Super User

Specialty paper producer Cartiere di Guarcino starts up Toscotec-rebuilt PM in Italy

Italian specialty paper manufacturer Cartiere di Guarcino has started up PM2 at its Guarcino paper mill after a successful rebuild of the forming and press sections supplied by Toscotec. PM2 produces high-quality decor specialty papers.

Targets achieved

The rebuild achieved its dual target of paper quality improvement and production increase. Firstly, the project ensured improved fiber distribution in Cross Direction (CD) by guaranteeing the efficient operation of the shaking system. As a result, Toscotec delivered enhanced formation and paper quality. Secondly, the press section rebuild increased post-press dryness, leading to a production capacity increase.

A fully customized rebuild

Based on the analysis of PM2’s operating conditions, Toscotec delivered a fully customized design solution applying both Toscotec’s and Voith’s technology in the forming and press sections.

In the forming section, Toscotec installed a customized breast roll and Voith’s FloatBearings to enhance paper formation by boosting the performance of an existing shaking unit. It installed Voith’s EdgeMasters on the forming wire to deliver optimal paper web edge, as well as successfully operationalized a new wire stretcher and tail cutting unit.

In the press section, the rebuild consisted in the installation of a new second nip with associated felt run, the overhauling of the hydraulic system, and a customized technological doctoring system equipped with savealls to improve water removal.

Simone Principia, Plant Manager of Cartiere di Guarcino, says: “Thanks to the good teamwork between Toscotec, Voith and CDG technicians, the start-up went very smoothly, and we continue to see performance improvements even beyond our expectations. The fully tailor-made technological solutions provided by Toscotec have increased PM2’s production and set a higher standard of quality, which is key for our customers.”

Enrico Fazio, Sales Director of Toscotec’s Paper & Board division, says: “The synergy with Voith was very successful on this rebuild, where we implemented the best tailor-made solution for Cartiere di Guarcino. In the high-end segment of decor papers, they are now fully equipped to meet the market’s demanding requirements, thanks to their solid papermaking capability.”

About Cartiere di Guarcino S.p.A.

Cartiere di Guarcino, part of Neodecortech Group, is an Italian manufacturer of decor specialty papers operating a production facility in Guarcino, Frosinone. It specializes in high quality products for application in office and home furniture and laminate flooring, including unicolours, print base papers, backer papers and underlays. In line with its sustainability-focused strategy, the paper mill uses electrical and thermal energy produced by Bio Energia Guarcino, a carbon-free cogeneration plant fuelled by animal fats and vegetable oil residues.

Valmet to deliver Valmet DNA Integrated Operations to Rohe Solutions Oy in Hamina, Finland

Valmet will deliver Valmet DNA Integrated Operations (IOP) for off-grid distribution management to Rohe Solutions Oy in Hamina, Finland.

The order was included in Valmet’s orders received of the first quarter of 2023. The value of the order will not be disclosed.

Rohe Solutions started a pilot with Valmet DNA Integrated Operations in October 2022 and were happy with the set-up and integration of IOP and the on-site gateway. They were also pleased with the strong safety features and the integration to Rohe’s internal Microsoft environment, enabling a safe and easy implementation.

Rohe Solutions started a pilot with Valmet DNA Integrated Operations in October 2022 and were happy with the set-up and integration of IOP and the on-site gateway. They were also pleased with the strong safety features and the integration to Rohe’s internal Microsoft environment, enabling a safe and easy implementation.

The platform is also suitable for biomethane container and hydrogen-based gases like synthetic methane, distribution, which makes it futureproof for the customer.

“Valmet DNA Integrated Operations can be taken into use easily and is a scalable solution for managing off-grid distribution of energy. It is an excellent fit for Rohe’s fast-paced operations,” says Tiina Stenvik, Director, Performance Solutions, Automation Systems, Valmet.

“We are aiming to provide the best customer experience and the Valmet solution is one piece to the puzzle to fulfill this target,” says Jani Hautaluoma, Head of Technology, Rohe Solutions.

Technical information about the delivery

The delivery will include the Valmet DNA Integrated Operations platform with the latest capabilities. The platform will measure levels and pressures of the gases transported as well as the plant operability in an Azure environment.

About the customer Rohe Solutions Oy

Rohe Solutions Oy is a joint venture of Hamina Energy and Alexela Energia. The company is engaged in the sales of natural gas and liquefied natural gas (LNG). Rohe provides LNG services based on the needs of industrial manufacture, heavy goods transport, and sea transport. The services range from the mere delivery of LNG to complete turnkey solutions.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Walki Group partners with The Paper Lid Company to make recyclable and printable paper lids

Walki Group has invested in Finnish start-up The Paper Lid Company (‘TPLC’). TPLC’s sustainable paper lid manufacturing site in Masku, Finland, is ready for scaling up production volumes supported by Walki’s material conversion and printing capabilities.

End users of hot and cold cup lids are increasingly looking for alternatives to replace plastic lids with more sustainable solutions. While the use of plastic lids has not yet been widely banned by regulation, restaurants, coffee chains, retailers and others are already taking action to transition away from single-use plastic lids.

TPLC has developed a unique way of manufacturing high-quality recyclable paper lids. The lid developed by TPLC fits firmly to the cup, has a pleasant touch and feel, can be customprinted and comes at a competitive price compared to plastic alternatives. The raw material for the lids is produced with dispersioncoating technology which makes the lid recyclable in paper waste streams.

Walki's startup investment initiative Walki Ventures has invested in TPLC and established a strategic partnership to support TPLC in implementation of the ambitious growth plan the founders have laid out. Walki will support TPLC in several areas, including development of recyclable raw material for the lids and printing services for custom and single-color printed lids. TPLC will also become a member of Walki’s R&D Community, helping the company to articulate sustainability benefits towards the customers in a fact-based manner.

“We are very excited to partner with Walki and get access to the resources that come with this partnership. Raw material plays a very important role both in our production process and quality of the end product. With Walki’s material knowhow, printing capabilities and other support, we are ready to start supplying the market in larger scale”, says Matti Salonoja, CEO and co-founder of TPLC.

About Walki

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero-waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials.

Walki is a fast growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. Our production facilities are located in Finland, Germany, Belgium, France, Spain, the UK, Poland, Russia and China. We are employing about 1 500 people globally and we expect a turnover for this year of more than 700 MEUR. To best cater to our global customers, we aim to continue investing in state-of-the-art production facilities and promoting our tradition of innovation and exceptional service worldwide.

European Commission closes its investigation into the wood pulp sector

As announced by Stora Enso on 12 October 2021, it was included in the European Commission's inspection of the wood pulp sector and subject to inspections at its premises. Today, the European Commission has announced that after a thorough and careful assessment, it has decided to close its investigation.

As announced by Stora Enso on 12 October 2021, it was included in the European Commission's inspection of the wood pulp sector and subject to inspections at its premises. Today, the European Commission has announced that after a thorough and careful assessment, it has decided to close its investigation.

Investor enquiries:

Anna-Lena Åström

SVP Investor Relations

Tel. +46 70 210 7691

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

STORA ENSO OYJ

Türkiye’s largest wood panel producer starts up third ANDRITZ MDF production line

Kastamonu Entegre Ağaç Sanayi ve Ticaret A.Ş. (KEAS) started up its new fiber preparation line for MDF (Medium Density Fiberboard) production at its mill in Balikesir, Türkiye. KEAS is the largest wood panel producer in Türkiye and now successfully operates three production lines supplied by ANDRITZ.

Hasan Akpinar, Global Investment and Projects Director of KEAS, says: “We have relied on ANDRITZ MDF technology and service for many years and are very satisfied with the results. Our new line from ANDRITZ is equipped with a pressurized refining system for low electricity and thermal energy consumption. This perfectly contributes to our sustainability strategy.”

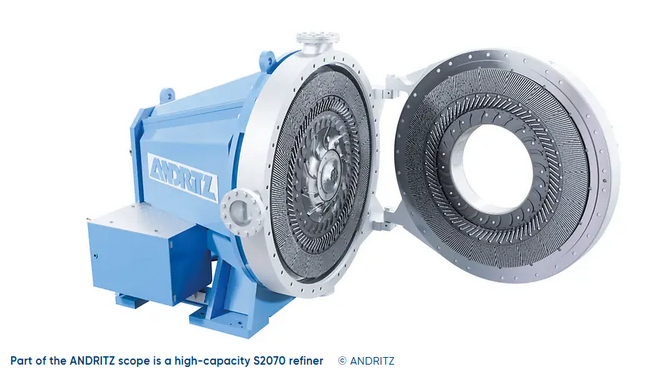

The new line has a capacity of 60 t/h and processes pine, beech and oak wood. Its centerpiece is the pressurized refining system, which includes a 24” plug screw feeder and a high-capacity S2070M refiner. The high dewatering efficiency of the plug screw feeder ahead of the high-pressure zone ensures low thermal and electrical energy consumption, which is one of the major benefits of the ANDRITZ pressurized refining system.

ANDRITZ’s scope also included supply of a gravity-fed HQ-Chipper, a chip bin discharger and a digester, as well as supervision of mechanical installation and start-up.

KEAS, part of Hayat Holding, was established in 1969 and specializes in the production of wood-based panels for the furniture, interior decoration, and construction industries. It has more than six locations in Türkiye and several manufacturing plants worldwide.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Valmet introduces a new optical consistency measurement for wet end applications

Valmet launches a new Valmet Optical Consistency Measurement model (Valmet OC2W), which has been developed for stock preparation’s short circulation applications in paper, tissue, and board machines. The cost-effective inline consistency measurement is especially suitable for wet end process monitoring.

Valmet OC2W utilizes the total consistency measurement method of the original Valmet Optical Consistency Measurement (Valmet OC) and comes with an added capability of ash content available as a second measured value. Particularly in low-consistency measurements, Valmet’s optical measurements are often the only possible technique to provide reliable results. Valmet OC2W can be easily installed with a measuring probe that enables insertion and removal without special tools or a process stop.

“The application specific models make Valmet Optical Consistency Measurement perform well in most pulp and paper applications. The new Valmet OC2W makes inline optical measurement available for wet end and adds a new option for wet end monitoring technology,” says Heikki Föhr, Product Manager, Valmet Optical Consistency Measurement, Automation Systems business line, Valmet.

Valmet OC2W has been developed for stock preparation’s short circulation applications in paper, tissue, and board machines.

Valmet OC2W has been developed for stock preparation’s short circulation applications in paper, tissue, and board machines.

Technical information about Valmet Optical Consistency Measurement (Valmet OC2W)

Valmet OC2W is part of the Valmet Optical Consistency Measurement family, each optimized for use with different kinds of wood pulps and recycled textile fibers. Installed in an area of turbulent flow, the temperature and vibration resistant probes are self-cleaning even in the demanding process environments. Valmet OC2W has been developed to measure ash and total consistency (0-12%) in the challenging wet end environment. Sharing the same basic components and modules, Valmet OC has gained a deserved reputation for accuracy, reliability, and ease of installation.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

DS Smith commissions Voith to rebuild PM 4 at Viana to increase production capacity and efficiency

DS Smith, a leading global manufacturer of sustainable containerboard and specialty papers, has commissioned Voith to rebuild its PM 4 at the company’s Viana site in Northern Portugal. Producing around of 400,000 tons of kraftliner and high-performance top kraftliner per year, the mill is a market leader in Southern Europe. The extensive rebuild will increase production and improve overall efficiency. Production will expand to around 428,000 tons per year with a machine design speed of 1,100 m/min. The start-up of the project is scheduled for the fourth quarter of 2023.

“We are happy to realize this project together with DS Smith. Our customized solutions will lead to the desired production capacity, efficiency and quality,” says Marcos Garcia de la Torre, Managing Director Voith Paper Spain. “DS Smith benefits from Voith’s expertise, state-of-the-art technology and outstanding project efforts. The commission confirms that we, as the full-line supplier to the paper industry, are the trusted partner for rebuilds.”

The rebuild scope includes modifications to the forming section to increase capacity and performance of the paper machine. The press section will be completely renewed, including installation of a Tandem NipcoFlex press that will significantly increase the dry content after press and reduce specific steam consumption.

The rebuild scope includes modifications to the forming section to increase capacity and performance of the paper machine. The press section will be completely renewed, including installation of a Tandem NipcoFlex press that will significantly increase the dry content after press and reduce specific steam consumption.

The transfer between press and dryer sections will be modified with state-of-the-art web transfer and tail threading technology to provide the best runability for lightweight grades. In addition, smaller modifications and upgrades in the stock preparation and approach flow line are planned. Finally, the scope of delivery includes a comprehensive fabrics package for the PM 4 start-up and subsequent supply, as well as spare parts.

About DS Smith

DS Smith is a leading provider of sustainable fiber-based packaging worldwide, supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast-moving consumer goods and industrials.

Through its purpose of “Redefining Packaging for a Changing World” and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sit at the heart of this response.

Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Stora Enso completes negotiations at Anjalankoski production unit concerning the closure of one paper line

Stora Enso has completed the negotiations concerning the consolidation of its book paper production and the permanent closure of one of the two paper machines at the Anjalankoski site in Finland. The closure will take place during the fourth quarter of 2023.

In April 2023, Stora Enso announced a plan to permanently close one of the two paper machines and concentrate all book paper production to one line at the integrated Anjalankoski site due to the prevailing weak paper demand and high input costs.

The closure of the line producing uncoated mechanical grades will reduce the site’s annual capacity by 250,000 tonnes and sales with approximately EUR 100 million. The closure will take place during the fourth quarter of 2023 and affect 89 people, of whom 50 will be made redundant. The majority of these redundancies are managed through pension arrangements.

“While it is very unfortunate that redundancies have to be made, we are pleased that the number of employees affected is significantly lower than anticipated. Stora Enso will continue to harness the Anjalankoski site’s synergies between board and paper production and with the remaining paper machine, the Group will be able to continue producing its selection of book paper grades,” says Hannu Kasurinen, EVP Packaging Materials division.

The integrated Anjalankoski site is reported under the Packaging Materials division since the beginning of 2023. The site includes the Ingerois packaging board production unit and the Anjala paper production unit, the latter of which was previously reported under the, now dissolved, Paper division.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY).storaenso.com/investors

SCA relies on latest digitalization and lifecycle management solutions from Voith and BTG along the entire paper machine to save resources

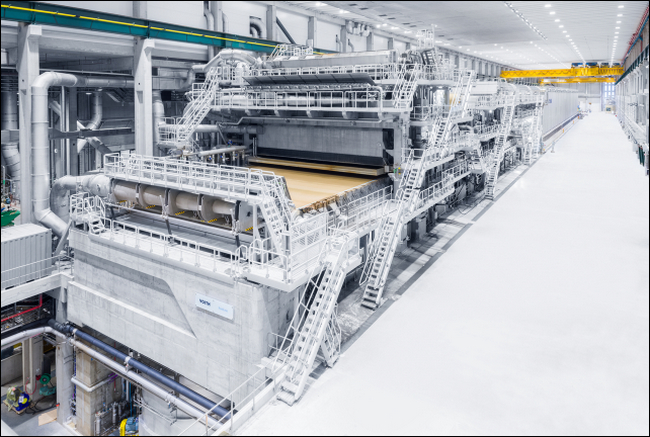

SCA is successfully utilizing Voith's digital and automation solutions with the aim of optimizing the production efficiency of its new XcelLine PM 2. Last year, the leading full-line supplier Voith successfully commissioned the paper machine at its Obbola site. The high-performance machine produces 725,000 tons of kraftliner annually with basis weights between 100 and 200 gsm and has a design speed of 1,400 meters per minute.

- SCA uses digitalization and automation solutions from the Papermaking 4.0 portfolio of Voith and BTG across the entire paper machine

- In addition, Voith works closely with SCA after installation as part of an Efficiency Partnership

- Solutions lead to significant resource savings in paper production

“The journey for SCA and Voith together has only just begun,” says Gustaf Nygren, Mill Manager Obbola at SCA. “We have a long-term partnership in place with the target of reaching the common vision of PM 2 in Obbola becoming the new reference for safety, efficiency and digitalization.”

To achieve its goals, SCA is using more than 10 innovative digitalization and automation solutions across the entire paper machine from the Papermaking 4.0 portfolio of Voith and its subsidiary. For example, solutions from the OnEfficiency family help increase line efficiency and stabilize product and process quality. The increased efficiency also contributes to more sustainable and resource-saving paper production. SCA also uses applications from the OnCare family to monitor productivity and take optimization measures quickly.

Machine availability is further increased by digital services such as the OnCall.Video remote maintenance service. The Voith Paper Webshop enables fast ordering of spare and wear parts as well as services. The digital portfolio is made available on Voith’s IIoT dataPARC cloud platform, which is characterized by the highest security standards.

“With the PM 2, we will take our next steps in the digitalization journey. The applications provided by Voith will help us to monitor the process and make the right decisions,” confirms Niclas Ahnmark, Paper Mill Manager at SCA.

SCA has also signed a long-term service agreement with Voith subsidiary BTG for process control. BTG's Lifecycle program ensures optimal consistency accuracy and control by providing preventive maintenance services for the entire consistency sensors install base, including regular calibration and routine checks. BTG Field Service Engineers assist in the planning, implementation and coordination of the various maintenance services, maximizing machine uptime and stability while maintaining SCA's high safety standards.

The collaboration with SCA is long-term and is particularly evident through the Efficiency Partnership. Throughout the process, the teams work closely together to ensure that the solutions are used optimally. Stephan Sicking, Vice President Sales FRS EMEA at Voith Paper, explains, "As part of a digitalization roadmap, we have defined common goals and KPIs in a cross-functional team, developed a customized concept and are now providing support for successive installation and employee training. Already, the benefits from this collaborative approach are clearly demonstrated." Learn more on our Voith website: Containerboard mill Obbola PM 2 | Voith.

About SCA

The core of SCA’s business is the growing forest, Europe’s largest private forest holding. Around this unique resource, we have built a well-developed value chain based on renewable raw material from our own and others’ forests. We offer packaging paper, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. 2022 the forest products company SCA had approximately 3,300 employees and sales amounted to approximately SEK 21 bn. SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden. More information at http://www.sca.com.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Valmet introduces Valmet Brown Stock Analyzer for high yield and brown pulp

Valmet has developed Valmet Brown Stock Analyzer to complement its online pulp quality analyzer family. The analyzer provides high analysis frequency for digester and brown stock washing control in kraft pulping. It is the most robust Kappa measurement for high yield and brown pulp, designed to measure the coarsest pulp starting from cooking blow line.

“This is the only analyzer in the market with dual sampling points for blow line Kappa, before and after refining. Accurate and frequent Kappa profile ensures superior process control and enables the mill to optimize cooking parameters, resulting in better yield and pulp quality,” says Timo Laurila, Business Manager, Pulp and Energy Analyzers, Automation Systems, Valmet.

“This is the only analyzer in the market with dual sampling points for blow line Kappa, before and after refining. Accurate and frequent Kappa profile ensures superior process control and enables the mill to optimize cooking parameters, resulting in better yield and pulp quality,” says Timo Laurila, Business Manager, Pulp and Energy Analyzers, Automation Systems, Valmet.

Technical information about Valmet Brown Stock Analyzer

Valmet Brown Stock Analyzer utilizes a well-proven sampling technology to extract a pulp sample and transport it to the analysis unit, where the dissolved lignin is thoroughly washed, and pulp Kappa number analyzed by an advanced optical measurement technology. The Kappa measurement range is 9–120.

The pulp sample handling principle minimizes water consumption, ensuring effective operation even with high shive content pulps. A low number of moving and wearing parts minimizes the need for maintenance.

The user-friendly analyzer design keeps operators away from the harsh process environment, ensuring that laboratory sampling is carried out in a convenient and safe location with the automated built-in laboratory collector. Only the process sampling device is connected to the pressurized pulp process.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com