tissue, and automation markets is estimated to remain satisfactory. The activity in the energy markets is expected to remain weak.

President and CEO Pasi Laine: Together with Automation, Valmet becomes a stronger company

When the acquisition of Process Automation Systems was completed on April 1, 2015, Valmet got its fourth business line, called Automation. Our customers appreciate that we have reunited the automation expertise with paper, pulp, and power plant technology and process know-how, within the same company. This change has energized and motivated our employees too.

Automation had a strong start as a part of Valmet, and over time I believe that we can achieve even greater benefits through good internal cooperation. With an integrated sales process, harmonized project execution, wider offering and enhanced product development, we will be able to serve our customers even better than before. All in all, Valmet will become a stronger company.

Valmet's performance in the second quarter of 2015 was solid: net sales increased, profitability improved and the EBITA margin reached our targeted range. Good development continued in the Services business line. Additionally we are continuing our focus on cost control and successful project execution.

In addition to expanding Valmet's offering, the automation business somewhat decreases cyclicality of Valmet's businesses. On annual level the automation business is typically fairly stable, thus increasing the stability and visibility of Valmet's business.

Key figures*

Valmet is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Valmet's Interim Review January 1 - June 30, 2015

Two new Valmet-supplied tissue lines started up at Hayat Kimya in Turkey and Russia

Hayat Kimya's new Advantage DCT 200TS tissue line, PM5, was started up in March 2015 by a joint Valmet and Hayat Kimya team. The new line, at the Mersin mill in Turkey, came smoothly on stream according to schedule and produced sellable paper from the very start.

This was the second start-up for the same team in three months, as Hayat Kimya's PM4 at the new Alabuga mill in Tartarstan, Russia was started up in December 2014. The time schedule was very tight but the paper was on reel as expected with good paper properties.

"This was for most of us, the third and fourth tissue line installation we have started together. During the years we have developed a mutual respect and high confidence in each other, which makes the coordination of the assembly and all commissioning activities very smooth and together we make things happen," says Rolf Tellack, Project Manager, Valmet.

"We share the same excitement with everyone who has contributed with patience and determination to make these projects successful. Even though the conditions were very different between the Russian and the Turkish installations both machines started up on time and are now producing top quality paper at high speed," says Lütfi Aydin, Director Paper Group, Hayat Kimya.

Hayat Kimya has now four tissue lines supplied by Valmet in their machine fleet and one more to start up in 2016. Recently the company announced the rebuild of their PM1 which means that all their tissue lines will be operating with the Advantage DCT technology from Valmet.

Hayat Kimya and Valmet team celebrating the PM5 start-up at the Mersin mill in Turkey

Hayat Kimya and Valmet team celebrating the PM4 start-up at the Alabuga mill in Tartarstan, Russia

Technical information

Both tissue machines have a width of 5.6 m and a design speed of 2,200 m/min. The design capacity for each machine is 70,000 tonnes a year. Both machines will produce high-quality facial, toilet and towel grades from virgin fiber and are optimized to save energy and enhance final product quality.

The two tissue production lines feature stock preparation systems and Advantage DCT 200TS tissue machines. The machines are equipped with OptiFlo headboxes and Valmet cast alloy Yankee cylinders as well as the Advantage technology including ViscoNip press, AirCap hood prepared for co-generation, WetDust sytem, sheet transfer system and SoftReel reel. The delivery also included an extensive automation package with Valmet DNA, process controls and Valmet IQ quality controls. Complete engineering, supervision, training, start-up and commissioning was also included in the delivery.

Information about the customer Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Rolf Tellack, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 62 75 65

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.