Displaying items by tag: valmet corporation

Two new Valmet-supplied tissue lines started up at Hayat Kimya in Turkey and Russia

Hayat Kimya's new Advantage DCT 200TS tissue line, PM5, was started up in March 2015 by a joint Valmet and Hayat Kimya team. The new line, at the Mersin mill in Turkey, came smoothly on stream according to schedule and produced sellable paper from the very start.

This was the second start-up for the same team in three months, as Hayat Kimya's PM4 at the new Alabuga mill in Tartarstan, Russia was started up in December 2014. The time schedule was very tight but the paper was on reel as expected with good paper properties.

"This was for most of us, the third and fourth tissue line installation we have started together. During the years we have developed a mutual respect and high confidence in each other, which makes the coordination of the assembly and all commissioning activities very smooth and together we make things happen," says Rolf Tellack, Project Manager, Valmet.

"We share the same excitement with everyone who has contributed with patience and determination to make these projects successful. Even though the conditions were very different between the Russian and the Turkish installations both machines started up on time and are now producing top quality paper at high speed," says Lütfi Aydin, Director Paper Group, Hayat Kimya.

Hayat Kimya has now four tissue lines supplied by Valmet in their machine fleet and one more to start up in 2016. Recently the company announced the rebuild of their PM1 which means that all their tissue lines will be operating with the Advantage DCT technology from Valmet.

Hayat Kimya and Valmet team celebrating the PM5 start-up at the Mersin mill in Turkey

Hayat Kimya and Valmet team celebrating the PM4 start-up at the Alabuga mill in Tartarstan, Russia

Technical information

Both tissue machines have a width of 5.6 m and a design speed of 2,200 m/min. The design capacity for each machine is 70,000 tonnes a year. Both machines will produce high-quality facial, toilet and towel grades from virgin fiber and are optimized to save energy and enhance final product quality.

The two tissue production lines feature stock preparation systems and Advantage DCT 200TS tissue machines. The machines are equipped with OptiFlo headboxes and Valmet cast alloy Yankee cylinders as well as the Advantage technology including ViscoNip press, AirCap hood prepared for co-generation, WetDust sytem, sheet transfer system and SoftReel reel. The delivery also included an extensive automation package with Valmet DNA, process controls and Valmet IQ quality controls. Complete engineering, supervision, training, start-up and commissioning was also included in the delivery.

Information about the customer Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 350,000 tonnes and a converting capacity of 200,000 tonnes per year. Through new investment and ongoing projects the total production capacity of Hayat Kimya will reach 420,000 tonnes.

For further information, please contact:

Björn Magnus, Sales Director, Tissue Mills business unit, Valmet, tel. +46 703 17 79 83

Rolf Tellack, Project Manager, Tissue Mills business unit, Valmet, tel. +46 705 62 75 65

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

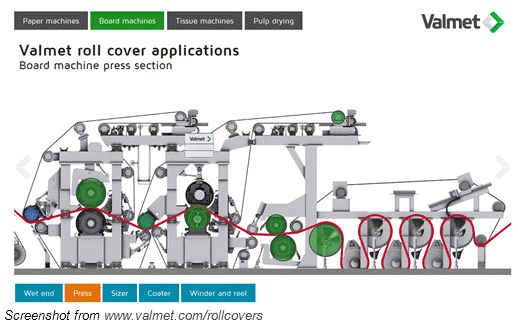

Valmet introduces new online tool for choosing optimal roll covers

Valmet has launched a new and intuitive roll cover online tool in April 2015. This interactive application enables users to locate and select the correct roll cover for any paper, board or tissue production line roll positions, as well as for pulp drying machines.

The new online tool will serve Valmet's customers even more efficiently by collating Valmet's entire roll cover and coating product range and presenting the products in one user-friendly view along with all related product information. You can find the application at www.valmet.com/rollcovers.

Easily browse through the entire Valmet roll cover range

"As an industry-leading roll cover supplier, we wanted to make it easy to search for and select a roll cover for each position. In addition to looking at roll cover options and qualities, this is also a quick way to open and download product datasheets", explains Samppa Ahmaniemi, director of Roll Covers at Valmet. The user-friendly online tool can be conveniently accessed even from tablet devices.

Fit-for-purpose roll covers for all applications

Valmet's roll cover portfolio contains a wide range of high technology solutions for all applications. For decades, Valmet has utilized the latest technology and research results in the development of roll covers. This work has resulted in modern roll cover materials and innovative coating solutions.

Regardless of the paper grade or machine brand, Valmet offers its customers a comprehensive selection of roll covers to suit their particular needs. Valmet has developed long-lasting, compliant covers ranging from rubber and polyurethane all the way to ultra-hard carbides and ceramics. These materials provide excellent wear resistance and long, disturbance-free run times. As a result, mills can increase their machine efficiency, extend roll running times and reduce their maintenance costs.

Further information, please contact:

Samppa Ahmaniemi, Director, Roll Covers, Valmet

tel. +358 10 672 6837

Juha Ruotsi, Global Technology Manager, Roll Covers, Valmet

tel. +358 10 672 0950

Valmet Tissue Technology Award granted to modification of hard wood pulp for tissue production

The winner of Valmet Tissue Technology Award was announced at the Tissue World Conference, Barcelona, Spain, on March 17, 2015. The award and the USD 25,000 prize amount was granted to Abdus Salam, Graduate Student from North Carolina State University, USA.

The purpose of the Valmet Tissue Technology Award is to promote university students' or scientists' work to develop environmentally sound products applicable to the tissue making processes. The award is granted every second year and the winner is selected by a panel of jurors representing universities, scientific organizations and Valmet.

Valmet Tissue Technology Award ceremonies at the Tissue World Conference in Barcelona

The focus area for the award this year was environmental efficiency. Mr. Salam is awarded for his work on modified hardwood pulp for tissue production. The objective of Mr. Salam's work has been to develop a method to provide unique tissue characteristics using only natural materials. By modifying hardwood pulp, it can be cross-linked with a biodegradable product to greatly improve absorbency properties. The modified fibers are elastic, very soft, highly porous and durable, and also have microbial properties.

"We are constantly searching for new innovations to make the tissue process more sustainable and environmentally efficient. Mr. Salam's innovation is well in line with our strategy and shows how biomaterials can be utilized to add new and improved properties to tissue products. This is an excellent example of how scientists and the academic world can contribute to the important work of developing sustainable solutions for the future of tissue-making," says Anders Björn, Vice President, Tissue Mills business unit, Valmet.

"I greatly appreciate the award committee's selection of my research for Valmet Tissue Technology Award of 2015. This is my first international award which has truly inspired me to develop new products and ideas for tissue and paper towel applications. I believe the research developments related to modifying hardwood pulp can significantly contribute to the personal health care sector as well as the global economy," says Abdus Salam, the winner of the Valmet Tissue Technology Award.

More information about the Valmet Tissue Technology Award including application regulations can be found at www.valmet.com/tissueaward.

For further information, please contact:

Anders Björn, Vice President, Tissue Mills business unit, Valmet, Tel. +46 705 17 13 38

Allan Grimm, Manager, Global Technology, Tissue Mills business unit, Valmet, Tel. +46 54 17 11 42

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Valmet's new BioTrac pilot plant for hydrolysis of biomass started up

Valmet has installed a new bio pilot plant in its research and development center in Sundsvall, Sweden. The equipment, called BioTrac, is a hydrolysis system which is used for process optimization and testing of raw materials based on biomass. This is part of Valmet's investment into developing new technologies for biorefinery applications, in order to deliver technology and process solutions to reduce CO2 emissions globally.

Valmet's BioTrac is flexible both when it comes to different raw materials and process alternatives, and can be adapted to several downstream process steps. Hydrolysis is often the first step in a biorefinery, and a step that has to be passed, regardless of subsequent process chosen. Further refining of the biomass can for example be production of bioethanol, bio based chemicals and biomaterial, such as bio based plastics.

"Many companies want to replace fossil fuels in favor of renewable raw materials. The product streams from our BioTrac system, and from the subsequent processes, can be used as bio based raw materials for production of for example plastics and chemicals. We are confident that our customers appreciate that they now can test their own ideas in our pilot plant, which in all essential parts correspond to the full scale equipment they are interested in," says Rickard Andersson, Vice President, Bio Technology and Environmental Systems, Valmet.

"In the new BioTrac system it is easy to handle a variety of biomasses and we can closely control and follow what is happening in the process. The system represents world class and is based on technology which was originally developed for the pulp and paper industry, where Valmet has extensive experience going over hundred years back," says Olof Melander, Manager, Valmet Fiber Technology Center in Sundsvall.

About hydrolysis

Hydrolysis is a chemical process that, under elevated temperature and pressure, makes cellulose and hemicellulose available to be split into different sugars and lignin in subsequent processes. The lignin is obtained as a solid residue. Both sugars and lignin can then be further refined.

Information about Valmet's Fiber Technology Center in Sundsvall, Sweden

Valmet's Fiber Technology Center in Sundsvall employs about 20 persons, among them a number of researchers. In addition to several different pilot plants, e.g. for washing, screening and refining, the technology center also houses a laboratory for bleaching trials and various chemical, pulp and paper analyses.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Notification according to chapter 9, section 5 of the Securities Market Act: Nordea Funds Oy's ownership in Valmet exceeds 5 percent

Valmet Corporation (business ID 2553019-8) has on August 18, 2014 received a notification referred to in Securities Market Act from Nordea Funds Oy (business ID 1737785-9), stating that the company's ownership and share of votes in Valmet Corporation has risen above the threshold of 5 percent (1/20).

Valmet Corporation (business ID 2553019-8) has on August 18, 2014 received a notification referred to in Securities Market Act from Nordea Funds Oy (business ID 1737785-9), stating that the company's ownership and share of votes in Valmet Corporation has risen above the threshold of 5 percent (1/20).

As a result of share transactions on August 15, 2014, the holding of Nordea Funds Oy increased to 7,502,743 shares (previously 7,445,447 shares), representing an ownership of 5.006 percent (previously 4.968 percent) of Valmet Corporation's total number of shares and share of votes.

Valmet Corporation has one series of shares in which each share carries one vote. The aggregate number of shares is 149,864,619.

Valmet enhances roll cover manufacturing capacity in Thailand

Valmet is investing in roll cover manufacturing capacity at its service center in Laem Chabang, Thailand. The investment will double Valmet's composite roll cover production capacity in the Asia-Pacific region. Production of Valmet's newest polyurethane products will begin by the end of June 2014.

The Laem Chabang service center is to begin manufacturing PressPolar press roll covers for board making, PressHusky press roll covers for tissue making, and CoteFalcon and CoteCondor covers for sizing and blade coating. These covers have a proven track record of providing energy savings, extending running times and lowering maintenance costs.

Calender composite cover capacity is also being expanded to meet growing demand from customers. This will improve delivery times and permit more flexible deliveries to meet varied customer needs with proven cover solutions - like the nanomaterial-based CalLeopard cover - throughout the Asia-Pacific area.

Manufacturing iRolls, Valmet's intelligent roll solution, has also been made possible with new roll cover products at Laem Chabang. iRolls are available for all main processes and positions in pulp, paper, board and tissue machines with the latest Valmet roll covers. The main benefit of iRoll technology is its accurate online profile measurement and process control in press, sizer, coater, reel and winder applications. Valmet's iRoll is the fastest, most sensitive online profile measurement tool in the industry.

Information about Valmet's service center in Thailand

Valmet's Laem Chabang service center is a one-stop service center for the pulp and paper industry in Asia-Pacific. The center features a fully equipped roll service workshop which can serve and cover even the most demanding process rolls of up to 12 m, as well as manufacturing suction roll seals and wear plates. It was inaugurated in January 1998.

Read more:

Laem Chabang service center

Valmet to supply new sizing technology for Papierfabrik Niederauer Mühle GmbH in Germany

Valmet will supply Papierfabrik Niederauer Mühle GmbH with a sizer and auxiliaries for its PM3 containerboard machine located in the company's Kreuzau mill in Germany. The target of the project is to improve the strength properties of the white top liner grades. This high quality paper is used for instance as printed cover layer for cardboards and as headliner. The sizer is scheduled to start up during the first quarter of 2015.

The order is included in Valmet's second quarter 2014 orders received. The value of the order will not be disclosed.

Valmet's innovative sizing technology will boost the quality of white top linerboard

In addition to the new sizer, Valmet's delivery will include a calender rebuild, an air dryer, starch preparation and starch supply systems as well as ropeless tail threading equipment.

"The new sizer will combine the best features of both spray application and film application, and improve the strength properties of the white top liner grades. The main advantages of the back side spray application technology compared to conventional starch application method are drying energy reduction, fast and accurate starch amount control as well as elimination of wearing parts. The top side film application ensures excellent properties of the white top liner surface," says Ilkka Naatti, Product Manager of coaters and sizers in Valmet.

"Niederauer Mühle will also be the first paper mill in the Central Europe to benefit from the advantages of safe, reliable and fully ropeless tail threading technology in the size press area. After the rebuild the tail threading process of PM3 will be totally ropeless for all machine parts."

About Papierfabrik Niederauer Mühle GmbH

Niederauer Mühle specializes in white corrugated medium paper of which basis weight ranges from 120 - 200 g/m2. Its production volume is more than 300,000 tons of paper per year today. The company has currently 155 employees.